wax remover

Dubond’s Wax Remover is an alkaline stripper especially fit for the removal of old layers of natural and synthetic waxes. Wax Remover quickly removes the wax and it is ideal for the washing and the dressing of floor surfaces before the application of new emulsions, sealers or waxes. The concentrated nature of the product allows easy dissolving of old layers of polish, wax residues, dirt, oils and grease with the minimum of effort. Old tiled floors are easily renovated and brought back to their natural beauty with the three-step system of removal, impregnating and polishing. For large areas a suitable cleaning machine may be used. Green Building Rating-Mineral > 30%, Low Emission, Solvent < 5 g/kg, Low Ecological Impact,Health Care,Water Based Areas of Application-All types of old floorings of tiles Old polished floorings natural stone,marbel,granite,ceramictiles,wooden floorings Old waxed floorings of stone,marbel,granite,ceramictiles,wooden flooringsFeatures & BenefitsAlkaline stripper especially fits for the removal of old layers of natural and synthetic waxes Dissolvesold layers of polish,wax residues,dirt,oilsand grease with the minimum of effort Work sin three-step system of removal of old wax&polish,impregnates and polishes the existing surface to be renovated and brought back to its natural beauty.Method of Application Dilute WaxRemover 1:10 with warmwater for general cleaning.Dilute 1:4 for particularly heavily soiled areas.When using as crubbing machine,dilute1:50or1:100 depending up on the level of cleaning required. Apply the diluted solution to the floor area and leave to work for approximately 5-10minutes depending onseverity. When using on porous surfaces such as terracot tatiles,bricketc.dampen with water prior to application to avoid cleaner being absorbed in to the surface. Scrub the floor using a stiff brush or an abrasive pad to emulsify dirt. Mop up excess liquid. Thoroughly rinse the floor 2-3 times with clean water to remove all traces of cleaner.Any residues may leave surfaces slippery and could also have an effect on subsequent treatments,i.e.polishesetc. Precautions & limitations Wax remover is an alkaline product. Do not use the pure producton polished marble sandstones. For the first rinse of these materials, Do not use tile cleaner nor cement cleaner,rinse in stead two times(atleast)with clean water. Shelf Life & Storage-12-24 months in original sealed packing kept in cool and dry place. Store in a dry place in the original container. Fortuitous leakage and waste disposal method-n case material is released or spilled,clean up most of the product.store the residue in plastic tanks neutralize with a solution of hydrochloric acid adjusting the ph to 6-7 then send to water conditioner or call for a specialized company personel.

Appearance : Limpid Liquid

PH : (5% Solution) : 11–12

Biodegradability : 90%

Flashing point : Not Flammable

...more

Quartz Stone Adhesive

Dubond Ultraflex is two-component solvent and water free adhesives which are flexible and waterproof. They are made up of a polyurethane base (component A) and a special hardener (component B). Dubond Ultrflex is an improved (2) reaction resin adhesive (R) and slip resistant (T) classfied as R2TFeatures & Benefits Easy workability. Excellent durability and resistant to ageing. Perfect adhesion on all surfaces used in building. Hardens by chemical reaction without shrinkage (until it becomes highly resistant High deformability.In the case of Ultraex, highly thixotropic: it can be applied vertically without slump and without le tting even heavy or large tiles slipArea of Application Fixing wall and oor tiles indoors and outdoors. Ceramic, stone material and mosaic. Fixing on screeds, renders, concrete, asphalt, wood, metal, PVC, reinforced polyester, asbestos -cement, gypsum, gypsum board, gypsum panels etc. Bonding ceramic tiles, stone material and all types of mosaic in showers and on sheets used for prefabricated bathrooms. Bonding ceramic tiles and mosaics on wooden work surfaces or in kitchens in order to achieve a waterproof substrate. Bonding ceramic tiles, stone material and mosaics on balconies, external terraces domes or at roofs subject to foot trafc. Bonding natural stones and reconstructed stone (marble of every t ype, slate etc.) also subject to movement and size variation due to the absorption of water (class C of size stability according to DUBOND standards) . Bonding ceramic tiles and stone material on surfaces subject to vibration and defection. Preparation of SubstrateThe substrate must be cured, mechanically strong, free o f loose particles, grease, oil, paint , wax and be sufficiently dry. Cement substrate must not be subject to shrinkage after the installation of the tiles. During spring and summer renders must be cured for at least one week for every centimeter of thickness and cementitious screeds must be cured for at least 28days , unless they have been made with DUBOND special binders for screeds such as DUCEM, DU GO SL. Where this not observed, the adhesion of Ultraflex to the substrate will be greatly compromised. Rust on iron surfaces must be removed by sandblasting. It is recommended to reinforce gypsum, gypsum board and anhydrite substrates with a coat of Primer. ApplicationTiles must be absolutely dry. Apply firm pressure to the ?les to ensure good contact and covering of the back. If the layer of fr esh Ultraflex is also to act as a waterproofing membrane, make sure that any ribs and lugs do not go through the layer. If Ultraflex is used for installing on particularly deformable substrates, all coverings larger than 5x5 cm must be installed with wide joints. The open time of Ultrafex under normal temperature an d moisture conditions is approximately 50 minutes. Any adjustment must be carried out within 90 minutes of installation.Precautions & Limitation Do not use on very damp surfaces or where there is a risk of rising damp. The packs are pre-measured, therefore mixing errors are impossible. Do not use partial quantities. A wrong mixing ratio could cause damage during the curing process. Use the products in temperature between +10 C to +30 C . In case of use on surfaces subject to continuous immersion in water, consult the DUBOND Technical Services Department beforehand . Do not use Ultraflex to bond transparent glass material. Shelf life & StorageUltraex are stable for at least 24 months when stored in sealed drums. Component B (hardener) must be stored in warm place to avoid crystallization during cold weather (at least at +10°C). Should crystallization occur, re -dissolve by warming before use. Stir the product before use.

...more

Tile Adhesive with Waterproofing

SWIMMING POOLSDubounds's TURBO is a technical marvel of shock absorbent system (SAS) technology to produce a single part adhesive that has absolute insensitivity to the action of water, for it has binders and stable co-polymers with alkali hydrolysis. Turbo doesn't give up its bond even in the testing of high external pressure due to of water and also condition water seeps to the high adhesive layer thus it finds favor presence with laying professionals of swimming pools and various water bodies.Green Building Rating Mineral≥30% Low Emission Low Ecological Impact Health Care Water Based Areas of ApplicationDesigned for interior & exterior floor and wall installation of all types of glass mosaic. Ideal for Swimming pools, tanks, flooring and walls, indoor/outdoor use, in domestic, industrial and commercial applications and for street furniture, In areas that are permanently damp and subject to thermal shock and freezing. Very good for swimming pools and various water bodies. It can be used to clad glass, tiles and natural stones / artificial stones.Features & Benefits Mineral adhesive for high-performance laying or overlaying with no vertical slip Single-component with very low volatile organic compound emissions, recyclable as an inert material at the end of its life It develops full stability to the action of alkaline hydrolysis, ensuring the effective laying of coverings in structures in constant contact with water Method of Application In general, cement-based substrates must be free from dust, oil and grease, dry and free from any rising damp, with no loose, flaky or imperfectly anchored parts such as residual traces of cement, lime and paint, which must be totally removed. The substrate must be stable and without cracks, must have already completed curing hygrometric shrinkage and must present suitable mechanical resistance levels. Undulated areas must be corrected with suitable smoothing and finishing products. Non-absorbent substrtes Smooth, non-absorbent substrates which are compact and wellanchored must be prepared by cleaning ith products suitable for the type of dirt present. If chemical cleaning cannot be carried out, proceed with mechanical abrasion by means of shot-blasting or carification of the superficial layer and, if necessary, correct the surface with suitable levelling products. High - absorpation substartesOn screeds and plasters which are highly absorbent and have dusty flaky surfaces it is advisable to apply one or more coats of HydroPrime a professional, concentrated water-base, surface insulation product, in accordance with the instructions, to reduce water absorption and toimprove spreadability of the adhesivePreparationPrepare Turbo in a clean container, first of all pouring in a quantity of water equal to approximately . of that which will be required. Gradually add Turbo to the water in the container, mixing the paste from the bottom upwards with a low-rpm ( 400/min.) helicoidal agitator. Then add more water until the desired consistency is obtained. The mixture must be homogeneous and without any lumps. For best results, and to mix larger quantities of adhesive, a stirring device with vertical blades and slow rotation is ecommended. Specific polymers with high-dispersion properties ensure that Turbo is immediately ready for use. The amount of water to be added, indicated on the packaging, is an approximate value and will vary . It is possible to obtain mixtures with a more or less thixotropic consistency, depending on the type of application. Adding extra water does not improve the workability of the product, and may cause shrinkage in the plastic phase of drying and result in less effective final performancewith a reduction in compressive strength and adhesion to the substrate.Application Turbo should be applied with a suitable toothed spreader, to be chosen according to the size and characteristics of the rear surface of the tiles. It is best to use the smooth part of the trowel to spread a fine initial layer, pressing down hard so as to obtain maximum adhesion to the substrate and to regulate waterabsorption, after which the thickness can be adjusted as required by tilting thespreader at an angle. Spread the adhesive over a surface area which will allow for laying of the covering materials within the indicated open time, and check for suitability of the adhesive at regular intervals. The open time may vary considerably even during the application, depending on various factors such as exposure to sunlight, air currents, absorbency of the substrate, temperature and relative humidity of the atmosphere. Press down each tile to allow for complete, uniform contact with the adhesive. In the case of laying in environments subject to heavy 2 traffic, in outdoor locations, on underfloor heating systems or with materials to be smoothed on-site and with formats > 900 cm , the double-spread technique must be used, which ensures laying procedures on fresh adhesive, 100% coverage of the rear of the tiles and maximum adhesion. In general, ceramic tiles do not require preliminary treatment, however these materials should be checked to ensure they are free from traces of residual dust or materials not properly anchored to the surface Special applicationsPartial replacement of mixing water with Tuffex AD professional elastomeric latex enhances the adhesive’s capacity for transversal deformation. The real necessity for deformability of the laying system must be verified, as use of an excessively deformable adhesive together with highly-rigid substrates and laying materials may cause breakage and early unexpected yielding of the covering materials when placed under heavy and concentrated strain or loads. To define the percentage of Tuffex AD to be added, on the basis of the various factors related to the system, consult the Dubond Products (India) Pvt Ltd’s official web site.Elastic jointsProvide desolidarisation joints and elastic fractionizing joints for areas of 20/25 m in indoor applications, 10/15 m in outdoor applications and for every 8 metres length in the case of long, narrow applications. Structural and string-course joints have to be marked on the external facade.Precautions & LimitationsDo not use on gypsum-base plasters and anhydrite screeds without the use of HydroPrime a professional concentrated, water-base, surface insulation product; on plastic or resilient materials, metals and wood; on substrates subject to continuous moisture rising Do not use the adhesive to correct substrate irregularities greater than 15mm Lay and press tiles onto fresh adhesive, making sure it has not formed a surface film the temperature, ventilation and absorption of the substrate and covering materials may vary the adhesive workability and setting times Protect against direct rain and freezing for at least 24 hours Use a toothed spreader suitable for the format of the tiles Use the double spread technique for all outdoor laying CoverageThis shall depend on the nature and flatness of the surface and the method of application, but at 15 mm thickness it is approximately 2 80-90 SqFt/ M 1.5mm for 20kgs bag . For good coverage, it is vitally important that all surfaces should be clean, smooth, plumb, level and free from defects and undulations.

...more

Tuffex Gt Grout

A synthetic polymer emulsions for use with dubond's cement based grouts. Suitable for use in interior and exterior locations in both dry and wet service conditions. Dubond TUFFEX GT is a polymer additive for dufill cement-based grouts. Not for use with adhesives. This admixture is manufactured under an approved quality assurance system conforming to BS EN ISO 9002 and in accordance with the requirements of the environmental standards and operational scope of BS 7750:1994. Green Building Rating Mineral > 30% Low Emission Low Ecological Impact Health Care Water Based Areas of ApplicationFor internal and external use ,in domestic, commercial and industrial applications for street furniture, in environments subject to heavy use, Natural stone, agglomerate materials, marble Flooring and walls, Suitable for use as an additive in cement-based grouts Suitable to grout homogeneous tiles, low thickness slabs, ceramic tiles, klinker, cotto, glass and ceramic mosaic of all types and formats Swimming pools, tanks and fountains, for grouting deformable substrates, also in areas subject toFeatures & Benefits Does not alter workability, ease of cleaning and interval before normal use Improves water repellence and surface hardness Increases the flexibility of grouts, guaranteeing the continuity of coverings laid on deformable substrates or subject to thermal expansion increases adherence Professional elastomeric latex Solvent-free Water-based flexibilizing agent for normal and rapid-setting mineral grouts A synthetic polymer emulsions for use with dubond's cement based grouts. Suitable for use in interior and exterior locations in both dry and wet service conditions. Dubond TUFFEX GT is a polymer additive for dufill cement-based grouts. Not for use with adhesives. This admixture is manufactured under an approved quality assurance system conforming to BS EN ISO 9002 and in accordance with the requirements of the environmental standards and operational scope of BS 7750:1994. Green Building Rating Mineral > 30% Low Emission Low Ecological Impact Health Care Water Based Areas of ApplicationFor internal and external use ,in domestic, commercial and industrial applications for street furniture, in environments subject to heavy use, Natural stone, agglomerate materials, marble Flooring and walls, Suitable for use as an additive in cement-based grouts Suitable to grout homogeneous tiles, low thickness slabs, ceramic tiles, klinker, cotto, glass and ceramic mosaic of all types and formats Swimming pools, tanks and fountains, for grouting deformable substrates.Features & BenefitsDoes not alter workability, ease of cleaning and interval before normal use Improves water repellence and surface hardness Increases the flexibility of grouts, guaranteeing the continuity of coverings laid on deformable substrates or subject to thermal expansion increases adherence Professional elastomeric latex Solvent-free Water-based flexibilizing agent for normal and rapid-setting mineral grouts.Method of Application : Mixing For most applications dilute 1 part Tuffex GT with 2 parts water use the TUFFEX GT : water blend to replace the gauging water when preparing the grout for use. For internal and external use ,in domestic, commercial and industrial applications for street furniture, in environments subject to heavy use, Natural stone, agglomerate materials, marble Flooring and walls, Suitable for use as an additive in cement-based grouts Suitable to grout homogeneous tiles, low thickness slabs, ceramic tiles, klinker, cotto, glass and ceramic mosaic of all types and formats Swimming pools, tanks and fountains, for grouting deformable substrates, also in areas subject to thermal shock and freezing Does not alter workability, ease of cleaning and interval before normal use Improves water repellence and surface hardness Increases the flexibility of grouts, guaranteeing the continuity of coverings laid on deformable substrates or subject to thermal expansion increases adherence Professional elastomeric latex Solvent-free Water-based flexibilizing agent for normal and rapid-setting mineral grouts, Mixing Dubond's Du Fill cement-based grouts modified with Tuffex GT should be applied as directed in the appropriate product data sheet. The working time of the polymer modified grout may be shorter than that of the unmodified material, especially in higher temperatures. the colour of the set grout may appear slightly darker than when unmodified. use the same mix proportions throughout an installation to ensure niform colour. Performance The addition of Dubond's TUFFEX GT to dubond's dufill cement-based grouts greatly improves their physical properties and characteristics. increased mechanical strength. Provides greater adhesion to tile edges e.g. glass mosaics and fully vitrified tiles. Provides greater abrasion resistance. particularly important in heavily trafficked areas such as shopping malls. increased flexural strength and flexibility. Enables grouts to be used where limited movement/vibration is anticipated e.g. heated screeds and timber floors. educed water permeability. Provides greater protection to water sensitive backgrounds and minimizing the risk of efflorescence. Precautions & LimitationsDo not use on floors and walls where specific chemical resistances or absolutely no water absorbency is required; to grout elastic expansion or fractionizing joints; on substrates which are highly deformable, not fully dry or subject to moisture rising; on tiles or materials with porous or rough surfaces that are difficult to clean. Strictly keep to the indicated mixing ratio Apply the mixed product to a trial section first to check how the porous or microporous surface ceramic tiles or natural stone react to cleaning, as they may not be suitable for the use of grouts with latex additivesHealth & Saftey Precautions Keep out of reach of children. wear suitable protective clothing, gloves, and eye / face protection. after contact with skin wash immediately with plenty of clean water. in case of contact with eyes, rinse immediately with plenty of clean water and seek medical advice Mixing For most applications dilute 1 part Tuffex GT with 2 parts water use the TUFFEX GT : water blend to replace the gauging water when preparing the grout for use. For internal and external use ,in domestic, commercial and industrial applications for street furniture, in environments subject to heavy use, Natural stone, agglomerate materials, marble Flooring and walls, Suitable for use as an additive in cement-based grouts Suitable to grout homogeneous tiles, low thickness slabs, ceramic tiles, klinker, cotto, glass and ceramic mosaic of all types and formats Swimming pools, tanks and fountains, for grouting deformable substrates, also in areas subject to thermal shock and freezing Does not alter workability, ease of cleaning and interval before normal use Improves water repellence and surface hardness Increases the flexibility of grouts, guaranteeing the continuity of coverings laid on deformable substrates or subject to thermal expansion increases adherence Professional elastomeric latex Solvent-free Water-based flexibilizing agent for normal and rapid-setting mineral grouts, Mixing Dubond's Du Fill cement-based grouts modified with Tuffex GT should be applied as directed in the appropriate product data sheet. The working time of the polymer modified grout may be shorter than that of the unmodified material, especially in higher temperatures. the colour of the set grout may appear slightly darker than when unmodified. use the same mix proportions throughout an installation to ensure uniform colour. Performance The addition of Dubond's TUFFEX GT to dubond's dufill cement-based grouts greatly improves their physical properties and characteristics. increased mechanical strength. Provides greater adhesion to tile edges e.g. glass mosaics and fully vitrified tiles. Provides greater abrasion resistance. particularly important in heavily trafficked areas such as shopping malls. increased flexural strength and flexibility. Enables grouts to be used where limited movement/vibration is anticipated e.g. heated screeds and timber floors. reduced water permeability. 4. Provides greater protection to water sensitive backgrounds and minimizing the risk of efflorescence. Precautions & Limitations Do not use on floors and walls where specific chemical resistances or absolutely no water absorbency is required; to grout elastic expansion or fractionizing joints; on substrates which are highly deformable, not fully dry or subject to moisture rising; on tiles or materials with porous or rough surfaces that are difficult to clean. Strictly keep to the indicated mixing ratio Apply the mixed product to a trial section first to check how the porous or microporous surface ceramic tiles or natural stone react to cleaning, as they may not be suitable for the use of grouts with latex additives Health & Saftey PrecautionsKeep out of reach of children. wear suitable protective clothing, gloves, and eye / face protection. after contact with skin wash immediately with plenty of clean water. in case of contact with eyes, rinse immediately with plenty of clean water and seek medical advice.

Dosage : 100 ml / 1 kg of polymer grout

Dosage : 1 ltr / 10 kg of polymer grout

Shelf Life : 12 month with original packing in dry place

Coverage : Depends upon the dosages.

...more

Admixture for Cementitious Adhesive

Dubond's Tuffex AD is high technology elastomeric latex and it is suitable for use as an additive for cement based adhesives, with normal and fast setting adhesives. Dubond's tuffex ad increases adhesion to substrates and improves the adhension.Green Building Rating Low Low Ecological ImpactEmission HealthCare Water Based Areas of ApplicationFlooring and walls. For internal and external use, in domestic, commercial and industrial applications for street furniture. In environments subject to heavy use, swimming pools, tanks and fountains, for laying on deformable substrates, Also in areas subject to thermal shock and freezing. Materials to be bonded as homogeneous tiles, ceramic tiles, klinker, cotto, glass and ceramic mosaic, of all types and formats natural stone, agglomerate materials, marbles.Features & BenefitsIncreases substrate adhesion. Does not alter interval before normal use. Recommended as an additive for substrates and materials subject to extreme deformation. Does not alter workability times of normal and extra-fast setting mineral adhesives. It increases the longitudinal and transversal deformation of adhesives guaranteeing unaltered workability and safe, easy and eco-friendly layingMethod of ApplicationSubstrates must be compact and consistent, free from dust, oil and grease, free from any rising damp, with no loose, flaky, or imperfectly anchored parts. The substrate must be stable, without cracks and have already completed the curing period of hygrometric shrinkage. Undulated areas must be corrected with suitable smoothing and finishing products.MixingTuffex AD is used as a partial or full substitute for mixing water. After having mixed the powder with the indicated quantity of Tuffex AD. It is necessary to adjust the consistency of the mixture by adding water according to the type of application required, until a homogeneous, lump-free paste is obtained.ApplicationAdhesives mixed with Tuffex AD must be applied with a suitable, toothed smooth spreader of the type and dimensions most appropriate for the format and type of tiles used. Using the smooth part of the spreader, apply an initial fine layer to adjust absorption of the substrate with such a quantity of product as will allow for laying of the covering material within the indicated open time In environments subject to heavy foot traffic, where surfaces are to be smoothed during their creation and in outdoor locations, Use the double-spread technique to ensure 100% application of the product to the rear of the tiles. ( It does not alter workability and hardening times of the adhesive. In warm, dry or windy climates check open times, which may be reduced as a consequenceof such conditions.)Precautions & LimitationsDo not use the adhesive to correct substrate irregularities lay and press tiles onto fresh adhesive making sure it has not formed a surface skin. Use the double-spread technique for all external laying The temperature, ventilation and absorption of the substrate and covering materials, may vary the adhesive workability and setting times. Do not use On external floors, on wet surfaces or substrates subjected to moisture rising; in environments where water is always present; with low absorption tiles on non-bsorbent substratesHealth & Saftey PrecautionsKeep out of reach of children. wear suitable protective clothing, gloves, and eye / face protection. after contact with skin wash immediately with plenty of clean water. in case of contact with eyes, rinse immediately with plenty of clean water and seek medical advice...

...more

Under Coat Primer for Tiles & Stones

Dubond's Tile & Stone Primer is a water base nano particle aqueous dispersion. It is designed as a barrier to prevent water, alkali and other compounds from reaching the substrate surface and to avoid efflorescence that can cause surface discoloration especially in cement substrates.Green Building Rating-Mineral > 30%, Low Emission, Low Ecological Impact,Health Care,Water BasedAreas Of Application-Stones and porous tiles. Interior & exterior Wall & floors Natural porous stones & tiles Concrete surfaces before painting or laying of tiles to prevent efflorescence and providing water resistance Upper substrate acts as a adhesion promoterFeature & Benefits-Water base nano particle aqueous dispersion It is designed as a barrier to prevent water, alkali and other compounds from reaching the substrate surface.Method Of Application-Wash the substrate by clean water and allow if to dry apply primer by soft bristle brush and led it to dry 6 to 8 hours. The surface area has been primed now apply any another product.Shelf Life & storage-6 months in original sealed packing kept in cool and dry place. store in a dry place in the original container.Health & safety Precautions-Keep out of reach of children. wear suitable protective clothing, gloves, and eye / face protection. after contact with skin wash immediately with plenty of clean water. in case of contact with eyes, rinse immediately with plenry of clean water and seek medical advice.

...more

Heavy Duty Cleaner for Cement Based Stain

Dubond’s Tile and stone polish is a high quality, water-based, metal cross-linked tile polish for internal use onfloors. The polish enriches the appearance of floor finishes by leaving a hard wearing, matt, satin finish,protecting tiles from the formation of stubborn dirt and stain and has good resistance to normal detergents, typical household spillages and general floor cleaners. Ideal for protecting unpolished natural stone, polished granite and dressed terracotta floors reen Building Rating-Mineral > 30%, Low Emission, Low Emission,Low Ecological Impact, Health Care, Water Based Ideal for usage over unpolished natural stone,polished granite and dressed terracotta floorsFeatures & Benefits-HighQuality Water based Metal cross linked product Protects tiles from the formation of stubborn dirt and stain Good resistance to normal detergents,typical household spillages and general floor cleaners Shelf Life & Storage12-24 months in original sealed packing kept in cool and dry place. store in a dry place in the original container.Health & Saftey PrecautionsKeep out of reach of children. wear suitable protective clothing, gloves, and eye / face protection. after contact with skin wash immediately with plenty of clean water. in case of contact with eyes, rinse immediately with plenty of clean water and seek medical advice.

...more

Stainless Steel Kitchen Glass Mosaic Tile

Size : 1x1ft, 20x80 Cm, 2x2ft, 30X60 Cm, 60x60cm

Shape : Irregular, Rhombus, Round, Square, Strip

Thickness : 0-5mm, 10-15mm, 15-20mm, 20-25mm, 5-10mm

Color : Blue, Brown, Grey

...more

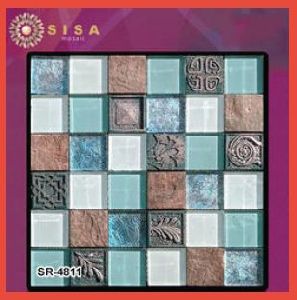

SR-4811 Sisa Glass Mosaic Tile

Size : 1x1ft, 20x80 Cm, 2x2ft, 30X60 Cm, 60x60cm

Shape : Irregular, Rhombus, Round, Square, Strip

Thickness : 0-5mm, 10-15mm, 15-20mm, 20-25mm, 5-10mm

Color : Blue, Brown, Grey

...more

Building Construction Sponge Cellulose

Size : 120X78X40 MM

Density : 8-17kg/cbm

Building Construction Spacer

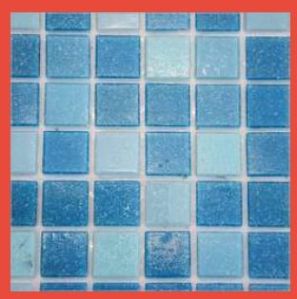

Sky Blue Glass Mosaic Tile

Thickness : 15-20mm, 20-25mm, 0-5mm

Color : Blue, Grey, Brown

Semi Hand Cut Diamond Mosaic Tile

Size : 1x1ft, 20x80 Cm, 2x2ft, 30X60 Cm, 60x60cm

Shape : Irregular, Rhombus, Round, Square, Strip

Thickness : 0-5mm, 10-15mm, 15-20mm, 20-25mm, 5-10mm

...more

Building Construction Scrubber

Application : Cleaning

Application : Foundries

Rust Remover

RUST REMOVER 100 is a one-component sulphate and chloride free liquid, which removes rust andprevents further rusting in just one action.UsesRUST REMOVER 100 removes rust and prevents further rusting of : New or old reinforcement steel in construction Embedded steel in repairable structures Various steel structures like Tanks, Water pipelines, Effluent pipelines, Trusses, Purling, Rafters etc. Ball bearings, Valves, Manifold, Tools etc. in machine shops and auto repair shops.Advantages RUST REMOVER 100 imparts the following advantages : Completely removes rust and prevents further rusting. Economical in use. Easy to Apply. Excellent for equipment and structural rust removal. Instruction For UseSurface PreparationApplicationFor corroded and heavily rusted surface it is economical to remove the loose rust by mechanical means like wire brushing, chipping, hammering etc depending on the extent of corrosion. RUST REMOVER 100 by brush, cotton waste swab or spray on the affected metal surface. Leave it in contact with the surface till the reddish color of the corroded surface has changed to nearest original black. Excess application may sometime give whitish black surface. After a minimum 24 hours remove the freed loose rust particles by brush Recoating After the removal of loose rust any reddish rusted surface still left has to be re treated with Rust Remover After the surface totally dries up (within around 48 hrs.) a preventive coating like Dubond’s RUST REMOVER 100 may be applied. The Surface should be dry.Limitations Minimum Substrate temperature shoule be + 05°C Maximum Substrate temperature shoule be + 50°C Handling PrecautionsDubond’s products are generally quite harmless, provided certain precautions are normally taken for handling chemicals. Avoid contact with foodstuff and food utensils. Avoid prolonged skin contact. In the event of contamination, wash thoroughly with water. If the eye or mouth is affected, wash with clean water immediately.

...more

Flexible Waterproof Roof Coating

Heavy Duty Reinforced Acrylic Waterproofing Coating for TerraceDubond's Roof Shield is a heavy duty terrace waterproofing system, composed of specially developed highly elastic & resilient acrylic polymers, properly selected & graded fillers, lightfast & weather durable pigments, micro-fibres, additives & best quality fungicidal in water medium. it is used as a liquid applied waterproofing membrane for all types of building terraces. Dubond's Roof Shield is a three-layer system with coats in different colours ensuring proper build-up of the thickness, making it a reliable waterproofing system.Areas of Application Building roofs / terraces – flat & slope. Over existing cementitious waterproofing treatments like brick-bat coba, concrete screeds, acrylic coatings, etc. Method of Application Surface Preparation Prepare the surface thoroughly by cleaning, washing and removing dust, dirt, oil, grease and loose particles. Ensure that the roof slope is a minimum of 1 in 100. In existing old terraces such as brick-bat-coba or screeds, the substrate must be checked for its soundness. Damaged or hollow portions, sharp edges, etc. must be cut and repaired with a polymer-modified screed. Surface cracks must be filled with Dubond's acrylic crack filler. Bitumen based waterproofing treatments must be completely removed by mechanical scarification or by any other effective mechanical means.. Application Apply one coat of Dubond's Hydro Prime without any dilution at the rate of 10-12 m per litre. allow it to dry for 2-3 hours. 2 Apply the first coat of Dubond's Roof shield at the rate of 2 m per litre and allow it to dry before taking up the second and third coats,the rate of application being the same. The sequence of colours viz-a-viz, green or terracota grey can be decided depending on the desired top coat colour. In case only two colours are being used, ensure that the colour of the first and the third coat are the same. this would ensure correct consumption of material that will deliver a total Dft of 1 mm. Drying time between coats will be 6 to 8 hours. Ensure that the primer and the 3 coats of Dubond's Roof Shield totally achieve a minimum thickness of 1 mm Dft. allow the system to air cure for 7 days minimum. Precautions & Limitations All corners, gaps, joints, protrusions & outlets shall be coated with two extra coats. Do not apply during rains; substrate Must be in SSD condition for application of primer. the product is designed only for foot traffic and not vehicular or movement of machinery or equipments. Note : To achieve the full proof waterproofing, parapet walls must be covered with Dubond’s Rainshield. Health & Safety Precautions Skin contact : Wash skin with soap & water. Remove contaminated clothes. On eye contact : Immediately splash eyes with plenty of water. Consult Physician if irritation persists. Ingestion : Do not induce vomiting. Never give anything by mouth to an unconscious person. Call a Physician.

Usage : No need to remove existing BB coba, plaster, concrete surface

Shelf Life : Shelf life is 12 months from the date of manufacturing in unopened condition.

...more

Building Construction Roller

Random Mix Glass Mosaic Tile

Size : 1x1ft, 20x80 Cm, 2x2ft, 30X60 Cm, 60x60cm

Shape : Irregular, Rhombus, Round, Square, Strip

Thickness : 0-5mm, 10-15mm, 15-20mm, 20-25mm, 5-10mm

Color : Blue, Brown, Grey

...more

Exterior Waterproofing Paint

Dubond's Rainshield is composed of high quality acrylic emulsion polymer, light fast & weather durable pigments, properly selected & graded fine fillers, additives & biocides. It is used as a waterproofing & protective coating for exterior walls of the buildings.Areas of ApplicationAll types of exterior masonry surfaces, concrete, cement sand renderings, etc. Method of Application Surface Preparation Priming All new cement-sand renderings /concrete surfaces should be allowed to age 6 to 8 weeks before surface coating. Surface for treatment must be thoroughly cleaned of all laitance, loose material, oil, grease, etc. by mechanical means such as wire brushing & shot blasting. Finally vacuum cleaning of all loose solids and liquids can be done, if required. All surface cracks up to 5 mm width should be filled up with Dubond's Acrylic Crack Filler. All types of exterior masonry surfaces, concrete, cement sand renderings, etc. Application Use Dubond's Rainshield directly from the container. Stir contents well before use. Apply two neat coats of Dubond's Rainshield without dilution by brush or roller at a time interval of 5-6 hours. For enhanced protection, apply additional coat of Dubond's Rainshield on rain lashing walls, chajjas and parapet walls. Allow the coated surface to air cure fully for 7 days. Precautions & Limitations Do not dilute Dubond's Rainshield. Recommended to be primed with Dubond's Hydro Prime only. Do not apply when ambient temperature is below 10 C or above 45 C. Do not apply in direct sunlight or during rains. Adhesion property may get affected over putty and very smooth surfaces. Coverage3.0 to 3.5 m per litre for 2 coats Coverage may vary depending upon the texture and porosity of the surface.Shelf Life & StorageShelf life is 24 months from the date of manufacturing in unopened conditions. Store in a cool and dry place. Keep away from direct sunlightHealth & Safety Precautions Skin contact : Wash skin with soap & water. Remove contaminated clothes. On eye contact : Immediately splash eyes with plenty of water. Consult Physician if irritation persists. Ingestion : Do not induce vomiting. Never give anything by mouth to an unconscious person. Call a Physician

...more

Building Construction Putty Knife

Condition : New

TOT Adhesive

Dubond's pure is a quartz based tile adhesive, that has excellent results for high resistance laying of ceramic tiles on floor, walls on cement based substrates. It is workable up to 10 mm thickness and the formulation ensures optimum-performance for tile setters. It is absolutely reliable and has its base in superiority of its conceptionGreen Building Rating Mineral > 30% Low Emission Low Ecological Impact Health Care Water Based Areas of ApplicationDesigned for ceramic floor and wall tiles for outdoor and indoor . The tiles can be make of cotta, double fire, single fire, ceramic. Floors and walls, for internal and external use, in domestic, industrial and commercial applications also in areas subject to freezing.Features & Benefits Eco-friendly. High-performance laying, ideal for use in industrial and commercial applications. Mineral adhesive for high adhesion. Pure contains recycled raw materials. Pure develops an extended open and adjustability time meaning even highly. porous tiles can be quickly and safely laid on very absorbent substrates. Thicknesses up to 10 mm Preperation of Substrate The substrates must be free from dust, oil and grease, must be in dry condition and free from any rising dampness, the residual traces of cement, lime and paint, shall be totally scraped & removed. The substrate must be stable without cracks, must have already been completely cured. Undulated areas must be corrected with suitable smoothing and finishing products. On screeds and plasters which are highly absorbent and have dusty and flaky surfaces it is advisable to apply one or more coats of HydroPrime a professional, concentrated water-base, surface insulation product and a primer which reduces the water absorption and to improve spreadability of the adhesive Method of ApplicationIn general, cement-based substrates must be free from dust, oil and grease, dry and free from any rising damp, with no loose, flaky or imperfectly anchored partssuch as residual traces of cement, lime and paint, which must be totally removed. The substrate must be stable and without cracks, must have already completed curing hygrometric shrinkage and must present suitable mechanical resistance levels. Undulated areas must be corrected with suitable smoothing and finishing products.Substrates with weak surface consistencyScreeds and plasters which present a weak crystalline structure in the initial mm of thickness and which can be easily abraded must be consolidated by means of Hydro Prime, the professional, water-base depth consolidant, to be applied with one or more coatings and according to the instructions, until a surface has been obtained which isstill absorbent but compact.High - absorption substrates :On screeds and plasters which are compact but highly absorbent, in warm climates and with direct ventilation, it is advisable to apply in advance Hydro Prime, a professional, concentrated, waterbase, surface insulation product, with one or more coatings and according to the instructions, to reduce water absorption and to improve spreadability of the adhesive.Preparation Prepare Pure in a clean container, first of all pouring in a quantity of water equal to approximately . of that which will be required. Gradually add Pure to the water in the container, mixing the paste from the bottom upwards with a low-rev ( 400 RPM /min.) helicoidal agitator. Then add more water until the desired consistency is obtained, the mixture must be homogeneous and without any lumps. For best results and to mix larger quantities of adhesive, a stirring device with vertical blades and slow rotation is recommended. Specific polymers with high-dispersion properties ensure that Pure is immediately ready for use. The amount of water to be added, indicated on the packaging. It is possible to obtain mixtures with a more or less thixotropic consistency. Type of applicationImportant :Adding extra water does not improve the workability of the product, may cause shrinkage in the plastic phase of drying and result in less effective final performance with a reduction in compressive strength and adhesion to the substrate.ApplicationPure should be applied with a suitable toothed spreader, to be chosen according to the size and characteristics of the rear surface of the tiles. It is best to use the smooth part of the trowel to spread a fine initial layer, pressing down hard so as to obtain maximum adhesion to the substrate and to regulate water absorption, after which the thickness can be adjusted as required by tilting the spreader at an angle. Spread the adhesive over a surface area which will allow for laying of the surface materials within the indicated open time and check for suitability of the adhesive at regular intervals, the open time may vary considerably during the same operation, depending on various factors such as exposure to sunlight, air currents, absorbency of the substrate, temperature and relative humidity of the atmosphere. Press down each tile to allow for complete, uniform contact with the adhesive. In the case of laying in environments subject to heavy traffic or in outdoor locations, the double-spread technique must be used, to ensure 100% coverage of the rear of the tiles. In general, ceramic tiles do not require preliminary treatment, however these materials should properly anchored to the substrate or which may modify the absorption characteristics of the tiles.Special applicationsReplacement of mixing water with Tuffex AD, the professional elastomer latex, provides the adhesive with greater capacity of transversal deformation and greater resistance to water and tensile stress without modifying the open time and adjustment interval. Pure with addition of tuffex AD exceeds the level of performance required by EN 12004 class C2 E. Please consult the Dubond Products (India) Pvt Ltd site to define use of this product for particular purposes such as: laying on deformable flooring and walls in plasterboard, laying on heat-radiant slabs, laying of large-format paving slabs in outdoor applications and in permanently humid environments, direct bonding on substrates in smoothed concrete with reduced water absorption.Precautions & LimitationsDo not use on substrates with a gypsum and anhydrite base without use of HydroPrime the professional, concentrated, water-base, surface insulation product1. Heat-radiant slabs.High-flexibility substrates Marble floor tiles and natural stone Metal and wood On old ceramic flooring On plasterboard; On plastic or resilient materials, On substrates which are wet, subject to moisture rising or in continuous contact with water. Do not use the adhesive to correct substrate irregularities greater than 10 mm Coverage 55 to 60 Sq E (3mm) approximately 60 Sq Ft for 20 Kg. bag with 6mm x 6mm square notch trowel for a bed thickness of 3mm.

...more

Shock Absorbing Technology Adhesive for Tiles & Stones

Dubonds's PRISTINE is a grey or white cement based higher grade polymer modified high-strength,flexible tile adhesive for fixing of any type of tiles on interior and exterior situation. It has a special function that works specifically to counter conditions such as external pressures on cladding tiles of the skyscrapers and large format tiles with overlaying on existing floors. it is a secure professional method of laying and has deform ability up to 10mm thickness.Green Building Rating Mineral≥30% Low Emission Low Ecological Impact Health Care Water Based Areas of Application Designed for fully water resistance and anti skid property Excellent for large format paving slabs. Fixing abscorbent floor and wall tiles outdoors and indoors. Fixing poorly absorbent or non absorbent materials such as synthetic marble, asbestos cement sheet, split tiles, refined porcelain stoneware, and glass block Fixing natural stone, synthetic stone and marble so long as they are not affected by environment. Fixing on heating floors. Fixing on minor shocking substrate Features & BenefitsMineral adhesive for high-performance laying or overlaying with no vertical slip Single-component It develops full stability to the action of alkaline hydrolysis, ensuring the effective laying of coverings in structures in costant contact with water SAS Technology ( Shock Absorbing System ) STC technology ( Surface Tension Compability )Preperation of Substrate The substrates must be free from dust, oil and grease, must be in dry condition and free from any rising dampness, the residual traces of cement, lime and paint, shall be totally scraped & removed. The substrate must be stable without cracks, must have already been completely cured. Undulated areas must be corrected with suitable smoothing and finishing products. On screeds and plasters which are highly absorbent and have dusty and flaky surfaces it is advisable to apply one or more coats of HydroPrime a professional, concentrated water-base, surface insulation product and a primer which reduces the water absorption and to improve spreadability of the adhesive Preparation of Adhesive pastePrepare PRISTINE in a clean and dry container, first pour the quantity of water equal to approximately ¾ of that which is required. Gradually add PRISTINE to the water in the container, Add more water until the desired consistency is obtained. The mixture must be homogeneous and without any lumps. For the best results, and to mix larger quantities of adhesive, a stirring device with vertical blades and slow rotation is recommended. Specific polymers with high-dispersion properties ensure that PRISTINE is immediately ready for use. The amount of water to be added, indicated on the packaging . It is possible to obtain mixtures with a more or less thixotropic stability depending on the type of application. Do not add extra water, this shall not improve the workability but rather may cause shrinkage in the plastic phase of drying which shall result in a very less effective final performance with a decrease in compressive strength and adhesion to the substrate.Application PRISTINE should be applied with a suitable notched spreader, chose according to the size and characteristics of the rear surface of the tiles. It is best to use the smooth part of the trowel to spread a fine initial layer. Press down very hard so the maximum adhesion to the substrate shall be obtained which shall regulate the water absorption also, after which the thickness can be adjusted as required by tilting the notched trowel at an angle. Spread the adhesive over a surface area which will allow for laying of the covering materials within the indicated open time, and check for suitability of the adhesive at regular intervals. The open time may vary considerably even during the application, depending on various factors such as exposure to sunlight, temprature, air currents, water absorbency of the substrate, and relative humidity of the atmosphere. Press down each tile to allow for complete, uniform contact with the adhesive. In the case of laying in environments subject to heavy traffic, the double-spread technique must be used, which ensures laying procedures on fresh adhesive, 100% coverage of the rear of the tiles and maximum adhesion. Precautions & Limitations Do not use on gypsum-base plasters and anhydrite screeds without the use of HydroPrime a professional concentrated, water-base, surface insulation product; on plastic or resilient materials, metals and wood; on substrates subject to continuous moisture rising Do not use the adhesive to correct substrate irregularities greater than 15mm Lay and press tiles onto fresh adhesive, making sure it has not formed a surface film the temperature, ventilation and absorption of the substrate and covering materials may vary the adhesive workability and setting times CoverageThis shall depend on the nature and flatness of the surface and the method of application, but at for a bed thickness of 4 mm. Dft. It is 2 approximately 65 sq. Ft for 20 kgs bag with 6mm x 6mm x 12mm square notch trowel 2.5 - 5 Kg/ M for 20kgs bag. For good coverage, it is vitally important that all surfaces should be clean, smooth, plumb, level and free from defects and undulations.

...more

cement putty

Dubond’s Prime Putty is a white cement-based fine powder. It serves as filler/ leveller for walls and ceilings. It provides a waterproof surface with excellent smoothness, good adhesion, good breathing properties, and seals porosity for uniform deposition of finished paint and enhances durability. It is a water resistant white cement based putty ideal for use on concrete/mortar walls (internal and external) and ceilings. It fills the fine pores of mortar/concrete walls and ceilings and provides a white, smooth and dry surface, essential for painting. It helps you combine the suave look with beauty for interiors and exteriors. No need to apply any kind of primer on it before application of paint or distemper. It prevents the growth of algae and fungi on walls.prime putty can be applied even on moist surface (internal/external). It has more adhesive strength, durability and enhances the life of paints. Being white cement based, does not require water curing. Green Building Rating Mineral > 30% Low Emission Low Ecological Impact Health Care Water Based Areas of Application Walls and cielings ideal for use on concrete/mortar walls (internal and external) It can be used any type of surface like concrete, rendered wall, hollow block, precast walls, concrete ceilings, calcium silicate bricks etc. Features & Benefits Prime Putty can be applied on both interior and exterior surfaces. Prime Putty does not require any curing. Prime Putty gives a smooth and glossy finish. Any kind of paint or distemper can be applied on it. Being a cementitious material it has better adhesiveness and durability. It can be applied on used surface after proper preparation. It is in dry powder form and does not produce any kind of unpleasant smell at the time of application. It is water resistant and can be applied on moist surface. It prevents the growth of algae and fungi on walls. No need to apply any kind of primer on it before application of paint/distemper Application Procedure Remove all loosely adhering material from the wall surface with the help of emery stone, putty blade or wire brush and clean water. The substrate should be clean, free from dust, grease and loose materials. Dry and absorbent surfaces should be moistened with sufficient quantity of clean water. Mix Prime putty with 30% - 35% clean water slowly to make paste. Continue the mixing for 10-15 minutes till a uniform paste is formed. After thoroughly mixing the Prime Putty apply the first coat on already moistened wall surface from bottom to upward direction uniformly with the help of putty blade. This would ensure less wastage and proper finish.5. After drying of first coat of putty just rub the surface gently with west sponge or rub the surface very gently with the putty blade in order to remove the loose particles. Allow the surface to dry for atleast 3 hours and then apply second coat of putty. Leave the surface to dry completely. After drying of second coat remove marks if any with the help of moist sponge or rub the surface very gently with the putty blade. Leave the surface to dry preferably for overnight. Always prepare a required quantity of putty and use it within 2-3 hrs. of mixing with water The total thickness of the coats should be limited to maximum 1.5mm. It is not essential to rub the surface done with Prime Putty however if you need to remove unevenness before applying any kind of paint/distemper, gently level the walls/ceiling surface with very fine water proof emery paper of not less that 500 number to get a glossy white surface. NoteGenerally the cause of efflorescence on the walls surface is the brick masonry, which is due to the quality of bricks, sand and water, If the effect of efflorescence on the brick masonry seems to be very high then proper care should be taken to control the efflorescence by applying Dubond’s Hydro Prime Single Coat. The efflorescence problem on brick masonry if exists impairs the bonding of Prime Putty as is with any other product.

...more

Power Tile Adhesives

Dubound's Power is a single component white adhesive. That is functional for high resistance laying of ceramic tiles, glass mosaics and homogeneous tiles. The tacking polymers deformability (superior speradability) and fine finishing of the material affixed.Areas of Application Facades, heat-radiant slabs, flooring and walls, indoor/outdoor use, in civil, industrial and commercial applications and for street furniture, in areas which are humid and subject to thermal shock and freezing. Floors and walls, for internal and external use Laying of ceramic and homogeneous tiles of all types, glass mosaic, stable marble and natural stone on flooring and walls, on cement-based deformable and non-absorbent substrates and heated subfloors. Suitable for homogeneous tiles, ceramics, large formats, low thickness slabs and stable natural stone Thicknesses up to 15 mm. Features & Benefits : Guaranteeing the long life of floors and coverings subject to large temperature variations Mineral adhesive for high-performance, high-deformation laying or overlaying with no vertical slip Power develops high transversal deformation along with high resistance to the stress of water and freeze/thaw cycles Single-component with very low volatile organic compound emissions Preparation of substrates In general, cement-based substrates must be free from dust, oil and grease, dry and free from any rising damp, with no loose, flaky or imperfectly anchored parts such as residual traces of cement, lime and paint, which must be totally removed. The substrate must be stable and without cracks, must have already completed curing hygrometric shrinkage and must present suitable mechanical resistance levels. Undulated areas must be corrected with suitable smoothing and finishing products. Non- absorbent substrates : Smooth, non-absorbent substrates which are compact and wellanchored must be prepared by cleaning with products suitable for the type of dirt present. If chemical cleaning cannot be carried out, proceed with mechanical abrasion by means of sand-blasting or scarification of the superficial layer and, if necessary, correct the surface with suitable levelling products. High- absorption substrates : On screeds and plasters which are highly absorbent and have dusty flaky surfaces it is advisable to apply one or more coats of HydroPrime a professional, concentrated water-base, surface insulation product, in accordance with the instructions, to reduce water absorption and to improve spreadability of the adhesive. Preparation of Adhesive Paste Prepare Power in a clean container, first of all pouring in a quantity of water equal to approximately . of that which will be required. Gradually add Power to the water in the container, mixing the paste from the bottom upwards with a low-rev (≈ 400/min.) helicoidal agitator. Then add more water until the desired consistency is obtained. The mixture must be homogeneous and without any lumps. For best results, and to mix larger quantities of adhesive, a stirring device with vertical blades and slow rotation is recommended. Specific polymers with high-dispersion properties ensure that Power is immediately ready for use. The amount of water to be added, indicated on the packaging, is an approximate value and will vary between the Power. It is possible to obtain mixtures with a more or less thixotropic consistency, depending on the type of application. Adding extra water does not improve the workability of the product, and may cause shrinkage in the plastic phase of drying and result in less effective final performance with a reduction in compressive strength and adhesion to the substrate. Application Power should be applied with a suitable toothed spreader, to be chosen according to the size and characteristics of the rear surface of the tiles. It is best to use the smooth part of the trowel to spread a fine initial layer, pressing down hard so as to obtain maximum adhesion to the substrate and to regulate water absorption, after which the thickness can be adjusted as required by tilting the spreader at an angle. Spread the adhesive over a surface area which will allow for laying of the covering materials within the indicated open time, and check for suitability of the adhesive at regular intervals. The open time may vary considerably even during the application, depending on various factors such as exposure to sunlight, air currents, absorbency of the substrate, temperature and relative humidity of the atmosphere. Press down each tile to allow for complete, uniform contact with the adhesive. In the case of laying in environments subject to heavy traffic, in outdoor locations, on underfloor heating systems or with materials to be smoothed on-site and with formats > 900 cm2, the double-spread technique must be used, which ensures laying procedures on fresh adhesive, 100% coverage of the rear of the tiles and maximum adhesion. In general, ceramic tiles do not require preliminary treatment, however these materials should be checked to ensure they are free from traces of residual dust or materials not properly anchored to the surface Special applications : Partial replacement of mixing water with Tuffex AD professional elastomeric latex enhances the adhesive’s capacity for transversal deformation. The real necessity for deformability of the laying system must be verified, as use of an excessively deformable adhesive together with highly-rigid substrates and laying materials may cause breakage and early unexpected yielding of the covering materials when placed under heavy and concentrated strain or loads. To define the percentage of Tuffex AD to be added, on the basis of the various factors related to the system, consult the Dubond Products (India) Pvt Ltd’s official web site. Elastic joints : Provide desolidarisation joints and elastic fractionizing joints for areas of 20/25 m2 in indoor applications, 10/15 m2 in outdoor applications and for every 8 metres length in the case of long, narrow applications. Structural and string-course joints have to be marked on the external facade. Elastic joints : Do not use on gypsum-base plasters and anhydrite screeds without the use of HydroPrime a professional concentrated, water-base, surface insulationproduct; on plastic or resilient materials, metals and wood; on substrates subject to continuous moisture rising Do not use the adhesive to correct substrate irregularities greater than 10mm Lay and press tiles onto fresh adhesive, making sure it has not formed a surface film the temperature, ventilation and absorption of the substrate and covering materials may vary the adhesive workability and setting times Protect against direct rain and freezing for at least 24 hours Use a toothed spreader suitable for the format of the tiles Use the double-spread technique for all outdoor laying Coverage This shall depend on the nature and flatness of the surface and the method of application, but at 1.5 mm thickness it is approximately 100 sq. ft for 20 kgs bag with a "v" notch (3mmx3mm) trowel when using a solid-bed trowel. For good coverage, itis vitally important tha tall surfaces should be clean, smooth, plumb, level and free from defects and undulations.

...moreBe first to Rate

Rate ThisOpening Hours