Transfer Turn Tables

Turn Tables are very useful devices for achieving accurate turning or re-positioning of the product during process / transfer. A wide variety of turn tables as manufactured in our Factory. Typical versions include, chain transfer, roller bed transfer, Pnuematic cylinder transfer etc

...more

Swing Conveyor

BUCKET ELEVATORS are specified for the conveyance of various powdered granular and lumpy material. Elevators are extensively employed in building material and chemical industries plant etc.Bucket elevators are used to transfer material from one floor level to another. These equipments are very useful and come handy when the available floor space is less as compared to incline conveyors, which occupy lot of space. This type of conveyor is further modified to suit specific needs like transferring unit loads like boxes, cartoons for loading and unloading.

...more

Slat Conveyors

Slat Conveyors Manufactured by us are used in Chemical industries, Assembly lines, Airports, Glass manufacturing plants and various other industrial units as per the specific requirements of Customer. Each Slat conveyor assembly under goes a proper design calculation, an equally strict and stringent manufacturing process with proper quality control and is tested in factory to assure a smooth and safe Equipment at customer’s premises. Type, size and speed of Slat Conveyors may vary as per the application where they are to be used. For detailed catalogue, please contact our office. Slat conveyors are used to convey heavy unit goods like refrigerator, automobile, machine parts etc. Typical construction consist of two parallel running chains with special attachment, guided throughout the conveyor length and driven by sprockets held securely in shafts. ‘C’ type folded slats are bolted to these chains and carry the load on top side. Slat return the loading point from bottom. Conveyor is powered by three phase A/C supply heavy duty motor and speed reduced by gear reducer. A wide range of Material of construction for slats is offered like, Mild steel, Stainless steel, Wood, Aluminum, Plastic, PVC etc.

...more

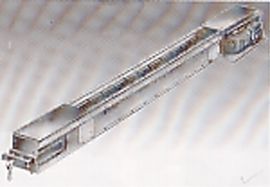

Screw Conveyors

The SCREW CONVEYORS is of simple design, easy to maintain, of small width, permits intermediate discharge of the material at several points (of special importance for dusty and hot materials, and also materials with an obnoxious odour ), is readily made dust-tight by jacketing the trough. ADVANCE EQUIPMENT CO. design various types of SCREW CONVEYORS viz. Twin Screw Conveyors, Screw Feeders, Paddle Conveyors, Mixing Conveyors, Right and Left Handed Screw Conveyor and Rotary Air Lock Valves etc. Screw conveyors made by us are in range from 100gms/min to 25T/hr. We also make center less screw know as Auger for feeding fine powder material. Material of construction offered is Mild steel, Stainless steel. Two screws are placed adjacent to each other to make twin screw conveyors and mixers.

...more

roller tables

We make a wide range of Roller Conveyors classified as - Powered and non powered version conveyors using standard Precision bearings for heavy loads (250 kgs and above) and pressed bearings for lighter loads..

...more

Roller Conveyors

ROLLER CONVEYORS serves to convey pieces-goods horizontally and up or down slightly as powerized and gravity roller conveyors. ADVANCE EQUIPMENT CO. offers a range of roller conveyors i.e. gravity driving accumulating, transfer conveyors through to peripherals control for medium to heavy duty application. Fully developed and tried construction techniques make these conveyors a reliable part of any material handling system offering future flexibility and compatibility of equipment. We make a wide range of Powered and non powered version roller conveyor using standard Precision bearings for heavy loads (250 kgs and above) and pressed bearings for lighter loads. Many combinations offered in terms of Roller pitch, roller diameter, roller moc, between frame width. Rollers are spring loaded with Hex axle or round axle. Please ask for our detailed catalogue. Belt Driven Live Roller Conveyors Belt Driven Live Roller Conveyor ( BDLR ) is designed primarily for handling hard to convey items, such as bundled materials, drums and pails, as well as other awkward and heavy items. •These conveyors are also recommended for use where interruption in work flow is required or where conveyed items must be taken from the line at specific points.Advantages of BDLR Conveyor:Equipped with rollers for easy removal and to simplify conveyor relocation.¤ Because they are powered by a friction belt beneath the roller, the rollers present a firm conveying surface that largely eliminates off-tracking and direct contact damage to the conveyor belt.¤ Pressure rollers are adjustable to minimize line pressure.¤ Available belt speed ranges from 30 to 100 FPM.¤ Travel direction is reversible in units up to 100 feet in length with a center drive.¤ Standard centers are 2.4", 3", 4" and 6" but multiples thereof may be provided.¤ Standard frame widths are 12", 15", 18", 21", 24", 30" 36", 42" and 48". (Dimensions are to the outside of the frame.)¤ The spring loaded rollers are 1.9" in diameter by 16 ga. with 7/16" hex axles, on required centers.¤ Availability of accumulation beds.

...more

Product Storage Silos

Silos are vertical storage tanks used in many industries like Cement, Fertilizer, Food etc to store bulk material as a reservoir. Typical mater

...more

Product Loading Conveyors

Many versions of product loading conveyors are made by us. These are used in assembly line for stocking the material in process and feeding automatically to next machine for further processing

...more

Pinch Roll Assembly

This equipment is used in steel plants for feeding hot ingots to rolling mills for rolling into steel sections like flats, rounds, channels etc. As the name suggests, the top roller clamps hot ingots and is conveyed in forward direction by driving the bottom roll. At fixed clamping pressure is maintained between the two rolls by a pneumatic / hydraulic cylinder located at the rear side.

...more

Paddle Conveyor

The SCREW CONVEYORS is of simple design, easy to maintain, of small width, permits intermediate discharge of the material at several points (of special importance for dusty and hot materials, and also materials with an obnoxious odour ), is readily made dust-tight by jacketing the trough.Screw conveyors made by us are in range from 100gmsmin to 25Thr. We also make center less screw know as Auger for feeding fine powder material. Material of construction offered is Mild steel, Stainless steel. Two screws are placed adjacent to each other to make twin screw conveyors and mixers.

...more

Material Testing Machines

→ Reports Contain: Peak load, Break load, Elongation at peak load, Elongation at break load, Tensile strength at peak load, Tensile strength at break load, % elongation at peak load, % elongation . at break load, Young’s modulus, Yield load, Yield stress, Flexural stress, Flexural modulus and Load Vs Elongation graph. → Data Entry: All Data through software or From Console. → Reports: Graphical + Data through software. → Units: Kg, Newton, Pound, cm, mm & inch. → Data Merging Facility: Available. → Load Cell: 1 no. (Others Optional). → Speed: 2 – 500 mmmin (others optional) .*** → Machine Capacity: Up to 1000 Kg (Others Optional). → Tests: Tensile; Flexural; Compression.

...more

Inclined Material Loading Conveyors

Advance Equipment Co. has supplied many types of Portable and stationary type of material loading / unloading conveyors. Conveying speeds range from 1 mtr /min to 25 mrts /min with top height adjusting feature. Many standard versions are available ready for shipment for your application.

...more

Conveyors

CONVEYORS can be specified as horizontal, inclined, vertical loop and closed-circuit installation. Its tough chain conveyor designed to handle the most severe application. Curved section let you design a systems that meets your exact needs with minimal efforts. The heavy-duty construction and long life of a CONVEYORS translate to millions of tons of material moved. Since all components are jig welded, interchangeability is assured. Carbon steel construction, with abrasion resistant divider plate and access panels, deliver strength and long life, Sprocket of flame-cut steel, heat treated, are made for years of service. CONVEYORS are totally dust-free.

...more

Conveying Equipment

we are one of the leading manufacturers, exporters and suppliers of industrial material handling equipment and systems such as conveyors, systems, elevators and bearings. With our range, we are catering to the diverse industrial requirement for material handling. Along with a range of products, we also offer value-added services for installation to facilitate our clients.

...more

Bucket Elevators

We are specialized in manufacturing of BUCKET ELEVATORS. we have the capability to furnish elevators with capacities over 5 to 160M3/hr. and height up to 40m. Their line of buckets range up to 50" wide and are adaptable to the complete line of elevators we offers, also offers design Arms and Swing Tray type Elevators. BUCKET ELEVATORS are specified for the conveyance of various powdered granular and lumpy material. Elevators are extensively employed in building material and chemical industries plant etc. We establishing Modern Techniques in Designing, Engineering and manufacturing such as Computerized Design and special Welding Methods. Bucket elevators are used to transfer material from one floor level to another. These equipments are very useful and come handy when the available floor space is less as compared to incline conveyors, which occupy lot of space. This type of conveyor is further modified to suit specific needs like transferring unit loads like boxes, cartoons for loading and unloading. Further automation is achieved in loading and un-loading by providing a small roller / belt conveyor at feeding and exit point which takes care of feeding the goods to elevator. If a precise control and faster transfer is needed, it is achieved by incorporating sensing devices like Limit switches, proximity switches etc. to suit individual application.

...more

Belt Conveyors

The AEC 100 Friction Driven Belt Bends ensures positive transfer of various products from small packages to bins.Designed to carry loads of up to 50kg at speeds from 5m/min to 60m/min without product position alteration. Versatile and economic positive handling• Strong solid framework• Standard range of modules ( specials on request)• High Density Conical End Rollers• 2Ply Non mono Belting• Vulcanised Belt joints• Positive Belt Guiding system• Low running noise, under 68Db• Belt Change within 30 minutes Belt conveyers are employed to convey a great variety of unit loads and bulk materials along horizontal or gently inclined paths and also to carry articles of light weight in line production from one operation to another. BELT CONVEYERS are the most relevant solutions and can be described as most commonly used conveying equipment in any plant. The wide range of materials that can be conveyed by this piece with little modifications, makes it an equipment which has come to stay in the field.ADVANCE EQUIPMENT CO. designs & manufactures various types of BELT CONVEYERS, which are classified as Stationary Portable & Mobile Conveyers, and also design special purpose Conveyers. In both Portable & Mobile Conveyers ADVANCE EQUIPMENT CO. has built the the Conveyers to carry the maximum load at the maximum incline. The AEC 150 Friction Driven Belt Bends ensures positive transfer of various products from medium packages to Airline Baggage.Designed to carry loads of up to 100kg at speeds from 10m/min to 120m/min without product position alteration.• Versatile and economic positive handling• Strong solid framework• Standard range of modules ( specials on request)• High Density Conical End Rollers• 2Ply Non mono Belting ( Flame Retardant to ISO 340 on request) • Vulcanised Belt joints• Positive Belt Guiding system• Low running noise, under 68Db• Belt change within 30 minutes

...more

Ball Transfer Units

We make a wide range of Ball transfer units. Standard ball sizes include ½”, ¾” and 1” center balls. These are arranged in diamond pattern to achieve transfer surface. Ball transfer unit are used for fairly flat bottom products like cartons, Metal trays etc. Precise machining, accurate fitment help in providing minimal gap only to assist removal of any foreign object drained out from bottom. We stock a huge inventory of these units ready for immediate delivery. Normal lead times are two to three weeks.

...more

Ball Transfer Unit

We make a wide range of Ball transfer units. Standard ball sizes include ½”, ¾” and 1” center balls. These are arranged in diamond pattern to achieve transfer surface. Ball transfer unit are used for fairly flat bottom products like cartons, Metal trays etc.Precise machining, accurate fitment help in providing minimal gap only to assist removal of any foreign object drained out from bottom. We stock a huge inventory of these units ready for immediate delivery. Normal lead times are two to three weeks.

...more

apron conveyors

They are used to carry Materials and pieces horizontally and inclined lines. These conveyors are made of pans with uneven edges to keep a check on material loss. Our conveyors are flexible for adaptation to lifting loads from hoppers bins. They can be regulated by adjustment of a sticker plate at the entrance point. Our conveyors have a heavy handle, which can handle abrasive and hot material. It is capable of handling material up to 2000 per hour. It does not produce any noise while carrying the material.

...more

conveyers system

industrial material handling equipment

conveyers systems

Be first to Rate

Rate ThisOpening Hours