Single Row Air Cooled Condenser

Single Row Tube Bundles generally are generally arrangements of flat fin tubes having Single Row in Tube Bundles. Since these tube bundles have single row that’s why they are called as Single Row Fin Tube Bundles.As compared to the multi-row arrangement single row heat exchangers have the following advantages: Optimal Resistance against freezing Less weight Higher Heat Transfer area

...more

Energy Saving FRP Fans

OverviewThe high cost of power has made manufacturers look into equipment to reduce power consumption. Cooling Towers, heat exchanger, humidification and ventilator are areas where a major saving is possible at reasonable cost for manufacturers.What is FRP Fans?Aerotech’s aerodynamically designed energy efficient FRP Hollow axial flow fans have helped in 20% reduction in power consumption and recovering the cost of fan in short time.Traditionally Cast aluminum fans consume more power due to low efficiency and heavy weight. The fans operate throughout 24 hours using excess power, which can be saved by using Aerotech’s energy efficient FRP Hollow bladed fans.Aerotech has designed and developed structurally strong FRP hollow fans which are light-in-weight with help of USA based NACA* computerized software, having more lift and low drag airfoil shape, Engineered twist, optimized chamber to increase the fan efficiency resulting a nominal low operating cost.Components of FRP FansAerotech method of Axial Flow Fan design is based on data obtained from the combination of the blade element theory, model fan tests in a wind tunnel, and tests of full scale fans in the field. The data are plotted as curves for fans of standard theory form, making the actual operation in designing the fan very short and simple. For the analysis or design of special blade which is not conforming to the standards, the modified blade element theory is used, with airfoil section characteristics, which give resultant powers and efficiencies checking the standard model data. APPLICATION OF AXIAL FLOW FANSThe axial flow fans are widely used for providing the required airflow for the heat & mass transfer operations in various industrial equipment and processes. These includes cooling tower for air conditioning & ventilation, humidifiers in textile mills, air–heat exchangers for various chemical processes, ventilation & exhaust as in mining industry etc. All major industries use large number of axial flow fans operation, such as : Cooling Towers Heat Exchangers Humidifiers Ventilation Industrial Air Circulator Man Cooler All type of Industrial Axial Flow Fan Products Energy efficient FRP Axial Flow Hollow fan Assemblies Aluminum Axial Flow Hollow fan Assemblies FRP fan Stack FRP Inlet Bell Mouth For ACC Drive Shaft Gear Box Range of FRP Axial Flow Fans: Fan diameter : 250mm to 15000mm Air Flow : 0.5 M3/s to 2500m3/s Pressure : 1mm to 100mm Tip speed Limit : Up to 70 M/s Range of Aluminum Axial Flow Fans : Fan diameter : 250mm to 5500mm Air Flow : 0.5 M3/s to 400m3/s Pressure : 1mm to 100mm Tip speed Limit : Up to 100 M/s Feature of Aerotech FRP Fans:Corrosion Free Material: The raw material i.e. Fiber Reinforced Plastics (FRP) provides the desired non-corrosive quality to the fan blades, resulting in the operation of the fans even in the chemical environment.Lightweight: FRP is Lightweight material which ensures a low moment of inertia, minimum wear & tears on motor, bearing and drive system. Hollow FRP blades is lighter than aluminum fan assembly which makes it easy to carry and due to light weight there is no possibility of damage to fan & drive during sudden stops.Tailor Made Designs: Composite structural design can be tailor made by using various glass fibers (Glass cloth & woven roving mat and roving) in right direction while moulding the fan blades with Epoxy resin thus imparting the desired mechanical strength by improving its industrial stability and enhanced mechanical properties.Aerotech design of the fan blades ensure more airflow, lower noise level & less power consumption means high efficiency. The AERODYNAMICALLY designed fan impeller of the fans, fabricated by composite material can be excellent alternative to ensure enhanced efficiency & appropriate energy saving apart from wide gamut of critical advantages.USP of Aerotech FRP Fans:HOLLOW FAN BLADES.The hollow design of fan blades The basic purpose of a “fan” is to move a mass of gas or vapor at the desired velocity. For achieving this objective there is a slight increase in the gas pressure across the fan rotor or impeller. However main aim remains to move air or gas without any appreciable increase in its pressure. The total pressure developed by the fan is of the order of a few millimeter of water gauge. A “blower” which is also referred to as “fan” in some literature deliver the gas or air with the appreciable race in pressure to overcome some kind of resistance in the flow. Some applications develop pressure of the order or 1000 mm W.G. or more. An axial flow fan stage in its simplest form consists of a rotor made up of number of blades fitted to the hub. When it is rotated by an electric motor or any other drive, a flow is established through the rotor. The actions of the rotor causes an increase in the stagnation pressure of air or gas across it. A cylindrical casing encloses the rotor.AERODYNAMIC DESIGN OF FRP HOLLOW BLADEAs mentioned previously the choice of correct twist and of special airfoil sections to reduce compressibility losses are of major importance in modern fan blades design. However other considerations still remain to be studied with care if the efficiency of the blade is to be kept at its maximum under severe operating conditions.CENTRIFUGAL AND AERODYNAMIC TWISTINGIn variable-pitch fan as described later the blades are turned in the hub about their longitudinal or pitch-change axis. Clearly the mechanism provided to produce this pitch change must be capable of exerting sufficient force to overcome any mechanical or aerodynamic opposing force set up by the blades themselves. It will be useful then to see exactly what these force are.The “mechanical force” involved is known as Centrifugal Twisting Moment (C.T.M)which as its name implies is closely allied to the normal centrifugal force acting on the blades when the fan is rotating about the shaft . It is turning couple brought about by the fact that the blade section are inclined at an angle to the fan of rotation and results in the natural tendency for any fan blade, when rotating turned about its longitudinal axis towards zero pitch so that the blades section are turned in to the fan blade rotation .THRUST AND TORQUE FORCES.The main factor that determines the force developed by an aerofoil section is the angle at which it is inclined to the relative airflow, i.e. the angle of attack in order, therefore, for the fan blade section to develop the requisite aerodynamic force for propulsion, each section along the blade must be inclined at the appropriate angle of attack to the relative airflow direction pertaining to the section hence knowing angle of attack is a simple mater to indicate the force developed as shown in figure 1) from which it will be noted that the total blade angle of attack and the helix angle.

Color : Blue

Condition : New

Automatic Grade : Automatic

Driven Type : Electric

Warranty : 1year

Material : FRP

...more

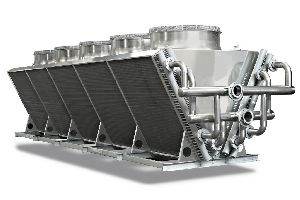

Evaporative Condenser

The medium to be cooled is allowed to flow through tubes. Water is sprayed over tubes to form a water film surface; cool air is blown over the tube surface with help of induced draft fans mounted at the top. Temperature of both cool air and sprayed water rises, partial water will transform from liquid phase to vapor. Latent heat of vaporization water will carried out massive heat. While, a negative pressure will be formed inside the heat exchanging tube cabinet under the effect of fan’s induced draft, which will enhance the evaporation of sprayed water, thus increasing heat transfer efficiency. Non-vaporized water will be cooled down during falling into the circulation water tank. The water inlet valve will automatically refill cooling water to keep a certain water level and a normal circulating operation. While the medium to be cooled remains in a closed circulation.

...more

cooling tower splash fill

Water falls over successive layers of horizontal splash bars, continuously breaking into smaller droplets, while also wetting the fill surface. Plastic splash fills promote better heat transfer than wood splash fills.

Application : Air Compressors

Color : Black

Condition : New

Warranty : 1year

Temperature : 50-100℃

Gauge Thickness : 15-20mm

...more

cooling tower nozzle

These spray water to wet the fill. Uniform water distribution at the top of the fill is essential to achieve proper wetting of the entire fill surface. Nozzles can either be fixed and spray in a round or square patterns, or they can be part of a rotating assembly as found in some circular cross-section towers.

Thickness : 5-10inch

Application : Cooling Tower

Grade : AISI, ASTM

Color : Metalic

Surface Finishing : Non Coated

Piston Length : 1.5-2ft

...more

Cooling Tower Frame

Frame and casing : Most towers have structural frames that support the exterior enclosures (casings), motors, fans, and other components. With some smaller designs, such as some glass fiber units, the casing may essentially be the frame.

Weight : As per size

Color : Grey

Warranty : 1year

Gauge Thickness : 15-20mm

...more

Cooling Tower Film Fill

Consists of thin, closely spaced plastic surfaces over which the water spreads, forming a thin film in contact with the air. These surfaces may be flat, corrugated, honeycombed, or other patterns. The film type of fill is the more efficient and provides same heat transfer in a smaller volume than the splash fill.

Application : Industrial

...more

Cooling Tower Fan

Axial Flow (propeller type) fans are used in towers. Generally, propeller fans are used in induced draft towers, fans are found in forced draft towers. Depending upon their size, the type of propeller fans used is either fixed or variable pitch. A fan with non-automatic adjustable pitch blades can be used over a wide kW range because the fan can be adjusted to deliver the desired air flow at the lowest power consumption.

Usage/Application : Air Conditioning

Power : 1-3kw

Blade Material : Aluminium, Stainless Steel

Warranty : 1yr

...more

cooling tower drift eliminator

These capture water droplets entrapped in the air stream that otherwise would be lost to the atmosphere.

Size : 28x28Inch, 28x30Inch, 30x30Inch

Thickness : 400-500mm

Weight : 20-40Kg

Color : Black

Feature : Eco Friendly, Perfect Shape

Condition : New

...more

Cooling Tower Cold-water Basin

The cold-water basin is located at or near the bottom of the tower, and it receives the cooled water that flows down through the tower and fill. The basin usually has a sump or low point for the cold-water discharge connection. In many tower designs, the cold-water basin is beneath the entire fill. In some forced draft counter flow design, however, the water at the bottom of the fill is channeled to a perimeter trough that functions as the cold-water basin. Propeller fans are mounted beneath the fill to blow the air up through the tower. With this design, the tower is mounted on legs, providing easy access to the fans and their motors

Material : FRP

Application : Water Cooling

Weight : 0-100kg,400-500kg

Color : Grey

Power : 1-3kw

Shape : Rectangular

Features : Easy Maintenance, High Performance

...more

Cooling Tower Casing Panel

Most towers have structural frames that support the exterior enclosures (casings), motors, fans, and other components. With some smaller designs, such as some glass fiber units, the casing may essentially be the frame.

Material : Pvc

Color : Grey

Capacity : 1000-1500L

Warranty : 1year

Gauge Thickness : 15-20mm

...more

Cooling Tower Air Inlet Louver

This is the point of entry for the air entering a tower. The inlet may take up an entire side of a tower (cross-flow design) or be located low on the side or the bottom of the tower (counter-flow design).

Size : Available in different sizes

Material : PVC, UPVC

Shape : Square, Rectangular

Application : Industrial Use

Color : Black

Feature : Fine Finished, Perfect Shape

...more

Cooling Tower

OverviewThis engineering note has been prepared to educating the Cooling Tower user, this deals with a very specific subjects, which Aerotech Energy Pvt Ltd appeal our capabilities to do the CT Up-Gradation Projects.Aerotech prepared the documents so that the user engineers can easily understand the cooling tower theory and possibilities to upgrade on existing Cooling TowersWhat is a cooling tower?Cooled water is needed for, for example, air conditioners, manufacturing processes or power generation. A cooling tower is an equipment used to reduce the temperature of a water stream by extracting heat from water and emitting it to the atmosphere. Cooling towers make use of evaporation whereby some of the water is evaporated into a moving air stream and subsequently discharged into the atmosphere. As a result, the remainder of the water is cooled down significantly. Cooling towers are able to lower the water temperatures more than devices that use only air to reject heat, like the radiator in a car, and are therefore more cost-effective and energy efficient.Components of a cooling towerThe basic components of a cooling tower include the frame and casing, fill, cold-water basin, drift eliminators, air inlet, louvers, nozzles and fans. These are described below.Frame and casing. Most towers have structural frames that support the exterior enclosures (casings), motors, fans, and other components. With some smaller designs, such as some glass fiber units, the casing may essentially be the frame. TYPES OF COOLING TOWERSThis section describes the two main types of cooling towers: the natural draft and mechanical draft cooling towers.Mechanical draft towers are available in a large range of capacities. Towers can be either factory built or field erected – for example concrete towers are only field erected.Many towers are constructed so that they can be grouped together to achieve the desired capacity. Thus, many cooling towers are assemblies of two or more individual cooling towers or “cells.” The number of cells they have, e.g., a eight-cell tower, often refers to such towers. Multiple-cell towers can be lineal, square, or round depending upon the shape of the individual cells and whether the air inlets are located on the sides or bottoms of the cells.The three types of mechanical draft towers Type of cooling tower Forced draft cooling tower: air is blown through the tower by a fan located in the air inlet Induced draft cross flow cooling tower water enters at top and passes over fill, air enters on one side (single-flow tower) or opposite sides (double-flow tower) , an induced draft fan draws air across fill towards exit at top of tower Induced draft counter flow cooling tower, hot water enters at the top, air enters bottom and exits at the top, uses forced and induced draft fans.

Warranty : 1 Year

...more

Air Finned Coolers

Air cooled Heat Exchangers (or) Fin fan Cooler or Air Fin Cooler are used for Heat rejecting from a hot process fluid to the surrounding atmosphere by using the atmospheric air as a cooling media.What is Air Finned Coolers?The Air Fin Coolers are basically designed with multiple rows of finned tubes in a series of surface and required numbers of fans are used to move the low temperature atmospheric ambient air over the finned tube coil surface in order to cool the hotter fluid mediaThe various types of headers are Welded Bonnet Header, Plug Header, Manifold header, Plug and pipe header etc., The various types of Fins are 'L' type Wrap-On Fins, 'G' type Embedded Fins and Bi-metallic Extruded Fins etc.. In some small type heat Exchanger wire/ strip type copper wounded / knurled Fins are also used.These Air Cooled Type Heat Exchangers are used in oil, gas, petrochemical, refinery, power and condensation plants. All type of fluids in process industries are cooled in Air Fin Coolers with the use of atmospheric air, as the cooling media which resulting in economy in running costs.Components of Air Finned CoolersAir Fin Coolers consist of number of bays. Each bays consists of the following major equipment: Heat Exchangers Fin Tube Bundles. Supporting structure for the Tube Bundles Fan arrangement with Gear Box and Motor or Belt & Pulley Drive. Piping with valves and instruments as per the requirement etc.

Material : Carbon Steel & Stainles Steel

Application : Evaporative Air Coolers, Industrial

Weight : Multiweight

Color : Grey

Voltage : 110V

...more

Air Cooled Steam Condenser

OverviewAir cooled steam condenser is required to condense the exhaust steam from the turbine into the condenser at constant pressure and temperature and required to maintain the backpressure at the turbine exhaust flange.What is a Air cooled steam condenser?Air cooled steam condenser comprises of Tube Bundles with Circular/Flat / Elliptical finned tubes fixed at a height on a “A” or V- frame structure at an angle of 60 Deg. Axial Flow fan mounted at the lower vertex of the ‘A’ or ‘V’ Frame throw the cooler air at ambient temperature into the ‘A’ or ‘V’ Frame. When the Air passes through the finned tube bundles it will cool the fluid inside the finned tubes or condenses the steam inside the tube by reducing the latent heat of steam.Components of Air cooled steam condenserAir cooled condenser comprises Cells / modules / bays. Each cell consists of the following major equipment: Steam Manifold / Steam Duct from Turbine exhaust flange to the ACC. A Frame structure supporting the Tube Bundles Axial Flow fan arrangement with Gear Box and Motor. Condensate & Hotwell Tank with Pumps Ejector for extraction of the Non condensable gases from the tube bundles. Piping with valves and instruments as per the requirement. Instrumentation and Electrical as per the ACC operational philosophy.

Weight : 1500-2000kg

Voltage : 110V

Automatic Grade : Automatic

Power : 1-2kw

Driven Type : Electric

Warranty : 1year

...more

Air Cooled Condenser

1 Pair (MOQ)

Manufacturer of ACC,CT, ACHE, Evaporative Condenser, Adiabatic Cooling Tower, FRP Energy Saving Fans

Type : Air Cooled Condenser

Certification : ISO 9001:2008

Application : Industrial

Voltage : 440V

Condition : New

Automatic Grade : Automatic

Driven Type : Electric

Country of Origin : India

Brand Name : AEROTECH

Structure : YES

After-Sales Service Provided : YES

Maximum Working Pressure : SPEC

...more

adiabatic cooling tower

Air Cooled Steam Condenser

Cooling Tower

Heat Exchangers

energy saving fans

frp fan stack

Tube Bundle

Cooling Towers

Heat Exchangers

Evaporative Condensers

energy saving device

performance improvement

Be first to Rate

Rate ThisOpening Hours