Air Separation Plant

Get Price Quote

Air separation plant utilise a very low temperature rectification method to produce nitogen, oxygen & argon gases. They can also be used to make other rare gases such as neon, krypton, helium & xenon via the cryogenic rectification of air. These plants can produce gaseous products for distribution of pipelines or cryogenic liquids.

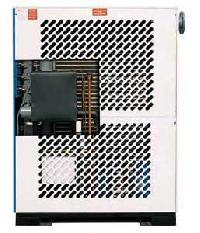

air drying plant

Get Price Quote

In Refrigerated Air Dryer plant used. Compressor used in this type of dryer usually of the hermetic type. The dryer work on the principle heat transfer. In the main dryer cooling carry our two stages. First stage air-to air and second stage air –to refrigeration. Process: Saturated compressed air enters to air to air heat exchanger, where it is precooled by outgoing cold dry air .Highly effective precooler reduces temperature considerably, and enables to use smaller and economical refrigeration system. Then the precooled, relatively low temperature compressed air enters to air to refrigerant heat exchanger where it is cooled down to 3 degree ( pressure dew point). At this temperature, moisture in vapors from condense to liquid form and separated from compressed air by moisture separator and discharge to drain valve. The cold dry compressed air passes back to air to air heat exchanger. And gain temperature by exchanging heat with incoming out from the dryer id ready to use for instrumentation and process air applications.

Best Deals from Air Drying Plant

air drying plant

Get Price Quote

air drying plant, Air Compressors, Chiller Plant, Filling Machine

Air Separation Plant

Get Price Quote

Air Separation Plant, Oxygen Gas Analyzer, Gas Purification System