Vacuumised Powder Conveying System

Salient Features : Used to transfer material having bulk density upto 1.0gm/cc. Smooth surfaces, No segregation or degradation of Product. Dust-free and gentle material handling / High-standard filters for pharma applications. Minimum of residual material inside the conveyor. Safe for operation with ignitable materials and for the use inside explosion zones. Easy disassembling and cleaning of the conveyors. Manual or automatic suction processes / Lightweight and mobile systems available. All contact parts SS304/ SS316/ SS316L & all gasket /seal - Silicone. Universal adaptability can be easily installed on any receiving equipment like process tank, ibc, conical mill,pin mill, blender, tablet press etc. Adaptors provided to suit existing inter opening on user's equipment No tool required for opening & cleaning All validation documents like DQ/IQ/OQ are supplied with the system Available in sizes for up to 150 / 200 /300 / 600 / 1200 /2000 / 3000 /4000/5000 kg/hr, depending on bulk density and nature of product Technical Specifications : System is designed based on the consideration, material having density 0.5 gm/cc will be having convey rate of approximately Capacity= 100 to 5000kg/hour. Material Of Construction= MOC- SS316; Rest- SS304. Filter Cleaning= Electro pneumatic sequential time based air blasted filter cleaning system. Discharge= Full opening / Level Sensing= Through auto level sensor. Filter made from non-woven fabric & washable. Vacuum Source= specially designed blower / Vacuum generator. Vacuum source is having silencer at suction and discharge port to reduce the noise level. Vacuum source is equipped with a suction air filter to prevent the entry of foreign particles. Vacuum Safety Valve for equipment safety. Vacuum Gauge and isolator valve on the Vacuum power source for ease of maintenance. Vacuum regulating valve at the vacuum power source to maintain the process harmony. Control Panel will be manufactured from Stainless Steel 304 having dust proof construction. Control Panel is sequential time base having 4- operation cycles. Material and Convey line is through static conductive, Non toxic flexible food grade hose pipe. All the pneumatic is of “Festo” Or Equivalent Typical Advantages Of Conveying System : SUITABILITY : Emptying or filling process equipment (reactors, dryers, blenders / mixers /centrifuges, etc.). DUST FREE : Material can be drawn directly from drums, Bags, storage containers, process.vessels- no messy dumping or manhandling. Charging of powder directly into closed vessels, including those under vacuum or pressure, preventing the formation of dust and the introduction of oxygen. Charging also possible in the presence of solvents. System can be completely sealed, any leakage in system will be inward- no noxious or hazardous materials discharged into work area. VERSATILE : Conveying lines can be routed between floors, through partitions, aroundmachinery- can easily be re-routed to accommodate process modifications. Adaptable to many process operations- easily integrated & automated. SANITARY : Materials of construction & finishes selected for the products being handled. Easily disassembled modular design facilities cleaning. ECONOMICAL : Lower service/ Lower cleaning costs / Minimum maintenance- few moving parts. AL!X Capabilities : Direct loading of blenders, mixers & other vacuum- tolerant vessels. Automatic weighing & batching of multiple ingredients. In-line check sieving while conveying. Dust-free transfer of ingredients to tablet presses & capsule fillers. Conveying tablets & empty or filled capsules. Delivering product, containers & closures to filling & packaging materials. Integration & automation of material transfer & process controls.

...more

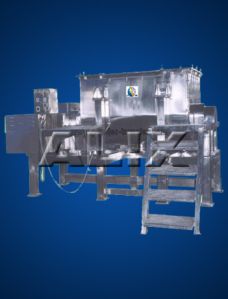

V Blender

The V blender is normally used for formulation granules blending, and will be fixed with two different frames. One end is driving and second will be supporting end. 'V' Blender, the rotating shell V-Type Blender is used only as dry mixers. Advantages of Blending operation in this Blender is minimal attrition when blending fragile granules, large capacity, and easy loading and unloading. Modification such as the addition of baffles to increase mixing shear have been made to these types of blenders. Salient Features : Basic equipment is made to facilitate vacuum charging system. Due to vacuum rated design we can load the blender through vacuum transfer system with inline Milling. Particle size reduction and attrition are minimized due to the absence of any moving blades. Hence it can be used for fragile materials. The Bin charging system can also be incorporated in it which provides complete dust free closed environment for charging and discharging. Discharge with specially designed adaptor assembly with T C connection, in case of damage of butter fly this will safe guard the material The absence of shaft projection eliminates product contamination. Capacity available from 100L -2000L. Optional Accessories : Documentation. Flame Proof Construction Stair Case with Platform Pneumatically Operated Butter Fly valve for discharge. Provision for Spray Ball

...more

SS Screw Conveyor

screw conveyor, helix conveyor or center less auger conveyor, consists of a spring steel or stainless steel, flexible screw that is enclosed in a flexible or rigid plastic tube, or a rigid steel tube and driven by an electric motor normally located at the discharge end of the conveyor. This simple design delivers efficient performance and high reliability while reducing maintenance and cost. When properly engineered according to the specific characteristics of the material being conveyed and the process into which it will be integrated, a flexible screw conveyor can outperform rigid screw conveyors, bucket elevators, drag chain conveyors, aero mechanical conveyors and other equipment intended to transport powder and bulk solid materials.The intake of a flexible screw conveyor is typically equipped with a charging adapter - a U-shaped trough that connects to the outlet of a hopper, or other equipment such as a bulk bag discharger, bag dump station, grinder, screener, blender, reactor, etc. At the intake end, the screw is exposed to the bulk materials to be transferred. When the screw is rotated by the driver, materials are propelled by the screw to the discharge end.During operation, the screw is automatically self-centered within the tube, providing clearance between the screw and tube wall. This offers sufficient space for particles to flow without damage, and reduce the possible rubs between the screw and the tube walls.There is only one moving part in this screw conveyor system - the screw. Thus the material does not come in contact with seals or bearings, which eliminates any possible contamination. Features & Advantages : Only one moving part for easy maintenance Free of oil contamination to the products without any bearing or seal Convey in any direction for short and middle distance Gentle handling and blending of bulk products Enclosed tube prevents dust contamination to the working area. Easy and fast cleaning by compressed air, water, steam, etc Mobile frame for easy movement (Optional)

...more

Shredding Machine

New U Type Basket Granulator provides trouble free granulation of your wet and dry material. This Granulator provides stepless speed control, selection of baskets and rotors for optimum performance. Further, all parts are easily accessible for cleaning.Granulator is mounted on easy to move trolley and can be connected directly on line to Centrifuge or any other m/c. for wet granulation. This granulator can also be adapted for granulation of dry products such as tray dried material or granulation of raw materials. Rates upto 3000 kg/hr are possible with 10 mm dia opening screen.Drive system consists of rugged spindle with sealed geared motor. This simple layout allows in line material flow while providing easy pull out access for cleaning and maintenance. There are no complicated maintenance procedures or seals to replace. Optional Nitrogen blanketing during granulation is offered. Process Specifications : Granulator will achieve peak capacity of 800 to 1000 kg/ hr This will enable granulator to process material during auto discharge from centrifugal or Bag charging on Top Hopper of the Granulator. Granulator screen size : R10T18 (10Dia opening on Triangular pitch of 18) Rotor Diameter: 400 mm Rotor Length: 400 mm Rotor speed: 60 RPM Displacement / revolution: 1 Liter Displacement per hour: 3600 Liter Theoretical sweep Power: 3/5 HP Technical Specifications : Area: FLP / Non FLP (as per customer’s requirement). This System will consist of basket granulator connected to discharge port of centrifugal. Wet cake falling from Centrifugal will be granulated and will move through PTS for charging in Reaction Vessel at a ht. of approx. 6 Mtrs. Nitrogen purging ports are provided on Granulator. Granulator will have pull out type U screen for easy access. Granulator will be Trio–fitting mounted from Bottom to easy fitting with PTS System. Outlet of granulator will be rectangular and will have rectangular to round converter connected. Manufacturing Specifications : MOC: All contact parts in SS316L duly finished. Non Contact: SS304/ Carbon steel covered in SS304 Electricals : 3HP/ 1440RPM/ 440Volts/ 3Phase Crompton/Remi Motor FLP Motor Drives: Rotomotive / Bonfiglioli to vary & achieve final 60RPM. Scope Of Supply : Granulator complete with all subsystems mentioned as Main Granulator with geared drive Exclusions : Provision of Utilities supply points near equipment. These utilities include: Power 460 VAC 3Ph 60Hz, 2.2 kW Compressed Instrument Quality 5 bar 2 Cu M/hr.

...more

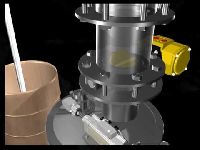

Rotary Air Lock Valve

Rotary Air Lock valve is fitted below the cyclone seperator & dust collector. It is also used like feeder. When the material mixes with the air it will separate the valve. The system ensures dust free operation.

...more

Roots Blower

This pneumatic conveyor in dilute phase, generally thrust, allows to carry pulverulent products at high throughput rate along important distances (not fragile products).This pneumatic conveyor in dilute phase by thrust lies in the use of wheel feeders (rotary valves) allowing to introduce measured doses of product in the piping.Regular application of pneumatic conveyor in dilute phase by thrust: silos emptying and silo filling. Advantages : In pneumatic conveyor in dilute phase by thrust, the product dilution rate in the air is very important, and therefore requires a high throughput rate of air to transfer the product. The greatest advantage of pneumatic conveyor in dilute phase by thrust is the ability to supply several reception points as from a supply point. The disadvantages of pneumatic conveyor in dilute phase by thrust : the least interesting speed to save during operation. Not convenient for fragile or abrasive materials or materials where the size of particles is highly variable.

...more

Ribbon Mixer

Ribbon Mixer is mixer for Intensive Mixing of wet and dry material used in the Food, Chemical, Pharmaceutical, Paint, Cement, Refractory, Adhesives, Building materials, Dyestuff and Allied Industry. It is a LOW SHEAR mixer and mostly used for SOLID / SOLID Mixing. Solid / Liquid mixing can also be achieved when high shearing force is not desired. It occupies less head room space for large volume mixing unlike Double Cone, 'V' Blenders etc.Ribbon Blender comprises of a U-shaped horizontal trough and a specially designed Double Helical Ribbon Agitator rotating within. The ribbons rotate at approximately 70 – 100 meters per minute and move the material both radially and laterally to ensure thorough blends in short cycle times. Salient Features : Available in two shapes - U & W. U-for Low to Medium volume Capacity (single shaft). W-for Large to Mega volume Capacity (double shaft). All contact parts in stainless steel 316. Bearing mounted on lanterns out of mixing zone to avoid Cross contamination. Reduced Material handling due to side discharge facility of processed materials. Meets all cGMP standards. Stuffing boxes with easily disassembled housings. PTFE gland packing provided. Air purge on the side entry seals for better cross contamination control. Continuous Ribbon design for complete discharge of the finished product. Belt driven power transmission for quieter environment and less maintenance. Paddle style agitator instead of Ribbon for Blending fragile materials. Capacity available 130 L to 10000L. (Larger volumes upto 20,000 L can also be provided)

...more

powder charging system

Pneumatic Automatic powder charging system is provided duly mounted on a swiveling davit interlocked with sensor to safeguard against blender. It is provided with a SS suction nozzle coupled to a flexible PVC food quality conveying pipe to enable for direct suction of the powder from container which will be discharged in blender and on complete charging of batch or maximum upto 70-80% by volume, filter bag of charging system may automatically be cleaned by auto reverse pulse jet mechanism thereby safeguarding against operator dependency, charging system may be swivelling on side and locked in that position which will actuate the sensor for that position, a dummy cover to be clamped on charging hole & homogeneous blending action can be initiated by starting the blender operation. After necessary blending period the material can be discharged & collected from bottom into container by manually opening the butterfly valve. The entire auto charging system is a tool free assembly.

...more

Polishing Pan

The gear box, motor & hot air blower are enclosed in a SS, in case of GMP models.Mounted on dynamounts to avoid foundations.Heaters interlocked with the blower fan.

...more

Octagonal Blender

AL!X - Octagonal Blender is a very precision machine, performing dry blending of powder or granules homogenously in only 10 to 30 minutes. This machine is utilized for mainly homogenizing, blending and also for granules lubrication as that facilitates better flowability at a tablet press while compressing this granules. Due to its octagonal shape is designed to process larger volume of material. It occupies less space compared to other similar blenders like 'V' / Double Cone. The blending takes place at low speed during operation. It is well balanced & smoother even in higher capacities. It is very useful for pharmaceutical industries wherein gentle blending of dry granules of powder is to be done. The important feature of the machine is easy to wash in place. Octagonal blender is supplied with a bin charging system or can be designed for vacuum charging. Dust free charging system is also incorporated, which is a completely closed system for charging and discharging of powders or granules.The power consumption is comparatively lower than other similar type of blenders. Basic machine consists of a blender container which is supported both ends by stub shafts which are supported on plummer block bearings. Entire assembly is placed on a structure which has drive unit consisting of electric motor, chain coupling and in case of heavy loads fluid couplings. All parts coming in contact with mix are of stainless steel 316 quality and are highly polished. Drive motors, electrical control panel and control station are supplied in non-flameproof as well as flameproof construction, as per clients requirement. In case of flameproof construction, the control panel should be located in low risk area.There is a baffle made of ss316 pipes inside which can be removed by losing the nut between the baffles. Baffles assembly also depends upon the customer’s specific requirements. Baffle ensures uneven movement of mass during tumbling and results in better homogenising. Blender has a discharge butterfly valve which if a client requires so can be operated through pneumatic actuators. Entire butterfly valve is of SS316 with seats of silicone rubber.The whole drive assembly is covered with S.S. side panel. All drives, pulleys and belt are adequately guarded. Interlock is provided for the railing so that operator does not have access to the container when it is in motion. Machine will stop automatically once the blender main railing is made to open. The inside of Octagonal body is mirror polished and the outside surface is matt polished. The material to be mixed is charged in machine either manually from top or bin charging system or vacuum charging system and then the port is locked positively. Then blender is started to preset blending time. At the end of process, machine is stopped and the product is transferred to process containers by opening the butterfly value. There are three methods to load Blenders. LOADING BY CONTAINER : Here the container brought close to the blender on special trolley having lifting arrangement. This lifting pellet ensures that the container is lifted and is aligned with the transition piece fixed with the blender outlet butterfly valve. This transition piece mouth is clamped with the outer periphery of the container using special types of clamps. Now after clamping the container(100 Lits approx) the blender is inched till the container is vertically inverted over the blender. Now once the container reaches upward inverted position, the butterfly valve is made to open by special hand wheel so that entire content of the container gets up loaded in to the blender. Once it becomes empty, the valve is closed & container is brought again downward by rotating the blender again by 180* and another container is fixed and raised and in similar way and this way entire powder content is unloaded. By this method, material is loaded in batches of 50Kg each. LOADING BY IPC : Here by using mobile hoist the IPC’s of 220 lits are raised over the blender and through dust free connection the entire powder content is unloaded in to the blender by opening the butterfly valve. Thus material gets loaded through IPC’s and also after blending the discharged material also gets unloaded in to IPC’s using another dust free connection set. There is a butterfly at the discharge. For loading blender there is one opening made on the lid of the blender or lid for manhole of the blender. This way entire transfer of material is dust free. LOADING BY VACUUM : Here by application of vacuum the entire blender is loaded using pneumatic conveying system. Blender container has two openings and through one such opening is connected to the vacuum blower and through other it is connected to the IPC’s bottom portion which has a triclover arrangement. So the powder from IPC’s gets transferred to the blender using vacuum conveying. This is entirely dust free but expensive method. Pneumatic Automatic powder charging system is provided duly mounted on a swiveling davit interlocked with sensor to safeguard against blender. It is provided with a SS suction nozzle coupled to a flexible PVC food quality conveying pipe to enable for direct suction of the powder from container which will be discharged in blender and on complete charging of batch or maximum upto 70-80% by volume, filter bag of charging system may automatically be cleaned by auto reverse pulse jet mechanism thereby safeguarding against operator dependency, charging system may be swivelling on side and locked in that position which will actuate the sensor for that position, a dummy cover to be clamped on charging hole & homogeneous blending action can be initiated by starting the blender operation. After necessary blending period the material can be discharged & collected from bottom into container by manually opening the butterfly valve. The entire auto charging system is a tool free assembly.

...more

jumbo bag unloading system

� Jumbo Bag Unloading System, also known as Jumbo bag dischargers and super sack unloaders are specifically designed to provide an easy, clean and economical way to discharge the entire contents of bulk and semi-bulk bags, especially when the material is less than free-flowing. Jumbo bags can be placed in the Jumbo bag unloader by fork lift, hoist or crane from floor level. An integral hoist on a monorail can be furnished if desired. Standard arrangement includes a bag frame to which the suspension loops of the bag can be attached while the bag is resting on the floor. The bag frame is then raised and positioned so the hooks on the frame engage a counter-balanced suspension frame in the superstructure of the unloader. When lowered, the bottom of the bag rests on a sealing ring in the unloader bed and the tension on the bag loops keeps the bag upright. Optional pneumatically operated actuator petals massage the lower portion of the bag to promote material flow toward the center of the bag. Material can discharge by gravity into storage, a process vessel or a conveying system for transfer to another location. Modular construction of the discharge portion underneath the bed facilitates the use of a wide range of devices such as feed screws, rotary valves, lump breakers, AL!X - Jumbo Bag unloader provides a safe, dust-free and convenient way to handle and discharge bulk bags. It is available in eight models to accommodate all styles of bulk bags and bulk bag discharger requirements. These range from a receiving hopper and frame for customer supported bulk bags to a complete bulk bag unloading station. Available options include an integral bulk bag hoist and trolley, manual or pneumatic flow shut off valve, vibratory agitation to aid material flow andor a bag massager for more difficult materials, conveyor, load cells and controls for a complete "turn-key" system

...more

Jumbo Bag Loading Station

Jumbo Bag Fillers insure fast, dust free and precise filling of Jumbo Bags. Available in a variety of configurations this ruggedly constructed filler allows its operators to easily insert, fill and remove bags. From simple volumetric filling to calibrated weighing, the AL!X - Jumbo Bag Filler is the unit that is custom built for your application.AL!X - has designed a number of jumbo bag loading frames for different applications and will aggressively respond to all bulk bag loading opportunities. The frames from AL!X are simple, sturdy frames of square tubular construction with four legs and permitting a great number of loading options, including the supports for these. A simple bungee cord bag neck damp offers a major advantage in being able to seal any bag neck from 13 inch diameter to 24 inch diameter without changing the bag neck spout. An inflatable cuff, which is common on competitive units, is offered as an option. The disadvantage of this device is that a single size cannot accommodate a wide range of bag necks. The versatile and simple single venturi power unit with venturi discharge provides a source of low pressure air for bag inflation. A filter for the air displaced from the bag is standard. Adjustment for different size bags is accomplished by raising or lowering the deck of the weigh frame. Heavy duty square tubular frame with welded top section and bolted legs. Internal weigh frame with four load Description : Sturdy welded tubular steel frame. One piece fill spout. Inflatable inlet spout seal with regulator. Vibrating platform for consistent filling. Adjustable height bag loop supports. Adjustable width bag loop supports. Dust connection vent. Pallet stops. Enamel Paint. Custom configurations available. Optional Items : Adjustable height frame. Load cells with isolation pads.. Partial or fully automated operation. Bag inflation system with butterfly valves. Inline air filter / regulator with local shut off valve. Dust collection system. Pneumatic vibrator. Inlet flow control valve. Epoxy Paint. Contact / Frame Materials : Carbon Steel 304 Stainless Steel 316 Stainless Steel Motors : Standard: 230-460v TENV motor enclosure Optional: Special motor voltages on request / Pneumatic

...more

Inline Sifter Conveying System

Inline Sifting Mc. is the new innovation to the industry with a combination of our experience and industry demand, for multiple selection in a single source.AL!X - Inline Vibro Sifter – (Vacuum rated Vibro Sifter) is excellent for high speed Sifting & Sizing of wet and dry products, used in Pharmaceuticals, Chemicals ,Cosmetics, Food Product, Ceramics, Dyestuff etc. The food & pharmaceutical industry demand extremely high degree of hygiene and safety during the process. That only can be achieved through basic equipment With high degree of versatility, quick response and Users friendly in a compliance of cGMP standard.Sifting is a beginning of Formulation process, Better shifting is a positive sign for future process that can be achieved through “AL!X -Sift”.“AL!X Sift” is specially designed with Vibro motor Principle in a vacuum rated construction. Enclosed And inline shifting is only possible through “AL!X Sift”. Applications : Dry Sifting Wet Sifting Typical features of Inline Sifting Machine : cGMP construction. All contact parts SS316 & non contact parts SS304. Suitable for manual or inline milling through pneumatic conveying system. Machine is designed for continuous operation. Encapsulated design with process visualization Trolley mount for ease to move. Detachable sieve design. Compact size online & Dust free model. All Components can easily be dismantled and cleaned for change of product. Detachable Lead free sieve design.Wide range of SS perforated and wire knitted screen available. Optional Features : Contact parts SS 316L Flame proof construction

...more

Dust Contained Milling System- Inline Co Mill

AL!X Inline Co-Mill is the new innovation to the industry with a combination of our experience and industry demand, for multiple selection in a single source.AL!X - Inline Co - Mill is excellent for high speed shreading, Sizing and Grinding of wet and dry products, used in Pharmaceuticals, Chemicals , Cosmetics, Food Product, Ceramics, Dyestuff etc. The food & pharmaceutical industry demand extremely high degree of hygiene and safety during the process. That only can be achieved through basic equipment With high degree of versatility, quick response and Users friendly in a compliance of cGMP standard. As compared to the four common principles of size reduction i.e. grinding, compression, impact and shearing, which often do not product controlled size reduction, this machine utilizes the principle of Centrifugal Shearing force. Advantages : Dry Milling Wet Milling Shreading of Tablets Typical features of Inline Co – Mill Machine : cGMP construction. All contact parts SS316 & non contact parts SS304. Suitable for manual or inline milling through pneumatic conveying system. Machine is designed for continuous operation. The Bin charging Loading system can also be incorporated in it which is a dust free closed system for charging and discharging of powders or granules. Detachable sieve design. Compact size online & Dust free model. All Components can easily be dismantled and cleaned for change of product. Vertical milling for higher productivity with minimum fines. Built in Variable Speed Drive. Optional Features : Speed control through frequency drive for better milling. Contact parts SS 316L Flame proof construction

...more

Divertor Valve

This gravity piston two way diverter valve is available fabricated in mild steel or stainless steel, making it ideal for the bulk handling of powders, pellets and granules in most process industries. The smooth internal faces ensure no lodgement areas and the diverting flap comprises Aluminum single piston block sandwiching a rubber wiper seal.Operation is by a pneumatic top mounting cylinder with solenoid system interlocking, controlled by a double solenoid valve. The solenoid valve is fitted with manual override for local manual control. Switches for electrical indication of valve positions are fitted as an optional extra. Switches and solenoid valves to customers' requirements, or for use in hazardous areas, may also be fitted. Features / Benefits : Gravity Piston Diverters Sizes 40 - 150mm Pneumatic operation Square or round. In mild steel or stainless steel. With food quality rubber wiper. For Pneumatic Conveying Diverter Valves Utilising our specialist valves, the AL!X - Inflatable seat butterfly valve and the Dome valve, actuated diverter valves may be configured to meet most application needs. In their simplest and most common form, diverter valves are configured as 2-way or 3-way units. More comprehensive systems are available in a tower formation and in recent time’s diverter towers have been supplied capable of redirecting product from one of four infeeds, to one of twelve destinations. Features Pneumatic B/fly Diverter Valves Sizes 40 - 150mm. A range of diverter angles. Pneumatic operation. In mild steel or stainless steel.

...more

Dilute Phase Conveying System

Dilute phase pneumatic conveying systems operate on the principle that the solids will be suspended in the conveying line air stream. This is achieved by feeding material in controlled quantity into a air stream. Generally velocities are greater than 20 mtr per second and material to air ratios are up to .10 to 1. Material conveyed will be separated from air stream through Cyclone & Bag filter. Commonly Conveyed Products : Products commonly conveyed in Dilute phase systems include Pharmaceutical Powder, speciality chemicals powders, flours, resins and compounds, ground feeds, and granular and pelletized products. In many cases, the product needs to be evaluated based on process needs to final system selection to ensure the desired results can be achieved. System Design : Pressure, vacuum, combination vacuum/pressure and vacuum sequencing are the common types of Dilute phase systems. The Carrying gas is typically generated by a positive displacement blower with pressure capability ranging from 0.1 to 0.8 Kg/ Sq CM. Pressure systems generally use a rotary airlock as a feed device. A vacuum system simply needs a product flow control device such as a probe box or screw feeder, although rotary airlocks are commonly used.

...more

dense phase conveying systems

Dense phase conveying is a highly reliable pneumatic conveying system with a low velocity and a high product/air ratio, suitable to convey powders and granule. With Dense Phase Conveyors the product is introduced into the conveying line through a pressure vessel and is suitable to convey products from a single point to one or more receiving points. Advantages : Low velocities Little segregation and degradation Smaller piping diameter Low air consumption Low investments Conveying abrasive products, low wear Conveying fragile products Little maintenance No moving or rotating part In addition, the system has the following features also: The material inlet valve provided with the system has a special inflatable rubber seal which is inflated with the help of air pressure on closure of the inlet valve, thus eliminating any chance of air leakage from the transporter top ensuring a 100% sealing at the vessel inlet. In our standard equipments & design range bends provided are of converging - diverging type i.e. wherein bend area decreases (thus thickness increases) at the segment outlet, which keeps the material floating and unsettled, thus eliminating the chances of choking in the bend section. The transporter is fitted with fluidizing nozzles, which produce a swirling air phenomenon, thus helping in prevention of bridging problem from fine power & adhering problem by hydroscopic elements.

...more

Cone Blender

The double cone blender is used dry & wet blending of powders & granules homogenously with adding the binder in granules. The blender consists of a Cylindrical Shell with two cones & is perfectly designed with its angle, shape & is an efficient and versatile machine homogeneous mixing / blending.One end of the blender has a hinged cover for quick opening and charging is done at an inclination & an lris Diaphragm / Butterfly Valve is used for discharge. The blender is enclosed by a Safety railing with limit switch. Manufactured in Stainless Steel, the design is aesthetically suited to the modern pharmaceutical plant. All the contact parts are made of SS316. The effective volume for optimum homogeneity is between 35-70% of gross volume. It is very useful for pharmaceutical, food, chemical, cosmetic products etc. Salient Features : Basic equipment is made to facilitates vacuum charging system. Due to vacuum rated design we can load the blender through vacuum transfer system with inline Milling. The conical shape at both end enables uniform mixing and easy discharge. The cone is statically balanced which protects the gear box and motor from any excessive load. Main structure is manufactured from heavy duty SS 304 square tube. Variable frequency drive is provided for step less drive. Self positioning sensor is provided for particular discharge position. Manually operated butter fly valve at discharge of blender. Depending on the characteristic of the product, paddle type baffles can be provided on the shaft for better mixing, uniform blending and de-agglomeration. Discharges with specially designed adaptor assembly with T C connection, in case of damage of butter fly this will safe guard the material. Dust Free bin charging system which h ensures minimum material handling. Capacities available from 100L to 4000L (Higher capacity up to 10000L on demand). Optional Accessories : Documentation PLC Based Color Touch Screen Display Flame Proof Construction Stair Case with Platform Pneumatically Operated Butter Fly valve for discharge. Provision for Spray Ball

...more

Co Mill

Co-Mill is the new innovation to the industry with a combination of our experience and industry demand, for multiple selection in a single source. AL!X - Inline Co - Mill is excellent for high speed shreading, Sizing and Grinding of wet and dry products, used in Pharmaceuticals, Chemicals , Cosmetics, Food Product, Ceramics, Dyestuff etc. The food & pharmaceutical industry demand extremely high degree of hygiene and safety during the process. That only can be achieved through basic equipment With high degree of versatility, quick response and Users friendly in a compliance of cGMP standard. As compared to the four common principles of size reduction i.e. grinding, compression, impact and shearing, which often do not product controlled size reduction, this machine utilizes the principle of Centrifugal Shearing force.

...more

Capsule Loading System

Specifically for empty or filled capsule transfer, the empty capsule conveyor provides a simple method of unloading of capsules and maintaining a supply to any make of capsule filling systemThe AL!X is a proven system in the transfer of hard-shelled gelatin capsules. Designed and built to overcome the problems associated with conventional mechanical systems, the AL!X is ideal for the automatic loading of high-speed capsule filling machines. Empty capsules are manually loaded into a large diameter, low-height capsule storage-hopper.A 250-litre storage-hopper has been designed to accommodate a full, standard sized box of capsules. When in operation, a tangentially positive airflow from a multistage fan is forced through a air blower. The empty capsules in the storage hopper are gradually picked up by the suction created by the venturi and gently conveyed in a low- pressure, high-volume airflow through the conveying pipe work to the receiving hopper on the top of capsule-filling machine. A fully adjustable optical sensor controls the level of capsules in the receiving hopper on the capsule filling machine, by automatically starting and stopping the convey cycle. Salient Features : Low charging height. High transfer rate with 100% transfer of capsules. Level sensor mounted on the filling machine Hopper for low/high fill protection No change parts required for different sizes of capsules. Simple control and 220V single phase power supply

...more

cage blender

Conta Blending system has replaced completely the conventional blenders like 'V' shape / Double cone or Ribbon type. Conta blenders are used mainly for blending of dry powders for capsule plant, for blending and homogenizing of dried granules for tablet production. Conta blender is latest cGMP concept with an emphasis on the dust free transfer of powders and granules at different stages from sizing /dispensing to compression/ filling of tablets or capsules.Conta Blender has a flexibility of Batch Volume. The process involves collecting the sized granules in a container, wheeling it to the blender, engage the same with clamping system, lift and tumble for the prevalidated time in set number of rotation. These granules can be mixed and lubricated in this blender. Main advantage of this system is that it is totally dust free. Also another advantage is adaptability of this system to handle more than one size of containers. For example Conta blender designed for 600 liters container can also be used to handle 400 ltrs to 600 ltrs of container ( For Granules weight from 160 to 250kg)This adaptability makes it a very useful machine for any tablet or capsule plant. Salient Features : 0° stopping for easy docking and undocking of the bin. A suitable fencing around the cage with an entry point for the bin on detachable trolley. Limit switch on entry door to prevent the accidental operation of the cage. Flexibility of accepting variable bin sizes providing wide range of batch volumes. cGMP construction with cladded polished SS sheets. The charging hole with cover is provided on top with quick opening and closing arrangement with dust proof joints for particle free transfer. Built-in Butterfly valve (150 mm dia) at the bottom suitable for discharge. Suitable leak proof vent on top. Highly effective for low volume active blending with as low as 1 % active. Processing of different sizes of production batches in single equipment with scale up data. Optional Features : Interchangeable Product Container AC Frequency variable drive for product container. PLC Controls with HMI touch screen, Flame proof motor and Push Button station. Safety Features : The container locking arm has a proximity switch which prevents the drive to run unless the locking arm is proper locked. Unless the container is securely locked the drive wont run. Entire working area of the blender is protected by a railing all aroung with a gate and single entry point for the bin in such a way that if the railing fencing is made to open the drive will stop immediately. Presence of the container in the lock area is sensed thus if container is not placed properly in the fork arm than sensor will not allow the blender to start. If blender stops due to powder shutdown than when you start it after resumption of powder the blender will run only for the remaining time and not total time. Brake motor arrangement for smooth operation.

...more

Bin Activators

Bin Activators have been proven worldwide to give a continuous, but controlled flow of difficult-to-handle materials from bulk storage silos, through the controlled use of vibration.AL!X – solves the difficulty by cutting off the lower cone section of the bin and replacing it with a Bin Activator consisting of a relatively flat dished head and baffle. These flat support surfaces carry the overhead load without permitting the additional compression that occurs in a conical bottom.The Bin Activator is flexibly hung from the upper bin by rubber-bushed forged steel hangers. An elastic sleeve of reinforced rubber seals the small gap between the main bin and movable bottom. An integral baffle relieves head load over the outlet.AL!X - line of dependable and economical Bin Dischargers are available to system suppliers and OEM’s. These units are ruggedly built, simple to install and come with AL!X’s - unconditional performance guarantee. Our Bin Discharger’s simple, compact design incorporates all of the important features customers have come to expect from AL!X.It has been established that under vibration the shear strength of the product in a storage vessel decreases. The action of the Bin Activator is to break down the shear strength and thus induce flow. When the Activator is switched off the material shear strength is restored and product once again ceases to flow.By careful design, the Bin Activator eliminates ratholing, degradation and segregation of products within the silo, ensuring an even flow of material on a mass-flow basis (the first-in, first out principle).Bin Activators are ideally suited to a cylindrical vessel, but can be successfully applied to square or rectangular bins. Their low profile allows for a substantial reduction in the silo height and its associated building costs.

...more

Batch Weighing Systems

The Batch-Weigh consists of a receiving hopper designed to suit the application, a hopper slide gate to contain the batch quantity, load cells, and the heart of the system, the control panel. The controls incorporate the latest electronic technology in AC Inverter drives and Programmable Logic Controllers (PLC's). Addressing the system is simply a push of a button on the front panel mounted keypad, with assistance through a menu-oriented LCD display. Weighing accuracies of greater than 99% of full scale are typical with the Batch-Weigh. Components are selected to suit any operating environment, including explosion hazard areas.In a formulation of a typical batch, many processes are required but the fundamental one is that of creating a mechanism to bought together precise quantities of different kinds of ingredients to make up a specific batch or formula. Which further involves metering materials individually into a weigh hopper, using a metering device such as a screw feeder, air lock or butterfly valve etc.In addition of this, through years of experience AL!X - has developed an unique kind of scale control package which has been designed specifically for bulk materials. Since different kinds of ingredients have varying speed, it can be fast or slow so to formulate a specific kind of batch with accuracy; we have developed automatic target weigh set, with auto log feature.Further on this, we have also developed much required customized multiple weigh hoppers, loss of weigh feeders especially we have designed an efficient liquid addition scale systems to make simple the whole process of batch formulating. The electronic batching controls which we are manufacturing currently have been custom designed for ease of operation and to provide a much needed flexibility of utilization. So, in nut shell, we are providing multitude of options to our clients, as far as batching systems are concerned. And if you are searching for a genuine supplier of top quality batching systems which predominantly include weigh batching systems which falls in the purview of a fully fledged batching system then only we manufacture / supply this on such a large scale and provide this to our customers at very competitive rates. Product Details : Automated, semi-automatic, and manual batching controllers as well as custom-tailored material transfer control strategies to meet specific needs. Fast, accurate, and always reliable, our controllers can be combined with high performance scale bases, weigh modules, or measuring cells to provide the complete solution for any batching application. The design and performance of this batching solution is based on the sector-specific requirements.

...more

Bag Dumping Station

bag dump stations (also known as manual dumping stations) collect dust generated whendumping powder and bulk solids from bags, boxes, drums and others containers and return thematerial to the hopper. The system reduces material waste and eliminates the need to clean a remote dust collection site, while protecting workers and preventing plant contamination.all units feature a high velocity vacuum fan that draws airborne dust away from the operator through the cartridge filters that are sized according to the application.to operate a bag dump station, the hopper lid is opened, the vacuum fan is activated, and material is dumped through the hopper screen. Airborne dust in the vicinity of the hopper opening is drawn in to the dust collector, protecting workers, preventing plant contamination and reduces material waste.an automatic reverse-pulse filter cleaning system employs timer-activated solenoid valves to release short blasts of compressed plant air inside the cartridge filters, causing dust build-up on the outer filter surface to fall into the hopper. Beacuse the filters are blasted alternately at the timed intervals, operation of the dust collection system is both continuous and efficient. Filters are access easily by removing the interior baffle, and replaced rapidly using quick-disconnect fittings. All manual dumping stations are available mounted on frames with boom and castors for in plant mobility. These systems can reduce material waste and eliminate the need to clean a remote dust collection site, while protecting workers and preventing plant contamination.

...moreBe first to Rate

Rate ThisOpening Hours