Wave Spring Seal

Wave Spring seals are internally mounted which are non-clogging. Single Wave Spring seals are designed to be bi-directional and apply for water, chemical industry, oil, food industry and so on.

Packaging Type : Carton Box

Specialities : Good Quality, Fine Finish

Material : Steel

Color : Silver

Finishing : Polished

Sealing Type : Mechanical

Usage : Gas Industry

...more

BSI-GF Cartridge Seals

Features Single end, Unbalanced, Independent direction of rotation, Cartridge shaft seals. Structure: Single End Pressure: Medium Pressure Mechanical Seals Speed: General Speed Mechanical Seal Temperature: General Temperature Mechanical Seal Performance: Wear and Weak Corrosion Standard: Specifically Designed for Grundfos Stamped Stainless Steel Centrifugal Pumps Model NO.: SSI-GF Balance: Unbalanced Specification: Inner Diameter: , 12 mm, 16 mm, 22 mm Materials Rotary Ring Face: Carbon/SiC/TC Stationary Ring Face: Carbon/SiC/TC Elastomers (elastomer bellows for GB-B): NBR/Viton/EPDM Springs: SS304/SS316 Metal Parts: SS304/SS316 Recommended applications Oil Water Weak acid Alkali Corrosive mediums.

Packaging Type : Carton Box

Material : Metal

Temperature : - 20

...more

BSI-8 Rubber Bellow Seals

Features Rubber bellows mechanical seals Unbalanced Single Seals dependent of direction of rotation Advantages This component sealwith a simple yet effective design that is easy to assemble.The bellow and the spring provide pressure compensation to the seal faces. The rubber bellow design prevents possible radial run-out so that the floatability of the rotary ring is increased. This mechanical seal is also known as KSB Part No. 433 mechanical seal. Many other pump manufacturers such as WILO are also using the same type of mechanical seal as their standard sealing solutions. Materials Rotary Ring: Carbon/SiC/TC Stationary Ring: Al2O2/SiC/TC Elastomers: NBR/EPDM/Viton Springs: SS304/SS316 Metal Parts: SS304/SS316 Recommended applications Food technology Sugar production Pulp and paper industry Oil industry Petrochemical industry Chemical industry Water, waste water, slurries (up to 5 % by weight) Pulp (up to 4 % otro) Latex Helical screw pumps Water and waste water pumps Industrial Standards : DIN24960 ISO3069 GB6556 EN12756.

Packaging Type : Carton Box

Inner Diameter : 10 Mm To 110 Mm

Material : Rubber

...more

BSI-7 Rubber Bellow Seals

Features Rubber bellows mechanical seals Unbalanced Single spring Independent of direction of rotation Advantages Single seal, unbalanced, fixed direction of rotation, rubber bellow transmission seal. this component seal with a simple yet effective design that is easy to assemble. the special spring arrangement allows a short axial installation length. the bellow and the spring provide pressure compensation to the sealing faces. the rubber bellow design can prevent radial run-out so the floatability of the rotary ring is increased, the spring is free from torque transmission. Materials Rotary ring: carbon/sic/tc Stationary ring: al2o2/sic/tc Elastomers: nbr/epdm/viton Springs: ss304/ss316 Metal parts: ss304/ss316 Recommended applications water and waste water technology sewage pumps vacuum equipment sewage treatment chemical industries pharmacy food processing paper making. Industrial Standards : DIN24250 ISO3069 GB6556 EN12756

Packaging Type : Carton Box

Inner Diameter : 10 Mm To 110 Mm

Material : Rubber

...more

BSI-6MU Multiple Spring Seals

Features Single End Standard: DIN24960, ISO3069, GB6556-94 UN Balanced Wave Multi spring Advantage Single end, multiple springs, un balanced, independent rotary direction, retainer driven mechanical seal. Materials Rotary Ring Face: SiC/TC Stationary Ring Face: SiC/TC Elastomers: Aflas/Viton/PTFE/FFKM Springs: SS316/SS316L/HC276 Metal Parts: SS316/SS316L/HC276 Recommended applications oil, water, salt, alkali, organic solvents. Light Abrasive Slurry High Viscosity Fluid Paint Shop with back to back Seal

Packaging Type : Carton Box

...more

BSI-55SUBC Cartridge Seals

Features Easy installation Fits ANSI Standard & Big Bore pumps Economical to repair Unbalanced Design ideal for low pressure applications Available in inch and metric sizes Inside mounted

Material : Metal

Temperature : - 20˚C TO +180˚C (-4 °F … 356) °F

...more

BSI-55MNC Cartridge Seals

Features Balanced Single acting Inside mounted Independent of direction of rotation Materials Seal Faces: (Dynamic & Stationary Ring) Carbon, Ceramic (99.5%), Silicon Carbide, Tungsten Carbide & which are suitable for fluid Secondary Seal: Viton, Silicon, Aflac, Karlez PTFE, GFT Hardware & Spring SS 316, SS 304 Carpenter-42 Alloy-20, Hastelloy – C Recommended applications Syrup pumps Food industries Water treatment Pulp & Paper industries General & light chemicals

Material : Metal

Temperature : - 40˚C TO +180˚C (-40 °F … 356) °F

...more

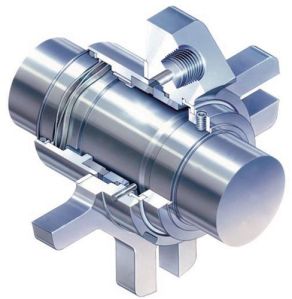

BSI-55 Cartridge Seals

Features Single Cartridge Seal Balance SEALS Easy Installation. Advantages Seal arrangements incorporate an elastomer O-ring as the secondary sealing member. A common seal head/mating ring set, utilized throughout all versions, is reversible to allow rotating. Seat/mating ring or rotating seal head operation, and is interchangeable with metal bellows seal heads. Seal has an optional quench gland with carbon ring throttle bushing. Balance Pusher Seals available in Single Configuration used for Sealing Environmentally. Dual Directional. Stationary spring design. Reversible Seal Head. No clogging Wave Spring outside the Product. Components in Cartridge Design are Builds for the Highest Reliability and Simple Installation. Materials Seal Ring Faces: TC and SiC Seat Faces:Sic and TC Elastomer: Viton, PTFE, FEP and FFKM End fitting MOC: SS 316, HAST-C and Carpenter 42 MOC: SS 316 – CHANGE OF MOC ON REQUEST Recommended applications Process industry Petrochemical industry Chemical industry Pharmaceutical industry Power plant technology Slurry Pumps Paints.

Material : Metal

...more

BSI-50DNC Cartridge Seals

Features Single seals without connections with flush and with quench combined with lip seal or throttle ring. Additional variants available for ANSI pumps and eccentric screw pumps. Double pressure balanced Integrated pumping devise Advantages Ideal seal for standardizations Universal applicable for packings conversions, retrofits or original equipment No dimensional modification of the seal chamber (centrifugal pumps) necessary No damage of the shaft by dynamically loaded O-Ring Extended service life Straightforward and easy installation due to pre-assembled unit Individual adaptation to pump design possible Ideal seal for standardizations Universal applicable for packings conversions, retrofits or OEM No dimensional modification of the seal chamber (centrifugal pumps) necessary, small radial installation height No damage of the shaft by dynamically loaded O-Ring Extended service life No damage caused by dirt entered during assembly Straightforward and easy installation due to pre-assembled unit Individual adaptation to pump design possible Recommended applications Process industry Petrochemical industry Chemical industry Pharmaceutical industry Power plant technology Pulp and paper industry Water and waste water technology Mining industry Food and beverage industry Sugar industry

Material : Metal

Temperature : - 20˚C TO +200˚C (-4 °F … 662) °F

...more

BSI-50DMC Cartridge Seals

Features Doubleseals Balanced Inside mounted Advantages SSI-50DMCCartridge seals are self-contained units consisting of a shaft sleeve, seal, and gland plate. Materials Seal Faces: Ceramic /Sic/Carbon Vs Ceramic /RB Sic./TC Secondary Seals: Viton/PTFE/GFT Metal Components: SS-316 Recommended applications Process industry Chemical industry Petrochemicals industry Pumps Special rotating equipment

Packaging Type : Carton Box

Material : Metal

...more

BSI-42U Multiple Spring Seals

Features Multi spring seal unbalanced seals easily assemble or dismantled Advantage Designated as for the unbalanced Versions with ‘0 Ring & PTFE wedge respectively. Shaft fretting is minimized due to lower spring loads provided through wedge or ‘0’ Rings, occupies less stuffing box area due to its narrow cross-section & compact design. Materials Seal Faces: Carbon vs Ceramic/Sic./TC Secondary Seals: Viton/PTFE/GFT Metal Components: SS-316 Recommended applications Petrochemicals, Light Hydrocarbons General Industrial Fluids.

Packaging Type : Carton Box

Specialities : Good Quality

...more

BSI-41B Multiple Spring Seals

Features Multi Spring Balanced Seal high-pressure Advantage these seals required lower stuffing box space for installation. These seals can be provided with single, double or tandem arrangement with external seal support systems & devices. Materials Seal Faces: Carbon vs Ceramic/Sic./TC Secondary Seals: Viton/PTFE/GFT Metal Components: SS-316 Recommended applications Petrochemicals, Petroleum refinery Light Hydrocarbons General Industrial fluids. Corrosive Chemicals

Material : Metal

Shape : Round

...more

BSI-39S Multiple Spring Seals

Features Single End Medium Pressure Mechanical Seals High Speed Mechanical Seal High Temperature Mechanical Seal Balance: Unbalanced Materials Rotary Ring Face: TC/SiC Stationary Ring Face: Carbon/SiC/TC Elastomers: FKM/NBR/EPDM Springs: SS304/SS316/HC276 Metal Parts: SS304/SS316/SS316L/2205/2507/Q235 Recommended applications mainly used in different types of mixers fermentation tanks, seeding tanks, stainless steel reaction kettles sewage treatment devices, water pumps, sewage pumps, paper pulp., mining, steel production, food and beverage, water treatment and management, geothermal, concentrated solar power bio-fuels industries.

Packaging Type : Packet

Material : Metal

...more

BSI-26 Multiple Spring Seals

Features Single Acting Mechanical Seal. Dual Directional Mechanical Seal. Outside Mounted Mechanical Seal. Reverse Balanced Design. Multi Spring design Mechanical Seal. Advantage SSI-26 Mechanical Seal are Externally Mounted Reverse Balanced Design Seal having ‘O’ Ring as a Secondary Sealing member. Secondary Sealing member can be changed as per Chemical Compatibility. All metal components including springs are Isolated from the Sealed, Aggressive Medium. Simple checkout method function and cleaning possibility as this Mechanical Seal located easily access outside the pump. Especially design Clamp Ring eliminate Slipping on Shaft. Recommended applications Chemical industry Refining technology Petrochemical industry Lubrication oil Light oil Gasoline Naphtha Water Process pumps

...more

BSI-22WNC Non Contact Seals

Features Single Seals Balanced Advantage Standard balanced single cartridge seal with protected spring and pentagonal drive. The protected-spring design makes this seal suitable for a wide range of applications Materials Friction faces Carbon impregnated resin (B1) Silicon carbide (U6). For the most difficult cases use friction faces made of nickel-tungsten carbide (U2). Supplied with FKM seals.

Material : Metal

Usage : Industrial

...more

BSI-22NC Non Contact Seals

Features Single End Medium Pressure Mechanical Seals Standard: Specifically, Customized Unbalanced Advantage independent direction of rotation, screw pin transmission. The axial length of this seal is small. The loads on the sealing faces are balanced and the seal is not limited with the rotary direction. All transmission components are assembled as one body so the seal is easy to install. The transmission is also balanced and the seal is easy to adjust with stable performance. Materials Rotary Ring Face: SiC/TC Stationary Ring Face: Carbon/SiC/TC Elastomers: NBR/FKM/PTFE Springs: SS304/SS316 Metal Parts: 2Cr13/SS304/SS316 Recommended applications oil, water acid alkali corrosive mediums.

Material : Metal

Pressure : 0

Temperature : – 20

...more

BSI-22MNC Non Contact Seals

Features Inside mounted Balanced Seal Advantage Capsulated Balanced seals designed for media containing solid slurry particles. The springs are protected from solidifying media resulting in high reliability of the seal. This sealare independent of direction of rotation. Recommended applications Food industry Mining Industry Sugar Industry Chemical Industry Water Treatment

Material : Metal

Pressure : 6 bars (Max)

Temperature : (-)20c to (+)100c

Speed : 2900 rpm (Max)

...more

BSI-16H Metal Bellow Seals

Features Stationary bellows seal Balanced Uniform seal face loading Independent of direction of rotation Advantages Over 35 years of running reference in the field Ideal seal for low as well as high temperature applications Ideal seal for high speed application Can take more shaft misalignment and run-out than rotary seals Seal is free from shaft vibration effect Materials Face Materials Silicon Carbide Tungsten Carbide Metallic Carbon Metal Parts - SS 31 Bellow Material AM350 Hastelloy-C Inconnel-718 Secondary Seal: Grafoil Recommended applications Process industry Oil and gas industry Refining technology Petrochemical industry Chemical industry Pharmaceutical industry Power plant technology Water and waste water technology Building services industry Food and beverage industry Sugar industry Horizontal and vertical pumps, agitators, mixers

Material : Metal

...more

BSI-16G Metal Bellow Seals

Features Rotating bellows seal Balanced No dynamic O-Ring, no hang-up, no shaft sleeve damage Uniform seal face loading Independent of direction of rotation Ideally suited for highly corrosive and abrasive media Compact design Advantages Resistant to abrasive particles Self-cleaning, non-clogging design Long seal life due to vibration dampeners at bellows Ideal seal for very low as well high temperatures Materials Seal face: Carbon graphite antimony impregnated, Silicon carbide Seat: Silicon carbide Bellows: Inconel® 718 hardened, Hastelloy® C-276 Metal parts: CrNiMosteel, Hastelloy® C-4 Recommended applications Process industry Oil and gas industry Refining technology Petrochemical industry Chemical industry Pharmaceutical industry Power plant technology Water and waste water technology Building services industry Food and beverage industry Sugar industry Horizontal and vertical pumps, agitators, mixers

Material : Metal

...more

BSI-16C Cartridge Seals

Features Single acting, inside mounted Balanced Easy to replace individual seal-wear parts, Independent of direction of rotation, Inside mounted, Sturdy drive mechanism design. Advantages TYPE SSI-16C: Metal Bellow Cartridge Seal is widely used in assembly pumps, clinker grinders, sludge pumps, pulp & syrup pumps, oil pipeline pumps and boiler feed water pumps. Further, our rigidly constructed product range is offered in various specifications to meet the requirements of clients. Materials Seal Faces: TC/TC, Sic/Sic, Sic/Ceramic Secondary Seals: Viton/PTFE/GFT/Karlez Metal Components: SS-316/Hast-C/Monel Recommended applications Process industry Chemical industry Petrochemicals industry Pumps Special rotating equipment

Material : Metal

Temperature : – 20˚C TO +200˚C (-4 °F … 662) °F

...more

BSI-16 Metal Bellow Seals

Features Rotating bellows seal Balanced Uniform seal face loading Independent of direction of rotation Ideally suited for highly corrosive and abrasive media Compact design Advantages Narrow cross-section allows the seal fitment in narrow stuffing boxes, The unique feature of this type of seal is that, there is no dynamic ‘O’ rings and therefore it will never hang-up or damage the shaft and sleeve, Self-cleaning, non-clogging design, Cost effective solution for corrosive and abrasive media, Long seal life. Materials Seal Faces: Carbon/TC/ Vs Sic./Tc Secondary Seals: Viton/PTFE/GFT/Graphite Metal Components: SS-316. Other material on request. Recommended applications Process industry Oil and gas industry Refining technology Petrochemical industry Chemical industry Pharmaceutical industry Power plant technology Water and waste water technology Building services industry Food and beverage industry Sugar industry Horizontal and vertical pumps, agitators, mixers

Material : Metal

...more

BSI-11RF PTFE Bellow Seals

Advantages SSI-11RF shaft seals chemically inert materials in all areas and on all surfaces in contact with the liquid being sealed. Metallic components, springs and clamp ring are located outside the pump seal chamber, isolated from the process liquid. The entire seal assembly and component parts employ mechanical drive to prevent slippage on the shaft or sleeve. Seal assembly is outside mounted and internally pressurized. Materials Face/Primary Ring Carbon / Silicon Carbide Clamp Ring 316 Stainless Steel Bellows PTFE Springs 316 Stainless Steel Recommended applications Corrosive chemicals Concentrated acids Salts Strong oxidizing Chemically active organic compounds PTFE filled pumps.

Material : PTFE

...more

BSI-11CB PTFE Bellow Seals

Features Outside mounted Reversed Balanced PTFE Bellow Advantages PTFE Bellow seals designed to handle highly corrosive liquids. These seals are outside mounted with simple installation procedure and hence cost effective for corrosive media sealing. This sealdesignated as Fixed & replaceable bellow face respectively. For replaceable version there is flexibility for selection of face material as per the media to sealed, which can be easily removed & replaced & is highly desirable in severe applications. to sealed, which can be easily removed & replaced & is highly desirable in severe applications. Materials Seal Faces: GFT/Sic./Carbon vs Ceramic/Sic. Secondary Seals: PTFE Metal Components: SS-316/Hast-C Recommended applications Chemical Industries Highly Corrosive service Acid industries Alkalis service

Material : PTFE

...more

BSI-108B Mixer and Agitator Seals

Features Structure: Double-End High Pressure Mechanical Seals Standard: HG21571-95 balanced and unbalanced Operating range Pressure: – 0.1 ~ 0.6 MPa (when the pressure is bigger than 0.6 MPa, the pressure balancing device is needed and its connection size can be customized) Temperature: – 20 ~ 150 ºC (cooling tank is required if the temperature is higher than 150 ºC and the installation height should be 100 mm higher than normal) Linear Speed: 2 m/s or less Materials Rotary Ring Face: SiC/Carbon Stationary Ring Face: TC/SiC Elastomers: NBR/Viton/EPDM/PTFE/FFKM Springs: SS304/SS316/HC-276 Metal Parts: SS304/SS316/SS316L Recommended applications Petro Chemicals General Chemicals Light Hydro Carbons Emitting Vapour Pharmaceutical Industries

...moreBe first to Rate

Rate ThisOpening Hours

BSC Engineering has made significant inroads in the sphere of industrial seals since its inception in 2010.

We, as a company, believe in quality and class in engineering our products to excellence and perfection. Our quality and market status is reflected in our client list that not only covers the Indian market but also the international market.

Our seals are tailored to weather even the roughest and toughest of conditions that are applicable in industries. We have the latest and most technologically advanced of all machinery that enables the quality production of goods that are of optimum class and standards.

We are a norms and standards company and, this has enabled us to maintain our quality consistently all throughout since we started. This consistency in quality has helped us retain our customer base and still remain the top seals manufacturing, supplying and exporting company from Mumbai in Maharashtra. As such, we have become a super stockist of standard mechanical seals and seals components.

As far as raw inputs are considered we are a company that believes in using the best to give the best to our clients to exceed customer satisfaction levels. We employ the usage of tungsten carbide, sintered silicon carbide, reaction bounded silicon carbide and carbon graphite in the production of our goods. All our raw materials are procured from reputed vendors on whom we have been able to pin our trust with the quality that they supply. This has made us the best manufacturer as of today.