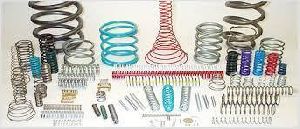

Compression Springs

10 Per Piece

1000 Piece (MOQ)

hot coiled springs

Get Price Quote

IIS Manufactures & Supplies Hot Coiled Springs Hot-coiled springs are generally used in elevated temperatures, high load applications or in a corrosive environment. The transportation industry, Agriculture equipments manufacturers, and construction equipments manufacturers are some of the largest users of the hot coiled springs. Generally springs with bar diameter greater than 12.7mm (0.5 in.) are hot coiled. Bars of carbon or alloy steel are generally used for hot-coiled springs. For most hot-coiled springs, finished hardness requirement is in the range of Rockwell C 44-53. IIS can manufacturer hot coiled springs up to 92mm or 3.62 inch wire diameter and OD 450mm or 17inches.

Best Deals from Compression Springs

4th Stage Air Compressor Valve Spring

975 - 1,100 Per piece

1 Piece (MOQ)

Extension Springs

Get Price Quote

100 Piece (MOQ)

metal spring

Get Price Quote

Electric Switch Springs

0 Per Piece

Spring Steel Wire

80 - 90 Per kgs

stainless steel compression spring

Get Price Quote

Wire Forms

Get Price Quote

We are the main supplier of this product.

Extension Springs

Get Price Quote

Unlike most compression and tension springs, torsion springs require a central support or core for testing, and custom mandrels to hold and turn the tails, which themselves are designed to purpose.

Die Springs

Get Price Quote

Die Springs Our firm is engaged in offering Die Springs that are ready to fit. Primarily a disc spring, this range is incorporated with trapezoidal cross section on both sides, thus enhancing its grip. Easy to fit, these washers sustain load and avoid the problem of loosening. Moreover, owing to the positive rib contact, these washers also provide resistivity against high vibration. Advantages : Proper radius selection avoids splitting and cracking during tightening, Concentric force helps in eliminating the bending of fastener, Flexible

Metal Compression Springs

Get Price Quote

We are the main supplier of this product.

hot coiled springs

Get Price Quote

Hot Coiled Springs are generally used in elevated temperatures, high load applications, in a corrosive environment. The transportation industry, Agriculture implement manufacturers, and construction equipments manufacturers are some of the largest users of the hot coiled springs. Generally springs with bar diameter greater than 12.7mm (0.5 in.) are hot coiled. Bars of carbon or alloy steel are generally used for hot-coiled springs.(Details of material used is below) Since the material is special bar quality, hot coiled springs are rather costly. For most hot-coiled springs, finished hardness requirement is in the range of Rockwell C 44-53. IIS can manufacturer hot coiled springs upto 92mm or 3.62 inch wire diameter and OD 450mm or 17inches. IIS hot coiled springs can be made from peeled & centerless ground bar test for crack in our bar crack detection machine to ensure no failure. All springs are heat treated in calibrated electric furnace with controlled temperature. Automatic Grinders allow excellent surface contact which ensure parallelism and squareness. IIS hot coiled springs initially wound to a greater length than finished length. Then they are pressed one or more times to make the specified length. Since presetting allows supporting greater loads because of residual stresses removal resulting from presetting, most hot coiled springs are preset. Shot Peering is also done on all hot coiled springs manufactured at IIS to increase service life. Magnetic particle inspection can be carried out if required

Die Spring

Get Price Quote

Die springs add life to your dies because they are made of high tensile strength chromium alloy steels. They withstand the heavy demands of shock loading and constant high speed deflections.die Spring has designed and manufactures a complete line of industrial springs. Generally used in die machinery, they are well-suited for many applications where high-static or shock-load stresses are required or when maximum cycle-life is important.

Vibrating Compression Springs

Get Price Quote

Huge compression spring used in mine machine such as Jaw Crusher,Gyratory Crusher, Cone Crusher, Compound Crusher. Compression spring also used in constructing machine,cement plant,steel plant,rolling mill,etc.

Torsion Springs

2 Per Piece

10000 Piece (MOQ)

Compression Springs

10 Per Pound

10000 Piece (MOQ)

metal spring

Get Price Quote

Die Spring

Get Price Quote

In order to meet the dissimilar necessities of the consumers, we offer a broad range of Die Spring. This die spring is widely employed in numerous pressure related equipment such as moulds, press tools, pressure and die-casting. These products are developed by adroit professionals, who have prosperous proficiency of this area. Owing to high demand, professionals make these products in diverse specifications. These products are extremely known in the market for their longer service life and low maintenance. Features: Low maintenance Longer working life Precision-engineered

helical coils

Get Price Quote

Torsion Springs

Get Price Quote

The company is engaged in manufacturing, importing and supplying of Torsion Springs with Torsion Bend. These torsion springs are durable, and can easily endure forces like lateral, angular, rotation and twist.

Torsion Springs

Get Price Quote

We are counted amongst the prominent Manufacturers, Suppliers, and Exporters of Torsion Springs. The Torsion Springs, assembled by us, are a type of spring that transmits torque in machines by bending in one or two directions, depending on the type of torque needed. A Torsion Spring can become deformed if it operates beyond its torsional strength limit.We offer superb quality Torsion Springs to our clients that are manufactured from high quality steel that provides strength and durability to the springs. Used in vast number of industrial applications, the helical Torsion Springs, offered by us, are available in various sizes and ends. Additionally, they are available in customized specifications in accordance to the customers’ needs. Last but not the least, these Torsion Springs can be availed at the most competitive prices from us.

strip spring

Get Price Quote

We are the main supplier of this product.

Metal Compression Springs

Get Price Quote

The clients can avail from us specially designed Metal Compression Springs. These Metal Compression Springs have an Open-Coil configuration designed that assures high performance in resisting the force applied. The Straight Cylindrical Coil Spring with squared ends offered by us is greatly demanded by the clients due to the excellent quality. The clients can further avail these Metal Compression Springs from us at very affordable price.

Garter Springs

Get Price Quote

Garter Springs are helical coil springs whose ends are connected together to form a circular shape to provide a strong Radial Force. Compression garter springs exert outward radial forces, while extension garter springs exert inward radial forces. They can easily handle pressure, viscosity, and temperature changes and prevent contamination from water, dust, dirt, lubrication, and chemicals. They can be supplied pre-assembled into loops, or in lengths – this is particularly useful for standard weights or diameters, as it allows you to cut and assemble your garter springs as needed.

Heavy Duty Springs

Get Price Quote

Wire Diameters: 8.10mm to 55.00mm • Types: Compression, Tension, Torsion & Wire Forms ((Max up to 16mm dia) • Shapes & Forms: Uniform Pitch, Variable Pitch, Pig Tail Ends, Custom Shapes / Forms • Materials: Unalloyed High Carbon Steels, Alloyed Carbon Steels (SiMn, CrSi, CrVa) • Finishing Processes: Electroplating, Galvanizing, Zinc Flaking, Painting, Powder Coating, Special Coatings

Compression Springs

20 Per Piece

We are offering compression springs.

Spiral Springs

Get Price Quote

Spiral springs are used as equalizing springs for smaller angles of rotation. The stored energy is used as an equalizing force or righting moment. The spring curve here rises almost linearly.

Springs

Get Price Quote

Inconel X-750 Compression Springs are manufactured from wire size 0.4 mm to 10 mm conforming to AMS 5699. Compression springs were checked fully for dimension and spring rate and results are within specific requirement of drawings.

Die Springs

Get Price Quote

DIE SPRINGS (ISO 10243 & JIS B 5012) Die Springs are type of Helical Compression Springs that are made of rectangular wire section. Die Springs are made of both Oil- Tempered & Chrome Alloy Materials. Colour Coded Die Springs: Green Colour – Light Duty Die Spring Blue Colour – Medium Duty Die Spring Red Colour – Heavy Duty Die Spring Yellow Colour – Extra Heavy Duty Die Spring