Vacuum Pressure Gauge

300 Per Piece

10 Piece (MOQ)

paneer making plant

Get Price Quote

1 Piece (MOQ)

Best Deals from Dairy Processing Plant

Vacuum Pressure Gauges

Get Price Quote

This industrial grade vacuum gauge has heavy-duty sensing elements and a stainless steel case for protection in harsh environments. A gauge like thisoffers greater accuracy than a general purpose gauge and is typically used in more demanding applications. This gauge has a built-in dampener which reduces needle fluttering. Features a convenient highlight at the 21″ Hg mark which is the ideal pressure for vacuum veneering. How to Order / Inquiry: Please advise the below Dial Size Connection Mounting Pressure range Application media Or Any other special requirement Application: Stainless Steel Gauges are suitable for Chemical, Pharmaceutical, Petro chemical, Oil & Gas, Refinery, Paper & Pulp, Sugar Breweries, Cement Industries etc.

Butter Making Machine

Get Price Quote

Designed for use in ambient temperature up to 50°C with laser-welded evaporator plates providing full surfaces for heat transfer. Bulk milk coolers are used extensively for cooling milk at the collection point, thus maintaining the quality of milk. These are hygienic, easy to use and available in various sizes. Bulk milk coolers are available in various configuration like direct expansion, indirect cooling using

CIP & SIP System

Get Price Quote

We are into manufacturingof complete process clean equipment's along with associated piping and accessories for Pharma, Biotech & Bio-Pharma industries. ASME-BPE STANDARD ASEPTIC TANKS Manufacturing Vessels with Bottom Entry Magnetic mixer or Top Entry agitator Ointrnent vessel Buffer vessel Pressure / Filling Vessel — Autoclavable type Storage Tanks CIP-SIP Systems Storage & Distribution system At Pharma water & WFI loop Fully , Semi or Manual control systems SALIENT FEATURES :- 100, Sterile with Zero hold up design CIP-SIP able design Online monitoring of various parameters like Temp, Pressure, Conductivity, pH etc. Volume monitoring by Load-cells or Level Sensors Capacity range from 500 ml to 5000 Ltrs. Online data-logging or Printing PLC based control with graphic & touch screen display

CIP AND SIP Systems

Get Price Quote

Clean-in-Place (CIP) is a method of cleaning the interior surfaces of pipes, vessels, process equipment, filters and associated fittings, without disassembly.The benefit to industries that use CIP is that the cleaning is faster, less labor intensive and more repeatable, and poses less of a chemical exposure risk to people. CIP started as a manual practice involving a balance tank, centrifugal pump, and connection to the system being cleaned.CIP has evolved to include fully automated systems with programmable logic controllers, multiple balance tanks, sensors, valves, heat exchangers, data acquisition and specially designed spray nozzle systems. Simple, manually operated CIP systems can still be found in use today.The Steam-In-Place (SIP) System is responsible for repeatedly steaming areas of product contact, including vessels, flow paths, and sample ports.This may be done to reduce the bio-burden on the system, or to kill harmful materials at the end of a batch.A typical SIP system will ensure that all areas being steamed have beenexposed to live steam for an adequate time to ensure the desired “kill”effect.The steam system must be able to measure and control steam temperature,pressure, and/or flow to ensure adequate steaming. Calculation of Fehrenheit or other measures is often required to meet process needs. The advantages of this method are: improved safety for workers involved in production of potential dangerous compounds, faster cleaning, reduced water usage, less labor spending, repeatable operations, possibility to include a programmed cleaning cycle that is fully automated (employing PLC, sensors, valves) with recirculating detergent and rinse solutions. Based on Time Action Flow Chemical Temperature cleaning cycle principles Defined module and automation Compliance to ISPE, ASME-BPE, cGMP guidelines Easy to integrate with existing process system with all the essential analytical instruments Custom designed as per process requirements Cost and reliability gains from reduced manual work and reduced risk of accidental recontamination Consistent cleaning efficiency with minimum CIP fluid requirements Ensures efficient, automatic cleaning of process lines and vessels Product Offerings: CIP/SIP Docking System One Tank CIP System Multiple Tank CIP System Mobile CIP recirculation & SIP trolley

digital vacuum gauge

12,500 - 22,000 Per Piece

Battery operated Digital Vacuum Gauges are used in vacuum systems for correct reading of vacuum in the process. We have battery operated as well as external powered Digital Vacuum Gauges.

Clean In Place System

Get Price Quote

The Bung Processor has inbuilt Clean In Place (CIP) system for washing the chamber and the rotating carriage to prevent the dirt or debris to be carried out from one cycle to another. This is very important before the start of the "Rinse with purified water" and "Sterilization" phases. CIP System Consists of : CIP Tank 50 Ltr to 5000 Ltr. CIP Skid with mobile trolley. Acid Carboy. Alkali Carboy. Acid Dosing Pump. Alkali Dosing Pump. Supply pump. Recirculation pump. Heat Exchanger if required. Air Vent Filter. Level Sensor. Pneumatic Diaphragm valves to control process. Steam trap. Temperature Sensor. pH sensor. Conductivity sensor. Control panel with PLC/HMI & Printer.

THE RMOCOUPLE VACUUM GAUGE

Get Price Quote

Available in analogue type. Measuring range : 0.5 mbar to 0.001 mbar Panel mounting type compatible to 19” rack 4U size Provision for single and double gauge head. Provision for relay out put.

Cip System

160,000 Per Piece

Dairy Processing Plant

Get Price Quote

Milk Processing Plant has prime use in processing a variety of milk made products. In this range, we offer customized turn- key solutions to dairy industries with highly proficient plants and machines. Get complete solution of the dairy processing plant machinery along with milk plant designing and products consulting from our highly skilled and experienced dairy technologies and engineers. Goma Engineering use advanced technology and the finest quality components to manufacture it strictly as per the defined ISO standards. The milk processing plant fabricated by us undergoes various tests prior to shipping the delivery to ensure its superiority and impeccability.

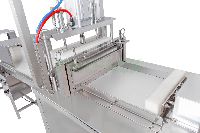

Paneer Cutting Machine

Get Price Quote

the machine is sturdy and compact in design and simple in operation. it consists of one horizontal blades frame and guided by uhmw bushes and connected to pneumatic cylinder for up and down operation. another horizontal actuator cylinder attached with uhmw pusher to index paneer accurately. all blades and structural frame are of s.s.304 poly carbonate doors are provided for visibility of cutting material. Air cleaning system provided with the machine.

Portable Cip System

Get Price Quote

Our firm offers an exclusive range of portable cip system, which is useful to wash, non movable equipment. Extensively demanded to be used on fbd, blenders, mixing tanks and storage tanks, these portable cip systems are easy to operate and need low maintenance. The portable cip system offered by us is chiefly manufactured from the fine quality material which comprises of metal components, flanges and fasteners, etc. One can avail our portable cip system at market leading prices from us. features cleaning fluid holding tanks (1, 2 or 3 as per clients' cleaning philosophy), with suitable heating arrangement wherever necessaryhigh pressure pump of suitable capacity and headhigh pressure jet nozzle with retractable hoseinterconnecting heater, piping, valves, etccontrol panel with starter, indicators, interlocking etccommon trolleytank capacity 100 ltr, & morepump capacity up to 25 ltr per minfull gmp compliant constructionparastalic pump can be providedplc & non plc can be provided

cheese press machine

Get Price Quote

Paneer Vat Paneer Hoops(Ss 304) Pneumatically Operated Paneer Press SS WorkingCutting Table with Cutting Knives SS Trays with Trolley Type Racks for Diced Cubes SS Showel of Suitable Size Paneer Cooling Tank with External Heat Exchanger Paneer Cutting Machine Vacuum Sealing Machine Remote Control Panel

Paneer Cutting Machine

Get Price Quote

paneer cutting machine offered by us is highly acclaimed by the clients due to its efficient functionality. paneer cutting machine is compactly designed and easily operated. paneer cutting machine has one vertical blade that is supported by main structural frame propelled by uhmw bushes and connected to pneumatic cylinder for up and down movements. another uhmw is supported with bracket and main frame and guided by unhw bushes and firmly connected to horizontal pneumatic cylinder for cutting the cube sizes. the horizontal cutter frame is mounted on main frame in front of pusher. all the blades and structural frame are out of s.s.304 material and machine is enclosed with s.s.304 covers. acrylic front door is provided for the visibility of cutting material. all the blades are teflon coated. prominent features sturdinesshigh end performancecompact designslong lasting

Vacuum Gauges

Get Price Quote

We deals in supplying of wide range of Vacuum Gauges.

Vacuum Gauge

Get Price Quote

Vacuum Gauge, Vacuum Furnace

Mini Dairy Plant

Get Price Quote

Mini Dairy Plant, Eye Drop Filling Machine, Nasal Spray Filling Machine

butter packing machine

Get Price Quote

butter packing machine, Trim Rewinder Unit

Vacuum Gauge

Get Price Quote

Vacuum Gauge, Flow Nozzle, PH And ORP Transmitter, Conductivity Meter

Vacuum Gauges

Get Price Quote

Vacuum Gauges, Mechanical Booster Pump, rotary piston pump, Vacuum Valve

Vacuum Gauges

Get Price Quote

Vacuum Gauges, Pressure Gauges, conductivity indicators, flow transmitters

Paneer Cutting Machine Slicing

Get Price Quote

Paneer Cutting Machine Slicing, Paneer Pressing Machine

Portable Cip System

Get Price Quote

Portable Cip System, Ointment Plant, Pneumatic Speed Shear Emulsifier