VENTS VUT2 200P-Suspended air handling units

VENTS VUT2 200P Suspended air handling units in heat- and sound-insulated casing with horizontal spigot orientation. Air capacity up to 220 m3/h, heat recovery efficiency up to 89 %. The suspended air handling units VUT2, VUE2 and VUTE2 200 P are the fully-featured ventilation units that ensure air filtration, fresh air supply and stale air extract. The model VUT2 ensures sensible heat recovery and the models VUE2 and VUTE2 ensure sensible heat and moisture recovery in two plate heat exchangers. The units are applied as components of ventilation and air conditioning networks for various premises. The units are featured with extremely low noise level due to the fans located between two heat exchangers. High heat recovery efficiency of the units meets the strict energy saving market demands. Compatible with round Ø125 mm air ducts. Modifications : VENTS VUT2 200 P –unit with two aluminium cross-flow heat exchangers. VENTS VUE2 200 P –unit with two cross-flow heat exchangers of polymerized cellulose. VENTS VUTE2 200 P –unit with two cross-flow heat exchangers (one made of polymerized cellulose and another made of aluminium). Casing : Made of aluzinc, internally filled with 10 mm cellular polypropylene heat- and sound-insulating layer. Filter : Supply and extract air flows are purified through two bag filters with filtering class G4. Fans : The unit is equipped with a supply and exhaust centrifugal fan with backward curved blades and integrated overheating protection thermostat with automatic restart. The motors and the impellers are dynamically balanced in two planes. Heat exchangers : The units incorporate two heat exchangers types: The aluminium heat exchangers are designed to ensure sensible heat energy transfer from extract to supply air flow. The heat exchangers are distinguished by long service life in a cold climate. The enthalpy polymerized cellulose heat exchanger are designed to recuperate sensible heat and latent energy contained in the extract air to warm up supply air flow. The heat exchangers are frostproof and produce no condensate. The units with such heat exchangers are recommended for use in air conditioned premises. The unit VUT2 200 P is equipped with two aluminium cross-flow heat exchangers with drain pans and heat exchanger freezing protection. The VUE2 200 P unit is equipped with two enthalpy polymerized cellulose counter-flow heat exchangers. The unit VUTE2 200 P is equipped with two cross-flow heat exchangers, one made of aluminium and another of polymerized cellulose. The unit has a drain pan to remove condensate from the aluminium heat exchanger. The unit is equipped with a switch that enables selection of one of three unit operation modes: standby mode, low speed (LOW) and medium speed (MED). The unit may be equipped with P3-1-300 switch that enables switching the unit on/off and setting one of three unit operation modes: low speed (LOW), medium speed (MED) and high speed (HIGH). The unit may be equipped with a CO2 sensor (not included into the delivery set). In case of high CO2 concentration it switches the unit to maximum (HIGH) speed. The unit may be equipped with A13 LCD control panel (not included into the delivery set) for turning the unit on/off, switching to low, medium and high speed as well as room temperature displaying. The integrated freezing protection system is designed to prevent the heat exchanger freezing at low temperatures. In case of freezing danger indication by the temperature sensor the supply fan is turned off to let warm extract air flow pass by the heat exchangers and warm them up. After freezing danger is no longer actual, the supply fan is turned on and the unit reverts to the standard operation mode. Mounting : The unit is designed for suspended ceiling mounting in balcony, storeroom, basement, attic and other auxiliary premises. The unit is also suitable for installation in major premises directly to the ceiling, behind the false ceiling or in the ceiling recess. Acess for servicing and cleaning through the bottom panel. The unit is suitable for wall mounting as well.

...more

VENTS VUE mini

Air handling units with heat recovery in the compact sound- and heat-insulated casing. Air capacity up to 106 m3/h. Heat recovery efficiency from 64 up to 76%. Compact air supply and exhaust ventilation unit VUE 100 P mini is a simple and effective energy-saving solution ventilation of apartments, cottages, single-family houses, workshops and trade premises. The unit is a fully-featured ventilation unit that provides air cleaning, fresh air supply to the premise and removal of extract air from the premise. Extract air thermal energy is transferred to the cross-flow heat exchanger and is used to warm up the supply air flow. Built-in heat exchanger prevents heat losses and saves operating costs for heating in winter and air conditioning in summer. Due to the compact casing and silent operation the VUE 100 P mini unit can be installed behind suspended ceiling. The unit is designed for connection to 125 mm round air ducts. Several rooms may be ventilated if they are connected with air distribution network. Air flow regulation with A3 (P3-1-300) speed switch. Casing : The casing is made of corrosion-resistant alumozink and sound-insulated with 15 mm сellular polyethylene layer. For easy mounting the casing is fitted with mounting brackets. The detachable panel is swivel connected to the unit to provide fast and easy access to the casing internal components for servicing and maintenance. The unit is equipped with two backdraft dampers, one in the supply and the other in the exhaust air duct. Filter : Supply and extract air flows are purified through two filters with filtering class G4. The filters prevent dirt and dust ingress into the room and protect the unit components against contaminations. Fans : The unit is equipped with reliable supply and exhaust fans with forward curved blades that are powered by motors with low energy demand. The motor has maintenance-free ball bearings that ensure long service life about 40 000 hrs and are greased for the operation period.

...more

VENTS VUE 100 P mini -Air handling units

Air handling units with heat recovery in the compact sound- and heat-insulated casing. Air capacity up to 106 m3/h. Heat recovery efficiency from 64 up to 76%. Compact air supply and exhaust ventilation unit VUE 100 P mini is a simple and effective energy-saving solution ventilation of apartments, cottages, single-family houses, workshops and trade premises. The unit is a fully-featured ventilation unit that provides air cleaning, fresh air supply to the premise and removal of extract air from the premise. Extract air thermal energy is transferred to the cross-flow heat exchanger and is used to warm up the supply air flow. Built-in heat exchanger prevents heat losses and saves operating costs for heating in winter and air conditioning in summer. Due to the compact casing and silent operation the VUE 100 P mini unit can be installed behind suspended ceiling. The unit is designed for connection to 125 mm round air ducts. Several rooms may be ventilated if they are connected with air distribution network. Air flow regulation with A3 (P3-1-300) speed switch. Casing : The casing is made of corrosion-resistant alumozink and sound-insulated with 15 mm сellular polyethylene layer. For easy mounting the casing is fitted with mounting brackets. The detachable panel is swivel connected to the unit to provide fast and easy access to the casing internal components for servicing and maintenance. The unit is equipped with two backdraft dampers, one in the supply and the other in the exhaust air duct. Filter : Supply and extract air flows are purified through two filters with filtering class G4. The filters prevent dirt and dust ingress into the room and protect the unit components against contaminations. Fans : The unit is equipped with reliable supply and exhaust fans with forward curved blades that are powered by motors with low energy demand. The motor has maintenance-free ball bearings that ensure long service life about 40 000 hrs and are greased for the operation period. Operating Logic » Warm extract air is moved by exhaust fan from the premise through the extract filter and heat exchanger, where it transfers thermal energy to its elements and then is exhausted outside. » Cold intake air from outside is moved by the supply fan first to the supply filter where it is purified, then to the heat exchanger where it absorbs thermal energy from extract air and then supplied to the room. » The heat exchanger reduces heat losses and saves operating costs for heating in winter and air conditioning in summer.

...more

Ventilation Fan

Industrial exhaust fans are very popular electrical equipment being used in various industrial sector to remove the heats & humidity from certain area. These ventilation fans control the whole atmosphere of any manufacturing unit or production unit by exhausting the defiled air from the working place. It is considered as the best option to keep the inside air clean & bearable. These kind Industrial exhaust fans not just help us to maintain our work space very clean, safe & highly productive but also help us in removing the contaminated air and acquiring fresh, cool air in the working place. Now days various types of ventilation fans are available in the market. You can easily get the overall size and type of exhaust fan that would be sufficient for your application. We as Devatech Engineers have developed some ventilation and exhaust solutions for various industrial sector. We use latest innovative technology & superior quality raw material in manufacturing of our products. Our offered products are mostly used in Greenhouses, Poultry, and Garment Manufacturing industries. Various range of exhaust fans with different sizes are available to us. These can be operated manually. We offer the products as per the different industrial requirements & Specifications of the clients. Ventilation Fan have the below Features........ » Quality Durability » Cost Efficiency as are designed Low energy Consumption » Visual and resource effective » Precision engineered » Sleek to deliver result » Perfect performance » Low maintenance and Reliability » Long life

...more

Twin Fresh Air Ventilators

Installation of single-room reverse ventilators with air regeneration TwinFresh is the most modern and practical way to arrange a comfortable microclimate and the required air exchange in refurbished premises, brand new recently inhabited houses or reconstructed apartments. The TwinFresh single room ventilators are applicable at any project stage and suitable for any room, starting from design of the ventilation system during construction of a new object, including reconstruction of existing buildings and premises, ordinary scheduled repair and finishing with ready-made premises, where installation of centralized ventilation devices is unfeasible. Twin Fresh have the below Features........ » Cost Saving » Energy Saving » Highly Efficient » Versatile » Simple and easy to use

...more

Special Drying Equipmment

Drying is a mass transfer process consisting of the removal of water or another solvent by evaporation from a solid, semi-solid or liquid. This process is often used as a final production step before selling or packaging products. To be considered "dried", the final product must be solid, in the form of a continuous sheet (e.g., paper), long pieces (e.g., wood), particles (e.g., cereal grains or corn flakes) or powder (e.g., sand, salt, washing powder, milk powder). A source of heat and an agent to remove the vapor produced by the process are often involved. In bioproducts like food, grains, and pharmaceuticals like vaccines, the solvent to be removed is almost invariably water. In some products having a relatively high initial moisture content, an initial linear reduction of the average product moisture content as a function of time may be observed for a limited time, often known as a "constant drying rate period". Usually, in this period, it is surface moisture outside individual particles that is being removed. The drying rate during this period is mostly dependent on the rate of heat transfer to the material being dried. Therefore, the maximum achievable drying rate is considered to be heat-transfer limited. If drying is continued, the slope of the curve, the drying rate, becomes less steep (falling rate period) and eventually tends to nearly horizontal at very long times. The product moisture content is then constant at the "equilibrium moisture content", where it is, in practice, in equilibrium with the dehydrating medium. In the falling-rate period, water migration from the product interior to the surface is mostly by molecular diffusion, i,e. the water flux is proportional to the moisture content gradient. DRYING EQUIPMENT : » Tray Dryers : In tray dryers, the food is spread out, generally quite thinly, on trays in which the drying takes place. Heating may be by an air current sweeping across the trays, by conduction from heated trays or heated shelves on which the trays lie, or by radiation from heated surfaces. Most tray dryers are heated by air, which also removes the moist vapours. » Tunnel Dryers : These may be regarded as developments of the tray dryer, in which the trays on trolleys move through a tunnel where the heat is applied and the vapours removed. In most cases, air is used in tunnel drying and the material can move through the dryer either parallel or counter current to the air flow. Sometimes the dryers are compartmented, and cross-flow may also be used. » Roller or Drum Dryers : In these the food is spread over the surface of a heated drum. The drum rotates, with the food being applied to the drum at one part of the cycle. The food remains on the drum surface for the greater part of the rotation, during which time the drying takes place, and is then scraped off. Drum drying may be regarded as conduction drying. » Fluidized Bed Dryers : In a fluidized bed dryer, the food material is maintained suspended against gravity in an upward-flowing air stream. There may also be a horizontal air flow helping to convey the food through the dryer. Heat is transferred from the air to the food material, mostly by convection. » Spray Dryers : In a spray dryer, liquid or fine solid material in a slurry is sprayed in the form of a fine droplet dispersion into a current of heated air. Air and solids may move in parallel or counterflow. Drying occurs very rapidly, so that this process is very useful for materials that are damaged by exposure to heat for any appreciable length of time. The dryer body is large so that the particles can settle, as they dry, without touching the walls on which they might otherwise stick. Commercial dryers can be very large of the order of 10 m diameter and 20 m high. » Pneumatic Dryers : In a pneumatic dryer, the solid food particles are conveyed rapidly in an air stream, the velocity and turbulence of the stream maintaining the particles in suspension. Heated air accomplishes the drying and often some form of classifying device is included in the equipment. In the classifier, the dried material is separated, the dry material passes out as product and the moist remainder is recirculated for further drying. » Rotary Dryers : The foodstuff is contained in a horizontal inclined cylinder through which it travels, being heated either by air flow through the cylinder, or by conduction of heat from the cylinder walls. In some cases, the cylinder rotates and in others the cylinder is stationary and a paddle or screw rotates within the cylinder conveying the material through. » Trough Dryers : The materials to be dried are contained in a trough-shaped conveyor belt, made from mesh, and air is blown through the bed of material. The movement of the conveyor continually turns over the material, exposing fresh surfaces to the hot air. » Bin Dryers : In bin dryers, the foodstuff is contained in a bin with a perforated bottom through which warm air is blown vertically upwards, passing through the material and so drying it. » Belt Dryers : The food is spread as a thin layer on a horizontal mesh or solid belt and air passes through or over the material. In most cases the belt is moving, though in some designs the belt is stationary and the material is transported by scrapers. » Vacuum Dryers : Batch vacuum dryers are substantially the same as tray dryers, except that they operate under a vacuum, and heat transfer is largely by conduction or by radiation. The trays are enclosed in a large cabinet, which is evacuated. The water vapour produced is generally condensed, so that the vacuum pumps have only to deal with non-condensible gases. Another type consists of an evacuated chamber containing a roller dryer. » Freeze Dryers : The material is held on shelves or belts in a chamber that is under high vacuum. In most cases, the food is frozen before being loaded into the dryer. Heat is transferred to the food by conduction or radiation and the vapour is removed by vacuum pump and then condensed. In one process, given the name accelerated freeze drying, heat transfer is by conduction; sheets of expanded metal are inserted between the foodstuffs and heated plates to improve heat transfer to the uneven surfaces, and moisture removal. The pieces of food are shaped so as to present the largest possible flat surface to the expanded metal and the plates to obtain good heat transfer. A refrigerated condenser may be used to condense the water vapour.

...more

Solar Powered Freezer

Product Type : solar deep freezer

Country of Origin : Maharashtra, India

Usage/Application : Refrigeration Parts

Weight : 38 kgs

Brand Name : Devatech Engineers Pvt Ltd

Refrigerant : R134a

Product Type : Solar DC 12V Deep Freezer 500L

Voltage : 12V

...more

Solar powered energy

Voltage : 12V

Type : solar deep freezer

Weight : 58 kgs

Certification : ISO

...more

Silica Gel Rotor

The provided rotor is manufactured with the optimum quality raw material as well as pioneered techniques under the supervision of our adroit professionals. Available in different technical specifications, this rotor is highly demanded in the market. Moreover, our esteemed clients can avail this rotor from us at industry leading prices.

...more

Rotary Heat Recovery Wheel

With honesty and hard work of our professionals, we have carved a niche for ourselves in this domain by offering rotary heat recovery wheel. This wheel is extensively used for humidity and heat recovery for air handling units, modular air-conditioning units, indoor air quality (iaq), and several civil and industrial air-conditioning system for energy saving.

...more

Resin Dryer Machine

We are using the latest technology for paper drying we use only three big rolls heated by electricity, steam or thermic oil. In this technology total heat transfer to roller surface and pass to wet paper directly. The surface contact area is 90-95% of roller surface area so we are using maximum heat without heating air and losing energy. We are using motorised squeezing roll assembly with pneumatic cylinder to give high pressure to rubber roll to remove maximum water from resin so our system is 50% higher energy saving then others. Due to only three rolls at low height it’s very easy to pass paper and the production capacity is 50% higher then others. The deep roll is mounted on body inside stainless steel tray better than putting on the floor without proper alignment as others.

...more

Resin Dryer

We are using the latest technology for paper drying we use only three big rolls heated by electricity, steam or thermic oil. In this technology total heat transfer to roller surface and pass to wet paper directly. The surface contact area is 90-95% of roller surface area so we are using maximum heat without heating air and losing energy. We are using motorised squeezing roll assembly with pneumatic cylinder to give high pressure to rubber roll to remove maximum water from resin so our system is 50% higher energy saving then others. Due to only three rolls at low height it’s very easy to pass paper and the production capacity is 50% higher then others. The deep roll is mounted on body inside stainless steel tray better than putting on the floor without proper alignment as others.

...more

Paper sheet cutting section Machine

PLC control pneumatic shearing machine. Pneumatic Control system. It is accurate and easy to operate.

...more

Paper sheet cutting section evaporative cooling pad production line

Brand Name : Devatech

Application : Green house, poultry farm

Weight : 3000kg

Certification : ISO

Warranty : 2 Years

Type : Cooling Pad Making Machine

After-Sales Service Provided : Engineers available to service machinery overseas

...more

paper sheet cutting machine

PLC control pneumatic shearing machine. Pneumatic Control system. It is accurate and easy to operate.

...more

Paper Machine

Voltage : 220V/50Hz

Brand Name : Devfresh

After-Sales Service Provided : Overseas third-party support available

Condition : New

Warranty : 1-Year

Weight : 7-105kgs

Material : Aluminum

...more

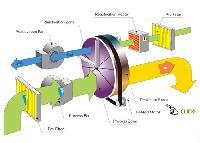

industrial ventilation

Devatech is a leading globel provider,as a world market leader we continuously push technology forward.Devatech Industrial Ventillation system is made by using Heat Exchanger Wheel.

...more

Industrial Air Cooler

DevCool Industrial Air Cooler - Designed to deliver superior performance in warm workplace settings, our air coolers are ideal for factories, offices, schools, malls, assembly halls, warehouses, and metro stations among others. They also ensure that the cooled spaces remain dust free. Devatech's newest technology in high capacity evaporative coolers is designed for maximum cooling with minimal equipment. Each industrial High-performance Premium Cooler is capable of providing air volume up to 60,000 CFM, and can withstand static pressure up to 2 inches Ideal for use in large factories, warehouses, agri-businesses, and other applications that require industrial-grade evaporative cooling solutions. DevCool High-performance Premium Coolers are second-to-none in performance and cooling capacity. About the Product We are a high-tech enterprise specializing in new types of energy saving and environment protecting evaporative air cooler. we Devlop new concept of Ductable Air cooler to Make Duct with Air cooler Central Cooling systems. To provide Air cooling Solutions and that are best in class technology integrating the professional competencies and methodologies thereby winning the confidence of our Clients. Our company is specialized in evaporative air cooler (Frelly Movable & Ductable Air Cooler For Factory and Commercial Purpose). During the past Days, by following the value philosophy 'Kindness, Fine, Speed, Development', Devatech staff made great efforts to producing the best quality evaporative air coolers. During the past Days, by following the value philosophy 'Kindness, Fine, Speed, Development', Sky staff made great efforts to producing the best quality evaporative air coolers. Professional makes perfect. Our strong R & D team guarantee we are always leading the most advanced evaporative cooler technology. Insisting on the faith, efficiency, innovation and harmony, we aretrying hard to creat a green and loe carbon environment, together with those who care, support and trust Sky. Changing Climate Conditions due to Global Warming .weather is getting extreme and severely effecting life on earth. Different Industrial work place or Social gathering Places needs to retain comfort. The Challenge to improve environment of such places at affordable cost derived unique products like ' Antarctica & Himalayas'. Movable Evaporative Air Coolers are about 30years old concept. Cooling Tower working principle or technique is improved to lower temperature by water evaporation & heat absorption through cooling pads , Temperature are reduced by 7 10 c from natural weather temperature and improves Oxygen levels. Due to simple principles & designs, cost of reducing temperature is very low compared to refrigeration gas based technique. It gives best result in all terms. Evaporative air coolers are very popular in deserts, Middle East and other high temperature zones of earth. We have done extensive study and improvement in all aspects of conventional air cooler to develop new break through coolers to suit today's need with most energy saving concept. Our coolers are designed to give you superior cooling over vast expanse of space, Improve oxygen levels, high energy efficiency and trouble free performance for years together. We have ensured that our coolers are aesthetically good & correct to get them gelled with your existing layouts & interiors in all aspects. Our coolers are tested for best efficiency & safety for direct installations at any major standard locations. We are committed to deliver best products, after sales services at best value for money for our esteem customers. Our organization has attained a distinguished position in the domain of supplying and exporting Industrial Air Cooler. Post procurement, all the products are checked so that only fully functional products are delivered to clients. Being efficient in providing cooling for longer time, these coolers are widely used in small to large industrial set-ups. These Industrial Air Cooler are made available in different models to suit the diversified needs of various industries.. Features: »Saves electricity bills »Corrosion resistant »Long service life Other information: »KLF 18A / B / CXP »Voltage: Single Phase 240V / 3 - Phase, 415V / 50 Hz »Power Consumption: 1100W »Noise: < 75 dB »Airflow Rate: 18,000 m3/h »Water Consumption: 30 ~ 40 L/h »Water Tank Capacity: 25 L »Net Weight: 65 kg »Physical Size: 110 x 110 x 110 cm Many modern buildings require cooling either for the comfort of the occupants or to protect the processes or equipment they contain. There are three typical methods which can be employed to cool these buildings; ventilation, evaporative cooling or a refrigeration based air conditioning system. The choice of system can have a dramatic effect on the total carbon emissions of the building and the energy consumed due to their different electrical demands. See our Air Conditioning comparison to compare the features of Air Conditioning with Evaporative Cooling. Ventilation systems can provide comfort cooling for most of the year. During prolonged periods of high temperatures they are unable to maintain internal temperatures below 25°C. Refrigeration based systems are effective but can be expensive to operate. Evaporative cooling, which can produce air consistently below 22 C in the UK climate, provides an intermediate solution which consumes only a fraction of the electricity. Why use DevCool? »The DevCool range is the only evaporative cooler designed specifically for the UK and European industrial and commercial market. We have been in operation now for over 10 years and have more than 1000 installations in the UK, many of our clients have used us for several different applications. We have a warehouse in Bury St Edmunds where we hold stock for all our coolers. »We pride ourselves on our service to our clients and consider ourselves to be at the forefront of evaporative cooling technology. What are the savings? »An evaporative cooling installation typically consumes less than 10% of the electricity compared to the equivalent rated refrigeration based cooling system. »Please click here to see an example of cost and carbon savings for a building in London requiring a 30kW peak load. »Should you want an estimate for the savings which could be achieved at your own site then please contact us. What is direct evaporative cooling and how does it work? »Evaporative cooling is a very simple method of cooling air without using refrigerants. A direct evaporative cooler, using wetted filter pads, cools air by bringing it into contact with water. Water evaporates into the air stream and cools it. The amount of cooling is dependent upon the temperature and relative humidity of the air. In the UK the maximum theoretical air off temperature is 22AC. click here for more information and animated drawing. What temperature will I get out of a cooler when it is hot outside? »The performance of an Cooler is dependent upon the temperature of the air and the relative humidity. The higher the temperature and the lower the humidity the greater the cooling. »n the UK the humidity is always low when the temperatures are high so we can achieve a drop in temperature of over 10C on the hottest days. In a tropical climate where humidity and temperatures are high we get very little cooling. DevCool is our revolutionary air conditioning system that utilizes sustainable technology to provide you cool conditions economically and without using harmful or costly refrigerants. It is a 100% fresh air system. It is also custom designed to suit your requirements. Useful in industrial air conditioning, it contains the muticycle lateral dry fog AHU unit, which is the only one of its kind in the world. DevCool is a muticycle dry fog evaporative cooling system, which uses fraction of energy of normal air conditioning systems. Depending various conditions including the geographical location of the building, turbo cool can totally substitute normal air conditioning systems. No more dry, recycled and stale air in your building. A combination of techniques are used to achieve the optimized solution including displacement ventilation, zoning techniques, maintaining air flow patterns etc and a variety of products including our wind driven roof ventilators/turbine ventilators–Turbovent to provide customized results. Our systems are flexible enough to provide precise temperature and humidity at a particular spot or zone. Our systems are also flexible enough to incorporate refrigerants for cooling, if your requirements specify the same. Turbo cool Systems are ideal for spot cooling, zone cooling, industrial cooling applications and is proven for its efficiency. DevCool Cooling Systems / Air Coolers »DevCool is an ideal solution for improving working comfort in the most economical manner. Increase in working comfort translates to increased productivity translates to more profit. Installation of fans around the industrial space only recirculates warm, stale, contaminated air, which only increases fatigue of the workmen thus affecting the efficiency and also roved harmful to the workmen in time.With turbo cool evaporative cooling solutions, we provide the require working comfort / man cooling to achieve remarkable production valves and finally product quality. »With DevCool 100% fresh air evaporative cooling solutions, we design systems to provide spot or zone cooling where working comfort is to be improved in the most optimal and cost effective manner with minimal energy and water consumption. ideal replacement for all your man circulating fans. »The operating costs of DevCool system is equivalent to normal fans but the results are almost 5 to 15 Deg Temperature reductions apart from the air changes provided to the workspace. Replace Air conditioning with our precise evaporative cooling solutions. Provide comfort for your commercial spaces, industrial spaces at very low costs. »Change the way commercial spaces including showrooms / office spaces are cooled. Provide immense comfort cooling and healthy air in comparison with unhealthy Air conditioners and save upto 90% in operation costs. SunGreen Precise Evaporative cooling solutions are ideally designed for various areas for specific applications and optimum results. Applications »Factory & Heavy Industry »Heavy Ducting »Industrail Air Cooler »Ducting Works »Steel Industry Cooling »Farm House »School & Colleges »Textile Industries »Warehouse »Offset Print Cooling »Conference Hall Cooling

...more

High Pressure Exhaust Fan

Our organization is highly popular in offering high pressure exhaust fan at feasible rates to our clients. Features: free from flaws excellent design quality approved

...more

Exhaust Fan

We are engaged in offering a wide range of Ventilation FansExhaust Fans that are used for several purposes like ventilating stores, shops, offices, factories and farm buildings. Our range of fans is appreciated for its features like less power consumption, exclusive designs, and sturdy construction.

...more

Honeycomb Pad

"devatech engineers private limited", are a fast growing manufacturer, exporter, importer and service provider of air treatment and ventilation systems. These products are appreciated for their sturdy construction, easy installation, low maintenance, durability and optimum performance.

...more

Heat Recovery Wheel Energy Recovery Wheel

DevFresh Heat Recovery Wheel is used to recover the heat & humidity from air conditioning units, air conditioning systems in many industrial applications. These are also called as energy recovery wheel which is made up of aluminum. Its surface is coated with Hygroscopic. About the Product DevFresh Heat Exchanger Wheel-HEW is a benefit for facility operators with regards to getting fresh Air and saving recurring expenses. Our Heat Wheels in the air-conditioning system means more outdoor air at lower energy cost reduced chiller load Energy Conservation Wheels, Energy Recovery Wheels, Enthalpy Wheels, Sensible Wheels, Hygroscopic Wheels, Condensation Wheels or Sorption Wheels. The Production Devatech as a Company wants to meet the Users requirement as exact and as precise as possible. Every National government regulation to preserve and proper utilisation of energy has resulted in increasing the use of energy recovery equipment. We strictly go with engineer's suggestions which is otherwise called as perfect technical utility and end user awareness as the Investment in energy recovery equipment significantly reduce the energy costs associated with conditioning ventilation air, and lowers the investment initial cost in lowering stream heating, cooling and humidification equipment. Benefits Devatech's Aluminium made hygroscopic coating of the storage combination pulls the additional advantage of recovering moisture. Summer operation is dehumidification of warm and humid supply air to reduce the energy consumption of the down stream cooling equipment. During Winter this feature recovers moisture from the exhaust air to reduce the humidification load. Energy Recovery from Devatech provides sound economic payback. Energy Conservation Wheels are easily integrated and retrofitted in new ventilation systems. It can be easily installed into existing systems also. Delivers fresh air throughout the year at all conditions and Helps to meet ventilation standard without raising energy cost. As it Pre-conditions incoming fresh air maintains humidity conditions at no additional cost. The Authority for Standard The HVAC industry has responded to this indoor air quality (IAQ) concerns through its professional organization The American Society of Heating and Refrigerating and Air Conditioning Engineers which is Popularly known as ASHRAE ASHRAE have issued IAQ Standard 62, entitled "Ventilation for Acceptable Indoor Air Quality". This standard specifies and stress on the need for continuous outdoor air ventilation as well as the importance of maintaining indoor humidity levels. How to Recover Heat? The combination of heat and humidity recovery of rotary heat exchangers is a highly efficient energy-saving. This is not a formula but is a Technology. In the most of installation, the wheel is mounted in air handling unit AHU. It is positioned Supply and exhaust air each pass through half of the wheel in counter flow directions. The rotor media is a rotating transfer media. In air-conditioning area, the cold air from air-condition room will pass through the half section of rotating honey comb cooling the metallic media which is Aluminium or other metal foil. This continuous rotating cooled media, after coming in other half section of frame, will cool the hot air coming from outside in the air-conditioned area. It temporarily takes up the heat from the warm air stream and releases it in the colder air stream. DevFresh Heat Exchanger Wheel (HEW) exchanger recovers both sensible (temperature) and latent (moisture) energy, and does effective job on Recovering the Heat and Humidity.

...more

Heat Exchanger Wheel

Helps to meet ventilation standard without raising energy cost. · maintains humidity conditions at no additional cost. · dev-fresh wheels has high performance and maximum efficiency can be near 80%. · low pressure drop · polished and hardened surface

...more

heat exchanger machine

Voltage : 220V/50Hz

Brand Name : Devfresh

Material : 3003 Aluminum

Warranty : 1-Year

Certification : ISO

Type : Plate Fin Typle

...moreBe first to Rate

Rate ThisOpening Hours