Rotary Vacuum Evaporator

Get Price Quote

1 Piece (MOQ)

With an industry experience and understanding of decades, we have emerged as successful manufacturer and supplier of superior quality that are Rotary Vacuum Evaporator used in chemical laboratories to remove the solvents from samples through evaporation. The offered evaporator is manufactured by utilizing optimum quality components with the aid of modern machinery in adherence with the global quality standards. The offered evaporator is widely acknowledged owing to its outstanding functionality. Our clients can avail this Rotary Vacuum Evaporator from us in distinct specifications at the most affordable prices. The apparatus consists of an evaporating flasks rotated by sparking induction motor in a heating water bath. Vacuum distillation of solvent at high and low temperature is achieved quickly and efficiency by use of a VARIABLE SPEED motor, which prevents foaming and bumping of the liquid (solvent) into the evaporating flask and also distillation under controlled atmosphere. The evaporating flask is pear shaped to give a large surface area of evaporation and is clamped to a glass duct which goes through the drive unit and protudes about 120 m.m. into the condenser. The condenser is fitterd with standard joint at the top and the bottom for receiver flask. The unit is fitted with a quick action jack.

Multi Effect Evaporator

Get Price Quote

In order to recover the clean condensed water and enable its reuse from the RO rejects and ETP solution we offer Multi effect evaporators. The system is used to reduce the water loss through double or triple Effect Combination Evaporator with one falling film type and one forced circulation type evaporators. The material of construction for all liquid contact parts in SS304 and Calandria tubes of SS304. All vapor and condensate contact parts will be in M.S.Complete system will be under pressure at 3 kg/cm2( g).and consists of following components : Feed Pump : A centrifugal direct driven pump is used for transferring the feed solution from the balance tank to the Calandria. The pump is provided with a single mechanical seal and electrical motor. All contact parts with liquid will be in S.S.304. Calandria : This Calandria is essentially a vertical shell and tube type vertical heat exchanger and is designed as per the Falling film /forced circulation principle. Steam is provided on the shell side and feed solutions is passed through tubes. The tubes of Calandria are of 25.4/ 31.75 mm OD. Adequate no. of tubes 4/6 M length are provided for the heat transfer duty. The tubes are welded on the tube sheet. The shell has nozzles for steam/vapor inlet and outlet, and temperature gauge. All Contact parts with liquid will be in S.S.304. Tubes will be of S.S.304. Thermic fluid/Steam and other non-contact parts will be in M.S. Vapor Separator : In vapor separator, the heated liquid coming from the Calandria is flashed. Saturated vapors coming out from top are sent to the next Calandria/condenser. Liquid concentrate coming out from bottom is withdrawn as feed to next Calandria/ as product. The separator shell has sight and light glass for viewing the concentrate level. Material of construction for all contact parts with liquid and vapor will be S.S.304 and non-contact parts will be in M.S. Re-circulation Pump : This pump is provided for re-circulation of slurry inside the heat exchanger, so as to increase the velocity of liquid inside the tubes and to get the required heat transfer. This is a Centrifugal Pump with double mechanical seal and motor. Contact parts will be in S.S.304. Concentrate outlet will be taken out from recirculation pump so the discharge head will be at around 5-6 meter only. Condenser is used to condense the evaporation rate at the outlet of system. It also consist of condensate pot, condensate pump and vacuum pump.

Best Deals from Evaporator

Nitrogen evaporator

242,000 Per Piece

1 Piece (MOQ)

wastewater evaporator

Get Price Quote

We are instrumental in offering the products in premium packaging material that is certified by the experts, followed by stern packaging of the products by the .professionals. Our team members help us completely to deliver exceptional range of products that is in conformance with the standards. Features : Quality approved Multifunctional Best working. Features : High productivity Hassle free operations Impeccable mechanism

rotary evaporators

Get Price Quote

> 6 Types of Flasks ranging from 50 ml to 3000ml.> HAHNVAPOR is Equipped with speed control > Digital Water Bath Covers Ambient Temprature up to 180 > If water Level At Heating bath goes Down, Power will be Cut Off automativally.> Speed Control 20 ~ 280 rpm.> Slant Condencer .> Standard Distillation.

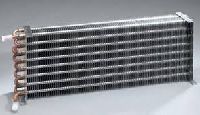

Finned Evaporator

Get Price Quote

We manufacture all types of Shell & Tube Heat Exchangers using different types of Tubes viz. Plain, Fin & Inner Grooved. Heat Exchanger can be Fixed Tube Sheet Type or Removable Bundle Type. Tubes are expanded or Welded to Tube Sheet.

Evaporator

Get Price Quote

Rotary Evaporator

Get Price Quote

Evaporation Plant

5,000,000 Per Units

wiped film evaporator

Get Price Quote

Introduction The Wiped Film Evaporator is used for concentration, distilling, stripping, dehydration and deodorisation of products which are heat sensitive or viscous. The equipment can handle a very wide range of feed compositions ranging from 1% to over 95% concentration. WFE has several advantages as stated in the table below. The operation is continuous with a single pass; the self cleaning continuous contact wipers produce and renew the thin film. Such an operation improves product yield, avoids residue and colour formation. It has an internal condenser (optional) that minimizes the pressure drop and maintains vacuum.

Chemical Evaporators

Get Price Quote

Chemical evaporators are becoming extremely conscious about the water usage of industry with water tables going down & quality of ground deteriorating, the companies are being forced to comply with norms of “Zero Liquid Discharge”.This means that the industry not only has to ensure treatment of the effluents being generated by them, but are also responsible to extract reusable water from it to the extent that they generate solid waste as final reject & permeate water as main product.

wiped film evaporator

Get Price Quote

The operation process in the WFE is simple but yet effective. Feed is introduced at the top of the unit and spread on the shell inner surface by the rotating distribution plate. Specially designed wipers wipe the feed thus creating and renewing the film. This thin film enables an efficient heat transfer even for highly viscous fluids. The low boiling component evaporates and passes through an entrainment separator. This minimizes the carry over of liquid droplets along with the vapors. The vapors are removed through the vapor line to an external condenser (optional) and condensed. For specific applications which demand low pressure drop, the central section of the evaporator is provided with a condenser, thus making the unit a short pathmolecular distillation unit. In this case, the vapors are allowed to condense on the outside of the tube bundle and flow out of the vaporator via the condensate outlet provided at the centre. The high boiling component flows along the shell wall and is discharged from the product outlet. Wiper action is important in promoting downward flow. The productconcentrate should be in fluid form at the operating temperature. Different designs of rotors are available depending upon the product, its viscosity and the process pressure.

RB solvent evaporator

Get Price Quote

The S-EVAP-RB solvent evaporator for round flasks allows for up to 5, 8 or 10 samples to be concentrated at once. S-EVAPs have a broad range of applications including oil and grease analysis using Freon and other approved solvents and concentrating extracted materials from Soxhlet operations. The instrument consists of a base and stand assembly, mounted in a shallow round bath. The entire instrument rotates so that all samples are accessible from the front. At each sample position the round sample flask rests on the bath cover disk and is heated by hot water and steam. The solvent boils from the flask and cools in the condenser which is attached to a centrally located water manifold. The solvent leaves the condenser through a specially designed side arm into either an individual collection flask or a centrally located solvent collection vessel. Solvent recovery through individual or central collection options reduces laboratory emissions and increases laboratory and environmental safety.

laboratory Sample Concentrator Nitrogen Evaporator

Get Price Quote

Rotary Vacuum Evaporator

90,000 Per Piece

Electric Evaporator

Get Price Quote

Evaporators

Get Price Quote

Tubular falling film evaporators are widely accepted as the optimum type of evaporators for the concentration of most of the products within the dairy and food industry, pharmaceutical industry and within many sectors of the chemical industry. The liquid feed is distributed as a thin film inside a battery of verical tubes, and while the film is falling down through the steam heated tubes, water is eavporated from the film. Vapour from one effect is utilized as the heating medium in the following effect. A typical industrial-size falling film evaporator comprises equipment for pretreatment & pasturisation, 3-6 evaporator effects & equipment for after treatment, condensation & water cooling. Fitwell Engineering offer & supply a comprehensive selection of falling film evaporators, designed to meet almost any requirements of products viscosity, thermal characteristics, degree of concentration & rate of production.

Steam Desuperheaters

Get Price Quote

The evolutionary series 800 Desuperheater i.e. Varitrol variable spray nozzles unit can be used in many applications to efficiently reduce the superheated steam or other vapours to temperature approaching saturation. The superheated vapour is passed through a section of pipe into which is fitted a spray nozzle that produces dispersed droplets from a supply of pressurized condensate. These finely atomized particles promote almost immediate evaporation. The required heat being absorbed from the superheated vapour, thus reducing the temperature.

Rotary Evaporator

Get Price Quote

Milk Evaporator

Get Price Quote

Goma manufactures agitated type vacuum pan, forced circulation & falling film types of evaporator, for concentrating fruit juices milk and other liquid foods. Our vacuum pan consists of main cylindrical vessel, vapor separation system, condenser, vacuum pump (water seal with silencer), and other necessary accessories and mountings. Vacuum pan is equipped with digital temperature sensor, vacuum gauge, sample valve, sight glass, air vent, vacuum release valve, condensate system (strainer, steam trap, by-pass valve), safety valve, pressure gauge, steam supply point etc.

wastewater evaporator

250,000 Per Piece

Rotary Evaporator

200,000 Per Piece

Hurricane Concentration Evaporator

Get Price Quote

We are offering hurricane concentration evaporator. Features heat-treat tempered glass - increased corrosion resistance against strong acid and base. precise gas nozzles in a manifold - long distance gas injection by precise nozzles in a manifold. evaporated solvent exhaust system - removal of evaporated harmful solvent by a built-in blower.

Industrial Evaporators

Get Price Quote

Features Can be ceiling suspended as well as floor mounted suitable for Freon as well as Ammonia. Ceiling suspended units in the range of 2 TR, 3 TR & 5 TR. Floor mounted units range from 5 TR, 7.5 TR, 10 TR, 15 TR & 20 TR. Coils can be in different configuration; SS tubes with Al. fins, Cu tubes with Al. fins. Al. tubes with Al. fins (imported coils). Coils provided with electric defrosting. Cabinets are made of 16 SWG CRCA duly treated zinc metalised (or) powder coated. Fans can be propeller or tube axial with TEFC Motors. Provision can be given for capacity control.

Clc Steam Curing Plant

Get Price Quote

Fully Automatic CLC Plant is highly appreciated for its rugged construction, better performance, low maintenance, noise free operations and corrosion resistance. These plants are generally suitable for higher production capacity. The advantages with these plants are less production cost, less lab our, better finish & curing.

evaporation plants

Get Price Quote

evaporation plants

Evaporator

Get Price Quote

Evaporator, Pressure Vessel, Blender, Distillation Unit, Column

Evaporators

Get Price Quote

Evaporators, chemical plant machinery, Mixer, Distillation Column

caustic recovery plants

Get Price Quote

caustic recovery plants, agitated thin film driers, effluent evaporators

Industrial Rotary Evaporator

Get Price Quote

Industrial Rotary Evaporator, baking trays, M.S. Boiler Chimney