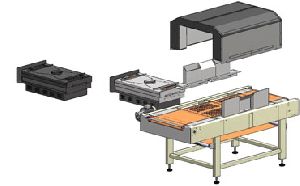

Steam Shrink Tunnel Machine

The FOREVIEW Shrink wrap tunnels are designed considering Pharma and food industries so considering food grade and Pharma acceptance requirements. Optional side plates (top and sides) for air flow patterning and quick changeover for different products, Live roller or stainless steel mesh belt conveyors; optional “dead” roller conveyor for polyethylene.

...more

Shrink Wrap Tunnels

The FOREVIEW Shrink wrap tunnels are designed considering Pharma and food industries so considering food grade and Pharma acceptance requirements. STANDARD SPECIFICATIONS AND FEATURES All-welded main frame from 12 gauge steel Live roller or stainless steel mesh belt conveyors; optional “dead” roller conveyor for polyethylene Sealed bearings (not bushings) on drive and idler shafts Adjustable digital solid state temperature control for a variety of films Four-directional air flow provides positive shrinking Variable air flow and air velocity for a variety of products and applications Bottom air flow adjustment – full on, ½ on, full off Large ducting creates more air volume inside tunnel Optional side plates (top and sides) for air flow patterning and quick changeover for different products Plugs available for patterned air flow Delayed cool down and over temperature protection Fold down electrical control panel for easy maintenance Conveyor speed up to 67 feet per minute Heavy duty casters for transportation within plant Leveling legs provide sturdy base once in place Custom two part epoxy finish resists scratching Available in 220v – single or 3-phase Easy to use design requires minimal training, maintenance, and trouble free operation

...more

Shrink Wrap Films

PolyVinylChloride (PVC), PolyPropylene (BOPP) Low Density Polyethylene (LDPE ) The most commonly used shrink wrap is polyolefin. It is available in a variety of thicknesses, clarities, strengths and shrink ratios. The two primary films can be either crosslinked, or non crosslinked. Other shrink films include PVC, Polyethylene, Polypropylene, and several other compositions. Coextrusions and laminations are available for specific mechanical and barrier properties for shrink wrapping food. For example, five layers might be configuration as EP/EVA/copolyester/EVA/EP, where EP is ethylene-propylene and EVA is ethylene-vinyl acetate copolymer.

...more

Semi Automatic Shrink Wrap Machine

Semi Automatic Shrink Wrap Machine is more suitable to any form or type or design like box, bottles irrespective of shape. The semi automatic shrink wrap machine is more suitable for low speed production lines for both pharma and food industries and for other respective applications. The required collation and matrix forming will take place on collation plate which placed near to web sealer section. Once the required matrix formation gets completed ,manually push the matrix pusher on to welding area and take back the pusher . The delay signal gets activated by sensor and gives the signal to seal bar accordingly seal bar comes down and sealing and cutting operation gets completed After the sealing and cutting operation seal bar ascends, the manual pusher advances to transfer the collation into the welding position, at the same time displacing the previously wrapped collation onto continuously moving shrink tunnel conveyor. The wrapped collation soon enters the shrink tunnel chamber where recirclulated hot air causes the wrap to shrink and tightly conform to the contours of the contents. Once the pack is out of the hot chamber , forced air cooling is used to tighten sleeve wrap to achieve a strong, secure pack ready for stacking on pallet or a placing on a shipping carton.

...more

ldpe shrink wrap

Low Density Polyethylene (LDPE) currently dominates the collation films market segment with its good shrink behavior, especially in trans-direction (TD). However LDPE exhibits significant benefits . When our LDPE is blended with other Linear Low Density Polyethylene and High Density Polyethylene, it offers the highest performance on all key shrink parameters for collation shrink films. We are a well known manufacturer of LDPE Shrink wrap Films. LDPE (Low Density Polyethylene) Shrink Film is used for wrapping products like pharmaceuticals, cosmetics, glass bottles, cans, tins, beverages, tetra packs, cartons, consumer durables, stationery and all sorts of industrial products. LDPE Shrink Film is mainly used for unitizing and bundling multiple units of products for better handling and ease of distribution. Our LDPE Shrink Film provides extra protection, and makes the pack pilfer proof and reduces theft in transit. Our LDPE Shrink Film is also used on automatic shrink wrapping machines. We offer customized shrink films to cater variety of customer varying on their requirements.

...more

automatic shrink wrapping machines

The fully automatic shrink-wrap machine is such a machine using such shrink-wrapping machine the products can be collect and can make proper matrix for the products manufactured in Pharma , non-pharma such as food and FMCG companies. The Fully automatic shrink wrapping machines are more applicable and are suitable for the high speed production filling and packing lines to complete the packing activities in short period. As the welding bar ascends, the pusher advances to transfer the new collation into the welding position, at the same time displacing the previously wrapped collation onto continuously moving shrink tunnel conveyor.

...moreBe first to Rate

Rate ThisOpening Hours