Rapid Mixer Granulator

Get Price Quote

100 Piece (MOQ)

Rapid Mixer Granulator

Get Price Quote

1 Piece (MOQ)

Your search for the best rapid Mixer granulator suppliers is over with us. Our company Sparklex Machines Private Limited is the right choice. Rapid Mixer Granulator is designed to achieve in reducing processing time, more homogenous mixing of consistent granules at lower operating cost and above all maintaining improved hygienic compliance to the cGMP norm. Application: Mixing different ingredients Usage: Pharmaceutical, Nutritional, Biotech, Health Supplement, Food Product & Cosmetics Salient Features: Better Productivity & short mixing granulation time. Uniform mixing & granulation. Bowl shape design to have no dead spaces. Less handling, more hygienic. Meets cGMP & FDA Norms. The contact parts are SS 316/316L. Working Principle Rapid Mixer Granulator working principles are based on two decisive factors essential for the intimate mixing system. Spinning close to the bottom of the mixing bowl. The impeller sets the entire mixture in whirling rising tumbling motion ensuring a quick & even distribution of all dry components. This leads to an even distribution of all dry components & an even wetting of every granule. Check our products and order now.

Best Deals from Granulator

Zinc granular, GR 99%+

Get Price Quote

Zinc is a chemical element with the symbol Zn and atomic number 30. It is the first element in group 12 of the periodic table.

Stainless Steel Rapid Mixer Granulator

400,000 - 2,500,000 Per Piece

1 Piece (MOQ)

Rapid Mixer Granulator

Get Price Quote

As a known name, we ensure safe and timely delivery of the orders at any desired Thane(India). We are offering our entire range of products in excellent quality packaging to guarantee zero damage during transit. For this, we have hired only professional packing personnel to ensure the same.Salient Features : Models available from 5 L to 800 L working capacity. Fully automatic operation based on PLC control. (OPTIONAL) Better productivity & lesser mixing time. Contact parts are SS 316 / 316L. Uniform mixing & granulation. Less handling. More hygienic.

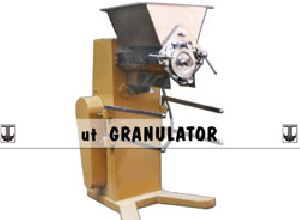

Oscillating Granulator

150,000 - 500,000 Per Piece

1 Pieces (MOQ)

Rapid Mixer Granulator

Get Price Quote

We store the entire range of products in our capacious warehouse and we follow the automated warehousing system for the safe assembling as well as storage of the products. Our organization is graded among receptive and responsible Suppliers of Rapid Mixer Granulator, involved in providing to purchasers across diverse marketplaces. Features : Highly functional Operational fluency Sturdiness Specification : 25 liters, 50 liters, and 100 liters are provided with working platform and railings. As for other models platform and railings are made to suit floor plan at the user's end. Material handling reduced considerably making the process more hygienic. Only one operator required. Uniformity of granule size almost achieved. Ideally preferred for light formulations. Steam jacketed drying also available on request to meet specific process requirements. Low headroom making it very user-friendly equipment

Rapid Mixer Granulator

Get Price Quote

High Shear Mixer Granulator has been developed for mixing of ingredients as well as wet granulation. The multi-bladed impeller is fitted close to the base of the mixing bowl whereas the chopper is mounted on the wall of the mixing bowl. Both the impeller & the chopper have dual-speed options for gently distributing the binder solution as it is added and creating the vortex of the material being mixed. STANDARD PROCESSING DURATION: Dry Mixing approx. 3 – 5 Mins. Wet Mixing approx. 5 – 10 Mins. Wet Granulation approx. 5 – 10 Mins. Discharge approx. 1 – 1.5 Mins. Granulator is designed to achieve all the requirements of cGMP – Current Good Manufacturing Practices. The components can be easily dismantled, cleaned thoroughly and assembled in quick time. The shaft seals are very effective to check any leakages and cross contamination due to adherents. The bowl and all the components are of highly polished Stainless Steel with smooth contours and is crevice free. SALIENT FEATURES: Uniform distribution of all formulation ingredients. Short mixing and granulation time. Useful working capacity of upto 80% to 40% of bowl volume. Uniform granules by gentle processing. Wide range of applications. Easy scale up & Scale down between machine sizes. Bowl shape designed to have no dead spaces. All Saizoner process advantages of Granules Manufacturing. Drying under vacuum, at lower temperature with solvent recovery system. CIP system included enhancing cGMP, reducing product change over time.

Rapid Mixer Granulator

Get Price Quote

Brilliant Pharma Mixer is designed to meet special needs of tablet manufacturing technology. This is achieved by reducing processing time, more homogenous mixing, uniformity of Granule size and above all maintaining improved hygienic standards within the highest GMP norms

Rapid Mixer Granulator

Get Price Quote

Our Rapid Mixer Granulator is designed to achieve excellent mixing and consistent granules at lower operating cost along with higher productivity. The High Speed Mixer Granulator manufactured bys us has better mixing and closed control of granule size leading to faster tableting speeds with improved quality and least rejections. The perfection and easy operations of our products makes us the apex Industrial Rapid Mixer Granulator Manufacturer.Salient Features All contact parts are made out of S.S.316 as per GMP standard. Three blades Design for efficient mixing with a high speed granulator (chopper) is inserted horizontally through the wall of the bowl to assist blending of powder and to break the product to granules of required size. Platform is SS 304 which is dimpled for anti slip property entire stand is also cladded by SS 304 to make the machine total GMP. Chopper housing is entirely made from SS 304 having air purging and special seals. Discharge piston has face sealing matching the vessel interior. Two stage housing for main impeller eliminating totally any chance of cross contamination between bearing grease and product mix. Lifter can be fitted for loading of material. 5 microns filter assembly will be provided on top lid in stainless steel housing to eliminate dusting in granulation area. All Electrial & pneumatic parts are pre wired to simplify installation. Discharge can be provided on either side to suit clients requirement. Optional Accessories / Attachments. PLC with touch screen MMI with printing facility. VFD can be provided to change the RPM of impeller . WIP system. Flame proof Construction. Online co-mill arrangement. Steam jacketed Bowl. Blinder charging with dosing pump. Emergency push button station at discharge. Granulation end point detection. SafetyProximity switches are provided on main lid and discharge valve interlocked with central control system for safe operation.Equipment air and purging air control via differential air switches.Location of the FBD bowl at discharges i.e. FBD bowl touch the proximity sensor then discharge will open.DocumentationElicon Rapid Mixer Granulator comes along with all documentation like DQ, IQ,OQ and FAT as a part of standard procedure. Dry mixing - 3 to 5 minutes Wet mixing - 5 to 10 minutes Wet granulation - 5 to 10 minutes Discharge - 1 to 1.5 minutes

Oscillating Granulator

Get Price Quote

High Speed Uniform Granulation ProcessApplication & Process :Oscillating granulator is used for gentle homogenization, size reduction, grading and sieving of dry, sensitive powders and granules in pharmaceutical, chemical and food industries.Oscillating Granulator has one rotor with five edges, which oscillate on horizontal axis at about 180 per minutes. There is one half round sieve mounted at the bottom of the rotor. Product is charged from the top through in feed hopper and material falls on the rotor lades. The particles are broken by a set of oscillating bars arranged in cylindrical form over a screen of suitable mesh. Due to the sharp edges on rotor, the downsizing of particle takes place and through sieve material gets pushed outward from the bottom opening.Features : Design is cGMP - Current Good Manufacturing Practices compliance All Product contact parts AISI 316 & non contact parts AISI 304. Uniformly granulation & fewer fines of wet material and dry materials. Rotor move oscillating motion with 180 stroke per minute. Easy to operate; move, clean, convenient, An Inline granulation & user friendly. Zero dusting & maintenance free.

high shear mixer granulator

Get Price Quote

Oscillating Granulator

Get Price Quote

Unique oscillatory rotor action ensures high outputs and a predictable product with minimum of fines. Adjustment, cleaning & operation are simple sturdy, durable, better productivity. Recommended Spares SS Trays Aluminum Trays SS Screens – available from 0.5 mm to 20 mm / Sandwitch type / With or without support V-belt

Rapid Mixer Granulator

Get Price Quote

POWERTECH Rapid Mixer Granulator was developed in close co-operation with pharmaceutical and chemical industry. With the help of RMG wet sifting is generally no longer necessary. After the mixing of the dry components, subsequent wet granulation occurs (without transfer of dry mixture) producing loose granules in RMG. RMG is specially designed to meet the GMP requirements of the pharmaceutical industry. WORKING RINCIPLE: • The RMG working principle is based on decisive factors essential for the mixing systems. • Spinning close to the bottom of the mixing bowl. • The impeller sets the entire mixture in a whirling-rising tumbling motion ensuring a quick and even distribution of all dry components which leads to an even distribution of all dry components which leads to an even wetting of every granule. The large lumps occurred during wet mixing are broken up, by the strategically located chopping tool rotating at 1440/2880 RPM. The mix can be discharged with the impeller running through the outlet located on the side of the mixing bowl flush to the bottom. Easy accessibility for cleaning is guaranteed by the low profile. The mixing tool is easily removed from the drive shaft providing an unobstructed mixing area which may be cleaned very easily

Rapid Mixer Granulator

500,000 Per Unit

1 Piece (MOQ)

Rapid Mixer Granulator

Get Price Quote

Rapid Mixer Granulator

Get Price Quote

Rapid mixer granulator is useful for Pharmaceutical, Chemical and Food Industries, for dry and wet granulation. Special Features of Vats & Vessels Ribbon Blender Specially designed chopper blades driven at high speed gives fast and even granulation. Pneumatically operated side Discharge Arrangement can be provided on either side to suit customer’s requirement. Constructed of SS 316, SS 304 and MS. Capacity – 10 Ltr. to 1000 Ltr. Working The basic equipment consists of machine base covered all around by SS flush type panels. The frame is provided with a SS staircase & railings. Over the frame there is RMG Bowl with pneumatically open able lid. It has two mixing blades. Material to be mixed is whirled and tumbled, close to the bottom of RMG bowl with the help of chopper blades. Chopper Tool located at the side prevents lump formation. RMG produces a highly efficient, fast & homogenous mixing.

Rapid Mixer Granulator

Get Price Quote

We make available a wide range of rapid mixer granulator. The rapid mixer granulator offered by us is characterized by the compact construction, modern design and all the user and maintenance friendly attributes. The ergonomics design in our rapid mixer granulator is essential for a wide range of industrial application. used for fast dry wet mixinghomogenizinghumidifying and granulating of the powder industries pharmaceuticalchemicalcosmeticfoodplastic salient features high speed mixing & granulatingdesign is cgmp – current good manufacturing practices complianceall contact parts aisi 316 & non contact parts aisi 304automatic cyclic on time based maxing and granulating processhigh mixing precision, short batch time, problem free cleaning and residue free dischargedual speed mixing impeller for mixing and intensify chopper for granulatingthe complete process under limit switch, enclosed drive, overload protection, air pressure switch and emergency stop for safetyoption for plc controls with hmi touch screen, flame proof motor, binder spraying system, online milling, loading system and jacketing for heatingthe rmg performs dry mixing & wet granulating by basic design of the special four arm of the mixing impellersequences of the mixing process in the cylindrical mixing drum with rounded connection to the base plate, achieve another special effectthe mixing process runs without varying pressure zone in the volume of mixing productseparately driven multiple choppers can effectively intensify the mixing result in particular when liquid or paste components are addedduring humidifying and granulating process of the products the chopper controls and regulates the granular spectrum and structure of the granules according to the product, chopper shape and timethe rmg system requires only small quantities of granulating liquid or pastes to obtain the required granulate structure. This reduces the amount of drying energy required

Oscillating Granulator

Get Price Quote

We offer high quality range of oscillating granulator. In tablet making practice the granulation process plays an important part because the quality of the final tablets will be determined by the virtue of the granules used for its compression. These are extensively used wherever tablets or pellets are produced. These are used for both wet and dry granulation process. Quality of granules are better compared to other processing machineries like multi mill, comminuting mill etc. the machine is complete in all respects and fitted with 1 h.p. T.e.f.c. Motor. Standard reduction box and a starter. The body of the machine is l shaped fabricated structure and fitted with castor wheels for ease and mobility. Model 8 & 12 are vertical models whereas 15 model is horizontal model. The difference between vertical model and horizontal model is that in vertical model the oscillation is done by a gear mechanism and a vertical shaft is suspended from the top and a propeller type grinder blade moves in oscillating motion and material is pushed through the mesh to get the output of desired mesh size. features : sturdy durable better productivity easy to clean screen holding simpler with tensioning device.

Rapid Mixer Granulator

Get Price Quote

We, as a reputed Rapid Mixer Granulator Manufacturer, ensure excellent mixing and closed control of granules. These Rapid Mixer Granulators are known for offering high performance with low power consumption. Our Rapid Mixer Granulator is highly appreciated for its fast tabulating speed and least rejections. Rapid Mixer Granulators manufactured by us offer maximum CIP effectiveness and are available in wide range of capacities. Operation Rapid Mixer Granulator is designed to achieve excellent mixing and consistent granules at lower operating cost along with higher productivityBetter mixing and closed control of granule size leads to faster tabulating speeds with improved quality and least rejections Features Homogeneous binder distributionMaximum CIP effectivenessAll internal contact parts are polished to the mirror finishAll moving part of the machine are totally enclosed to eliminate accidentAll contact parts are made out of SS304. SS316 provided on demand at extra costShort batch time and reduced cleaning timeAir purge sealing system for main stirrer shaft and granulator shaftPLC based operating panel for precise control of process & automationA high-speed granulator is inserted horizontally through wall of bowl to assist blending of powder and to break the product to the granules of required sizeThe seal housing and drive shaft may be flushed with cleaning water, which is then drained away from the machine through built in drain tubesGranulator motor is provided with a removable Stainless Steel shroud which covers the motor and simplify cleaningThe machine cannot be started unless and until the mixer cover is properly closedFlush wall type discharge valve eliminates pockets at the port of discharge valve Availability Model available from 15 Liters to 600 Liters capacity gross capacity Optional Facility Available On Demand At Extra Cost Flameproof motors with flameproof operating panelWater jacketed product container with temperature sensor for productPneumatic system for opening and closing of the top lidA.C. frequency drive for speed variation of Main Motor & Granulator MotorDischarge provided on left or right side ( as per granulation room layout)to suit client's requirementIPC lifter or vacuum loading system for dust free material chargingGeneral Structure made out of completely from SS304 material instead of SS304 cladding on mild steel structureTri-clover ended connection on top cover for fitting of spray ball for inbuilt cleaningTri-clover ended connection on top cover for fitting of spray nozzle for spray of binders

High Speed Granulator

Get Price Quote

Granulation is a Mechanical process in which the product is pressed through a sieve with a specially shaped rotor-arm to obtain a desired particle size. This process results in a narrow distribution spectrum as only the product having the right shape, size and position, is broken and passed through the sieve. The oscillating motion of the rotor improves the granulating process. This sensitive handling of the product emulates the hand operation of an experienced pharmacist.

Multi Mill Granulator

Get Price Quote

The company is enlisted among the topmost Manufacturers, Exporters and Suppliers of Multi Mill Granulator in India. Our Granulator is available in different capacities to suit the different demands of buyers. Multi Mill Granulator that we provide is easy to break down and clean. It comes with dry and heat mechanical seal. Our Granulator is manufactured using high-grade raw materials to ensure supreme quality. Buyers can acquire Multi Mill Granulator from us at affordable price. Highlights : MOC : SS 304, SS 316,SS 316L Capacity : 1HP,3HP 5HP MODEL Beaters & Scrapper blades in SS Easily Dismantled and Cleaned VFD with Direct Drive Can Be Provided Single Drive with Dry / Heat Mechanical Seal

Rapid Mixer Granulator

Get Price Quote

Rapid Mixer Granulator was developed in close co-operation with pharmaceutical and chemical industry. With the help of RMG wet sifting is generally no longer necessary. After the mixing of the dry components, subsequent wet granulation occurs (without transfer of dry mixture) producing loose granules in RMG. RMG is specially designed to meet the GMP requirements of the pharmaceutical industry.

high shear mixer granulator

Get Price Quote

The SAAN granulators are extremely quick and efficient mixers of powder. Dry mixing is the first step of the process. After the products are mixed by means of our unique, bottom drive rotating tool (impeller), a binder is introduced into the product. The binder can be added in dry form or sprayed in as part of a binding solution. Spraying occurs though one or more spray nozzles and is quickly dispersed into the product by mixing action of the main mixing tool (impeller) and the chopper blade. The chopper blade, which is positioned in the highest circumferential area of the product acids in de-lumping. Once all of the solution is in the granulator, the impeller and chopper work together during the wet massing phase to produce dense granules of uniform particle size. The system quickly forms granules that are then easily and automatically discharged from a port in the bowl’s side. The wet granules are generally milled as they come out of the granulator. The granules then need to be dried in SAAN Fluid Bed Dryer machine. Back

Oscillating Granulator

Get Price Quote

Oscillating Granulator, Conta Blender, Plough Shear Mixer, bin blender

Carbon

Get Price Quote

Carbon, Forging Steel, EN Series Round Bars, Alloys, Square Bars

Granulator

Get Price Quote

Granulator, Jaw crusher, jar mill, Agitator, concentrating table

Rapid Mixer Granulator

Get Price Quote

Rapid Mixer Granulator, Capsule Polishing Cum Inspection Machine

Rapid Mixer Granulator

Get Price Quote

Rapid Mixer Granulator, Pneumatic Speed Shear Emulsifier, fluidized bed dryer

Granulation with Oscillatory Granulator

Get Price Quote

Granulation with Oscillatory Granulator, Bag Dump Station