Shrink Tunnel

30,000 Per Piece

1 Piece(s) (MOQ)

Shrink Tunnel Machine

Get Price Quote

We are engaged in offering a comprehensive range of Shrink Tunnel that offers superior performance, easy operation and precise functioning to our clients

Best Deals from Heat Shrink Tunnel Machine

Shrink Sleeving / Labelling Tunnels.

Get Price Quote

The tread for better & attractive packaging is continously demanded for, as it plays an important role with respect to shelf display of the product. Previously all containers / bottles containing Talcom Powder, Deodrents, Lotions & all other cosmetic products, the containers either used to be screen printed which is not very attractive & prone to scratches or paper labeled in which case there is a possibility of the label getting peeled . Therefore today most containers / bottles containing cosmetic products are PVC Label Shrink Sleeved. In some cases where the empty bottles are required to first label sleeved, we have designed a special conveyor with mandrel attachments, to label sleeve the bottles inverted (upside down) thus ensuring that they remain stable. In case of Pesticides, the bottles are full sleeved in a Flame Proof Tunnel as the product being alcohol based is inflameable. In this system the heaters are housed in flame proof junction boxes outside the shrink zone & most electrical components like motors, thermostats, switches etc are also flame proof.

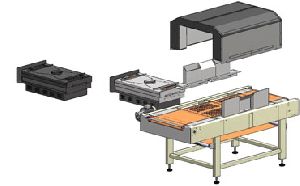

Shrink Wrap Tunnels

Get Price Quote

The FOREVIEW Shrink wrap tunnels are designed considering Pharma and food industries so considering food grade and Pharma acceptance requirements. STANDARD SPECIFICATIONS AND FEATURES All-welded main frame from 12 gauge steel Live roller or stainless steel mesh belt conveyors; optional “dead” roller conveyor for polyethylene Sealed bearings (not bushings) on drive and idler shafts Adjustable digital solid state temperature control for a variety of films Four-directional air flow provides positive shrinking Variable air flow and air velocity for a variety of products and applications Bottom air flow adjustment – full on, ½ on, full off Large ducting creates more air volume inside tunnel Optional side plates (top and sides) for air flow patterning and quick changeover for different products Plugs available for patterned air flow Delayed cool down and over temperature protection Fold down electrical control panel for easy maintenance Conveyor speed up to 67 feet per minute Heavy duty casters for transportation within plant Leveling legs provide sturdy base once in place Custom two part epoxy finish resists scratching Available in 220v – single or 3-phase Easy to use design requires minimal training, maintenance, and trouble free operation

Heat Shrink Tunnel

Get Price Quote

Easy to operate. • Virtually low maintenance. • Low Power Consumption. • Electronic Digital Temperature Controller. • High efficiency heaters. • Suitable for PVC & LDPE films. • Separate Key System Door. • Fixed / Variable Conveyer Speed. Technical Specification of the Equipments

Automations Silver Heat Shrink Tunnel,

Get Price Quote

Shrink Tunnel Machine

Get Price Quote

Shrink Tunnel Machine, steam machine, snap on capper, Shrink Tunnel

Shrink Tunnel

Get Price Quote

Shrink Tunnel

Shrink Tunnel

Get Price Quote

Shrink Tunnel, packaging machines and shrink tunnel, pharmaceutical furniture

Shrink Tunnel Machines

Get Price Quote

Shrink Tunnel Machines, coding machine

Shrink Tunnel

Get Price Quote

Shrink Tunnel, jacketed storage tank

shrink packing tunnels

Get Price Quote

shrink packing tunnels, Automatic Weighing Machine