Salt Bath Furnace

Get Price Quote

Lead Bath & salt bath Furnaces For quenching of carbon steel strips For bluing of carbon steel strips

Heat Treatment Courses

Get Price Quote

This steel is mainly used in Auto industries where light weight components with very good tensile properties are required. Most of conventional steels after alloying easily achieve mechanical properties as desired. But Ductility drops when Tensile strength is increased . It is difficult to draw components from this steel. Hence as an alternate to high strength materials Dual phase steels are developed. This course is on how to manufacture a steel with similar tensile properties and at the same time possessing very good ductility. This course is on how to manufacture this steel and what are the tensile and metallurgical properties.Next step Register for the course by filling up following details. (as per attachment). Attend course and get certificate Course Fee Per person₹2000 / US $ 26

Best Deals from Heating Furnace

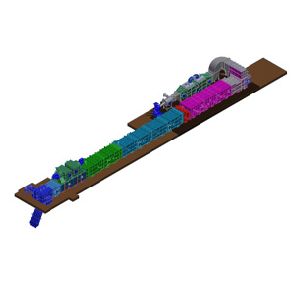

Pusher Type Reheating Furnace

Get Price Quote

Our customers can choose from a wide range of Pusher type Reheating Furnaces that we offer. The Pusher Type Reheating Furnaces are designed and manufactured as per the specifications of the customers. Our Pusher Type Reheating Furnace is capable of meeting every demand of the customers related to any engineering industry. These furnaces are known for delivering outstanding performance and are reliable in operation. Attributes : Optimal performanceHigh efficiencyEasy to operateMinimal maintenance

Continuous Mesh Belt Furnace

Get Price Quote

glass melting furnace

Get Price Quote

Initially, the working field had diversified in different industry for undertaking refractory lining job. But later on , we got opportunities to work with many reputed consultant, designers and timely as per requirements , the scope of our activites had been expanded by development of our infrastructure in all aspects.

Annealing Furnace

Get Price Quote

Continuous Type Sintering Furnace

Get Price Quote

Product Description Agnee Engineering & manufactures Continuous Sintering Furnace (these can be continuous pusher furnaces or continuous mesh belt furnaces based on temperature) or Batch Sintering Furnaces for powder metallurgical and ceramic applications. These furnaces work under controlled atmospheres, usually hydrogen or cracked ammonia based, and have a robust leak tight construction. Continuous Sintering Furnaces can be completely automated. Standard operating temperatures are upto 1750°C. Please get in touch for higher requirements. Product Specification Minimum Order Quantity : 1 Piece(s)

Salt Bath Furnace

Get Price Quote

Salt bath furnace Indirect Heating Is Design For Liquid Fuel & Direct Heating Is Design In Electrical With Induction Rod.

heat treatment furnace

Get Price Quote

We manufacture optimum quality heat treatment furnaces, which are fabricated using finest quality raw materials. Our furnaces enable various heat treating applications with solid state temperature controls along with energy saving insulation. Our standard 1000° c and 1200° c furnaces are cost effective and high performance furnaces ideally suited for general purpose heat treating of tools, dies & other parts.

Controlled Atmosphere Braze Furnace

Get Price Quote

We offer controlled atmosphere braze furnace. Seco warwick make controlled atmosphere aluminum brazing, otherwise known as cab brazing, is the preferred process for manufacturing aluminum heat exchangers. seco warwick cab brazing systems are used in automotive and hvacr manufacturing for brazing radiators,condensers,oil coolers,evaporators,heaters and charge air coolers. we also offer cuprobraze copper-brass brazing technology, a process for heavy duty truck and off-road radiators and charge air coolers. since entering the cab market in 1983,seco warwick has introduced many product innovations including improved muffle designs,convection heating technology,atmosphere controls,accubraze pcplc controls,heating control systems,energy and space saving designs. aluminum brazing involves joining of components with a braze alloy ( cladding) whose melting point is appreciably lower than that of the parent material( base alloy). The assembly is heated to a temperature where the cladding material melts and the parent material does not. Upon cooling , the cladding forms a metallurgical bond between the joining surfaces of the component. the brazing process occurs in a furnace under the following parameters. 1.operating temperature 580 degrees c to 620 degrees c. 2.job temperature uniformity of +- 3 degrees c, oxygen free. 3.nitrogen atmosphere of (-) 4 degrees c and 100 ppm of o2 content. the main constituents of a continuous controlled atmosphere brazing furnace are 1.thermal de-greaser oven and cooling section 2.wet fluxing section 3.dry off oven 4.inlet purge section 5.pre-heat furnace 6.braze furnace 7.inspection chamber 8.atmosphere cooling section 9.outlet purge section 10.cooling sections 11.scrubber unit 12.control and plc panel etc.

Furnace Recuperator

Get Price Quote

mini blast furnace

Get Price Quote

Mini Blast Furnace (MBF): A Blast furnace of working volume 350 M3 designed by MECON Ltd. to produce 3,00,000 MT annum of basic grade hot metal has been installed and sucessfully commissioned. The hot metal is mainly used in the steel melting shop as a raw material and surplus hot metal poured in pig casting machine. The Pig casting machine is designed by KBS Paramount & capacity 800 Tonnes per day (TPD). The Blast furnace gas is used for stoves heating, heating of preheating furnace of bar and section mill, heating of boiler ,sinter plant. Slag which is a byproduct is mainly sold to cement plants.

Gas Tilt Controlled Atmosphere Furnaces

Get Price Quote

Galvanising Furnace

Get Price Quote

Salient Features Horizontal, ‘L’ Shape, & Vertical Design Non-Ox Type Process Non-Ox Furnace suitable for processing very thin gauges (0.15mm) Non-Water Cooled Roll Design Gas Fired & Electrical Radiant Tube Section Horizontal & Vertical Soaking as per the requirement of product Jet Cooler with electric Heaters for processing thin strips Furnace Bridle to maintain differential Tension Furnaces suitable for GI & GL production Special design of Calm Zone for arresting of Zinc Fumes in case of GL production Heated Down Chute for GL Production Flexibility in operation Strip Temperature Control and Zone Temperature Control Protective Atmosphere Control

galvanizing furnace

Get Price Quote

Industrial Galvanize Furnace is a furnace in which the subject material is isolated from the fuel and all of the products of combustion including gases and flying ash. recognized for long working life, our range is used in foundry and mini steel plants for various processes such as such as calculation, ageing, homogenizing, baking, sinleing and heat treatment.

galvanizing furnace

Get Price Quote

galvanizing furnace

Vacuum Heat Treatment Furnace

Get Price Quote

Vacuum Heat Treatment Furnace, Heat Treatment, Vacuum Metallizer

Crucible Furnace

Get Price Quote

We are offering crucible furnace etc. We are offering cement testing machine “tempo” make crucible furnace are designed & manufactured to comply requirements of laboratory & industrial applications. It is used for engineering tests of soils and aggregates, cement testing, ashing organic and inorganic samples, gravimetric analysis, ignition tests, etc. technical data max. Temp. Range : 930 1150°c supply : 230v, ac standard model inner made of ceramic pot & outer made from thick gauge mild steel (crca) sheet.

Pusher type Reheating furnaces

Get Price Quote

We are leading supplier of huge range of pusher type reheating furnaces.

Salt Bath Furnace

Get Price Quote

Salt Bath Furnace, Electric Water Heaters, Tilting Furnace