Industrial Furnace

Get Price Quote

Seeking a trusted Industrial Furnace supplier? Our organization is the best one and able to fulfill wholesale orders. Our well-structured warehouse is properly managed and maintained by our adroit professionals. Moreover, we keep on updating the unit for better safety. Steps involved in Conversion : Calculation of load requirement Sizing of Producer gas plant & its accessories to match exiting load requirement Design, fabricate, supply, erection & commission of Producer gas plant Design, fabricate, supply of single dual fired burner Removal of exiting burner assembly installing new single dual fuel burner assembly Operation, general maintenance & supply of fuel on chargeable basis

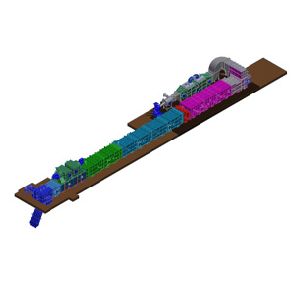

Reheating Furnace

Get Price Quote

Our products are formed under the supervisor of experienced quality control managers utilizing only premium materials and the latest technologies. Located in Hyderabad(India), our company is involved in making available wide array of products that are in conformance with the industry standards.

Best Deals from Industrial Furnace

Gas Burner

75,000 Per Piece

Continuous Rotary Hearth Furnace

Get Price Quote

Furnace Ejector

Get Price Quote

Hot Blast Valve

Get Price Quote

Fabricated construction• Minimizing of heat loss of process temperature due to optimized thermal insulation of body, bonnet (uncooled) and paddle.• Thermal insulation comprising various Materials.• Optimization of thermal insulation, allowing for water cooling of only the body seats and paddle• Special design cooling water passages provide optimum flow• Sealing in both directions, floating paddle Design• Valve actuation in accordance with customer’s requirements • Pressure rating up to PN 6 (Max)• Service temperatures up to 1650 °C (3000 °F)• Nominal diameters up to 3500 mm (140 inch)• Other sizes or operating conditions on request This design guarantees:• Considerable reduction of required quantity of cooling water (also during emergency operation)• Extended operational life of the valve due to increased thermal insulation, reducing thermal stresses to the valve.• No deposits in cooling water channels• Due to optimized design valve is easily Maintained• Reduced operating costs due to: - decreased heat loss of process temperature - reduction in amount of cooling water required.

Muffle Furnace

Get Price Quote

We are offering muffle furnace is light weight with ceramic fibrewool insulation and fast heating equipment. This muffle furnace is mostly used for ashing, fashions, lgniting and heat treating of small parts in chemical, industrial field and colleges. specifications : outside body made up of heavy gauge m.s. With powder coated and inner muffle with high temp. Insulating material. maximum working temperature is 9300c/11300c. temp. Controlled by digital temperature controller cum indicator. heaters are made of nichrome wire, uniformly wound on the muffle. control panel fitted on bottom of the units with indicating lamps, switches, digital controller and sensor. a special solid state silver fuse is used for protection to heater in case of overheating. working on 230 volts, single phase, 50 hz. size in inches rating 9”x4”x4” 1.6 kw 10”x5”x5” 2.0 kw 12”x6”x6” 3.5 kw 18”x9”x9” 6.0 kw

Muffle Furnace

Get Price Quote

A furnace in which the subject material is isolated from the fuel and all of the products of combustion, including gases and flying ash. Salient Features : Triple walled unit for better thermal safety Temperature range upto: 900/ 1000 / 1100 / 1200 / 1300 / 1450 Ceramic fibre insulation PID temperature indicator cum controller K type / B type thermocouple Heating element : Kanthal A1 grade wire Size: 4 x 4 x 9 (A) inches, 6 x 6 x 12 (B) inches, 8 x 8 x 18 (C) inches Specifications : Temperature Range: Upto 1200oC Working Temperature: 1150oC Temperature Resolution: 1C Control Accuracy:+1% OF FSD Dimensions : 9″x4″x4″ 10″x5″x5″ 12″x6″x6″ 18″x9″x9″ Optional : Electronic Digital Timer Range 0 to 999 minutes Single channel Data Logger with printing arrangement RS 485 for PC communication with Software Meta-Logger

kiln burner

Get Price Quote

Supplier & Manufacturer of Rotary Furnace Burners & Rotary Furnace Burner. Our product range also comprises of Burner Spare Part, ECO Flame Gas Burner and ECO Flame Light Oil Burner. We are also offering Ceramic kiln burner with combustion systems.

Galvanising Furnace

Get Price Quote

Salient Features Horizontal, ‘L’ Shape, & Vertical Design Non-Ox Type Process Non-Ox Furnace suitable for processing very thin gauges (0.15mm) Non-Water Cooled Roll Design Gas Fired & Electrical Radiant Tube Section Horizontal & Vertical Soaking as per the requirement of product Jet Cooler with electric Heaters for processing thin strips Furnace Bridle to maintain differential Tension Furnaces suitable for GI & GL production Special design of Calm Zone for arresting of Zinc Fumes in case of GL production Heated Down Chute for GL Production Flexibility in operation Strip Temperature Control and Zone Temperature Control Protective Atmosphere Control

Self Recuperative Radiant Tube Burner

Get Price Quote

Features 15 to 250 kw turndown range 10:1 fuel: natural gaspropanelpg preheated air upto 700ºc electrodes can be easily replaced flame tube:silicon carbide applications heat treatment furnace tunnel furnace reheating furnace strip line ceramic furnace.

galvanizing furnace

Get Price Quote

galvanizing furnace

BLAST FURNACE-COKE OVEN VALVES

Get Price Quote

BLAST FURNACE-COKE OVEN VALVES, steel plant valves, OXYGEN-NITROGEN VALVES

galvanizing equipment

Get Price Quote

galvanizing equipment, Pickling Tank, Slitting Machine

Shaker Hearth Furnaces

Get Price Quote

Bag Filter Lime Slurry Tank, Heavy Mechanical & Civil Fabrication Works

Hot Blast Valve

Get Price Quote

Hot Blast Valve

Stainless Steel Wire Annealing Furnace

Get Price Quote

Stainless Steel Wire Annealing Furnace, Solution Annealing Furnace

Muffle Furnace

Get Price Quote

Smoke Density Tester, Constant Temperature Bath

galvanizing furnace

Get Price Quote

galvanizing furnace, Ovens Incineration System, continuous pickling line