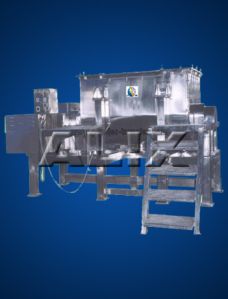

Ribbon Mixer

Get Price Quote

Ribbon Mixer is mixer for Intensive Mixing of wet and dry material used in the Food, Chemical, Pharmaceutical, Paint, Cement, Refractory, Adhesives, Building materials, Dyestuff and Allied Industry. It is a LOW SHEAR mixer and mostly used for SOLID / SOLID Mixing. Solid / Liquid mixing can also be achieved when high shearing force is not desired. It occupies less head room space for large volume mixing unlike Double Cone, 'V' Blenders etc.Ribbon Blender comprises of a U-shaped horizontal trough and a specially designed Double Helical Ribbon Agitator rotating within. The ribbons rotate at approximately 70 – 100 meters per minute and move the material both radially and laterally to ensure thorough blends in short cycle times. Salient Features : Available in two shapes - U & W. U-for Low to Medium volume Capacity (single shaft). W-for Large to Mega volume Capacity (double shaft). All contact parts in stainless steel 316. Bearing mounted on lanterns out of mixing zone to avoid Cross contamination. Reduced Material handling due to side discharge facility of processed materials. Meets all cGMP standards. Stuffing boxes with easily disassembled housings. PTFE gland packing provided. Air purge on the side entry seals for better cross contamination control. Continuous Ribbon design for complete discharge of the finished product. Belt driven power transmission for quieter environment and less maintenance. Paddle style agitator instead of Ribbon for Blending fragile materials. Capacity available 130 L to 10000L. (Larger volumes upto 20,000 L can also be provided)

Drum Blender

Get Price Quote

The field of usefulness of Double cone for rapid, homogeneous blending and efficient drying is practically unlimited. As blender gently revolves a folding, spreading action ensures thorough uniform mixing, irrespective of material proportions or number of materials charged. Addition of liquid line & atomizer which remains stationary can give controlled uniform addition of liquid to dry powder. To avoid formation of lumps or re aggregation, internal lump breaker of different types can also be provided.

Best Deals from Industrial Mixers

Laboratory High Speed Stirrers

Get Price Quote

Designed to meet requirements of laboratories demanding wide flexibility of stirring operations, these stirrers are available in various models. Choice of model will be dependant on the batch size /volume to be stirred. Salient Features > Multipurpose stirrers for general purpose & PUF stirring.> Pulley driven / Heavy duty stirrers for polit plant, bench scale process & small batch production.> Models also available with digital speed indicator for speed indication & process validation. PMDC Lab stirrers PMDC Stirrers are specially designed for routine laboratory work, research and development. QA analsis and sample preparations. Stirrers have uniform speed control with digital RMP indicator which goves speed read outs, valuable for applications where process validation and reproducibility required. RQ-121/D. RQ-123/D and RQ-129/D models use direct drive motors & are ideal for day to day laboratoty use with aqueous & low viscosity liquids such as light oils. Sailent Features : > PMDC motor for powerful stirring.> Reliable performance even in continuous use.> Stepless eletronic speed regulator with digital display.> Hollow shaft in geared models permotting height adjustment.> Chuck for easy interchangeability of shaft.> Strirring shaft SS346; Retort Rods SS304.

bin blender

Get Price Quote

Description One of the perfect example of batch blending where sized granules collected in a container, docked to the blender arm, clamped, lifted from a single end and tumbled for the pre-validated time. The low shear blending action prevents excessive fines or changes to particle shape or size. Fast loading, complete discharge, short cycle time, low powder requirement and minimum maintenance are some of the features. Conta blending improves efficiency compared to conventional blenders because of mixing in the diagonal and eccentric planes. Enormous flexibility – different capacity of bins (for e.g. 200 Ltrs., 400 Ltrs., 600 Ltrs.) can be docked in the single fork of the same conta blender. Also various shapes of bin can be accommodated. (For eg: You could dock an Octagonal / V Shaped Blender body in the same arm of the Conta bin) The arm of the bin blender does not have any nylon rollers or pins. It is a simple sliding system with a wedge arrangement for resting.

Used SS Mixing Vessel

100,000 Per Piece

1 Piece Piece(s) (MOQ)

Features : Support Horizontal Orientation Vertical Orientation Level Indicator Equipped High Temperature Resistant

Plantery Mixing Machine

Get Price Quote

We are an eminent manufacturer and supplier of planetary Mixing Machine manufactured using high quality raw materials. Cake Mixing Machine is used for mixing cream, pedi at bakeries and hotels. Our Cake Mixing Machine is known for low power consumption and unmatched performance among our clients. Known For High performance High durability Low power consumption Easy to clean Used For Mixing Pedi and Cream Specifications Available In four speeds Capacity : 20kg.dram size Propelled : Electrical Motor : 2 H.P. 1440 R.P.M

Mass Mixer

Get Price Quote

Mass Mixer has been well-designed to facilitate thorough mixing of dry / damp powders & Granules and is especially suitable for granulation. The powerful geared drive and sturdy mixing paddle makes Mass Mixer ideal for mixing with all kind of products in various applications Manual Tilting mechanism is provided for discharging. Lid is provided with product charging facility interlocked with main drive to ensure operator safety Optional : Available in STD/GMP models Construction SS 304 / 316 / 316L Motorized tilting for discharge Variable Speed drive optional Flame proof motor, push button station and limit switch. Control panel with timer. Applications : Widely Used in Pharmaceutical, Cosmetics, Chemical and food industries.