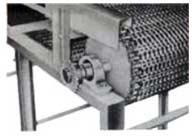

Wire Mesh Belt Conveyor

Our range of wire mesh belt conveyors is assembled with the use of stainless steel and pins which are in turn fitted in hollow pin chain. These conveyors are used to feed hot billet to forging press and also to feed forged job to trim press from forging press. Wire mesh conveyor belts are also used in worldwide industries such as heat treating, forging, foundry, food processing, snack food, baking, ceramics, glass, automotive etc. The Jaycon make Wire Mesh Belts are manufacturing with latest technology that provide high performance level. These can also be customized as per the specification detailed by our clients. We use high grade Material of Construction like carbon and stainless steel that is procured from the renowned vendors across the country. Feature of Wire Mesh Belt: • Linear Speed: UP TO 30 Mtr./Min. • Chain: 1” OR 1.5” pitch hollow pin chain in stainless steel • Can carry hot forgings up to 1000 Deg. C.

...more

Wire Belt

Our range of wire mesh belt conveyors is assembled with the use of stainless steel and pins which are in turn fitted in hollow pin chain. These conveyors are used to feed hot billet to forging press and also to feed forged job to trim press from forging press. Wire mesh conveyor belts are also used in worldwide industries such as heat treating, forging, foundry, food processing, snack food, baking, ceramics, glass, automotive etc.

...more

Triplex Roller Chain

The size of chain defined by pitch of chain (distance between center of consecutive rollers in chain), Diameter of Roller which is designed on basis of Diameter of Sprocket and no. of teethes on sprocket, thickness of plates calculated by load to be taken etc. Simplex Roller Chain, Duplex Roller Chain, Triplex Roller Chain are various designs of chain on the basis of load to be taken. Specific application and design of chain is categorized in varieties of chains like Conveyor Roller Chain, Transmission Roller Chain, Link Chain, Attachment Chain, Bucket Elevator Chain, Stainless Steel Chain etc. This entire are has basic design of Roller Chain and end application categorize it by specific name. This becomes easy for manufacturer and end user to define the requirements in machines or mechanism. Applications of Roller Chains: • Oilfield Industries • Escalators • Cement Industries • Heavy duty applications • Bakery Industries • Coal mining and quarrying • Theme Park • Palm Oil Mills • Steel Industries • Road pavers • Glass Industries • Sugar Industries • Agricultural Equipment • Water Industry / Sewage Treatment • Crawler cranes

...more

Transmission Chain

Roller Chain or Bush Roller Chains are the basic of chaining system. All major chains are made from this principle. The basic application of such chains is transmission of power from one sprocket or toothed wheel to other. Even no of sprockets can be used in series for transmission of power. So it is also well known as Transmission Chain or Transmission Roller Chains. Most common example of such chains is Bicycle or Motorcycle Chain etc.

...more

Standard Sprocket

A sprocket is a profiled wheel with teeth that meshes with a chain, track or other perforated or indented material. It is distinguished from a gear in that sprockets are never meshed together directly, and from a pulley by not usually having a flange at each side. In Transmission of power sprockets are equally important as Roller chain. It’s the media through which the chain can transmit the power. Sprockets wide range and designs as the chains are manufactured. Variety of sprockets manufactured like Sprockets for roller chains, Sprockets for accumulator chains, Plate sprockets, Chain couplings, Special sprockets, Chain Sprockets, Industrial Sprockets, Timing Sprockets and Miscellaneous other sprockets etc. The Jaycon make sprocket production uses state-of-the-art technology. We can supply sprockets and plate sprockets with all requested tooth designs including standard, special, low-backlash and conveyor chain toothing. All sprockets are tailored to suit our customers' requirements and are manufactured in our precise and well-tested quality. Standard sprockets with a hub on one side are suitable for simplex, duplex and triplex Roller chains. Additionally, we can offer our customers a wide range of stainless steel sprockets for roller chains. Sprockets for accumulator chains are used in conveying systems. As to their geometry they are perfectly matched to the characteristics of the chains. Both components are optimally linked and thus allow for an efficient and permanent operation of the plant. Common Sprockets are being defined by no. of teeth, Diameter, center distance etc. For optimum wear life, centre distance between two sprockets should normally be within the range 30 to 50 times the chain pitch. The minimum centre distance is sometimes governed by the amount of chain lap on the driver sprocket. These Sprockets are manufactured from Mild Steel, Stainless Steel, Alloy Steel, Hardened and Tempered Steels, Case Hardened Steels, Induction hardened, Cast Iron or any other specified material Applications of Sprockets: • Oilfield Industries • Cement Industries • Bakery Industries • Theme Park • Steel Industries • Glass Industries • Agricultural Equipment • Crawler cranes • Escalators • Heavy duty applications • Coal mining and quarrying • Palm Oil Mills • Road pavers • Sugar Industries • Water Industry / Sewage Treatment

...more

Stainless Steel Sprockets

Stainless Steel chain is named due to construction of chain from stainless steel material. Specific application of Roller chain and Conveyor chain has be manufactured from stainless steel material. Stainless steel Chains are corrosion resistant as compared to standard Roller chains and so quite longer life than conventional Roller or Conveyor Chains. These chains are ideal for acidic or alkaline environments, or where the chain will be exposed to water, and for very high or very low temperature locations, where resistance to corrosion is a requirement. Stainless Steel chain should be selected when resistance to chemical reaction is critical. Stainless Steel is manufactured using FDA approved material and is pre-lubricated with a USDA H1 approved lubricant.

...more

Stainless Steel Roller

Stainless Steel chain is named due to construction of chain from stainless steel material. Specific application of Roller chain and Conveyor chain has be manufactured from stainless steel material. Stainless steel Chains are corrosion resistant as compared to standard Roller chains and so quite longer life than conventional Roller or Conveyor Chains. These chains are ideal for acidic or alkaline environments, or where the chain will be exposed to water, and for very high or very low temperature locations, where resistance to corrosion is a requirement. Stainless Steel chain should be selected when resistance to chemical reaction is critical. Stainless Steel is manufactured using FDA approved material and is pre-lubricated with a USDA H1 approved lubricant. Features of Stainless Steel Chain: • Excellent corrosion protection • Chemical Resistant • Wide temperature range • Austenitic stainless steel • USDA H1 approved lubrication as standard • Solid stainless steel roller • Standard attachments available • Easily cut to length Application of Stainless Steel Chains: • Food and Packaging industry • Corrosive atmospheres • Ideal for wash down with caustic solutions • Regulations require the use of stainless steel • Food packaging machines • High temperature food processing applications

...more

Stainless Steel Roller Chain

Stainless Steel chain is named due to construction of chain from stainless steel material. Specific application of Roller chain and Conveyor chain has be manufactured from stainless steel material. Stainless steel Chains are corrosion resistant as compared to standard Roller chains and so quite longer life than conventional Roller or Conveyor Chains. These chains are ideal for acidic or alkaline environments, or where the chain will be exposed to water, and for very high or very low temperature locations, where resistance to corrosion is a requirement. Stainless Steel chain should be selected when resistance to chemical reaction is critical. Stainless Steel is manufactured using FDA approved material and is pre-lubricated with a USDA H1 approved lubricant. Features of Stainless Steel Chain: • Excellent corrosion protection • Chemical Resistant • Wide temperature range • Austenitic stainless steel • USDA H1 approved lubrication as standard • Solid stainless steel roller • Standard attachments available • Easily cut to length

...more

Stainless Steel Mesh Conveyor

Our range of wire mesh belt conveyors is assembled with the use of stainless steel and pins which are in turn fitted in hollow pin chain. These conveyors are used to feed hot billet to forging press and also to feed forged job to trim press from forging press. Wire mesh conveyor belts are also used in worldwide industries such as heat treating, forging, foundry, food processing, snack food, baking, ceramics, glass, automotive etc. Feature of Wire Mesh Belt: • Linear Speed: UP TO 30 Mtr.Min. • Chain: 1” OR 1.5” pitch hollow pin chain in stainless steel • Can carry hot forgings up to 1000 Deg. C.

...more

Slat Conveyor Chain

Slat chain conveyors are another type of chain conveyor which uses many types of interleaving segments to form a slat type chain of either synthetic polymer or stainless steel construction, in either low friction or friction grip styles. They are used in high wear areas often handling individual packets or cans in can filling or bottling operations. They are also used extensively in food manufacturing applications. Heavy versions of the slat conveyors are often found in freight handling applications where loads and impact are quite high. Traditionally heavy slat conveyors are constructed using hardwood slats fixed onto parallel chains. Hinge Belt conveyor finds application in stamping sheet metal press shops to handle scrap at a moderate capacity. The conveyor frame can be open type made from heavy structural steel sections or closed type made from heavy gauge steel plates. Modular construction of the conveyor makes it possible to add or remove conveyor segments at a later date depending on requirement.

...more

Slat Chains

Slat chain conveyors are another type of chain conveyor which uses many types of interleaving segments to form a slat type chain of either synthetic polymer or stainless steel construction, in either low friction or friction grip styles. They are used in high wear areas often handling individual packets or cans in can filling or bottling operations. They are also used extensively in food manufacturing applications. Heavy versions of the slat conveyors are often found in freight handling applications where loads and impact are quite high. Traditionally heavy slat conveyors are constructed using hardwood slats fixed onto parallel chains.

...more

Hinged Chains

Slat chain conveyors are another type of chain conveyor which uses many types of interleaving segments to form a slat type chain of either synthetic polymer or stainless steel construction, in either low friction or friction grip styles. They are used in high wear areas often handling individual packets or cans in can filling or bottling operations. They are also used extensively in food manufacturing applications. Heavy versions of the slat conveyors are often found in freight handling applications where loads and impact are quite high. Traditionally heavy slat conveyors are constructed using hardwood slats fixed onto parallel chains. Hinge Belt conveyor finds application in stamping/ sheet metal press shops to handle scrap at a moderate capacity. The conveyor frame can be open type made from heavy structural steel sections or closed type made from heavy gauge steel plates. Modular construction of the conveyor makes it possible to add or remove conveyor segments at a later date depending on requirement.

...more

Slat Chain Conveyors

Slat chain conveyors are another type of chain conveyor which uses many types of interleaving segments to form a slat type chain of either synthetic polymer or stainless steel construction, in either low friction or friction grip styles. They are used in high wear areas often handling individual packets or cans in can filling or bottling operations. They are also used extensively in food manufacturing applications. Heavy versions of the slat conveyors are often found in freight handling applications where loads and impact are quite high. Traditionally heavy slat conveyors are constructed using hardwood slats fixed onto parallel chains.

...more

Simplex Roller Chain

Roller Chain or Bush Roller Chains are the basic of chaining system. All major chains are made from this principle. The basic application of such chains is transmission of power from one sprocket or toothed wheel to other. Even no of sprockets can be used in series for transmission of power. So it is also well known as Transmission Chain or Transmission Roller Chains. Most common example of such chains is Bicycle or Motorcycle Chain etc.

...more

Roller Chain Sprockets

A sprocket is a profiled wheel with teeth that meshes with a chain, track or other perforated or indented material. It is distinguished from a gear in that sprockets are never meshed together directly, and from a pulley by not usually having a flange at each side. In Transmission of power sprockets are equally important as Roller chain. It’s the media through which the chain can transmit the power. Sprockets wide range and designs as the chains are manufactured. Variety of sprockets manufactured like Sprockets for roller chains, Sprockets for accumulator chains, Plate sprockets, Chain couplings, Special sprockets, Chain Sprockets, Industrial Sprockets, Timing Sprockets and Miscellaneous other sprockets etc.

...more

power transmission chain

Roller Chain or Bush Roller Chains are the basic of chaining system. All major chains are made from this principle. The basic application of such chains is transmission of power from one sprocket or toothed wheel to other. Even no of sprockets can be used in series for transmission of power. So it is also well known as Transmission Chain or Transmission Roller Chains. Most common example of such chains is Bicycle or Motorcycle Chain etc.

...more

Mesh Belt

Our range of wire mesh belt conveyors is assembled with the use of stainless steel and pins which are in turn fitted in hollow pin chain. These conveyors are used to feed hot billet to forging press and also to feed forged job to trim press from forging press. Wire mesh conveyor belts are also used in worldwide industries such as heat treating, forging, foundry, food processing, snack food, baking, ceramics, glass, automotive etc.

...more

leaf chain

Leaf Chains are used for fork lift masts, as balancers between head and counterweight in machine tools, or for low-speed pulling (tension linkage). This type of chain is also called "Balance Chain," and is regulated by ANSI. In roller chains, all the link plates have higher fatigue resistance due to the compressive stress of press fits. In Leaf Chains, only two outer plates are press fit. Therefore, the tensile strength of Leaf Chains is high, but the maximum allowable tension is low. It is advisable to use safety guards at all times, and be particularly alert to assure the safety factor. Leaf chains are made especially for applications requiring flexible, high strength tension linkages for reciprocating motion devices. These chains operate over sheaves rather than sprockets and are often found on fork lift trucks, or as counter-weight chains for machine tools or similar balancing applications. These chains are usually supplied cut-to-length and may be supplied with "male" (inside link) or "female" (outside link) ends. Chains to be supplied in an even number of pitches possess one female and one male end. If an odd number of pitches are required please specify whether the ends should be "male" or "female". The type of clevis used will determine the end style required. There basically two type of series are manufactured named AL Series and BL Series. AL Series Leaf chains are made for light duty applications. It is recommended that when designing for new applications the "BL Series" to be specified as the ANSI organization has discontinued the AL Series. In the future AL series chains will become rare in application. BL Series Leaf chains are made for moderate to heavy duty lifting applications. Pins and link plates of the BL Series are made from one size larger ANSI chain to allow for operation in moderate to heavy load applications. The range of leaf chain for material handling applications is used worldwide for straddle carriers, fork lift trucks and on major civil engineering works such as flood defense barriers.

...more

metallic conveyor belts

These metallic conveyor belts are used in material handling, food processing, dairy, biscuit plants, bakeries and high temperature ovens and furnaces industries. Jaycon Engineering manufactures Laminated Type with Plate as per customer's requirements in stainless steel of grade 304. We also use grades of high carbon steel and galvanized iron like 316, 310 and 314. These are one type of Conveyor Belts with special design and special applications. These Belts are constructed by flattening the plates and crossed and interlocked. These are always in typical design for application in similar industries and so the design has to be specific for those applications.

...more

Honeycomb Conveyor Belts

The honey comb belt Flat Wire Belt are constructed from cross rods and a flat metal strip. At the sides of the belt the cross rods have a welded ring (welded edges). In a number of dimensions it is possible to give the sides of the belt a clinged edge. There are a number of predefined belt executions with different pitches and material dimensions. The belt can also be provided with side plates or flights. The belt width is determined by the belt specification and the number of odd spaces. The honey comb belt is positively driven by sprockets, and can be used at conveyor speeds of less than 1 meter per minute to about 25 meters per minute, which are considered normal speeds. Speeds above 25 meters per minute are considered to be high speeds and can affect the life of the belt. The construction of the conveyor system and the process conditions are also important considerations. The extensive range of Honeycomb Conveyor belts are used in the application such as food processing, freezing, baking, drying, painting, cleaning, transferring as well as parts washing. These provide an open mesh for easy flow of air, or gases through the belts and have been appreciated all over the globe. Honeycomb conveyor belts are manufactured from high Carbon, Steel, Galvanizes, 304 Stainless Steel and 316 Stainless Steel.

...more

Flat Wire Belts

The honey comb belt / Flat Wire Belt are constructed from cross rods and a flat metal strip. At the sides of the belt the cross rods have a welded ring (welded edges). In a number of dimensions it is possible to give the sides of the belt a clinged edge. There are a number of predefined belt executions with different pitches and material dimensions. The belt can also be provided with side plates or flights. The belt width is determined by the belt specification and the number of odd spaces. The honey comb belt is positively driven by sprockets, and can be used at conveyor speeds of less than 1 meter per minute to about 25 meters per minute, which are considered normal speeds. Speeds above 25 meters per minute are considered to be high speeds and can affect the life of the belt. The construction of the conveyor system and the process conditions are also important considerations. The extensive range of Honeycomb Conveyor belts are used in the application such as food processing, freezing, baking, drying, painting, cleaning, transferring as well as parts washing. These provide an open mesh for easy flow of air, or gases through the belts and have been appreciated all over the globe. Honeycomb conveyor belts are manufactured from high Carbon, Steel, Galvanizes, 304 Stainless Steel and 316 Stainless Steel. Features of Honeycomb Belt: • Flat surface • Easily cleanable and • Easy maintenance Application of Honey comb belts: • Cooling systems • Drying systems • Bread production systems • Washing systems • Sorting systems • Product handling systems

...more

Honeycomb Belt Conveyor

The honey comb belt Flat Wire Belt are constructed from cross rods and a flat metal strip. At the sides of the belt the cross rods have a welded ring (welded edges). In a number of dimensions it is possible to give the sides of the belt a clinged edge. There are a number of predefined belt executions with different pitches and material dimensions. The belt can also be provided with side plates or flights. The belt width is determined by the belt specification and the number of odd spaces.

...more

Enrober Belt Conveyor

Enrober Belts are made of stainless steel wire of spring wire. Wire diameters varies from 0,9 until 2,8 mm. Pitches from 4 mm until 19,05 mm, and belt widths from 10 mm until 3 metre. We can develop a big range of standard dimensions, and also can manufacture all the (non standard) dimensions too because of the multi adjustable production machinery. Belts executed with single loop (most common) or double looped edges for special occasions. Enrober Belts can be made for straight conveyors and for curve conveyors. Enrober Belts can be equipped with little cams, or with special formed internal wire to carry the product on a special way. The very small ‘chains’ are used in spreader conveyors. Enrober Belts are normally driven by toothed sprockets, made of (stainless) steel or plastic. These sprockets are made to fit the belt and are adapted to the diameter you wish. The number of teeth is free to choose and can be made for every new or existing conveyor. Enrober Belt is made from pre shaped wires with the same form, weaving together. The standard execution of a single looped edge belt is most common and double looped edge (only small pitches, and wire diameter from 0,9 until 1,2 mm) belt are suitable for straight conveyors. The belt is determined by the pitch (P) de wire diameter (D), the number of the spaces and the dimensions of these spaces (E and F). The looped edge (G) is determined by the wire diameter. The width of the belt is free to choose. Application of Enrober Belts is often in conveyors for the food industry for the production of • snacks • meat • fish • candy • pizzas • small potatoes • vegetables • biscuits • bread • chocolate • pastry • nuts and fruits Enrober Belts are also used on other industries to convey products like little parcels in packing and plasticization machinery.Enrober Belts are an effective choice for a wide variety of light duty applications in metal working, food processing and other industries.

...more

duplex roller chains

The Jaycon make roller chain design reduces friction compared to simpler conventional designs, resulting in higher efficiency and less wear. Still Continuous lubrication of pin, cleaning, lubrication of roller chains is of primary importance for efficient operation and long life. The need of lubrication is not just to the outside of the chain but especially to the inner surfaces between the pins and bushings and to the bushings and rollers, is a source of irritation for almost all users of roller chains. Smooth revolving of roller on pin increases the efficiency of chain and avoids wear & tear of chain.

...moreBe first to Rate

Rate ThisOpening Hours