Reversing cold rolling mill

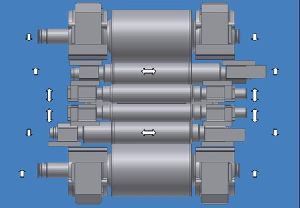

Reversing Cold Rolling Mill for Stainless Steel Salient Features Speeds up to 500 mpm Option of DC & AC drive system True Circle Tension Reel Mandrels with Grippers and Outboard Bearing Support / Solid Drum Mandrel at tension reel Sleeve loading at Tension Reel using coil car Roll coolant system – Neat oil with supamic filter or Emulsion with vacuum band paper filter. Paper winder / un-winder at POR, ETR & DTR Contact or Non-contact type strip thickness measurement Dynamic Tension Stability Control Backup Roll Drives - Independent Zoned Type Work Roll Cooling Headers Quick Work Roll and Intermediate Roll Change system (QWRC) with Side Shifting Hydraulic Cylinder operated Back up Roll Change Grease Lubrication for BUR, IMR & WR

...more

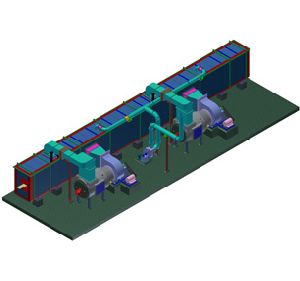

Ovens Incineration System

Salient Features Catenary & flotation type Oven Oven construction suitable for processing material for structural & white goods application Convection Heating of strip Designed for 25% LEL limit Oven Construction with explosion opening as per NFPA Recirculation fan with variable speed drive for each zone Variable speed drive for oven exhaust fan for controlling oven ventilation Panel type oven construction Oven Internal surface aluminized & External galvanized sheet Plenum arranged to suit to strip catenary shape Catenary sensor for catenary control Pitot tube type sensor for measurement of oven exhaust flow. Direct / Indirect heating system for each zone Individual zone temperature control using temperature sensor LEL monitor Adjustable slot type nozzle for plenum Thermal incinerator with high solvent destruction efficiency Primary & secondary heat exchangers to recuperate waste heat Waste Heat Thermic fluid heater Hot fresh air supply to oven

...more

Galvanising Furnace

Salient Features Horizontal, ‘L’ Shape, & Vertical Design Non-Ox Type Process Non-Ox Furnace suitable for processing very thin gauges (0.15mm) Non-Water Cooled Roll Design Gas Fired & Electrical Radiant Tube Section Horizontal & Vertical Soaking as per the requirement of product Jet Cooler with electric Heaters for processing thin strips Furnace Bridle to maintain differential Tension Furnaces suitable for GI & GL production Special design of Calm Zone for arresting of Zinc Fumes in case of GL production Heated Down Chute for GL Production Flexibility in operation Strip Temperature Control and Zone Temperature Control Protective Atmosphere Control

...more

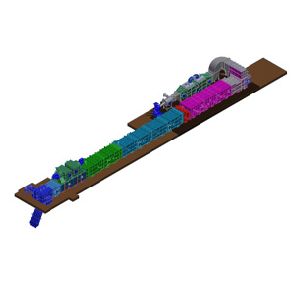

Colour Coating Line

Stitcher Joiner for continuous operation, Accumulators at Entry & Exit for Continuous operation of line, Inline Tension Leveler (TL), Ovens Designs Suitable for White Goods (Fresh Air System) and Structural application, Incineration of oven exhaust using Thermal Incinerator or Regenerative Thermal Incinerator (RTO), Possibility of installing Printing with Clear Coat, Guard Film Applicator cold Laminator.

...moreBe first to Rate

Rate ThisOpening Hours