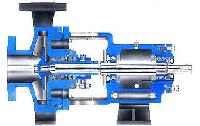

SCP-SERIES Metallic Pumps

Get Price Quote

Technical Features : All the wetted parts are made from INVESTMENT CASTINGS using lost wax process, giving excellent surface finish, sound castings, giving minimum resistance to flow resulting in better efficiencies. Chemical process pumps in investment castings Heavy duty design features for total range of process services. Maximum interchangeability, gives minimum spare parts inventory. Greater quality control and accuracy in production of every pump with the modern machining operations. Back pull-out design, permits quick inspection or repairs of rotating elements without disturbing electrical and piping connections resulting in minimum down time. Hydraulic performance maintained by simple external axial adjustment of impeller wear. Exclusive balanced thrust. Standard dimension, cut layout design cost. Standard foundations save installation and drawing time, talent and money. Fully open impeller with back pump -out vanes reduces stuffing box pressure and prevents entrance of solids and meets low NPSH requirements. Long life Low maintainence Reliable operation Pumps available in CF 8 M (SS-316), Alloy-20, CD 4 MCU, SS 316 L(CF3 M), Hastalloy B and Hastalloy C Maximum Sealing Facility Inside unbalanced Seal. Inside balanced seal. Optional quench gland using throttle bushing Optional throat bushing inside stuffing box cover. Outside mounted teflon bellow seal. Double mechanical seal. Specially developed seal for tough slurry applications (can take slurry upto 40%) Service coverage SCP-SM pump cover 60% of all process industry requirements. SCP-MD Pumps are meant for high capacity high head requirements and cover 80% of the requirements of the process Industry. SCP-LC Pumps are low cost pumps and cover almost 40-50% of process Industry requirements.