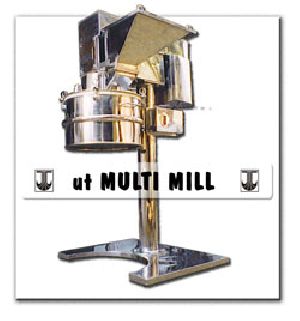

stainless steel multi mill machine

90,000 - 400,000 Per piece

1 Piece (MOQ)

Boinns Multi mill is used for high-speed Granulating, Pulverizing, Mixing, Shredding and Chopping, etc. of a wide range of wet and dry materials without special attachments. Multi mill operates on the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to get the required size reduction. Material fed in the hopper, goes down to the processing chamber where it moves to the periphery and passes through the screen radially and tangentially avoiding chocking and temperature rise. Finally, the processed material gets collected in the container kept below the processing chamber. Output and quality of the final product depends on three main factors: Shape of beaters (knife/impact edges) Speed Screen. FEATURES Machine Portable on Castor wheels, High output with Process uniformity, All contact parts are in SS 316, Built in Variable Frequency Drive for multiple speeds Direction of the Blade rotation can be changed using a Reversing switch for Hammer or Knife operation Multiple combinations of Screens / Speeds / Screens / Speeds / Amount of Blades / Direction of blade rotation for every Product type Higher Screen opening area, Minimal material handling resulting in Total Dust free operation Easy Dismantling and Cleaning of all Components reducing Production Downtime and increasing Productivity Wide range of SS perforated and Wire knitted screen available for every Product type Additional perforated screen at the bottom of pulverizing chamber ensuring Higher Fineness and Controlled Size of Granules

Multi Mill

Get Price Quote

10 Piece (MOQ)

Multimill is used for high speed granulating, pulverizing, mixing, shredding and chopping, etc of a wide range of wet and dry materials without special attachments. As compared to the four common principles of size reductions i.e. grinding, compression, impact and shearing, which often do not produce controlled size reduction, this machine utilizes the principle of variable force swing hammer blades having both knife and impact edges rotating with a carefully selected screen to control size reduction. Flow path of material in vertical rotor machine is streamlined. During Communication , material entering the chamber travels to the periphery and passes through the screen tangentially and radially avoiding chocking and temperature rise.Salient Features: Widely used for wet and dry granulation, shreading, pulverisation etc. in Pharmaceutical, Chemicals and Other Industries. Standard and Lab Models available. GMP/ Flameproof/ SS 316 construction on demand. Direction of beaters can be changed by reversible switch. All contact parts can be easily and quickly dismantled and cleaned. Machine is designed for continuous operation. Cylindrical screen for higher output. Castors provided for ease of mobility. Beaters and scrapper blades of SS 410 quality are hardened and polished to mirror buff.

Best Deals from Multi Mill

Multi Mill

Get Price Quote

1 Piece (MOQ)

Sparklex Machines Private Limited is the best Multi Mill Supplier in India. Being one of the best Multi Mill Manufacturers in India we aim at providing a wide variety of Multi Mills that are precisely engineered and manufactured by using superior quality raw materials. Our Multi Mills are in high demand on the global market as they are corrosion resistant, come equipped with flameproof motor & flameproof rotary switch as per clients requirement. The Multi Mill offered by us is made out of the best quality stainless steel and contains four rollers which make the machine movable as and when required. Multi Mills are used in multiple places and applications like pharmaceutical formulation, food products, creams and cosmetics which require multiple processing styles like grinding, extracting, emulsifying, dispersing, homogenizing and mixing. We, as Multi Mill manufacturer in India are aimed towards offering our clients models that are upgradeable and different sized at affordable prices. Hire us and get our services and products today.

Multi Mill

Get Price Quote

Our products are packed under controlled conditions to ensure their quality is not compromised and buyers are presented with brand new products. We have an ultramodern facility to pack our products. With us, payment transactions will always remain secured, as we have adopted modern payment procedures that guarantee instant and hassle-free transactions.Salient Features : All contact parts are made out of SS 316 quality material. Machine rated for continuous operation. High output with process uniformity. Various combinations of screens / speeds / number of blades / direction of rotation blade, can be selected. All contact parts can easily be dismantled and cleaned for change of product. . Wide range of SS perforated and wire knitted screen available. Machine portable on castor wheels. Flame Proof electrical motor can be incorporated.

Multi Mill

Get Price Quote

Multi mill is used for high speed Granulating, Pulverizing, Mixing, Shredding and Chopping, etc, of a wide range of wet and dry materials without special attachments. This machine utilizes the principle of variable force swing hammer blades having both knife and impact edges rotating with a carefully selected screen to control size reduction. Flow path of material in vertical rotor machine is streamlined. During comminuting, material entering the chamber travels to the periphery and passes through the screen tangentially and radially avoiding chocking and temperature rise.

Multi Mill

Get Price Quote

We have marked a distinct position in the market by providing Multi Mill. The Mill is manufactured utilizing high grade raw materials under the guidance of experienced professionals in compliance with international standards. Our clients can avail this Mill from us in different specifications as per their specific requirements. Clients can avail the offered range from us at highly affordable prices. Features : Sturdy Construction Corrosion Resistance Durable Finish Standards Specifications : Material : SS304/316/316L Aisi quality Out Put: 50 Kgs/Hr To 200 Kgs/hr

Multi Mill

Get Price Quote

Multi Mill is used in different functions involving wet& dry granulation pulvensation etc. of Pharmaceutical, Chemical, Bulk drug, Cosmetic, Colors, Dyestrutts, Food products etc. The Industrial Multi Mill consists of stainless steel hopper, processing chamber with beater assembly, Motor, DOL stater, three speed puley, screen and study body. We are known in the market as a leading Pharmaceutical Multi Mill Machine Manufacturer in Thane Maharashtra. Features All contact parts made of SS 316 as per GMP standard. Machine is designed for continuous operation. Beaters and scrapper blades of SS 316 quality. Direction of beaters can be changed by reversible switch. All contact parts can be easily and quickly dismantled and cleaned. Lab. Model also available. Optional Accessories/Attachments Flame Proof Construction. VFD. Dry mechanical seal. Safe earthing system. Documentation Documentation like DQ, IQ, OQ and FAT provided with the machine.

Multi Mill Machine

Get Price Quote

We are offering a range of multimill that is designed for wet and dry granulation pulverization, shredding & chopping in pharmaceuticals, chemicals & various industries. Co- mill, which is a safe contained portable unit that utilizes the principle of variable force swing hamper plate that have knife and impact edges rotating on both the sides with a screen and the speed to control the reduction. We can change the speed from minimum 750 to 3000 maximum. Although the materials entering the chamber travels to the periphery and passes through the screen tangentially, the speed can still be controlled with the help of a.c. Frequency drive used for tabletfood processing department, confectioneries, bakeries,chemical, dyestuff, cosmetics and pesticides. multi mill model sfe-mm-prod. Sfe-mm-lab-r&d maximumout put hour 200 kgs. 30 kgs. Electricals 415 v, 50 hz, 1440 rpm motor 3 hp 0.5 hp starter star-delta, no load & over load protector s.s. Perforated screen (holes dia mm) (a)0.5 ,1.0,1.5 sizes (b) 2 , 3 , 4 , 5 , 6 (c) 7 , 8 , 10 , 15 , 20 , 25 s.s. Wire mesh sieve (a)4,6,8,10,12,14,16,20,24,30,40,50,60 (b) 80,100. Optional features belt less multi mill flp electricals vfd speed controls

Multi Mill

Get Price Quote

Our range of Multi Mill can be utilized for high speed granulating, pulverizing, mixing, shredding and chopping almost any kind of wet and dry materials. Multi Mill uses the principle of variable force and the swing hammer blades are equipped with both knife and impact edges. These edges rotate to offer highly controlled size reduction. The Multi Mill offers superior performance as compared to conventional methods of grinding, compressing, impact and shearing, which generally fail to produce controlled size reduction. Description A material enters the channel during comminution in a streamlined flow path and travels to the periphery and passing through the screen tangentially and radially, thereby, preventing chocking and temperature rise. The availability of castor wheels assists in the easy maneuverability. Our Multi Mill has multi speed drive for grading of various product

Multi Mill

Get Price Quote

Our organization is graded among receptive and responsible Suppliers of Multi Mill, involved in providing to purchasers across diverse marketplaces. As we ensure complete safety of the products at our end, we follow stringent and organized warehousing system in our state-of-the-art warehouse. Moreover, the system is supervised by experts. Features : Smooth finish Hassle free operations Tough built Specifications : Multi speed drive for various product grading. Easy dismantling and cleaning. Various size sieves. (Optional) Low energy consumption. High degree of surface finish & GMP Standard / Laboratory Models.

Multi Mill

Get Price Quote

Multimill is a self contained portable unit useful for high speed Granulating, Pulverising, Mixing, Shredding, Chopping etc. A wide range of wet & dry materials without special attachments. As compared to the four common principles of size reduction, this machine utilises the principle of variable force swing hammer blades having both knife and impact edges rotating with a carefully selected screen to control reduction. Flow path of material in vertical rotor machine is streamlined. During comminuting, material entering the chamber travels to the periphery and passes through the screen tangentially and radially avoiding choking and rise in temperature.

Multi Mill

Get Price Quote

Multimill is a self contained portable unit useful for high speed Granulating, Pulverising, Mixing, Shredding, Chopping etc. A wide range of wet & dry materials without special attachments.

Multi Mill

Get Price Quote

Working Principle Multimill is designed to utilize the principle of variable forces swing beaters having both knife and impact edges rotating within a selected screen to control the particle reduction. Material fed in to the processing chamber moves to the periphery and passes through the screen radically and tangentially. Finally the processed material gets collected into the container kept below the processing chamber. Salient Features Multi speed drive for various product grinding Easy dismantling and cleaning High degree of surface finish Easy portability AC frequency drive option available

Multi Mill

Get Price Quote

Tapasya's Multi-mill is ideal for high speed Granulating, Pulverising, Mixing, Shredding and Chopping of a wide range of wet and dry materials without special attachments. This machine utilises the principle of variable force swing hammer blades, having both knife and impact edges, rotating with a carefully selected screen to control size reduction. The product enjoys wide applications in the Chemicals, Pharmaceuticals, dyestuff, colours, ceramics, food products, cosmetics, pesticides, fertilizers, plastics, spices, bakeries, resins, insecticide and other industries. Features Efficient Dust contained Multi mill Machine Portable on Castor wheels High output with Process uniformity All contact parts are in SS 316L Direction of the Blade rotation can be changed using a Reversing switch for Hammer or Knife operation for various product type Multiple combinations of Screens / Speeds / Number of Blades available for every Product type Higher Screen opening area for Higher Throughput Easy Dismantling and Cleaning of all Components reducing Production Downtime and increasing Productivity Additional perforated screen at the bottom of pulverising chamber ensuring Higher Fineness and Controlled Size of Granules Built in Variable Frequency Drive for multiple speeds Benefits For You High speed operations Minimal material handling Dust-free operations Easy to handle Higher throughput Easy maintenance Multi Mill used in Industries Pharmaceutical Nutraceutical

Vessels Multi Mills

Get Price Quote

Vats & Vessels Multi Mills are serving in chemicals, pharmaceuticals, dyestuff, paints, ceramics, food industries, cosmetics, pesticides, fertilizers, plastics, spices, bakeries, resins, insecticides etc. Multi Mill is widely used for Granulation, Pulverization and Mixing. Swinging Hammer Blades and Scrapers arrangement gives Shredding & Chopping Effect. Construction -The unit consists of Motor drive & Rotor assembly. The rotor assembly is equipped with swinging hammer blades & scrapers. The rotor has 4 different speeds - 750 / 1500 / 2000 / 3000. The speed variation is achieved by aluminum cone pulley & belt arrangement on motor & rotor. Interchangeable Perforated Screen with Charging & Discharging Hopper is provided as per requirement. All internal & external SS parts are mirror polished. / Special Features of Vats & Vessels Multi Mill cGMP Models, Units with FLP are available The base is mounted on 4 Nos. castor wheels Constructed in SS 304 / SS 316 / MS. Complete unit with S.S. cover and all surfaces polished to mirror dull finish. MS parts dull painted to smooth finish Wide range of SS perforated or wire knit screens available Higher output with process uniformity Different designs & Shapes of mixing beaters to suit particular mixing requirement for wide variety of materials

Pharma Multi mill machine

Get Price Quote

Multi Mill Machine

Get Price Quote

Multi Mill

Get Price Quote

The company has attained a top-niche in the market, as one of the reputed Manufacturers and Suppliers of Multi Mill. Multi Mill is used for handling jobs such as granulating, pulverizing, mixing, chopping, etc. We offer Multi Mill in various grades and specifications. Moreover, clients can avail Multi Mill, from us, at the market leading prices.

Multi Mill

Get Price Quote

We offer high quality range of multi mill. These are widely used for wet and dry granulation, pulverization etc. In pharmaceuticals, chemicals, cosmetics, ceramics, colours, dyestuff, food products. These also finds application in pesticides, fertilizers, spices, detergents, insecticides, plastics and resins industries. We offer our range at market leading prices. features : direction of beaters can be changed by reversible switch from knife to impact forward and vice versa all contact parts can be easily and quickly dismantled and cleaned machine is designed for continuous operation cylindrical screen for higher output castors provided for mobility flame proof electrical can be provided at extra cost beaters and scrapper blades of ss 304 quality

multi purpose mill

Get Price Quote

Depending upon product (material density, nature, moisture content, weight & screen mesh size) Optional accessories / attachments Modified Straight Discharge Hopper (for maximum output rate of flow) Dusting arrangement for pulverizing of fine powder to avoid dusting in the air provided on Discharge Hopper with Perforated Bucket & Cloth S. S. Jacket on Intermediate Hopper with inlet, outlet & vent connections Recommended Spares S. S. Screen - 0.5 mm to 20 mm Special screens are available in # (mesh) in sandwich type Rubber gasket- charging & discharging hopper Teflon-ring / gasket SS Blades set - cutting / scraper / swing / pins / beater boss / beater cap SS Blade – Hexsaw type cutter to increase the fines of the powdero SS Beater / SS Shaft