Slide Sleeve Type Expansion Joint

The “LEELA” M.S.Expansion Joints offer a very compact and easy to install product to be used for absorbing the expansion and contraction movements of a pipeline system. We are counted amongst the most preferred sleeve type expansion joint manufacturer and exporter in India. It has been perfectly designed and developed with due concern over customer satisfaction. The market reputed sleeve type expansion joint manufacturer is also able to cater the customer's specific requirements.

...more

Pipe Sleeve Couplings

We are considered as a prominent manufacturer and exporter of high quality pipe sleeve couplings that are available in huge variety at affordable prices. An extensive range of highly usable pipe sleeve couplings have immense advantages over modern methodologies of joining pipes such as welding/flanging/flaring so that widely acknowledged due to its advanced features. We are India’s most preferred pipe sleeve couplings manufacturer and exporter that is focused to provide complete satisfaction to its diverse industrial customers. These pipe couplings have various advantages over conventional methods of joining pipes such as welding/flanging/flaring etc.as illustrated in the catalogue enclosed herewith. Typical use include: Air conditioning and refrigeration equipment piping. Industrial oil & chemical piping. Irrigation systems piping. Ash / slurry / coal pipelines. Sewage treatment piping Desalination plants piping Ships piping Gas & water distribution piping Transformer & tank piping.

...more

pipe sleeve coupling

We are offering We are considered as a preeminent manufacturer and exporter of high quality pipe sleeve couplings that are available in huge variety at affordable prices. An extensive range of highly usable pipe sleeve couplings have immense advantages over modern methodologies of joining pipes such as eldingflangingflaring so that widely acknowledged due to its advanced features....

...more

pipe repair clamps

The “WRAP EASY” repair clamps are flexible clamps consisting of one or more stainless steel rubber lined band sections. They find use for a quick, easy and permanent repair of corroded, damaged or broken pipes. We are one of the renowned manufacturers and exporters of pipe repair clamps which is most appreciated by the global customers. It has been well examined and remarked by our highly skilled professionals to ensure its hassle free performance. We design and develop a highly functional range of pipe repair clamps that enable us to cater the ever-changing market requirements. As a renowned pipe repair clamps manufacturer, we bring forth an enormous array of pipe repair clamps at market leading prices.

...more

metal compensators

We at Peleecon Linker, manufacture reliable metal compensators designed to perform under most demanding service conditions. These compensators are useful to absorb thermal expansion due to temperatures, to absorb and isolate vibrations, to reduce and eliminate the transmission of noise in other systems, to take care of movement caused by irregularities in pressure and installation in the pressurized piping system. We are amongst the largest integrated metal compensators manufacturers and exporters that are most appreciated and acclaimed due to its high functionality. It can be availed as per the given specifications of our valued customers so as to cater the ever-changing customer’s requirements. At par with industrial accreditations, we conduct rigorous testing procedures to fulfill the customer’s ever-changing requirements. We are using high quality raw material to ensure the flawless functionality of our products that enable us to carve a niche for ourselves. We are counted amongst the renowned metal compensators manufacturers and exporters in India.

...more

Flange Adaptors

We are engaged in manufacturing and exporting an enormous array of flange adaptors which is meticulously designed and fabricated by our in-house team of quality controllers. The finest quality flange adapters are specially fabricated by industrial experts adapting innovative production process that assisted us to provide the complete satisfaction to our most valued customers. Our comprehensive range of flange adapters are complying with industrial quality standards so that we have carved a niche for ourselves. As a reputed flange adaptors manufacturer and exporter, we have gained a lot of admiration from the worldwide customers and most acknowledged due to its efficiency, durability, reliability of our most usable flange adaptors. We are rewarded by the repeated orders of our esteemed customers because of our unmatched quality products.Flange adaptors allow flanged fittings and valves/meters/pumps to be installed in plain ended pipe systems.This flange adaptor offers the same advantages as the LEELA sleeve pipe couplings — and more. The flange adaptor is the ideal solution for connecting valves and pumps in your piping system, absorbing damaging stresses that are transmitted along the pipeline and eliminating costly downtime for repair. Also the flange adaptors can be installed quickly and easily.Adaptors are supplied standard flat faced (Fig. A). Raised face flanges are supplied upon request. Flange drilling can be made according to all international flange specifications.STANDARD FLANGE ADAPTORSThese are available in three basic styles with different sleeve designsA. Straight Sleeve The standard flange adaptor has a straight sleeve and a flat face. The PCD for the flange drilling varies according to the pressure rating of the flange as well as it’s nominal size.B. Expanded Sleeve Generally for use with very thick walled pipe such as asbestos cemen or concrete. The expanded sleeve can also be used when the nominal sizes of the flange and the pipe are different ( e.g. connecting 250NB/12" nom. pipe to a 200NB/8” nom. valve)C. Tapped flange As an alternative to the expanded sleeve, mismatched components may be joined using a tapped flange (Fig. D ). It has a straight sleeve giving a greater pipe insertion length, especially important when the system is subject to excessive movement or temperature fluctuations. Studs, instead of bolts, are used to make the connection to the mating flange. Dimensions B on Fig.D varies with the flange thickness‘t’, relative to the tapping diameter.LEELA flange adaptorsMATERIAL SPECIFICATION Flange adaptor - Rolled steel section - Mild steel plate, BS-436D, IS- 2062 GR-A 1992. OR graded grey cast iron IS- 210 FG- 260 grade 20/25, OR SG Ductile iron To BS- 2789, grade 420/12. End flange - Rolled steel section - Mild steel plate, BS-4360, IS-2062 GR-A 1992. OR graded grey cast iron lS-210 FG-260 Grade 20/25, OR SG Ductile iron to BS-2789. grade 420/12. Bolt & Nut - BS-970, IS-1367-1980. Rubber - Nitrile as standard. EPDM/Natural/Silicon/Viton are also available. Coating - Flange adaptor body, middlering, endrings are coated epoxy. Bolts & nuts are zinc plated. If coating reqd. Other than this please specify.

...more

Expansion Joint

The "LEELA" M.S.Expansion Joints offer a very compact and easy to install product to be used for absorbing the expansion and contraction movements of a pipeline system.

...more

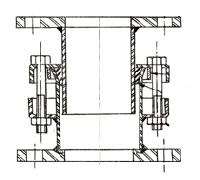

Dismantling Joints

We manufacture dismantling joints that are used to dismantling the equipment fitted in the pipe line. An enormous array of dismantling joints are being used to apply before butterfly valves, pumps and other equipment and are known to provide flexibility to the equipment installations by joining flanged spigot and flanged coupling adapter into one assembly. As a quality driven dismantling joint manufacturer, we have been export a comprehensive range of products at reasonable prices. We meticulously designed and fabricated an extensive range of dismantling joints using high quality material procured from the market trusted sources.This Dismantling joint is a double flanged fitting that allows longitudinal adjustment in flanged pipe systems. It has been developed to provide greater flexibility at both the planning and Installation stages of flanged pipework systems and for subsequent maintenance.TYPICAL APPLICATIONS The Dismantling Joint is particularly suitable for simplifying the installation and removal of: Isolation valves Non return valves Flow metering equipment Pump sets Pressure reducing valves Flanged pipe and fittings FEATURES & BENEFITS:Longitudinal adjustment The Dismantling Joints are capable of accommodating up to 50mm / 2" longitudinal adjustment dependant on diameter. This adjustability is provided by the telescopic action of the flanged spigot within the flange adaptor. The Dismantling Joint can be locked at that length with the tie bars supplied. Longitudinal adjustment of this magnitude allows for fast and simple maintenance of valves, pumps etc. and simplifies future pipework modifications, often resulting in reduced down time and eliminating the need for more complex anchoring systems.Ease of Installation The Dismantling Joint can be installed with the aid of a spanner and a torque wrench, no specialist equipment is required.Speed of installation The Dismantling Joints re supplied with high tensile steel tie bars to IS-1363. Because of the high quality of the tie bar material, fewer tie bars are required. Consequently there are fewer flu bars than flange holes (additional flange connecting bolts not supplied). The tie bars supplied with the Dismantling Joint also act as flange grouting bolts, reducing the number of flange bolts required.Sealing Unlike other styles of Dismantling Joint, the gasket of the Dismantle rig Joint Is compressed independently of the tie bars. Compression of the gasket is & achieved by following standard flange adaptor installation procedures and speeding installation. lt also allows for a socket and torque wrench to be used. Ensuring that seating failure cannot occur as the gasket is compressed to the required torque.Range This Dismantling Joint can be supplied in any nominal size from DN4O(1.1/2) upwards with mcst common flange drillings such as PN16, N10.ANSl etc. Dismantling Joint specials for specific project requirements can also be produced.Corrosion and Protection The flange adaptor and flange spigot components of a Dismantling Joint are coated with the epoxy coating as standard ensuring that dismantling joints are well equipped to withstand transport, storage, site and corrosion damage. Alternative finishes are also available. All tie bars are Zinc plated.Working Pressure All z4 Dismantling Joints are fully end load resistant and have a pressure rating equal to that of the flange.Full Face Flange For applications where a full face flange is required i.e. wafer and butterfly valves , the flange of spigot pIece provides a full flange sealing area.Product Quality Dismantling Joints are designed and manufactured under a quality management system and have tested by the comprehensive in house research facilities to the most exacting performance requirements of WRC Water Bye-laws scheme (WBS).As with all the products, Dismantling Joints are designed to outlast the pipes on which they are fitted.GasketsDismantling Joints are fitted with EPDM water quality gaskets as standard. For other applications or alternative please ask for details. MATERIAL SPECIFICATION Spigot piece 8 Flange Adaptor - Rolled steel section - Mild steel plate. BS-4360, IS- 2062 GR-A 1992. OR graded grey cast iron IS- 210 FG- 260 grade 20/25, OR SG Ductile iron to BS- 2789. Grade 420/1 2. Tie bars: High tensile steel carbon steel to IS-1363 Rubber ring: EPDM as standard. Natural/Silicon/Viton is also available. Coating: Flange adaptor & Flange spigot are coated epoxy. Tie bars, nut & washers are Zinc coated. If coating reqd. other than this, please specify

...more

Dismantling Joint

We are offering We manufacture dismantling joints that are used to dismantling the equipment fitted in the pipe line. An enormous array of dismantling joints are being used to apply before butterfly valves, pumps and other equipment and are known to provide flexibility to the equipment installations by joining flanged spigot and flanged coupling adapter into one assembly.

...moreBe first to Rate

Rate This