Unidirectional Air Flow System

Backed by rich industry experience, we are presenting vast variety of Unidirectional Air Flow Systems. This range of unidirectional air flow systems is acclaimed in the market for its flow in a single pass and direction, via an air device or clean zone with generally parallel streamlines. Besides, the offered range is available in different configurations like horizontal, vertical & inclined as per the demands of patrons. The offered range is delivered to customers in voluminous quantity.

...more

Sterilizing Tunnel

Our company specializes in offering qualitative range of Sterilizing Tunnel. This range of sterilization tunnels is designed using modern machinery, which makes these ideal for sterilization and drying of ampules and varied bottles like vials and oral liquid bottles in pharmaceutical industry. Along with this, the offered range is categorized in 3 wings (preheating zone, heating zone and cooling zone) in accordance with the diverse demands of clients.

...more

Pre Filters

We are a reputed Manufacturer and Supplier of Pre Filters known for efficiency and high performance. Our Pre Filters remove all the particles down to 5 micron from high particle airgas passing through them. Our Pre Filters are very efficient offering an efficiency of more than 765 percent. Our Pre Filters are designed to ensure a large filtration area in ratio to the face area. The filter element of the Pre Filters is constructed from “glass fiber” papers, which is sandwiched between 2 layers for 5 micron and 1 layer for 10 micron. The filter media is fire retardant while the filter house is bonded on side using long life adhesive. The filter house is made from high-grade stainless steel sheet frame with flange. Types of Pre Filters : 3 Micron Pre Filter 5 Micron Pre Filter 10 Micron Pre Filter Properties : Resistant to mildew Resistant to fungal Resistant to bacteria Resistant to corrosive chemical fumes Resistant to hydrofluoric acid Features : Easy handling Easy removable Easy cleaning Easy install Use to temp. Range (100o-600oc).

...more

Modular Clean Room

Pharma Air Modular Systems Clean Room Partitioning System is designed for ease of installation and practical functionality, while maintaining modular flexibility to interchange by way of easy of demountability. Whether you are adding on, modifying an existing facility, or constructing a new facility, the Pharma air modular systems panel system offers materials to suit your specific application. The PAMS system can be integrated with a wide range of new or existing systems to coordinate any clean room facility or manufacturing environment. Simplified construction methods and our progressive/ non-progressive system will help minimise overall construction time. Solid Panels for Clean Room Partitions Pharma Air Modular Systems monoblock/modular solid partitioning walls are fabricated by way of nominal 2x1/0.8/1mm hot dipped galvanized steel sheets conforming to JISG 3302/94, LFQ, light chromated, zero spangle with a zinc coating of 120gsm. They are bonded with an infill of honeycomb paper core or high density mineral wool, forming a rigid 80mm thick panel to modular widths of 160mm to 1200mm and 2445mm to 6000mm in height. Pharma Air Modular Systems modular walls have been installed in clean rooms throughout the world in a range of applications from high technology electronic manufacturing to legislation-controlled healthcare packaging. The system is readily adaptable to meet the requirements of most clean room classifications as determined by PAMS grades used in pharmaceutical applications. Make-up panels are produced within the sizing layout of the drawing. Pre-treatment of panels is done by way of Corro-Zinc 97 and epoxy polyester powder coating of 60/80 microns forming a smooth surface finish. A complete range of partition walls and ceiling systems are available to meet the technical specifications of controlled environment rooms. Ceilings as well as partitions are inert, non particle-shedding, forming part of a clean room aseptic envelope to enable compliance with FDA validation procedures and PAMS standards. Full details of the complementary range of ceiling systems are available on request. Metal DoorsetsMetal doorsets are manufactured from prime quality stretched cold formed steel sheet to ASTM A527 ASTM A525, JISG 3302/1994, BS 2989. Door frames are pressed from 1.5 mm thick galvanized steel sheet with mitred and welded construction.Hinge reinforcements for either 1 pair or 11/2 pair of hinges are manufactured from 4mm thick steel plate and welded to the frame.The door leaf is manufactured from 0.8/1mm thick galvanized steel sheet with lock formed edges. It is insulated and bonded with infill of honeycombed paper core/mineral wool, forming a rigid flush-fitting stress-free level leaf that will withstand high levels of duty without failure.Innovative flush double glazed 400x800mm vision panels are available, constructed with vacuum-sealed 6mm clear toughened glazing units. Finished in polyester powder coating of 60/80 microns forming a smooth surface finish. Metal Type Electro Galvanized Steel, EG (Pure Zn, ASTM A591) Galvannealed Steel (with A60 Zinc Coating conformation to ASTM A25) Cold Rolled Steel (ASTM 366-91) Stainless Steel (Type 304 stainless steel,# 4 finish PVC coated)

...more

Stainless Steel Cleaning Cart

To move your sterile products in a safe manner, we are offering Stainless Steel Cleaning Cart. Backed by our highly competent team of professionals and sound infrastructure, we assure about the high performance of our Stainless Steel Cleaning Cart. Our Stainless Steel Cleaning Cart is mobile and light in weight due to which it can be used for transporting sterile products under ISO class 5 particle free work area. We offer the Stainless Steel Cleaning Cart in different varieties including SS 304 SS 316 SS 316L, CRCA powder coated.Unit Description : Construction : stainless steel body or CRCA powder coated Differential pressure gauge Glass stainless steel door Milky light Feather touch Ultra violate light Hour meter 35 to 40 minute battery backup Castor wheel Motor blower assemblies : 0.5 hp, ~230 v, 1 phase, 50 hz HEPA filters (final filter) : h13, efficiency 99.97% down to 0.3µ Pre filters : eu6, efficiency 95% down to 5µ

...more

Hvac system

You’ve probably heard of the term from different contractors, engineers, or perhaps colleagues and business partners; but you’re still wondering what the initialism means. Well, HVAC (“H-V-A-C” or “H-VAK”) stands for Heating, Ventilation, and Air-Conditioning—three closely related fundamental functions found in homes, offices, and other building structures. The beginning of HVAC is not clear, though as early as second century, a lot of Roman cities were using a central heating system known as hypocaust. This is further popularized during the Industrial Revolution as big factories used it. Now most modern buildings that you see have integrated HVAC. The HVAC system is also known as climate control. This is because these three functions are essential in maintaining comfort in every dwelling. The primary use of HVAC is to regulate room temperature, humidity, and air flow, ensuring that such elements remain within their acceptable ranges. Effective control of such factors minimizes health-related risks. A very humid atmosphere impairs the body’s ability to regulate body temperature as it prevents the evaporation of sweat. High humidity also decreases physical strength, which usually leads to fatigue. An unhealthy surrounding can also affect people’s thinking abilities. Hypothermia, heat stroke, and hyperpyrexia, among others, are some of the illnesses that may also occur. Application of HVAC Clean Rooms Pharmaceutical Organization, Hospital environments Nano technology Biotechnology Micro electronics Aerospace Office spaces Other Building facilities

...more

Horizontal Laminar Air Flow System

We hold expertise in offering a superior quality range of Horizontal Laminar Air Flow System Cabinets. This range of horizontal flow cabinets is designed using high-grade raw material, sourced from authentic vendors. In addition to this, these horizontal flow cabinets direct the air via pre filter at the bottom level, hence the air flows horizontally via HEPA filter towards the flow area. After air is discharged back into the room, these horizontal flow cabinets render product protection.

...more

HEPA Filters

We are offering to our customers HEPA Filters with high dust retention and flow rate. We offer the interchangeable HEPA Filters in different sizes to cater to varying the customer’s demand. The filter media is fire retardant assembled in a rigid aluminum frame. The filer medium also comprises a locking insert and is bonded in the frame using fire retardant adhesive. The fire retardant gasket of the HEPA Filters offer protection against leakages. We manufacture our HEPA Filters as per the standard industrial parameters. The particles are removed down to 0.3 micron from high particle airgas flow passing through the HEPA Filters with efficiency more than 99.97%. Having a large filtration area, the HEPA Filters are constructed from non-woven fiberglass media paper.Types of HEPA Filter : Minipleat HEPA Filter High temperature HEPA Filter Aluminum HEPA Filter (100% DOP) Aluminum HEPA Filter (50% DOP) Properties : Resists to mildew Resistant to fungal Resistant to bacteria Resistant to corrosive chemical fumes Resistant to hydrofluoric acid Features : Easy handling Easy cleaning Easy removable Easy install Use to temp. Range (100o-600oc)

...more

Garment Storage Cubicle

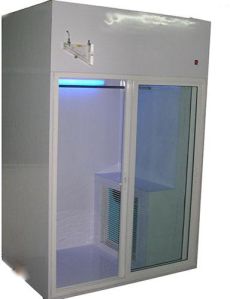

Get from us an effective range of Garment Storage Cubicle fabricated using the latest technologies. Our Garment Storage Cubicle is designed to offer optimum protection for the samples and processes. Our Garment Storage Cubicle is manufactured as per the industrial standard to suit the varied customer’s demand. We provide the Garment Storage Cubicle in different sizes including SS 304 SS 316 SS 316l and CRCA powder coated. The Garment Storage Cubicle is equipped with a HEPA Filter to offer maximum prevention from contamination entering through the media of clothes. Type of Units : Vertical Garment Storage Cubicle Horizontal Garment Storage Cubicle Unit Description : Construction are stainless steel body or crca powder coated Differential pressure gauge Milky light Feather touch Heater Charcoal filters Ultra violate light Hour meter Glass stainless steel door Motor blower assemblies : 0.5 hp, ~230 v, 1 phase, 50 hz Hapa filters (final filter) : h13, efficiency 99.97% down to 0.3µ Prefilters : eu6, efficiency 95% down to 5µ

...more

Fume Hood

A Fume Hood or fume cupboard is a type of ventilation device that is designed to limit the user's exposure to hazardous or noxious fumes, vapors or dusts. A fume hood is typically a large piece of equipment enclosing five sides of a work area, the bottom of which is most commonly located at a standing work height. Fume hoods serve to control exposure to toxic, offensive or flammable vapors, gases and aerosols. Fume hoods are the primary method of exposure control in the laboratory. Fume Hood cabinet inside Negative pressure, there for control exposure to toxic, offensive or flammable vapors, gases and aerosols. Two main types exist, ducted and reticulating. The principle is the same for both types: air is drawn in from the front (open) side of the cabinet, and either expelled outside the building or made safe through filtration and fed back into the room. Fume Hood is available in, SS 304 / SS 316 / SS 316L, CRCA Powder coated. Unit Description Construction are Stainless Steel Body OR CRCA Powder coated Differential Pressure Gauge Milky White Light Feather Touch Motor Blower Assemblies : 0.5 HP, ~230 V, 1 phase, 50 Hz HAPA Filters (Final Filter) : H13, Efficiency 99.97% down to 0.3µ Exhaust HAPA Filters : H13, Efficiency 99.97% down to 0.3µ Prefilters : EU6, Efficiency 95% down to 5µ Ultra violate Light Hour Meter Sliding Glass Door Optional Accessories Stainless steel perforated grille for HEPA Filter Filter blocked alarms

...more

Dispensing Booth

Dispensing and Sampling Booth

Innovation is our forte and we strive to design and develop a precision engineered range of Dispensing and Sampling Booths. These dispensing and sampling booths are best suited for sampling, mixing, weighing and dispensing of powder. Additionally, the offered range is available in number of sizes with respect to the emerging requirements of clients. In the vertical reverse flow unit, the left behind dispersed particles are pulled or sucked towards the pre-filter.

...more

Air Shower

We are offering Air Shower, a self-contained air chamber installed at the entrance to clean rooms and other environments. Our Air Shower is equipped with adjustable nozzles that deliver a spray of HEPA-filtered air at approximately 6000 FPM offering a clean and controlled environment. The Air Shower can be installed in the ceiling or the opposing walls to remove any lint and dust from the surface of the garments entering through the room. Air shower is available in, SS 304 SS 316 SS 316l, CRCA powder coated variety. Unit Description : Construction: stainless steel body or CRCA powder coated View glass with door Air nozzle Electro magnet interlocking system Door closer Motor blower assemblies : 0.5 hp, ~230 v, 1 phase, 50 hz Hapa filters (final filter) : h13, efficiency 99.97% down to 0.3µ Prefilters : eu6, efficiency 95% down to 5µ

...more

Biological Safety Cabinet

When properly maintained and used in conjunction with good laboratory techniques, BSCs provide effective primary containment for work with human pathogens. In containment level 2 facilities, BSCs are used for procedures with the potential to produce infectious aerosols and for high concentrations or large volumes of infectious material. In containment levels 3 and 4, all open vessel activities with infectious materials are conducted in a BSC. Every employee working in a BSC must be trained in its correct use and have a good understanding of the different types of cabinets and how they work.Classes and Characteristics of Biological Safety CabinetsThere are three classes of BSC: Class I, Class II and Class III. Selection of the proper class of BSC requires careful evaluation of the activities to be carried out. Horizontal, clean benches that direct air towards the operator are not biological safety cabinets and must not be used for handling infectious, toxic or sensitizing materials.Class I Cabinets (Figures 1a and 1b)These cabinets have unrecirculated airflow away from the operator that is discharged to the atmosphere after filtration through a HEPA filter. They provide good operator protection but do not protect the material within the cabinet (the product) from contamination.Class II Cabinets (Figures 2-5)Class II cabinets are designed for personnel, product and environmental protection. They are designed for work involving microorganisms in containment levels 2, 3 and 4 laboratories and are divided into two types (A and B) on the basis of construction type, airflow velocities and patterns, and exhaust systems.Within type (A), there are two subtypes, A1 (formerly designated type A) and A2 (formerly designated type B3). Within type (B), there are two subtypes, B1 and B2. Class II cabinets are most commonly used in biomedical research laboratories because of their characteristics.Class II, Type A1 Cabinets (Figure 2)Cabinet air may be recirculated back into the laboratory or ducted out of the building by means of a "thimble" connection (i.e., a small opening around the cabinet exhaust filter housing) whereby the balance of the cabinet is not disturbed by fluctuations in the building exhaust system. The thimble must be designed to allow for proper certification of the cabinet (i.e., provide access to permit scan testing of the HEPA filter).Maintain a minimum average face velocity of 0.38 m/s (75 ft/min).May have positive pressure contaminated ducts and plenums. Are not suitable for work with low levels of volatile toxic chemicals and volatile radionuclides.Class II, Type A2 Cabinets (Figure 3) Cabinet air may be recirculated back into the laboratory or ducted out of the building by means of a "thimble" connection (i.e., a small opening around the cabinet exhaust filter housing) whereby the balance of the cabinet is not disturbed by fluctuations in the building exhaust system. The thimble must be designed to allow for proper certification of the cabinet (i.e., provide access to permit scan testing of the HEPA filter). Maintain a minimum average face velocity of 0.5 m/s (100 ft/min). Have ducts and plenums under negative pressure. Is suitable for work with minute quantities of volatile toxic chemicals and trace amounts of radionuclides. Class II, Type B1 Cabinets (Figure 4) Hard-ducted through a dedicated duct exhausted to the atmosphere after passage through a HEPA filter; contain negative pressure plena. Maintain a minimum average face velocity of 0.5 m/s (100 ft/min). Recirculate 30% of the air within the cabinet. Suitable for work with low levels of volatile toxic chemicals and trace amounts of radionuclides. Class II, Type B2 Cabinets (Figure 5) Does not recirculate air within the cabinet. Maintain a minimum average face velocity of 0.5 m/s (100 ft/min). Hard-ducted through a dedicated duct exhausted to the atmosphere, 100% of cabinet air, after passage through a HEPA filter; contain negative pressure plena. Suitable for work with volatile toxic chemicals and radionuclides. The exhaust canopy must allow for proper BSC certification. An alarm should be provided that is audible at the cabinet to indicate loss of exhaust flow from the building exhaust system. The cabinet internal fan should also be interlocked to shut down when the building exhaust system fan fails, to prevent pressurization of the cabinet.Class III Cabinets (Figure 6)Class III cabinets are totally enclosed and gas-tight with HEPA filtered supply and exhaust air. Work is performed with attached long-sleeved gloves. The cabinet is kept under negative pressure of at least 120 Pa (0.5 in. w.g.), and airflow is maintained by a dedicated exterior exhaust system. Class III cabinets protect the worker and the product. They are designed for work with level 4 pathogens and provide an alternative to the positive-pressure suit made for maximum containment laboratories. Cabinet lines consisting of several Class III cabinets (e.g., for centrifuges, animal cages, incubators, refrigerators) and transfer devices joined together are traditionally custom built. Specific guidance on the unique requirements for constructing, installing, certifying and using Class III cabinet lines can be found elsewhere. The exhaust air is double HEPA filtered or treated by HEPA filter and incineration. Removal of materials from the cabinet must be through a dunk tank, double door autoclave or air-lock pass-through for decontamination. Interlock or protocols must be used for the autoclave and pass-through doors to prevent both doors from being open at the same time. Use of the CabinetFollow these start-up procedures when preparing for work in the BSC : Turn off UV lights if in use and ensure that the sash is in the appropriate position. Turn on fluorescent light and cabinet blower, if off. Check the air intake and exhaust grilles for obstructions. If the cabinet is equipped with an alarm, test the alarm and switch it to the "on" position. Confirm inward airflow by holding a tissue at the middle of the edge of the viewing panel and ensuring that it is drawn in. Disinfect the interior surfaces with a suitable, noncorrosive disinfectant. Assemble all materials required for the procedure and load them into the cabinet; do not obstruct the air grilles; the working surface may be lined with absorbent paper with plastic backing; segregate "clean" items from "contaminated" items. Wait 5 minutes to purge airborne contaminants from the work area. Follow these procedures for working in the cabinet : Don protective clothing and gloves as appropriate. Perform operations as far to the rear of the work area as possible. Avoid movement of materials or excessive movement of hands and arms through the front access opening during use; when you do enter or exit the cabinet, do so from straight on; allow the cabinet to stabilize before resuming work. Keep discarded, contaminated material to the rear of the cabinet; do not discard materials in containers outside of the cabinet. Do not work with open flames inside the cabinet. If there is a spill during use, surface decontaminate all objects in the cabinet; disinfect the working area of the cabinet while it is still in operation (do not turn the cabinet off). Follow these procedures upon completion of the work : Allow the cabinet to run for 5 minutes with no activity. Close or cover open containers before removing them from the cabinet. Surface disinfect objects in contact with contaminated material before removal from the cabinet. Remove contaminated gloves and dispose of them as appropriate; wash hands. Don clean gloves, and ensure that all materials are placed into biohazard bags within the cabinet. Using a suitable non-corrosive disinfectant (e.g., 70% ethanol), disinfect interior surfaces of cabinet; periodically remove the work surface and disinfect the area beneath it (including the catch pan) and wipe the surface of the UV light with disinfectant. Turn off the fluorescent light and cabinet blower when appropriate (some cabinets must be left on at all times; if you are unsure, check with your cabinet certifier, safety officer or building maintenance personnel). Turn on the UV light if appropriate (do not turn on when people are working close by); UV must be tested to ensure that it is emitting a germicidal wavelength (ask your cabinet certifier to perform this test). Unit Description Construction are Stainless Steel Body OR CRCA Powder coated Differential Pressure Gauge Milky White Light Feather Touch Motor Blower Assemblies : 0.5 HP, ~230 V, 1 phase, 50 Hz HAPA Filters (Final Filter) : H13, Efficiency 99.97% down to 0.3µ Prefilters : EU6, Efficiency 95% down to 5µ OPTIONAL ACCESSORISE Stainless steel perforated grille for HEPA Filter Glove ports Filter blocked alarms Stands Hour meter Ultraviolet light Biological Safety Cabinet is with a variety of standard dimensions. Also our booth.

...more

Vertical Laminar Air Flow System

We manufacture, supply and export is fabricated using supreme quality materials. The Vertical Laminar Air Flow System Unit offered by us is widely demand owing to its high end performance and reliability. Moreover, reasonable price has been fixed for the Vertical Laminar Air Flow Unit.Specifications High product protection by provision of ISO Class 5 particle free work area Able enough to handle critical process Proven protection for the samples and processes The work area is continuously supplied with positive pressure HEPA filtered vertical air flow Vertical unidirectional airflow peed prevents contamination from operator and environment to work area. Laminarity of the flow handles cross contamination between the items in the working space. Made available in powder coated Mild Steel and SS 304 / SS 316/ SS 316L or a combination of both Two Stage filtration EU6 – Prefilter (95% down to 5 micron) EU14 - HEPA Filter – Supply (99.999% down to 0.3 micron) Dynamically balanced Motor-blower provided with suspension arrangement to minimize the noise level SS work table with due reinforcement Glass side panels Fluorescent Lights with Milky White Diffuser Differential Pressure Gauge : 1 No. On / Off Switch Clean Down Timer with Operation HOLD indicator DOP Test Port 5/15 Amp Switch Socket for external equipment Accessories Made Available Front doors (hinged/pneumatic cylinder) Night Mode Operation SS Air / Gas Cock U. V. Light with Hour Meter Velocity display with alarms (audible and visible) Filter blocked alarms (audible and visible) Explosion proof electrics for Flame-proof applications Audio / Visual alarm for blower tripping with Fault Acknowledgement & Reset Switch Photohelic Gauge with Audio / Visual Alarm in lieu of Magnehelic Gauge with High / Low Indicators Digital Pressure Gauge in lieu of Magnehelic Gauge On Line Velocity Indicator with Audio / Visual Alarm with High / Low Indicators Suitable for handling of non hazardous products Sensible to dust Susceptible to contamination where operator protection not necessary

...more

Sampling Booth

Be first to Rate

Rate ThisOpening Hours