Tablet Deduster

Get Price Quote

We at Das Electronics are involved in manufacturing and supplying a superlative range of tablet deduster in the market. The tablet deduster is a pharmaceutical processing equipment that removes the fine dust from the surface and edges of the tablets using the vibratory effect. Our tablet dedusters are duly tested on various parameters by our quality controllers. These devices are highly praised among the client base due to their smooth finish, robust designs, proper functioning, safe operation, and longer service life. Additionally, we ensure the delivery of the product in the promised time frame. Get in touch with us to avail these devices at industry leading prices.

Extruder Spheronizer

Get Price Quote

We have carved a distinct position in the market as a leading Manufacturer and Supplier of Extruder Spheronizer. Manufactured using superior grade raw materials, the Extruder Spheronizer we provide comply with set industry standard and specification. Extruder Spheronizer is used for driving and control the feeding system in processing equipment. Adding to this, we offer Extruder Spheronizer at market leading rates and within given period of time to our clients.

Best Deals from Pharmaceutical Machines

Octagonal Blender

1 - 1,000,000 Per Piece

1 Pieces (MOQ)

Design as per stringent cGMP requirements. Powerful reduction gearbox drive with coupling Safety guard. Available 5 Itr. to 2500 Itr. capacity. All contact parts SS 316 `A' type rigid machine structure with SS 304 cladding Electric control panel with cycle timer Option - bin loading and vacuum loading and unloading system.

pharmaceutical tray dryer

Get Price Quote

With the assistance of skilled professionals and high-grade packaging system, we can easily furnish customized packaging requirements of the customers. We are well supported by a team of experienced personnel who take care of the storage facility ensuring zero damage to the products till the final dispatch of the orders.

Rapid Mixer Granulator

Get Price Quote

High Shear Mixer Granulator has been developed for mixing of ingredients as well as wet granulation. The multi-bladed impeller is fitted close to the base of the mixing bowl whereas the chopper is mounted on the wall of the mixing bowl. Both the impeller & the chopper have dual-speed options for gently distributing the binder solution as it is added and creating the vortex of the material being mixed. STANDARD PROCESSING DURATION: Dry Mixing approx. 3 – 5 Mins. Wet Mixing approx. 5 – 10 Mins. Wet Granulation approx. 5 – 10 Mins. Discharge approx. 1 – 1.5 Mins. Granulator is designed to achieve all the requirements of cGMP – Current Good Manufacturing Practices. The components can be easily dismantled, cleaned thoroughly and assembled in quick time. The shaft seals are very effective to check any leakages and cross contamination due to adherents. The bowl and all the components are of highly polished Stainless Steel with smooth contours and is crevice free. SALIENT FEATURES: Uniform distribution of all formulation ingredients. Short mixing and granulation time. Useful working capacity of upto 80% to 40% of bowl volume. Uniform granules by gentle processing. Wide range of applications. Easy scale up & Scale down between machine sizes. Bowl shape designed to have no dead spaces. All Saizoner process advantages of Granules Manufacturing. Drying under vacuum, at lower temperature with solvent recovery system. CIP system included enhancing cGMP, reducing product change over time.

Containment Isolator

800,000 Per number

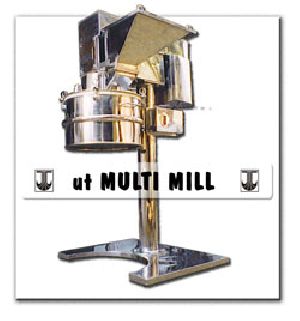

Multi Mill

Get Price Quote

Our products are packed under controlled conditions to ensure their quality is not compromised and buyers are presented with brand new products. We have an ultramodern facility to pack our products. With us, payment transactions will always remain secured, as we have adopted modern payment procedures that guarantee instant and hassle-free transactions.Salient Features : All contact parts are made out of SS 316 quality material. Machine rated for continuous operation. High output with process uniformity. Various combinations of screens / speeds / number of blades / direction of rotation blade, can be selected. All contact parts can easily be dismantled and cleaned for change of product. . Wide range of SS perforated and wire knitted screen available. Machine portable on castor wheels. Flame Proof electrical motor can be incorporated.

Octagonal Blender

Get Price Quote

We are a premier Pharmaceutical Octagonal Blender Exporter from Thane, Maharashtra. The Industrial Octagonal Blender we offer has proved its utility in pharmaceutical industries for bending of dry powders for capsules and bending of dried granules for tablets. Our Octagonal Blender is highly commended by our international clients from Middle East, Africa, Syria, Nigeria, and Malaysia for precise size of capsules and tablets it produces. Features All the contact parts made of SS 316 as per GMP standard. Zero retention design. Bump less rotation assured because of specially designed transmission chain sprocket. To enhance the mixing, baffles are provided on central shaft. Internal finish confirming 220 grits to 320 grits, outside mat finish180 grits. Discharge out put via. Butter fly valve. (Pneumatic discharge can be provided). Safety guards provided with limit switch interlocked to motor which ensures safe operation. Optional Accessories/ Attachments. Flame Proof Construction. PLC with MMI. VFD. Charging drum arrangement with Mechanical / hydraulic trolley Safe earthing system. Applications Blending of dry powders for capsules. Blending of dried granules for tablets. Documentation Documentation like DQ, IQ, OQ and FAT provided with the machine.

Pharmaceutical Machine Parts

Get Price Quote

We have hired team of professionals who make sure that the material, required for manufacturing products, is of high quality standards and sourced from the trusted places only. We ensure that the products will remain in a safe condition and for this; we have hired experts who keep a strict vigilance on the entire unit. Moreover, our unit is timely upgraded ensuring more safety.

Rapid Mixer Granulator

Get Price Quote

We, as a reputed Rapid Mixer Granulator Manufacturer, ensure excellent mixing and closed control of granules. These Rapid Mixer Granulators are known for offering high performance with low power consumption. Our Rapid Mixer Granulator is highly appreciated for its fast tabulating speed and least rejections. Rapid Mixer Granulators manufactured by us offer maximum CIP effectiveness and are available in wide range of capacities. Operation Rapid Mixer Granulator is designed to achieve excellent mixing and consistent granules at lower operating cost along with higher productivityBetter mixing and closed control of granule size leads to faster tabulating speeds with improved quality and least rejections Features Homogeneous binder distributionMaximum CIP effectivenessAll internal contact parts are polished to the mirror finishAll moving part of the machine are totally enclosed to eliminate accidentAll contact parts are made out of SS304. SS316 provided on demand at extra costShort batch time and reduced cleaning timeAir purge sealing system for main stirrer shaft and granulator shaftPLC based operating panel for precise control of process & automationA high-speed granulator is inserted horizontally through wall of bowl to assist blending of powder and to break the product to the granules of required sizeThe seal housing and drive shaft may be flushed with cleaning water, which is then drained away from the machine through built in drain tubesGranulator motor is provided with a removable Stainless Steel shroud which covers the motor and simplify cleaningThe machine cannot be started unless and until the mixer cover is properly closedFlush wall type discharge valve eliminates pockets at the port of discharge valve Availability Model available from 15 Liters to 600 Liters capacity gross capacity Optional Facility Available On Demand At Extra Cost Flameproof motors with flameproof operating panelWater jacketed product container with temperature sensor for productPneumatic system for opening and closing of the top lidA.C. frequency drive for speed variation of Main Motor & Granulator MotorDischarge provided on left or right side ( as per granulation room layout)to suit client's requirementIPC lifter or vacuum loading system for dust free material chargingGeneral Structure made out of completely from SS304 material instead of SS304 cladding on mild steel structureTri-clover ended connection on top cover for fitting of spray ball for inbuilt cleaningTri-clover ended connection on top cover for fitting of spray nozzle for spray of binders

multi purpose mill

Get Price Quote

Depending upon product (material density, nature, moisture content, weight & screen mesh size) Optional accessories / attachments Modified Straight Discharge Hopper (for maximum output rate of flow) Dusting arrangement for pulverizing of fine powder to avoid dusting in the air provided on Discharge Hopper with Perforated Bucket & Cloth S. S. Jacket on Intermediate Hopper with inlet, outlet & vent connections Recommended Spares S. S. Screen - 0.5 mm to 20 mm Special screens are available in # (mesh) in sandwich type Rubber gasket- charging & discharging hopper Teflon-ring / gasket SS Blades set - cutting / scraper / swing / pins / beater boss / beater cap SS Blade – Hexsaw type cutter to increase the fines of the powdero SS Beater / SS Shaft

capsule loader machine

107,000 Per Piece

Rapid Mixer Granulator

Get Price Quote

Upper Cam Plate Tablet Press

1,800 - 2,000 Per Piece

Vessels. Vibro separators

Get Price Quote

Vats & Vessels. Vibro separators are circular gyratory screens used to separate solids from solids and liquid from solidVibro Sifter consists of Specially Designed Motor mounted vertically at the center of the base plate of the Screen. The Screen is in between feeding hopper and bowl. The material is fed on to the centre of top screen. The undersize material passes rapidly through the screen during its travel to the periphery. The over size material get continuously discharged through a tangential outlet. This is achieved by specially designed Vibratory Motor along with eccentric Top and Bottom Weights. Working Principle The top weight on the motor shaft rotates in a plane close to the centre of the mass of assembly. Rotation of the top eccentric weights creates vibration in the horizontal plane which causes material to move across the screen cloth to periphery increasing the horizontal throw, causing oversize material to discharge at a faster rate. The bottom eccentric weight rotates below the centre of mass creating tilt on the screen giving vibration in vertical and tangential plane. Increasing the vertical component of motion, this promotes turn over of material on the screen surface helping maximum quantity of undersize material to pass through the screen. Rugged Springs placed over the circular motor base amplifies the vibration Special Features of Vats & Vessels Vibro Sifter Faster Separation due to springs Multi deck models available Same sieve as used in Mechanical sifter. Lesser Maintenance and Power Consumption than the Conventional Sifter. Simple & Compact construction.

Manual Capsule Filling Machine

Get Price Quote

The company is an eminent manual capsule filling machine 300 holes manufacturer, exporter, and supplier in india. Manual capsule filling machine 300 holes is a versatile capsule filling machine, suitable for all classes of pharmaceutical manufacturers. Additionally, manual capsule filling machine 300 holes has also established its value in the r & d section. The manual capsule filling machine 300 holes can be used in pharmaceutical companies, for smaller batches, trial, and as a standby. The manual capsule filling machine 300 holes is simple to operate, and gives negligible rejections, with no weight variations. operations fill loading tray with empty capsulesplace tray in bedoperate cam handle to separate capsules cap from bodyplace powder tray in position, fill with accurate quantity of powder and spread with scraperoperate pin plate to compress can and bodyremove tray and empty filled capsules model pt – 300ss/pt – 300 std – 300 holesthe ss- stainless steel model is fabricated completely form stainless steel 304 quality and non-contact parts are made out of non-corrosive metal duly plated or painted interchangeability interchangeable parts can be supplied for all standard sized capsulesrecommended interchangeability for optimum output i.e., 0/00-0/1/2/2-3/4/5 special features functional design for simplified operation – giving precise results with negligible rejection, sturdy, & easily movableeasily dismantled and reassembled even by unskilled laborall contact parts are of ss 304 quality and all other parts are hard chrome platedexcellent cost benefit ratio

Vibro Sifter

Get Price Quote

The company is the foremost Manufacturer and Supplier of Vibro Sifter, based in Maharashtra. Vibro Sifter is extensively used in Chemical, Pharmaceutical, Food and several other industries. Vibro Sifter is thoroughly examined by the quality auditors before the final delivery. Moreover, we hold expertise in bulk production of Vibro Sifter as per the requirement of the clients.

Hand Operated Capsule Filling Machine

Get Price Quote

Vial Washing Machin

Get Price Quote

Machine for Packing Tablet

Get Price Quote

Application: The Machine operates on the principle filling of volumetric dish counting system. It is suitable for automatic packaging of medicine & food stuff products such as Sugar Coat Tablet, Medicine Tablet, Chocolate Pill, Round Sugar Ball etc. Sealing Type : 3 side sealing / 4 side sealing / centre sealing Packing Size : 100mm - 280mm (film length) 200mm - 400mm (film width) (Enlarge type can be made upon order) Packing Range : 55gms - 35gms (Depending on specific gravity of material to be packed) Speed : 20 - 22 pouches / min. (Depending on flow rate & volume of the product) Packing Material : All heat sealable laminate PET/POLY, PET/FOIL/POLY MET, PET/POLY/CPP/OPP etc.

Gyro Vibratory Sieve Separator

Get Price Quote

Gyro Vibratory Sieve separators are self-contained, compact, production machines which make precise mechanical separations according to particle size through efficient use of multiplane inertial vibrations techniques. These sieve separator are designed and built to solve the most difficult classifying, separating and dewatering problems. Material to be screened is fed to the top screen. Oversize particles are moved by the multiplane motion to the screen periphery where it gets discharged. Undersize particle or liquid passes rapidly through the screen. Gyro Vibratory Sieve Separators are equipped to handle up to five screens. The 3 dimensional inertial vibration of Gyro Vibratory Sieve Separator is based on a principle in which motor rotation imparts vibration to an entire screen assembly in both vertical and horizontal planes. The top eccentric weight of the double extension shaft motor operates in a plane which is close to the center of the mass of the assembly. This generates a horizontal throw to the screen assembly. The bottom eccentric weight rotates below the center of mass, which creates a high frequency tilt on the screen. The third dimension is a tangentile component produced by the combination of the horizontal and vertical movements. The tangential components moves oversize material laterally across the screen while encouraging undersize particles to flow through the screen. Both top and bottom eccentric weights are independently variable of mass and angular relationship, giving a great degree of control over all vibration components. This results in the ability to obtain optimum conditions for screening nearly any material.

Double Sided Rotary Tablet Press

Get Price Quote

Tray Dryer

Get Price Quote

We are offering Tray Dryer at very market leading prices company.

stainless steel scoop

Get Price Quote

stainless steel scoop, pharmaceutical products, stainless steel locker

Pharmaceutical Blenders

Get Price Quote

Pharmaceutical Blenders, Octagonal Blender, Pharmaceutical Equipments

pharmaceuticals machinery

Get Price Quote

pharmaceuticals machinery, Ayurvedic Products, bakery, Confectionery Items

pharmaceutical injectable machinery

Get Price Quote

pharmaceutical injectable machinery, pharmaceutical capsule machinery

capsule sorting machine

Get Price Quote

capsule sorting machine

ALU-alu Blister Packing Machine Model -120

Get Price Quote

ALU-alu Blister Packing Machine Model -120, Metal Detector

pharmaceutical machines

Get Price Quote

pharmaceutical machines, Needle Valve, Sight Glass, Basket Type Strainers