vibro screening machine

Get Price Quote

1 Piece (MOQ)

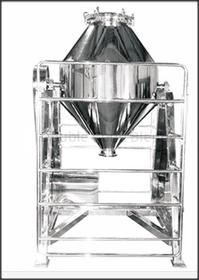

Double Cone Blender

Get Price Quote

1 Piece (MOQ)

Sparklex Machines Private Limited offers the best double Cone Blender Suppliers. Double cone blenders are quite useful in creating a homogenous mixture by mixing up two or more ingredients together. With so many industries looking after the needs of consumers, it is important to possess machinery that would be able to produce large quantities of products in a short period. One of the most important machines that are used quite frequently in the industry is a double-cone blender, which is manufactured by us at Sparklex Machines Private Limited. The lists of substances or materials that are mixed in this manner include: • Coffee beans and ground coffee and seeds • Semolina flour, starch and baby food • Pharmaceutical granules, detergent granules and chocolate granules or flakes • Dehydrated creams or soups • Powdered milk and soap flakes • Plastic in powder and fibreglass • Artificial Fertilizers Other than the aforementioned materials, there are even more substances that are used in creating homogenous mixtures. The use of this blender is most frequently seen in factories that produce products such as food, healthcare, chemicals, detergents, cosmetics, plastics and fertilizers. We take orders in bulk and deliver on time. Therefore order now.

Best Deals from Pharmaceutical Processing Equipment

Vibro Separator

100,000 - 10,000,000 Per Pcs

1 Pcs (MOQ)

Stainless Steel Vibro Sifter

60,000 - 180,000 Per Piece

1 Piece (MOQ)

Vibro Sifter Machine

75,000 Per Piece

1 Piece (MOQ)

Tablet Deduster

Get Price Quote

We at Das Electronics are involved in manufacturing and supplying a superlative range of tablet deduster in the market. The tablet deduster is a pharmaceutical processing equipment that removes the fine dust from the surface and edges of the tablets using the vibratory effect. Our tablet dedusters are duly tested on various parameters by our quality controllers. These devices are highly praised among the client base due to their smooth finish, robust designs, proper functioning, safe operation, and longer service life. Additionally, we ensure the delivery of the product in the promised time frame. Get in touch with us to avail these devices at industry leading prices.

Double Cone Blender

Get Price Quote

100 Piece (MOQ)

We are offering Double Cone Blender that are manufactured with great precision and expertise. These have a complex rugged structure and are highly efficient and durable. These are demanded in diverse industries for their high performance, no maintenance and high out put. All these blenders are manufactured keeping in mind the variegated requirements of customers. Furthermore, we customize these blenders as per the requirements of our clients.Salient Features : For Gentle and Diffusive Blending of Dense Powders suitable for Blending of Large Batch Volumes in a short time. Easy and dustless operation. Model available 25 kgs. to 500 kgs. cap. GMP/Flameproof/ SS 316 Construction on demand. Provided with inching arrangement and Limit switch on demand. Mucon/ butterfly valve provided for quick discharge for higher cap. Model. Steam Jacketed Model available on demand.

stainless steel scoop

Get Price Quote

Double Cone Blender

Get Price Quote

We make use of user-friendly interface that enables us to network and control the sorting, loading and unloading of all the finished products from a single location. By this, we make sure that the voluminous consignments are kept safely till the final send off. Consider our name for acquiring qualitative products in any quantity, safe and time-bound deliveries are what we ensure.Salient Features : The conical shape at both ends of Double Cone Blender enables uniform mixing and easy discharge. All contact parts are made out of stainless 304 or 316 quality material, as required by customer. Manual rotating facility with hand wheel for inching. Suitable size of butter fly valve at one end of the cone provided for material discharge & hole with openable cover provided at other end of the cone for material charging & cleaning. Worm reduction gear use for speed reduction. Capacity from 25 ltrs to 5000 ltrs.

Double Cone Blender

Get Price Quote

We are one of the leading manufacturers and suppliers of Double Cone blenders in Maharashtra. Double blenders are commonly used in the chemical, pharma and food industries, and can effectively mix all densities of dry powders and granules to a fine homogeneous mass, using low shearing force. The slant of the double cone prevents dead spots, which usually occur in other double cone blenders. Made of high quality steel and built in a way so as to enable safe operation, the container rotates at a speed of 8 RPM, and can be customized as per our client’s requirement. Construction And Operation The conical shape at both ends enables uniform mixing and easy discharge.All contact parts are made out of stainless 304 or 316 quality material, as required by customer. Maximum care has been taken to ensure safe operation of the unit.Manual rotating facility with hand wheel for inching.The same will be provided with ss cover & limit switch. ( In 200 Kgs. & above model ) Two nos. of safety road will be provided at back side. ( One LH side & one RH side ) Suitable size of butter fly valve at one end of the cone provided for material discharge & hole with openable cover provided at other end of the cone for material charging & cleaning.One shaft with 04 nos. of fixed buffels with mirror polished provided inside the cone.Cone will be mirror polished from the inside & outside & structure will be matt polished.All moving parts covered with SS304 covers. Safety guards made from SS304 pipes provided in front of the m/c with limit switch.Panel fabricated from SS304 material with facility of three phase indication, D.O.L. tarter, digital timer & Amp. Meter. As per customer requirement machine will be provided with left side drive or with right side drive.The conical shape at both ends enables uniform mixing and easy discharge. All contact parts are made out of SS304/316(as per customer requirement) quality material. Maximum care has been taken to ensure safe operation of the unit. Worm reduction gear use for speed reduction. Food grade rubber gasket will be used on both end of cone as well as in butterfly valve. Inside & outside of the cone will be polished to the mirror finished. General structure made out of SS304 and Polished to the matt / mirror finish (as required by you) in GMP Model. All safety guards & covers made out of SS304 in GMP Model. Hand wheel will be provided for manual tilting of cone.Safety guards provided with limit switch to not start the machine when safety guards are not in proper position. Salient Features : Design is cGMP - Current Good Manufacturing Practices compliance All Product contact parts AISI 316 & non contact parts AISI 304. Double Cone shape product container for Ideal dry mixer for lubrication of granules and homogenization mixing of multiple batches in to single batch. Available Capacity model in octagonal blender 25 kg to 2500 kg batch size.. Enclosed rigid drive with reduction gear box and motor. "A" type rigid structure of the machine with two sides resting of product container. Product container having discharge with butterfly valve and man hole. Charging hole with hinged lid with seal for charging and cleaning. The product container rotates on sped 8 RPM. Safety reeling provided for rotating area of product container. Fixed baffles provided for lumps braking. Electric controls panel with cycle time. Safety Features : Safety reeling with limit switch. Overload protection and emergency stop. Optional Features : Charging Option : Loading & Unloading by Product container with Jacking trolley. Vacuum conveying system. Bin loading by hydraulic hoist. Rotary Intensifier with AC variable drive. AC Frequency variable drive for product container. PLC Controls with HMI touch screen, Flame proof motor and Push Button station. Inline milling and loading with vacuum transfer systems. Applications of Double Blenders : Double Cone blenders can be designed to operate in both batch and continuous modes. Batch type blenders can be built up to capacities of 50 m3. The folloSFEg are the applications of the Blender : Blending large volumes of dry solids. Mixing of bulk drugs, chemicals, and cosmetic powders. Dry Blending of capsule formulations. Coating solid particles with small amounts of liquids to produce formulations. Materials commonly blended in the ribbon blender are as follows : Pesticides and herbicides Animal feeds Pet foods Pharmaceuticals Fertilizers Plastic powders Chemicals Spice blends Dietary supplements Dried food products

Vibro Sifter

Get Price Quote

Harnessing our experience in the industry, we take the responsibility to deliver utmost quality to the customers. As a Manufacturer and Supplier, we offer a range of Vibro Sifter. This range includes different specifications and customizations. Our team of expert professionals keeps quality on the top of our priority list. Lay your hands on it for economical rates. We provide an option to deliver for our customers.Vibro Sifter – Nishi Techno Sys Vibro Sifter are circular gyratory screens used to separate solids from solids and liquid from solid. Vibro Sifter consists of Specially Designed Motor mounted vertically at the center of the base plate of the Screen. The Screen is in between Top Spacing Frame and Base Tray ( Dome ). For efficient performance The material is fed on to the centre of top screen. The undersize material passes rapidly through the screen during its travel to the periphery. The over size material get continuously discharged through a tangential outlet. This is achieved by specially designed Vibratory Motor along with eccentric Top and Bottom Weights.

Tablet Metal Detector

Get Price Quote

Tablet metal detectors are widely used in the industry to detect presence of metal products nearby or in the item scanned. We offer a high quality Pharma tablet metal detectors which are extensively used for online inspection of Tablet, Capsules and separate Metal contaminated product without production disruption from a flow of tablets or capsules. Tablet Metal Detector provides highly accurate online metal detection which is widely used in various pharmaceutical industry. The tablet metal detector is manufactured from stainless steel through out to provide a hygienic and clean inspection. The product comes in different sizes and is customized to tailor needs and requirements of various customers.

Vibro Sifter

Get Price Quote

With our rich industry experience and knowledge, we are engaged in offering high quality Vibro Shifter. This Shifter is manufactured using supreme grade raw materials with the help of latest tools and technology. In order to ensure its quality, this Shifter is stringently tested on various parameters. We offer this product in various specifications as per the requirements of clients. Features : Corrosion resistance Compact design High durability Specifications: Model : 24/ 30/ 40" Drive Motor : 0.5/0.75/1.0 HP Screen diameter : 600/750/990 mm All contact parts are made out of SS304 quality material Output : 24 up to 150 Kgs./Hr, 30 : up to 200 Kgs./Hr, 40 : up to 300 Kgs./Hr Wide range of seats available in sizes from 4 mesh to 150 mesh

tablet compression machine

Get Price Quote

Reckoned for our extensive array of products, we efficiently serve our customers from Maharashtra(India). Engaged in the industry as a prominent Supplier of tablet compression machine, we present the finest range of products.

Vibro Sifter

Get Price Quote

Assistance of diligent professionals and modern packaging facility give our clients and us a win-win situation at the time of tailored packaging requirements. In order to settle the financial transaction with our clients through the transfer of monetary value, we offer diverse options including online and offline payment procedures. Features : Reliable Effective Find functionality Specifications : Possibility of multiple sieving Low energy consumption Easy dismantling and cleaning. High degree of surface finish. Dust proof sieve rack available on request. Additional spreader unit available (Optional) for increased performance. Mechanical Sifters are also available.

Stainless Steel Atta Scoop

Get Price Quote

Vibro Sifter

Get Price Quote

The clients can avail from us the Vibro Sifter Machines that are known for their robust construction, smooth operation and low maintenance cost. Available in different specifications, Vibro Sifter is suitable for various noiseless and maintenance free operations in varied industries. Even if a particle is small it would pass through a screen only if its configuration relating to the opening is favorable. Salient Features Noiseless, Maintenance free & high speeds Lower energy consumption compared to reciprocating vibratory system Standard machines are with TEFC motor All contact parts and screen of 316Q Stainless Steel material Available in two, three & four deck also Wide range of screen available sizes 4 - 600 mesh

Vibro Sifter

Get Price Quote

Double Cone Blender

Get Price Quote

We are the main supplier of this product.

Vibro Sifter

Get Price Quote

The Vibro Sifter offered by us is high class equipment that has a circular gyratory screen which is used to separate mass composition of solids from solids, liquid from solid and for gradation of materials as per particle sizes, having a very wide range of user friendly application. Our Vibro Sifter Machines are available with a wide range of possible screen size (mesh) options for multiple deck separation is also possible. The precision and easy operations of our product make us the best High Speed Vibro Sifter Exporter from Maharashtra, India. Features All contact parts made of SS 316 as per GMP standard Easy dismantling and cleaning Faster output at low power consumption High Degree of surface finish Double deck arrangement can be provided Safe earthing system Documentation Documentation like DQ, IQ, OQ and FAT provided with the machine.

Vibro Separator

Get Price Quote

Our Vibro Separators are designed to provide optimum performance. We Offers 6 different model Vibro Separator F-600, 750, 900, 1200, 1500, 1800 etc. And also we offered with MOC of SS-304, SS-316, SS316L, and Carbon Steel as per customer requirement. On Special request, MOC of non-ferrous can also be provided.

Double Cone Blender

Get Price Quote

GMP compliant contact parts manufactured in stainless steel. The “double cone” ensures good rolling and cross mixing. A-shaped frames provide stability of structure

Vibro shifter

Get Price Quote

Our comprehensive collection of Vibro Shifter is available in the market with multi-deck dust proof covers. Our products are fabricated using superior quality raw components and designed on the basis of clients' specifications. These products are used for sieving and screening of chemicals, cosmetics and pharmaceuticals. The principle of these products is vibrating, rotary and magnetic. Furthermore, we have made these products available in the market at very competitive prices.

Vibro Sifter

Get Price Quote

Vessels Double Cone Blenders

Get Price Quote

Vats & Vessels Double Cone Blenders are useful for Pharmaceutical, Food, Chemical and Cosmetic products etc Double Cone Blender is an efficient for mixing dry powder and granulates homogeneously. This is the ideal machine for gentle blending, capable of handling large volumes; easily cleaned. It is suitable for dense powders and abrasive materials. It is mounted on ‘A’ type stand with the help of Plummer blocks and suitable openings for discharge and charging are provided with lock nuts. All Vats & Vessels Double Cone Blender are custom designed and built to meet specific production requirements Special Features of Vats & Vessels Double Cone Blender The conical shape at both ends enables uniform mixing and easy discharge Maximum care has been taken ensure safe operation of the unit The cone is balanced to avoid excessive load, which increases the life of gear box and motor Depending upon the product, paddle types baffles can be provided on the shaft for better mixing Simplicity, Easy loading and unloading Minimal maintenance Constructed of 316 stainless, 304 stainless and carbon steel Capacity - 10 Ltr. to 5000 Ltr.

double cone blender machine

Get Price Quote

Compression Testing Machine

Get Price Quote

Compression Testing Machine 1000KN or 2000KN (100 Tons or 200 Tons) Capacity (Economy Channel Model) Hand Operated fitted with 15 cm dia load gauge. Designed for testing of Cement, Concrete Moulds of Various sizes 15cm x 15cm x cubes, 10cm x 10cm x cubes, 7.06 cm x 7.06 cm cubes, 15cm x 30cm cylindrical mould, bricks can also be tested by the help of adjustable hand wheel.

double cone blender machine

Get Price Quote

specifications double cone blender machine ideal for mixing of powder and homogeneous lubrication of granules powertech industrial equipments offer - double cone blender machine about powertech industrial equipments powertech industrial equipment, have brought in both experience and the requisite skills into the organization. Owing to the hard work and efforts put in by these professionals, powertech industrial equipment are able to design and develop a broad range of hydraulic products. Clients can contact us for availing double door autoclaves, lab autoclaves autoclave and steam sterilizer, beveling machine, condenser and boiler tube cleaners, tube installation tools, hydraulic cylinders, oil seal, bolting tools, silicon rubber sheet, rubber gasket, rubber sheet and steam sterilizer. In our product line, we also have hydraulic products like hydraulic nut sterilizer, hydraulic cnc chuck, hydraulic cylinders and hydraulic power packs. All these products are appreciated for features like sturdy built, compact design, anti-corrosive body and ease of installation and usage. Powertech industrial equipments also deals into: # machinery and accessories.

Vibro Sifter

Get Price Quote

Vibro Sifter works on gyro principle. The required gyratory motion is obtained from specially designed gyro motor, which is fitted underneath the vibrating assembly. The complete vibrating assembly is isolated from the base by means of specially designed rugged springs. Gyro-motor is fitted with top & bottom eccentric weights designed as per required centrifugal force.

Pharma Processing Equipments

Get Price Quote

Pharmaceutical & Food Grade Equipments We manufacture equipments to suit the requirements of Pharmaceutical & Food Processing Industries using Good Engineering Practices. Finish is the key element for this Industry and we ensure this key element is met with for all our supply. Other Equipments From Ball Mills to Screw Conveyors to Rotary Valves to Dosing Systems, everything requested we have made for our Clients. We expand our capability by achieving everything our Client entrusts us with in the form of their specific requirements.