Temperature Thermowell

Get Price Quote

Our Temperature Thermowell is custom built using high quality brass, MS, and stainless steel with NPT thread as per the set industry norms. Thermowell comes in a welded construction with parallel or tapered well, designed and built to suit the specific operational requirements of patrons. Thermowell can withstand high-pressure applications and is corrosion resistant.

stainless steel sight glass

Get Price Quote

Best Deals from Pipeline Accessories

Offset Strainer cum Air Eliminator

Get Price Quote

Strainer Cum Air Eliminator: Our company specializes in offering best quality range of Strainer Cum Air Eliminator (Offset & Line) to our prestigious clients. The provided eliminator is manufactured by our skilled professionals using the best grade raw material and modern technology. Available in 12", 3" & 4"

Thermowells

Get Price Quote

TBT Threaded Bar-stock Termowell Construction : Straight/ Tapper / Steeped Material : AISI 304SS/ 316SS / Monel / Brass Process Connection : 1/2" to 2" Immersion Length : 50mm to 1000mm TBF Bar-stock, Flanged Termowall Construction : Straight/ Tapper / Steeped Material : AISI 304SS/ AISI 316SS / Monel Process Connection : 1/2" to 4" Flanges sizes Immersion Length : 50mm to 1000mm TFS Socket Weld Termowall Construction : Straight/ Tapper / Steeped Material : AISI 304SS/ AISI 316SS / Monel Process Connection : 14mm to 56mm Immersion Length : 50mm to 300mm TFT Threaded Fabricated Termowall Construction : Straight Material : AISI 304SS/ AISI 316SS / Monel Process Connection : 1/2" to 2" Immersion Length : 50mm to 1000mm TFF Fabricated, Flanged Termowell Construction : Straight Material : AISI 304SS/ AISI 316SS / Monel Process Connection : 1/2" to 4" Flanges sizes Immersion Length : 50mm to 1000mm TBV Van-stone Termowall Construction : Straight / Tapper / Stepped Material : AISI 304SS/ AISI 316SS / Monel Process Connection : 3/4", 1-1/2", 2" RF diameter Immersion Length : 50mm to 1000mm

back up ring

Get Price Quote

Backup Rings prevent extrusion of O Rings In high pressures usually above 1500 PSI & compensate for loose fitting components. If only one backup ring is used, the O Ring should be placed between the pressure source & the backup ring. One backup ring should be used on each side of the O Ring in double acting assemblies if possible two backups should be used even in single acting assemblies.

back up ring

Get Price Quote

Backup Rings prevent extrusion of O Rings In high pressures usually above 1500 PSI & compensate for loose fitting components.If only one backup ring is used, the O Ring should be placed between the pressure source & the backup ring.One backup ring should be used on each side of the O Ring in double acting assemblies if possible two backups should be used even in single acting assemblies.

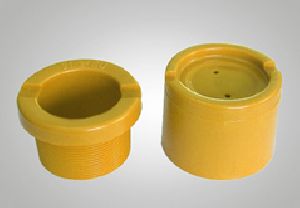

Plastic Thread Protector Tubing

Get Price Quote

We manufactures and supplies a wide range of Plastic Thread Protectors for Tubings. The standard sizes available are as follows, however we can manufacture protectors based on your special requirements.

Threaded Thermowell

Get Price Quote

Hammer Union

Get Price Quote

Hammer union,swivel joint, x -over, cross, tee, ell, pup joint, plug valve, plug valve repair kit, swages nipple for oil and gas industries,.

Anti Extrusion Back Up Rings

Get Price Quote

We are engaged in offering Anti Extrusion Back Up Rings, which are used for preventing the extrusion of O-Rings in high pressures (usually above 1500 PSI) and also for compensating for loose fitting components. Each Anti Extrusion Back Up Ring is used on each side of the O Ring in double acting assemblies, but if there is a possibility then two Anti Extrusion Back Up Rings should be used even in single acting assemblies. If a single Anti Extrusion Back Up Ring is used, the "O" Ring should be placed between the pressure source & the backup ring. Highlights : SturdinessDurabilityEasy installation Reasonable pricing Construction Materials : Anti Extrusion Back Up Rings are Manufactured from over 15 different Polymers which include : Nitrile (NBR)Fluorocarbon (Viton®)Silicon (VMQ)Fluorosilicone (FVMQ)PolyurethanePTFE (Teflon®)Natural Rubber (NR)Ethylene Propylene (EPDM)Hydrogenated Nitrile Rubber (H-NBR)Carboxylated Nitrile Rubber(X-NBR)Styrene Butadiene Rubber (SBR)Perfluoroelastomer (FFKM), Chloroprene (Neoprene®)

Hammer Union

Get Price Quote

FLAT BACK UP RING

Get Price Quote

FLAT BACK UP RING, X Rings, O RING CORDS, Rod Seals, Compact Piston Seals