pneumatic actuator ball valve

11,000 Per Piece

1 Piece (MOQ)

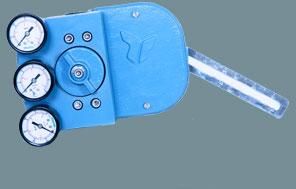

ELECTRO PVEUMATIC VALVE POSITIONER

14,000 - 35,000 Per piece

The Electro-Pneumatic Positioner YT-1000L is used for operation of pneumatic linear YT-1000R is used for operation of pneumatic rotary valve actuators by means of electrical controller or control system with an analog output signal of DC 4 to 20 mA or split Ranges.

Best Deals from Pneumatic Actuator

Ball Valve Pneumatic Actuator

Get Price Quote

1 Piece (MOQ)

ball valve pneumatic actuator are used in air, gas, chemical, water and in other industries. We manufacture, supply and export ball valve pneumatic actuator that are perfectly finished. Our ball valve pneumatic actuator are trunnion mounted and fe floating type. Moreover, these ball valve pneumatic actuator have high rating. features : design : ball valve pneumatic actuator fire safe blow out proof stem construction ball & trims : ss 304, 304l,316,316l,monel material : cs astm a 216 gr. Wcb, lcb, lcc, cf8, cf8 m etc. seat : ptfe, gft, cft rating : asa 150, 300, 600, 900, 1500, 2500 action : manual, lever, gear operated with pneumatic actuator ends conn. : flanged ends but weld mfg. : bs 5351/b16.34 /api 6d-iso 14313/ api 609/mss sp 72 port : full & reduce application : air, gas, water, chemicals, pharma, oil, acid, steam, foods, vacuum, heat treatment ,paper & sugar industries testing : api 598 / bs 6755

Electro Pneumatic Valve Positioner

Get Price Quote

Electro pneumatic is used for controlling movement of final control element such as Linear Cylinder, Diaphragm Control valve or Rotary actuator device which accept directly variable electronic signal & EP positioner is a precision with the help of auxiliary high pressure supply accurately controls movement of final control element corresponding to set point. No air consumption under balance condition hence saving of energy, Auto start fu, No air consumption under balance condition hence saving of energy, Unit can be modified for use with electrical actuator.

Pneumatic Actuator

Get Price Quote

Pneumatic Actuator, Ball Float Steam Trap, Pressure Seal Gate Valves

pneumatic rotary actuator

Get Price Quote

Actuator Body: Extruded Aluminium Alloy body is hard anodized to protect the internal and external components against corrosion, Special Honed Internal Surface reduces the friction on moving pistons and extends the life cycle of the actuators. Alternative coatings are available such as ENP (Electroless Nickle Plating), Fiber Powder Coated, PFA, ECTFE for more aggressive environments. End Caps: Diecasted aluminum end caps are primerely Alodine Chromatized coated which provides longer life cycles against corrosion and reduces wearing resistance. Secondary standard coating is powder polyester coating and also ENP, PFA, ECTFE etc coatings are offered alternatively for agressive environments. Pistons: Diecasted aluminum twin rack pistons are equipped with slide guides and seals in high engineered plastic. Alodine Chromatized coated pistons ensure longer life cycles against corrosion and wearing resistance. Pistons that are identical on both sides allow reverse rotation simply by inverting the pistons. Travel Adjustment: Bi-directional external travel stop adjustment bolts can adjust the position ± 5° between 85° to 95° at both opening and closing directions for accurate valve allignment. 0-90° full scale limit position adjustment can also be offered optionally. Pinion (Drive Shaft): Anti Blow Out proof alloy steel pinion is electroless nickel plated in order to reduce the friction, provide maximum wear resistance and protection against corrosion under severe conditions as it fully conforms to the latest standards of ISO5211, DIN3337,NAMUR. Double square, paralel or diagonal square or key way type shaft can be supplied in accordance with customer demands. Preloaded Springs: Modular Pre Loaded Spring Cartridge design in high grade coated steel springs provide great safety and corrosion resistance in fail safe and emergency shut down operations. Also these springs can be used for both high & Low Temperature applications. Position Indicator: All actuators are equipped with regular position indicator showing the current state of the actuators and valves. Top of Actuator has a NAMUR slot to engage with all popular sensors and positioners. Bearings: Low friction Bearing & guides provide high life cycle to ensure trouble free operations and stability during operation of actuators. Seals: NBR rubber O-rings provide trouble free operation at standard temperature ranges between -20 °C to +80 °C temperature ranges. For high and low temperature applications Viton (-20 °C ~ +150 °C) and Silicone (-35 °C ~ +80 °C) seals are available optionally. Fasteners: Stainless steel fasteners for long life corrosion resistant application. Traceability: Each Individual actuator is assigned an unique identification number allowing full traceability.

MASONEILAN POSITIONER

Get Price Quote

Description GE’s Masoneilan 4700P is a user friendly pneumatic Positioner that uses a precision feedback cam for accurate positioning, faster response, and customized control characteristics for control valves. These positioners can be used with either rotary or reciprocating actuators. The 4700P offers a multi-lobe cam, simple zero and span adjustments, corrosion resistant materials, fully enclosed and with FM, CSA, ATEX approvals. Mounting kits are available as standard for GE Masoneilan control valves as well as adaption for other control valve designs. The Masoneilan Model 4700 control valve positioners offer flexibility and consistency with modular design construction and corrosion resistant packaging. They can be configured either as a standard pneumatic valve positioner or as an electro-pneumatic device by simply assembling the separate I/P transducer module to the base pneumatic valve positioner. These instruments are for either reciprocating or rotary type valves, and are available in optional configurations for hazardous area applications. Features And Benefits Flexibility to use with either reciprocating or rotary control valves assists in optimizing process control performance through customizable cam characterization. Optional high capacity pneumatic bloc 4800 model for accurate positioning and fast response times on large size actuators. Rugged turnbuckle and lever assembly couples stem motion to the cam when mounting reciprocating actuators. Modular design construction makes it a simple and easy-to-maintain device, also easy to assemble, calibrate, and operate in many control applications. Configurable for direct or reverse operation utilizing the same mounting orientation.

Valve Positioner

Get Price Quote

RK VALVE POSITIONERS positions the Control Valve accurately with respect to the input signal from the controller, regardless of Packing box friction, actuator hysteresis or unbalanced forces on the valve plug. Thus, RK Valve Positioner ensures a reliable and accurate operation of Control Valve. Application : Accurate positioning of control valve in accordance with input signal Features: Minimizes the stem frictional force Fast response High accuracy & stability Based on pneumatic force - balance principle Employs a sensitive bellows Adjustable stroke range upto 4" provides flexibility to use with any actuator Direct and Reverse action option VP5 model can be used for rotary movement 60°/90° VP5 model can be used for double acting actuators Stainless steel version available in VP5 model Responds to extremely small changes in control signal Reduces time lag of the signal from the controller to the valve Useful for operating actuators with spring range higher than the control signal range, thereby reducing actuator size Permits split range operation of control valves Specifications : Input Signal 3 to 15 psig or 0.2 - 1.0 kg / cm2g as standard, split range available on request

Pneumatic valve positioner

Get Price Quote

The PNEUCON PNEUMATIC VALVE POSITIONER is an instrument working on force balance principle to position the Control Valve stem in accordance to a pneumatic signal received from a controller or manual loading station, regardless of packing box friction, actuator hysteresis or unbalanced forces on the valve plug. Thus, the positioner ensures a reliable and accurate operation of Control Valve. NON-STANDARD CONTROLLER OUTPUT : The positioner is used to operate a valve with 3-15 psi spring range when controller signal is other than 3 –15 psi. NON-STANDARD ACTUATOR SPRING RANGE : The positioner is used to operate valves Having non standard actuator spring ranges by controllers having the standard 3-15 psi Signal pressure. REMOTE VALVE LOCATION : When air operated control valves are located far from control Instrument, positioners will reduce lag, thereby speeding up valve operation. SPLIT RANGE : Some processes require the dual or sequential operation of two to three Control valves by a single controller with a 3-15 psi output signal range.

pneumatic positioners

Get Price Quote

Tecnik's Pneumatic Positioners are available as single or double acting, force-balanced instruments that provide fast, sensitive and accurate positioning of diaphragm or cylinder actuators. Designed for high performance these Positioners are compact, field-reversible and ruggedly built for reliability in severe industrial environments.

rotary actuator

Get Price Quote

rotary actuator, pneumatic diaphragm control valves

Pneumatic Actuator

Get Price Quote

Pneumatic Actuator, steam utilization products, Pneumatic Equipments

Electro Pneumatic Valve Positioner

Get Price Quote

Electro Pneumatic Valve Positioner, industrial globe valves

Rack And Pinion Actuators

Get Price Quote

Rack And Pinion Actuators, Gas Over Oil Control Cabinet Valve

Actuator for Rotary Valves

Get Price Quote

Actuator for Rotary Valves, Biometric Access Control Systems