polypropylene chemical process pump

10,000 - 12,000 Per Piece

1 Piece (MOQ)

Dewatering Submersible Pump

Get Price Quote

1 Piece (MOQ)

Best Deals from Process Pumps

Coolant Pump

Get Price Quote

Hydrocarbon Processing pump

Get Price Quote

SSR Series Chemical Process Pump

Get Price Quote

1 Piece (MOQ)

Air Operated Double Diaphragm Pump

14,500 - 175,000 Per Piece

1 Piece (MOQ)

Pvdf Pumps

Get Price Quote

The Fluorinated Polymer are widely appreciated for their remarkable chemical inertness and their excellent resistance to ageing. POLYVINYLIDENE FLUORIDE (PVDF) offers the specific advantage of easy processing in accordance with all the convection methods used in the plastic industry. PVDF, polymerized, according to its own special process, offers a high degree of crystallinity to that by other processes, resulting among other things, in superior thermomechanical properties. The intrinsic technical superiority is one of the reasons for the success which PVDF has achieved on the world market for more than 20 years. Easy processing by : extrusion, injection, compression, rotational moulding, blow moulding etc. Chemically inert to most acids, aliphatic and aromatic organic solvents, alcohals etc. Very high purity. Excellent mechanical properties over a wide range of temperatures : tensile yield strength up to 55 MPa at 23°C and 10 MPa at 150°C. Abrasion resistance comparable to that of polyamides, and relatively low coefficient of friction. Continuous use at temperatures as high as 150°C for the homopolymer grades (without mechanical stress). Excellent thermal aging resistance : tensile yield strength retention over 90% after 25,000 hours at 150°C in a ventilated oven. Unaffected by UV (>232nm) and good resistance to gamma radiation. Excellent intrinsic fire resistance. Very easily joined by welding and good capability for thermoforming. Physiologically harmless and approved for contact with food products (FDA).

Air Operated Double Diaphragm Pump

Get Price Quote

1 Bag(s) (MOQ)

max flow rate : 23lpm (6gpm)port size : inlet: 12.70mm (1/2" bsp)discharge: 12.70mm (1/2" bsp)air inlet: 6.35mm (1/4" bsp)air exhaust: 12.70mm (1/2" bsp)suction lift : dry: 1.45m (4.75') wet: 2.83m (9.28')teflon : dry: 0.05m (1.64') wet: 0.90m (2.95')max particle size (dia) : 2mm (0.078").

Dewatering Pump

16,000 - 55,000 Per piece

1 Piece (MOQ)

Air Operated Double Diaphragm Pump

Get Price Quote

We are the main supplier of this product.

Water Circulating Pump

Get Price Quote

Grundfos in India - What began as a liaison office for Grundfos Gulf Distribution in Mumbai in 1997, Grundfos India has expanded by leaps and bounds with a Head office, Warehouse and Service-cum-Training centre in Chennai and 10 regional offices at Mumbai, Delhi, Bangalore, Kolkata, Hyderabad, Cochin, Pune, Ahmedabad, Nagpur and Vizag.

Dewatering Pump

30,000 - 31,000 Per Piece

Fluorin Plastic Single-stage Centrifugal Pump

Get Price Quote

Applications Alkali making industry Colored metallurgy Acid making industry Synthetic fibre & plastic industry Paper making Fertilizer industry Pharmacy Environmental protection Petrolic chemical Standard material F24 or F46, HT200 Description: Simple structure, Non-corrosive MOC, Suitable for wide range of corrosive liquids

Manual Bilge Pump

2,000 Per Piece

01 Piece (MOQ)

Laboratory Models Liquid Ring Vacuum Pumps

Get Price Quote

We offer Laboratory Models Liquid Ring Vacuum Pumps. HTC Liquid Ring Vacuum Pumps are positive displacement pumps of simple and robust monoblock direct driven design. HTC offer these small, compact, single stage liquid ring vacuum pumps of this design have the following important features: HTC Pumps are supplied ready for connection. Installation of separate motors and bed plates is eliminated. Compact design ensures that a minimum of space is requires. Pumps require a minimum of maintenance. Low noise and vibration levels. Virtually isothermal compression. Can be used for dry gases or for vapors. Limited quantities of liquid can be handled in addition to the gas or vapor being pumped. Service liquids other than water can be used. Thus, the service liquid can be chosen so that it is compatible with the process gas or vapor.

Process Pumps

Get Price Quote

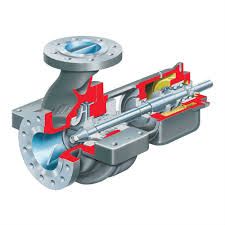

Chemical Process Pumps

Get Price Quote

Leveraging on our expertise, we manufacture and fabricate quality Chemical Process Pumps. Our range of pumps find a wide application in chemicals, petrochemicals, fertilizers, oil refineries, paper mills, sugar mills, dairy, pesticides, pharmaceutical industries and steel plants. Apart from manufacturing, we also provide fabrication services to our clients. Depending on the nature of the liquid to be handled, we accordingly seal and pack the product. Our range of chemical pumps are widely known for high performance and reliability. Chemical Process Pumps ( Series FCP-R ) We hold expertise in providing a wide assortment of Chemical Process Pumps, which is manufactured using high-grade C.I., C.S., S.S. 304, SS 316, SS316L, Alloy 20, Hast-alloy monel and Ni-hard. It is considered ideal to be used for all chemicals, acids, alkalies, corrosive slurries, solvents and hydrocarbons. Our range of Chemical Process Pumps meets the application requirements of numerous industries and possesses the following specifications: Capacity : Up to 800 m3/hr. Head : Up to 230 mtrs. Temperature : Up to 2600C Working Pressure : Up to 26kg/cm2 Speed : Up to 3000 rpm Shaft Sealing : Gland / mech. seal Enlisted below are the quality attributes of our range: Designed as per ANSI D73.1 1974 Horizontal centrifugal back pull out type Single stage, end suction, top centerline discharge Covers a large range of 32 sizes with interchangeable mounting dimensions Easy to facilitate installation, maintenance and maximum dimensional interchangeability Minimize spares inventory Designed as sturdy, reliable and trouble free equipment for handling even hard to handle corrosive liquids and slurries Bearing housing cooling jacket, a integral part of design Reliable various mechanical seal options, mountings and flushing plants for clear liquids or even slurries Give zero leakage and prolong life of seals

Circulating Pump

Get Price Quote

Coolant Pump

Get Price Quote

Evaporator Pumps

Get Price Quote

Evaporator is a device used for efficient and gentle removal of solvents from samples by evaporation. Vacuum evaporation is a classic function because of lower pressure which in turn lowers the boiling point of liquids and helps in faster solvent removal. Liquid solvents which are often complex and sensitive solvent solute combination can be removed without excessive heating. Solvents with higher boiling point such as water, DMF, can also be evaporated with sufficient low pressure. AD2C is powerful and efficient Diaphragm Vacuum Pump which is instrumental in creating the lower pressure. Under lower pressure the evaporation is faster which needs to be condensed with chilled media. RTo8025 is an efficient Chiller which helps in 95% recovery of the solvents which are being evaporated. ...stands for an overheat protection design that prevents water baths running dry, provides a detachable cable for superior ease of use. Offers a proven vacuum seal and vapor tube system guaranteed for years of operation.