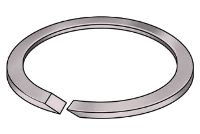

Laminar Retaining Ring

10 - 20 Per Piece

1000 Piece (MOQ)

Spiral Retaining Rings

280 Per Piece

Purchasers can rely on us to make on time distribution of orders, as we have cooperated with established transportation facility providers. We cater to the personalized packaging requirements of the clients. We make use of premium packing material for ensuring safety of the products during handling, warehousing and transportation. Features : Supreme quality Corrosion resistant Easy to handle Specifications : Material - Carbon EN 42, High Carbon EN 47, S.S. 304, S.S 316, S.S 316L and other Specific metal as per requirement Size - Customized

Best Deals from Retaining Ring

Circlips & Retaining Rings

Get Price Quote

At Intact360, we manufacture wide range of Internal Circlips & External Circlips as per customer requirements and Industry Standards. Types of Circlips & Retaining Rings: Circlips/ Retaining Rings for Shafts - DIN 471 Circlips/ Retaining Rings for Bores - DIN 472 Adjusting Ring/ Shaft Collars Set Screw- DIN 705 External Circlips AK Type - DIN 983 Internal Circlips BK Type - DIN 984 E Type Circlips - DIN 6799 VA Ring for Shaft - DIN 5108 VB Ring for Bore - DIN 5008 External Snap Ring - DIN 7993 Part A External Snap Ring - DIN 5417 B Internal Snap Ring - DIN 7993 B External Snap Ring - DIN 5417

Medium & Heavy Duty Rings

Get Price Quote

100 Piece (MOQ)

Driven by technical excellence, we International Industrial Springs are counted as the reputed manufacturer and exporter of excellent quality Medium and Heavy Duty Ring.This is manufactured under the direction of our ingenious experts by utilizing the best quality material with the help of pioneered technology. It is ideal for high-pressure but low-volume blowers in metal, chemical and plastic industries. In addition, the provided medium and Heavy Duty Ring can be customized to countless specifications according to the desired need of clients. Features of Medium And Heavy Duty Ring Smooth functioning Impeccable performance Longer functional life As Per Client Specifications Choose us and order our products as we are the best Heavy Duty Rings supplier in India.

Graphite Die Molded Rings

Get Price Quote

Retaining Ring

Get Price Quote

We design and manufacture a wide range of snap rings. Snap rings required for securing bearing with ring groove.The purpose of the slot in the pins is to allow compression when inserted in the hole.

Retaining Ring

Get Price Quote

We at Accurate Springs have mastered the art of manufacturing Retaining Rings. Retaining Rings is often an alternative means of sealing components in assemblies from contamination. We at Accurate Springs have mastered the art of manufacturing Retaining Rings. Retaining Rings is often an alternative means of sealing components in assemblies from contamination. Since they are produced from metal {not rubber, or other non metallic material} retaining rings can often withstand higher temperature and more corrosive environments and other more extreme conditions than common O-Rings or conventional rubber seals. This is the primary reason why design engineers prefer retaining rings in many applications. Retaining rings offer higher clamping force when installed in the bore or on the shaft and are suited for higher operating speeds having 3600 [no axle gap} contact. One typical application is where high amount of dirt and dust are present and the ring sets provide the necessary seal against contamination from outside elements. Retaining rings are also used to protect contacting radial seals, rubber seals, o-rings and other oil seals. Retaining ring can be manufactured from spring steel flat wires and stainless steel flat wire. Many years of experience in making retaining rings has helped accurate springs to become a reliable supplier of quality retaining rings.

back up ring

Get Price Quote

Backup Rings prevent extrusion of O Rings In high pressures usually above 1500 PSI & compensate for loose fitting components.If only one backup ring is used, the O Ring should be placed between the pressure source & the backup ring.One backup ring should be used on each side of the O Ring in double acting assemblies if possible two backups should be used even in single acting assemblies.

Self Locking Retaining Rings

Get Price Quote

The company is engaged in manufacturing, supplying, and exporting the premium quality Self-Locking Retaining Rings. Our Self-Locking Retaining Ring is the fastener that holds components or assemblies onto a shaft or in a housingbore when installed in a groove. Once these Self-Locking Retaining Rings are installed, the exposed portion acts as a shoulder which retains the specific component or assembly. Self-Locking Retaining Rings may be installed in applications where no groove exists. Self-Locking Retaining Rings are typically made from carbon steel, stainless steel or beryllium copper and may feature a variety of finishes for corrosion protection depending on the type of environment in which they are used.Highlights Superior quality Accurate dimension Corrosion resistance Light weight

back up ring

Get Price Quote

Backup Rings prevent extrusion of O Rings In high pressures usually above 1500 PSI & compensate for loose fitting components. If only one backup ring is used, the O Ring should be placed between the pressure source & the backup ring. One backup ring should be used on each side of the O Ring in double acting assemblies if possible two backups should be used even in single acting assemblies.

Retaining Ring

1 Per Piece

Retaining Rings

Get Price Quote

We are one of the famous company, who are manufacturer of retaining rings.

Retaining Rings

Get Price Quote

Retaining Rings, precision metal stampings, Springs, Disc Springs

Anti Extrusion Back Up Rings

Get Price Quote

We are engaged in offering Anti Extrusion Back Up Rings, which are used for preventing the extrusion of O-Rings in high pressures (usually above 1500 PSI) and also for compensating for loose fitting components. Each Anti Extrusion Back Up Ring is used on each side of the O Ring in double acting assemblies, but if there is a possibility then two Anti Extrusion Back Up Rings should be used even in single acting assemblies. If a single Anti Extrusion Back Up Ring is used, the "O" Ring should be placed between the pressure source & the backup ring. Highlights : SturdinessDurabilityEasy installation Reasonable pricing Construction Materials : Anti Extrusion Back Up Rings are Manufactured from over 15 different Polymers which include : Nitrile (NBR)Fluorocarbon (Viton®)Silicon (VMQ)Fluorosilicone (FVMQ)PolyurethanePTFE (Teflon®)Natural Rubber (NR)Ethylene Propylene (EPDM)Hydrogenated Nitrile Rubber (H-NBR)Carboxylated Nitrile Rubber(X-NBR)Styrene Butadiene Rubber (SBR)Perfluoroelastomer (FFKM), Chloroprene (Neoprene®)

Self Locking Retaining Rings

Get Price Quote

Self Locking Retaining Rings, Compression Springs, Wire Form Springs

FLAT BACK UP RING

Get Price Quote

FLAT BACK UP RING, X Rings, O RING CORDS, Rod Seals, Compact Piston Seals