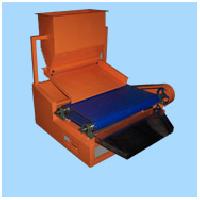

vibro destoner

We are one of the manufacturer, exporter & supplier of a wide range of Destoner and have carved a niche for ourselves in this product category. Debris like glass, stones and metal are effectively separated. These are manufactured using heavy gauge steel and are driven by a unique eccentric drive whose innovative mechanism results in years of trouble-free operation. We provide destoners in four sizes with various types of deck configurations and other types of tailor made destoners to fulfill specific customer needs. These specially designed customized destoners fall in our product line up of intermediate range engineering equipments, recently we have include a new product destoner, in a bid to be a one stop shop for getting all kinds of mid level engineering equipments. These are fabricated keeping the smallest detail in mind to ensure high performance of the equipments to the end user. Each spare part of the equipments is accurately tested and grounded and is in high demand owing to their exquisite finish and elegant design. It is mostly used in food processing industries for separating heavier materials such as stones, glass, and metal from food grains and other dry granular material. It has various features like time saving, high productivity, easy to operate and efficient.

...more

Vibratory Screen Separator

Screen Separator is a unique particle size gradable separator designed for greater capacity per meter square of screening area & over size material discharge with relatively much less percentage fines than other screening machines. Our company has ACED in manufacturing and supplying a vast variety of screen separator to various industries across the country. We offer horizontal screen separator and circular screen separator which come with many special features. Our screen separator is known for their high performance, innovative designs, and affordable prices making them extremely popular among customers. The motivation is through a unbalanced motor with a double extended shaft, fitted at both ends with eccentric weights .The top weight on the motor shaft rotates in a plane close to the center of the mass of assembly. Rotation of the top eccentric weights creates vibration in the horizontal plane, which causes material to move across the screen cloth to periphery increasing the horizontal throw, causing oversize material to discharge at a faster rate. The bottom eccentric weight rotates below the center of mass creating tilt on the screen giving vibration in vertical and tangential plane. Increasing the vertical component of motion, this promotes turnover of material on the screen surface helping maximum quantity of under size material to pass through the screen. Rugged Springs placed over the circular motor base amplifies the vibration.

...more

Vibratory Motor

A new range of Unbalanced Vibratory Motor from 0.09 kw to 10 kw and Centrifugal Force up to 1,00,000 N. The Vibrating Motors are manufactured in 2 poles – 4 pole and 6 pole designs. Confirming to I.S. specification. These vibro motors are being manufactured by SAIDEEP and sold all over the globe.

...more

Vibratory Feeder

We are offering vibratory feeder. Principle of operation the electromagnetic vibratory feeder consists of a tray made of mild steel and a body housing the electromagnet. The tray which is connected to the armature of the magnet vibrates as the magnet gets energised. The vibration sets the material in motion. Controlling of vibration gives the controlled flow of the material. The body housing the electromagnet is made in totally enclosed design to prevent dusting.

...more

Vibratory Conveyor

The motorised vibratory conveyor consists of a horizontal tray made of mild steel or stainless steel. The horizontal tray is fixed to the frame, The vibrations are provided by two special unbalance motors fixed on either sides of the tray. The complete assembly of tray with motors rest on a set of coil springs so that, no vibrations are transmitted to the stand and ground. As the Motor starts, the vibration sets in motion. Controlling of vibrations gives the controlled flow of the material. The housing of the motor is in totally enclosed design to prevent dusting. The motor operates at 400440v 3phase A.C. system at 1440 RPM. Motorised vibrating conveyor can be supplied in different capacities depending up on type of the material required to be handled.

...more

Vibrator Sand Screening Machine

Unbalanced Vibratory Motor from 0.09 kw to 10 kw and Centrifugal Force up to 1,00,000 N. The Vibrating Motors are manufactured in 2 poles – 4 pole and 6 pole designs. Confirming to I.S. specification. These vibro motors are being manufactuVibrator Motors can be used as flow aids, on screens, hoppers or silos to improve material discharge, or as drives on vibrating machines for several purposes such as conveying, screening, sizing, or compacting in a variety of industries. Vibratory Table, Rectangular Vibro Screen, De-Stoners , Rice Mill Machinery, Spiral Elevators, Agricultural Machinery, Bins & Silos, Vibrating Feeders, Pharma Equipments, Mining Machinery etc.Centrifugal force: 20 ~ 26,000 kg, acuum-impregnated windings using Class F insulating materials, Premium quality bearings, Highly Efficient & Low Maintenance, Adjustable Vibrations.

...more

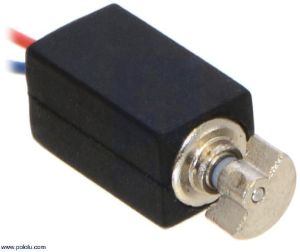

Vibration motor

Unbalanced Vibratory Motor from 0.09 kw to 10 kw and Centrifugal Force up to 1,00,000 N. The Vibrating Motors are manufactured in 2 poles 4 pole and 6 pole designs. Confirming to I.S. specification. These vibro motors are being manufactured by SAIDEEP and sold all over the globe. Vibrator Motors can be used as flow aids, on screens, hoppers or silos to improve material discharge, or as drives on vibrating machines for several purposes such as conveying, screening, sizing, or compacting in a variety of industries.

...more

Vibrating Screen

We are offering vibrating screen. “saideep” has come out with a most advance design of screens for grading of fine, wet and difficult to screen materials. The vibrating screen works on the principle of gyratory motion. The unique features of this type of sieve is its high capacity using minimum space and less power. The vibrating screen has specially designed multi-directional vibration system which prevents blinding of sieves. The material to be screened is fed from the top and collected simultaneously from outlets of different decks. These vibrating screen can handle wide range of materials such as heavy, light, dry, wet, coarse or fine. The company manufactures various sizes to suit individual requirement in m s and s s construction.

...more

Vibrating Conveyors

Vibrating Conveyor

The motorised vibratory conveyor consists of a horizontal tray made of mild steel or stainless steel. The horizontal tray is fixed to the frame, The vibrations are provided by two special unbalance motors fixed on either sides of the tray. The complete assembly of tray with motors rest on a set of coil springs so that, no vibrations are transmitted to the stand and ground. As the Motor starts, the vibration sets in motion. Controlling of vibrations gives the controlled flow of the material. The housing of the motor is in totally enclosed design to prevent dusting. The motor operates at 400440v 3phase A.C. system at 1440 RPM.

...more

Unbalance Vibro Motor

Turbine Vibrators

Turbine Type Pneumatic Vibrator (SPGT) Emptying of bunkers,Screen filters,Vibrating tables,Preventing adhesions in pipelines and silos, Transporting of fine powders, Moving of bulk material.

...more

Suspension Magnet

we offer Suspension Magnets and Over band Magnetic Separator are back bone of continuous process industry. The permanent magnetic suspension magnets are suspended over conveyor line and are used to remove iron impurities mixed with product moving on conveyor belt. It can also be used for any other material feeding system to avoid damage to the crushers, grinders and other material handling equipments. These magnets can be made in self-cleaning design if required (Over band Magnetic Separator).

...more

Sand Vibrator

Rectangular Vibrating Screens are equipped with two vibrating motors rotating in opposite directions. This dual motor configuration causes the screens frame to vibrate in a linear or straight-line motion perpendicular to the plane of the motors. This result in excellent forward conveyance of oversize particles , even when the screens frame is in an uphill position. Depending upon the application, the Rectangular screens frame can be position at various degrees downhill. Maximum capacity is achieved in the uphill position, causing the formation of a pool at the feed end of the machine. The head or pressure from the pool increase fluid throughout. The horizontal vibrating screens of the screens frame efficiently conveys the oversize particles out of the pool area where they are then discharged.Rectangular vibrating screens offer a highly efficient approach to screening. This single development has resulted in tremendous advantages as far as reduced maintenance, compactness and simplicity are concerned. Besides the simplicity of the drive, many other features have been incorporated to provide a machine which is specifically designed for heavy duty applications, long life, and low operating and maintenance costs, at a competitive price. The standard range of screens is presented later in the brochure, and these are normally available on short delivery

...more

roll feeder

Vibration has been very fascinating subject for man since ancient times. With the advent of new technologies, man has mastered the art of creating and controlling vibrations. In our design of the bowl feeder, the vibrations are created in spiral fashion so that, the components placed on the bowl which is fixed to the vibrating unit start moving round and round. The bowl being custom built for the perticular component, has a peculiar geometry. As component moves round and round up the track till it gets oriented and comes out in the desired form. This process of orienting is very useful on assembly line and packing operations, as no manual labour is employed for feeding of components.

...more

Rectangular Vibrating Screen

Rectangular vibrating screens offer a highly efficient approach to screening. This single development has resulted in tremendous advantages as far as reduced maintenance, compactness and simplicity are concerned. Besides the simplicity of the drive, many other features have been incorporated to provide a machine which is specifically designed for heavy duty applications, long life, and low operating and maintenance costs, at a competitive price. The standard range of screens is presented later in the brochure, and these are normally available on short delivery. Vibrating Screens are equipped with two vibrating motors rotating in opposite directions. This dual motor configuration causes the screens frame to vibrate in a linear or straight-line motion perpendicular to the plane of the motors. This result in excellent forward conveyance of oversize particles , even when the screens frame is in an uphill position. Depending upon the application, the Rectangular screens frame can be position at various degrees downhill. Maximum capacity is achieved in the uphill position, causing the formation of a pool at the feed end of the machine. The head or pressure from the pool increase fluid throughout. The horizontal vibrating screens of the screens frame efficiently conveys the oversize particles out of the pool area where they are then discharged.

...more

Pneumatic Vibrators

Due to their characteristics, many powders inside silos, hoppers, chutes, piping, tanks or any other container will tend to stick to the surface. Any small change in the opening of the outlet,a rough surface, bends, shallow angles, the shape of the container, as well as the particle shape of the material handled might slow down the flow of the product, thus generating waste. Pneumatic Vibrators are designed to solve issues caused by design errors or by the characteristics of the powder or granules handled. Moreover, they increase process efficiency and improve plant safety.

...more

Permanent Suspension Magnet

The permanent magnetic suspension magnets are suspended over conveyor line and are used to remove iron impurities mixed with product moving on conveyor belt. It can also be used for any other material feeding system to avoid damage to the crushers, grinders and other material handling equipments. These magnets can be made in self-cleaning design if required (Over band Magnetic Separator). Over band Magnetic Separator are self-cleaning units where the iron pieces attracted are thrown off and collected separately automatically with the help of cross belt.he design of magnet depends on the feed material, size and feed depth. The design also depends on width and speed of your belt conveyor. Suspension Magnet, Over band Magnet can be introduced in existing system. Please send details of your product with sketch of existing system.

...more

Magnetic Pulley

Manufacture a wide range of Rare Earth and Ferrite Magnetic Pulleys. These Pulleys are widely used to remove tramp iron mixed with the material moving on a conveyor belt. The Magnet pulleys are always installed at the discharge point of the conveyor to separate tramp iron from the product moving on the conveyor belt. The permanent magnetic pulley is dual-purpose equipment used for protection of crusher Jaws or other machinery and also for purification and concentration of magnetic material from the mines. It has the widest application in food, chemical, ceramic, paper, coal handling, foundry operation and mining industry.

...more

Magnetic Hump

Magnetic Hump is used for removing tramp Iron mixed with powder flowing down the vertical pipe. Magnet consists of two Super Power Rare Earth Magnetic Plates hinged on the zigzag path as shown. The hinged magnetic plate can be opened and cleaned easily. When the material falls it strikes directly on the first magnet plate. Major Iron contamination gets deposited here. The material then flows to the second magnet where escaped Iron particles are removed. This insures a clean Iron free material.

...more

Magnetic Grills

Our Super Power Rare Earth Magnetic Grids are useful for removing very fine weakly magnetic impurities from free flowing powder and granular material. Magnetic Grills are assembled from 1” Magnetic Grills, Dia Rods in SS – 304 o SS – 316 Material having super power Magnetic force on the surface. These grids can be made rectangular, Round and Draw out type grids for easy cleaning to suit customer’s application and are available in single or multiple rows, fitted in housing as shown. Rare Earth magnetic grids are used to purify products such as Food, Chemicals and Minerals. These Magnetic Grills are also used in other Industries such as Foundries, Glass, and Plastic etc.

...more

Magna Roll

We design and supply precision-engineered magna roll machines that are magnetic separators with high intensity rare earth permanent magnet roll used for elimination of paramagnetic particles and fine iron particle or in other words purification or elimination.

...more

industrial magnetic equipment

High Power Magnet

Magnetic drum separators provide an efficient means for extracting ferrous material from dry, bulk products in free-flowing processing systems. They are comprised of a stationary permanent magnet, either standard Ferrite Magnets or High Power Rare Earth Magnets enclosed in a non-magnetic stainless-steel drum. Product flow is diverted so that it falls onto the top and flows across the surface of the drum. Ferrous matter contained in the product flow is drawn to the drum's surface (and held against it) by the powerful magnet housed inside. While non-ferrous products falls from the side of the drum in a normal manner, ferrous metal clings to its surface. As the portion of the drum with the ferrous material rotates to the side opposite the product flow, the magnetic field is reduced so that the ferrous matter falls from the drum into a collection container. The end result is purified product ready for processing without the worry of costly damage caused by tramp metal. Rare Earth, Neodymium is 5 times stronger than Ceramic Magnets and can remove micron sized particles.

...moreBe first to Rate

Rate This