Zircon Sand

150 Per Kilogram

50 Kilogram (MOQ)

Material : Zicron

Application : Industrial Coatings

Color : Brown

Packaging Type : Loose

...more

White Tip Fill Cement

26 - 28 Per perkg

Application : Used In Tipfilling Machine

Color : Off White

Packaging Type : Loose

Form : Powder

...more

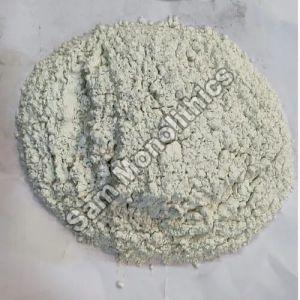

Silica Ramming Mass

12 Per Kilogram

50 Kilogram (MOQ)

Proper mixing of binder leading to optimum mixture. Less wastage, as mixing is done by machines. Only use imported Boric Acid is used to give best results. Consistent and longer lining and patching life. One less item in inventory.

Color : White

Packaging Type : Loose

State : Powder

Material : Silica

Usage/Application : Induction Furnaces for Melting of Scrap to Liquid Steel

Shelf Life : 4 Months

...more

Silica Based Nozzle Filling Compound

15 Per Kilogram

50 Kilogram (MOQ)

Application : Industrial Use

Color : Black

Form : Crystal

Packaging Size : Loose

...more

Perlite Ore

26 Per Kilogram

50 Kilogram (MOQ)

Size : 0-3 MM

Color : Grey

Patching Powder

55 Per Kilogram

50 Kilogram (MOQ)

Sr Cast 60 Monolithic Castables

55 Per Kilogram

50 Kilogram (MOQ)

Packaging Type : Loose

Color : Grey

Form : Powder

...more

SR Cast 90 Refractory Castables

36 Per Kilogram

50 Kilogram (MOQ)

Packaging Type : Loose

Color : Grey

State : Powder

...more

Foundry Grade Laddle Ramming Mass

18 Per Kilogram

50 Kilogram (MOQ)

Grade : Foundry Grade

Packaging Type : Loose

State : Powder

Color : Brown

Shelf Life : 4 Months

...more

Attapulgite Powder

26 Per Kilogram

50 Kilogram (MOQ)

Application : For Mould Paints Use In Foundry

Color : Brown

Form : Powder

Packaging Type : Loose

...more

Chromite Sand

40 Per Kilogram

50 Kilogram (MOQ)

Material : Chromite Sand

Grade : Foundry Grade

Color : Black

Packaging Type : Loose

Form : Powder

...more

Chrome Based Nozzle Filling Compound

45 Per Kilogram

50 Kilogram (MOQ)

Color : Black

Packaging Size : Loose

Form : Crystal

...more

Black Tip Fill Cement

28 - 32 Per perkg

Application : Construction Use

Color : Brown

Packaging Type : Loose

...more

Brown Sillimanite Sand

34 Per Kilogram

50 Kilogram (MOQ)

Material : Siliminate

Packaging Type : Loose

Form : Powder

...more

Basic Ramming Mass

55 Per Kilogram

Material : Quartzite

Grade : Magnesite Base

Packaging Size : 50 Kgs

Packaging Type : Packet

...more

Back Filling Ramming Mass

18 Per Kilogram

50 Kilogram (MOQ)

Packaging Type : Loose

Color : Grey

Shelf Life : 4 Months

Usage : For Safety Lining Brick

...more

back filling mass mini steel plant

17 - 21 Per Perkg

Back filling mass is mgo base product. This product use in aod in mini steel plant for filling the gaps & protect the high alumina bricks

...more

Nozzle Filling Compound

15 Per Kilogram

We are making nozzle filling compound in 3 types silica base ,chrome base & zircon base .we are making high alumina castables also. 60 % alumina 90 % alumina approximate rate is 60 % is rs.24 per kg & 90 % is rs.34 per kg

...moreOpening Hours

As a leading supplier of Zircon Sand, Brown Sillimanite Sand, Chromite Sand, Patching Powder, and Coat Paint Powder, Sam Monolithics Pvt Ltd was founded in the year 2016. Due to the flawless manufacturing of our extensive product lines, we have developed a name of great respect within the industry over years of dedicated service.

By keeping open lines of communication, we sincerely try to meet the requirements and standards of our customers on a regular basis. Our customer service team is careful to follow the client\'s specific needs and respond to them to offer the best solutions within reasonable price ranges.

We have built our organisation on a foundation of cutting-edge infrastructure. Our numerous divisions, each with a wide range of specialities, collaborate to deliver outcomes that are unrivalled in our business. Each department is staffed with seasoned experts who are skilled in their particular field and work in an orderly way to support a regular production process.

Why Us?

We take extreme care to consistently provide products of the highest calibre. Every day, our teams of experts strive to make sure that every product is flawless. High-quality raw materials and cutting-edge manufacturing techniques provide our products with the best production outcomes possible.

Our client servicing division makes sure that all pertinent needs are handled with the utmost precision and consistently monitors customer satisfaction levels.