Split Seals

BGH: Semi-split mechanical seals are used if there is a sufficient axial clearance to pull off the seal housing and seal housings until the sliding parts are accessible. I. e. only the wearing parts proper, such as the seal face and stationary seal as well as O-rings are split. The seal face and stationary seal, springs and O-rings can thus be replaced without requiring complete disassembly. Springs are arranged to be protected from the medium. The split stationary seal can be used in either side.

...more

Seal Supply Systems

FR 1000: Fluid Reservoirs are used to supply fluid to single or tandem mechanical seals. They act as a convenient fluid reservoir. The exchange of fluid takes place by the thermosyphon principle or by forced circulation, e.g. with a pumping screw. The FR 1000 is made of transparent polyethylene, complete with clips made of stainless steel. The FR 1000 is resistant to water, glycerine, glycols and methanol; not resistant to mineral oils and toluene. BFS 1000: With BFS 1016 system it is possible to supply buffer/barrier fluid to double and tandem mechanical seals for a broad range of applications. The BFS 1016 thermosyphon vessel is available in 2 standard sizes with flat ends, sight-glasses for level monitoring and with or without cooling coil. BFS vessels are equipped as standard with all the necessary system connections and brackets. BFS 6000: The BFS 6000 range of systems meet all the requirements to supply mechanical seals in accordance with the API 682 guidelines. The vessels are equipped with all essential connections for fitting additional components. The range is available in two standard vessel sizes (shown: BFS 6000) with dished heads; a version which can be dismantled is also available as an option. ARU: The ARU is used as an automatic refill unit and for barrier fluid pressurization in seal circuits. It is possible to use pneumatic or electric power, or a combination of both for the pressurization. The refill unit tank is designed for pressure less operation and is equipped with a level switch and a sight-glass. The refill unit has all pipe work as far as the distributor unit. HE: HE are used to cool process/barrier fluids in seal supply circuits. Designed as a tubular heat exchanger with integrated guide plates, the process/barrier medium is directed through the shell of the HE and the cooling medium through the tubes. BPU: Barrier pressure units of the BPU range perform all the functions of a barrier system essential for operating double seals (circulation and cooling of the barrier medium, pressurization of the barrier fluid and compensation of leakage).

...more

Pusher Seals

B700N: The B700N mechanical seal range is designed for universal application and the interchangeable parts concept is ideal for stock rationalization. B100N: Mechanical seals of the B100 range have a short installation length (axial). The B100 is a compact ready-to-fit seal which can be installed in the same axial length as a "lip-seal" and can be used to seal differential pressures of up to 25 bar. B120N: Mechanical Seals of the B120N series are a cost effective version of a balanced seal. They feature the same robust and reliable construction as the unbalanced spring seals in the Sealmatic range.. B740-D: Double seals of the B740-D series have the same design-features as the "B700N" family of single seals. BJ920N: Mechanical seals of the BJ920N series are designed for media containing solids or with high viscosity e.g. sugar, paper, sewage and waste water industry. The spring is not in direct contact with the product. The robust and reliable design avoids sticking and clogging. U200N: The U200N mechanical seal range features a spring loaded solid carbon graphite seal face. They are cost effective for basic applications. U300N: The U300N mechanical seals are popular. Extremely rugged and reliable, they cover a wide spectrum of applications – in water pumps, sewage pumps, submerged pumps, chemical pumps, etc. U700N: The U700N mechanical seal range is designed for universal application and ideally suited for standardization. U740-D: Double seals in the U740-D series have the same design-features as the "U700N" family of single seals

...more

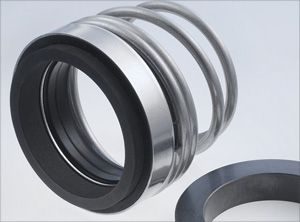

Metal Bellow Seals

UFL650: The UFL650 mechanical seals are specially developed for high temperature applications with wide range of sliding velocities. Its torque transmission exerts no strain on the bellows. This seal design requires no elastomer secondary seals. UFL850N: Mechanical seals in the UF850N series have a universal field of application. They are designed for extreme temperatures for high viscous medias. UFLWT800: Seal faces are positively driven to protect the bellows from torsional stress. Secondary seals are made of high temperature resistance flexible graphites.

...more

engineered seals

BR: Mechanical Seals of the BR series are special-purpose seals for use in media containing solids without external flushing or product circulation. Key features are a rotating seal positioned immediately next to the pump impeller, an open seal chamber facing the impeller, and a spring protection sleeve which has proven to be effective in actual service. BR mechanical seals find application mainly in the scrubbing sections of power station flue gas desulphurization systems, and they are also used successfully in the paper industry. BRC: Mechanical seals of the BRC series were developed specially for use in standard chemical pumps. The radial and axial space has been optimized to provide ideal conditions for maximum operational reliability. BRN: The new stationary mechanical seal is ideal for use in dirty, abrasive media containing solids, e.g. in waste water systems and the chemicals industry. The stationary part has multiple springs and faces away from the product. It is thus protected from possible effects of the medium such as sticking and clogging. SB: Mechanical Seals of the SB-range were developed for use in thermal power stations and for pumps in oil production and transport processes.

...more

Elastomer Bellow Seals

UG100: Mechanical seals of the UG100 series are amongst the most commonly used. The bellow is not subjected to any torsional stress and its ingenious design incorporates several functions, as seal face carrier, secondary sealing element and drive collar. The seal face is driven through the spring and "L"-rings. There are not bonded joints and all the face materials are interchangeable without having to modify any dimensions. Highly recommended for duties with media containing solids e.g. in waste water and sewage applications. UG900: The UG900 is designed for application in the medium pressure and stress range and, within its operating limits, can be universally used in pumps. Just one bellows unit per diameter can be used for all installation lengths. Bellows and spring are free of torsional strain.

...more

Compressor Seals

SB-D: Mechanical Seals of the SB-D range are high-speed seals for turbo compressors, screw compressors, gear compressors or rotary piston blowers. The rotating seat is driven by a friction clamp. Good heat transfer and low turbulence losses are endured by guidance of the buffer medium. The product pressure keeps the seal closed if the oil system is switched off on shut down of the compressor.

...more

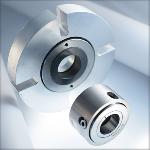

Cartridge Seals

CTX: CTX are fully preassembled. They are balanced, can be used in either direction of rotation and come with all the connections you need for the most common modes of operation.

...more

Agitator Seals

BS-D: Vessels seals of the BS-D range are designed for medium-to-high pressure applications BSH(V)-D: Vessel seals of the BSH(V)-D range are designed and built specially for high-pressure applications. They are operated solely with pressurized buffer fluid. U164K(L)-D: Vessel seals of the U164K(L)-D range are factory assembled and tested cartridge units ready for fitting in special applications on glass-lined vessels.. All parts exposed to the product are of non-metallic construction. U184K(L)-D: Agitator seals of the U184K(L)-D range are factory assembled and tested units. For use on carbon steel and stainless steel reactors. UR-D: Agitator seals of the UR-D range are ideal for applications involving sticky, viscous or dry media. They have been used successfully for many years to seal all kinds of mixers, driers, mills and reactors in the plastic, paint, food and pharmaceutical industries. MXS: MXS the dry-running agitator seal. Developed to seal the gas blanket in mixers and agitators with top drive, e.g. in the chemical and pharmaceutical industry. The MXS is designed for applications where simple sealing systems are adequate but the benefits of a mechanical seal are desirable or demanded.

...moreBe first to Rate

Rate This