Cross Flow Separator

210,000 Per Piece

1 Piece(s) (MOQ)

We, as a Manufacturer and Supplier, are involved in offering Cross Flow Separator. It is durable and robust. Our team of well trained staff keeps manufacturing process under stringent supervision to ensure our quality is in conformity with different standards set by industry. Hence, our customers can rest assured of the quality. We offer a range of designs and specificationsCross Flow Separator Nishi Techno-Sys offering Cross Flow separator which gives more ourput per unit time, this equipment is having 2 motors either side of equipment generating vertical vibration which produce vibration directly to wire mesh result of which it give 20- 25% extra capacity than standard circular Vibratory Screen Discharge of screening material getting from bottom. Advantage of this screening machine is direct vibration closer to mesh frame hence for more cycles per unit area, which helps 25% more productivity than standard vibratory screen also lesser chances of mesh clogging. Cross Flow Separator useful in Food Industry, Chemical Industry and Pharmaceutical Industry. You can also install this screen above SILOs, Hopper, or you can directly pack solid screened material in to bags.

Centrifuge Separators

Get Price Quote

Our Parts have following features : • High Quality • Cost Effective • More than 5000 different items in ex stock available which can be dispatched at short notice. • We provide solutions others just provide spares. We deal in following machines spare parts. • MAB - 103,104,204,205,206,207,209 • MIB - 303 • MMB - 203,304,305 • WSB - 104,203,204,305 • MAPX - 204,205,207,209,210,309,313 • MOPX - 205, 207, 209,210,213, 309 • WHPX - 405,407,409,410,413,505,507,508,510,513 • FOPX - 605,607,609,610,611,613,614 • LOPX - 705,707,709,710,713,719 • WSPX - 204,207,213,303,307 • Also SU and PU purifier spares. Quick action, Quality service, and low price are always our key principles to win customer trust.

Best Deals from Separation Equipment

Vibro Sifter

Get Price Quote

Assistance of diligent professionals and modern packaging facility give our clients and us a win-win situation at the time of tailored packaging requirements. In order to settle the financial transaction with our clients through the transfer of monetary value, we offer diverse options including online and offline payment procedures. Features : Reliable Effective Find functionality Specifications : Possibility of multiple sieving Low energy consumption Easy dismantling and cleaning. High degree of surface finish. Dust proof sieve rack available on request. Additional spreader unit available (Optional) for increased performance. Mechanical Sifters are also available.

Grease Separator,

Get Price Quote

Hydro Cyclone Puroflux

Get Price Quote

Hydro Cyclone separators are designed specifically to improve the quality of process fluids where space requirements are limited. These separators provide an excellent method for removing dirt, sand, silt, precipitates and suspended solids from a variety of process fluids. Equipped with a removable dome the interior of the separator can easily be accessed for inspection. A separator has a simple and reliable design which offers long lasting trouble free service. Separators have no moving part to wear out or replace, eliminating malfunction or breakdown. Separators can be applied to a variety of applications ranging from single pass/full flow to multiple pass/side stream systems. Optional configurations can be engineered to meet specific requirements. FEATURES Available in flow rates from 220 to 12,000 Particulate removal efficiency of 98% at 74 microns and larger expected 150 psi working pressure. Fusion bonded polyester coated carbon steel vessel. Accumulation chamber clean-out standard. True tangential Industrial grade manual purge valve. 1/4" manual air bleed valve. 0-160 psi gauges on inlet/outlet. Options: Auto purge, higher pressure ratings, ASME code stamp and stainless steel construction MSSIPL is a authorised representative of Puroflux in India.

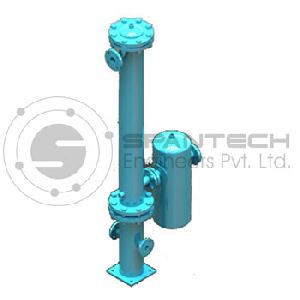

moisture separator after cooler

Get Price Quote

Hot compressed air coming from Air Compressor cannot be used directly in most applications. It is therefore cooled to a temp of around 40o C, which is done in the Aftercooler This is a shell & tube type Heat Exchanger where compressed air in the shell is cooled by plant cooling water circulating in the. tubes. The liquids which condensed due to cooling are separated by the in- built Moisture Separator. Draining can be done manually or by Auto Drain Valve.

Vibro shifter

Get Price Quote

Vibro shifter, Industrial Machines, Coating Pan, Mass Mixer

Digital Heavy Duty Note Sorting Machine

Get Price Quote

Digital Heavy Duty Note Sorting Machine, Biometric Lock Safes