VPSA Oxygen Generators

We are offering vpsa oxygen generators. Oxygen is conventionally produced from air by cryogenic separation process. This is a power intensive & high pressure process which requires power of approx. 1.2 kwhnm3 of oxygen. The vpsa process separates oxygen from air at a low pressure

...more

psa oxygen generators

We are offering psa oxygen generators. The psa oxygen generation system produces oxygen suitable for many applications such as brazingsoldering, ozone generation, chemical oxidation, fermentation, waste water & sewage treatment, healthcare, glass & neon manufacture, pulp & paper, furnace air enrichment, preheating of metals, battery manufacture, metal smelting , etc .

...more

PSA Nitrogen Generators

We offer psa nitrogen generators. Nitrogen is presently being used in a broad spectrum of industries, laboratories, tank farms, mines, etc. In most applications, the n2 pressure required is less than 6 bar. Despite this, high pressure n2 cylinders are commonly used as source of n2, whose handling is quite hazardous & risky. A better option would be to produce your own low pressure n2 by installing our nitrogen generator.

...more

OZONE Generation System

The Ozone Generation System has an Air Compressor which provides the compressed air to the PSA Oxygen Generator Module where O2 is produced and then stored in the Oxygen Vessel. This O2 gas is subjected to a high voltage, AC electric corona (similar to lightning) in the Ozonator Module, where the molecular oxygen breaks down to atomic oxygen. Some of the atoms of oxygen thus liberated re-form into ozone, while others recombine to form oxygen. The resultant product gas containing ozone is in the circulating water in the Ozone Injection System. The Ozonated water is then used for required application. In some other applications ozone is injected directly in the water or air, as required. Some applications include: COD/BOD Reduction, Cyanide Destruction, Dye Removal, Organic Oxidation, etc. of Water & Wastewater. Cooling Tower Treatment (Bio-fouling control/Chemical replacement). Drinking Water (Pre / Post treatment). Food Processing (Sterilization / Fruit Washing). Chlorine replacement in Commercial Laundry Water. Micro Flocculation of Suspended Solids (Chemical replacement). Odor Removal, Control and Elimination (Water & Air). Pharmaceutical Industry (Process & Ultra purity water). Disinfection of Aquaculture/Fish farms (Chemical replacement). Semiconductor Manufacturing (Ultra-pure / D.I. Water).

...more

Oxygen Generation System

The PSA Oxygen Generation System produces oxygen suitable for many applications such as brazing/soldering, ozone generation, chemical oxidation, fermentation, waste water & sewage treatment, healthcare, glass & neon manufacture, pulp & paper, furnace air enrichment, preheating of metals, battery manufacture, metal smelting , etc . The PSA Oxygen Generation System consists of two parts – Dry Air System where dry & oil-free compressed air is produced by filters & Dryer and the other is the PSA System where O2 is produced and stored. In the PSA System, dry & oil-free compressed air is passed through a bed of Zeolite Molecular Sieves (ZMS) which has a property of very high degree of affinity to nitrogen, which it retains & releases oxygen as product gas. There are two adsorbers filled with ZMS with one in production cycle while the other is regenerated by depressurization. The two adsorbers are switched from adsorption to desorption automatically. For large capacity systems, a VPSA System is used, where adsorption is done at low pressure and the regeneration is done by vacuum. This helps in reducing power consumption substantially.

...more

Nitrogen Generator

Nitrogen is presently being used in a broad spectrum of industries, laboratories, tank farms, mines, etc. In most applications, the N2 pressure required is less than 6 bar. Despite this, high pressure N2 cylinders are commonly used as source of N2, whose handling is quite hazardous & risky. A better option would be to produce your own low pressure N2 by installing our Nitrogen Generator. What are the benefits of producing your own N2 ?(a) You save money – N2 from Generator costs 30% to 50% of N2 from cylinder. Payback periods are generally less than one year, which can reduce further if you have compressed air already available in your mfg facility. (b) It gives N2 of better and consistent purity than that available from cylinders where O2 content can vary from 0.5% to 4% (based on actual measurements taken by us). In our Generator, continuous online O2 measurement is available. (c) Elimination of risk of accidents which may take place due to handling of N2 cylinders as well as due to excess O2 in cylinders.

...more

moisture separator after cooler

Hot compressed air coming from Air Compressor cannot be used directly in most applications. It is therefore cooled to a temp of around 40o C, which is done in the Aftercooler This is a shell & tube type Heat Exchanger where compressed air in the shell is cooled by plant cooling water circulating in the. tubes. The liquids which condensed due to cooling are separated by the in- built Moisture Separator. Draining can be done manually or by Auto Drain Valve.

...more

LAB Nitrogen Generator

Nitrogen as an inert gas is a very valued lab gas and is used for a number of lab applications. Application: Nitrogen finds it’s application in labs in Auto samplers, GC’s, LC/MS, Spectrometer, Nuclear Magnetic resonance (NMR), Protein analyzer, Solvent evaporators, Thermal galvanic Analyzer(TGA), Total Organic Carbon Analyzer etc. For Gas chromatography (GC) Nitrogen is widely used in Gas chromatography because Most gas chromatography column stationary phases are based on modified polysiloxane or polyethylene glycol materials. These materials oxidize in the presence of oxygen at elevated temperatures. This behavior, known in part as bleed, will very quickly degrade the performance of the column.

...more

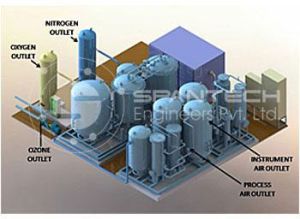

integrated gas generator system

Compressed air, nitrogen & oxygen are important Utility gases in all types of industries. The Compressed air system is installed in virtually all facilities, while the other gases are purchased. Recently developed processes have led to dramatically increased use of oxygen, nitrogen & ozone to improve economics & efficiency as well as satisfy environment concerns. Because of increased usage, it became more economical to produce nitrogen & oxygen rather than purchasing them. This can be done by installing our PSA Nitrogen & Oxygen Generators which produce nitrogen & oxygen from compressed air onsite, thereby reducing their costs. This cost reduction has made it possible to use oxygen and nitrogen in applications where it was earlier not economically viable. Some applications: Ozone is used to treat industrial & municipal waste water , for elimination of microbial growth in cooling water. Reduces use of chlorine-based chemicals. Oxygen can be used for enrichment of combustion air used in ferrous & non-ferrous furnaces, lime kilns, glass melting, gasification plants, etc. Improves fuel efficiency & reduces harmful emissions. Pulp delignification & bleaching by Oxygen/Ozone. Dry Nitrogen is used for micronizing of APIs & other products in Air Jet Mills and drying of solvent laden products in Fluid Bed Dryers. Direct oxygen injection in aerobic fermentation improves productivity of biotech products. Producing dry, oil-free compressed air is the first step in Gas Generation, which s done by cooling, filtering, drying & storing the compressed air in a Dry Air Receiver. A part of this dry, oil-free air is used for process & instrument used. Another part is used to produce nitrogen and rest is used to produce oxygen. A part of this oxygen is used to produce ozone and the balance is used for other applications. The Integrated Gas Generation System further improves economics of gas generation by producing all four gases (dry & oil-free compressed air, nitrogen, oxygen & ozone) in a single System. Utilization of excess compressed air is available in your facility will increase your savings further. The System can be tailored to produce whatever gases required in your facility, with compressed air being the mother gas. Details of the individual Gas Generators and their applications are given in respective web pages.

...more

Integrated Gas Generation system

We offer gas generation system. Compressed air, nitrogen & oxygen are important utility gases in all types of industries. The compressed air system is installed in virtually all facilities, while the other gases are purchased.

...more

HEAT LESS AIR DRYER

Compressed air coming from the Receiver containing solid, liquid & vapour contaminants enters the Dryer through the Pre-filter (where solid & liquid contaminants are removed). It then passes through Oil Removal Filter and enters into Adsorption Tower A1 through a 3-way valve (CV-1) where it gets dried and then passes out of the Dryer through the After-filter. A part of this dry air passes through Tower A2 through the Purge Control Valve, where it picks up the moisture from the adsorbent thereby regenerating it and making it ready for the adsorption cycle. The purge air exhausts out of the Dryer through Purge Exhaust Valve (CV-2) of Tower A2. After a fixed time, the functions of Towers A1 & A2 have to be reversed but doing this when the towers are at unequal pressures (Tower A1 is at line pressure & Tower A2 is at atmospheric pressure) will result in : adsorbent being subject to pressure shock and also starvation of air at outlet till Tower A2 attains line pressure in Tower A2. To avoid this, CV-2 is closed before the change-over and pressure in Tower A2 slowly rises to line pressure. The change-over is then effected by operating CV-1 and opening Purge Exhaust Valve CV-3 of Tower A1. The Adsorption Towers are now fully reversed, with Tower A2 under adsorption and Tower A1 under regeneration. At the end of this cycle, the tower functions will again be reversed. This cyclic operation is done through a Sequence Timer and the Dryer runs automatically.

...more

DRY Air System

Compressed air produced by a Compressor is hot, dirty & humid and cannot be used in this state by pneumatic devices or other uses like producing nitrogen / oxygen, powder coating, pneumatic conveying, sand / shot blasting, micronizing, etc. Our Compressed Air System is a ready-to-use package producing oil & moisture-free compressed air to the purity level required by the end-use. Standard Systems at 7 bar working pressure will give air quality of ISO-8573-1, Class 3:3:2. (Particulates < 5µ, Moisture PDP of - 20 ºC & Oil < 0.1mg/M³) If the end-use moisture content is not stringent (Moisture PDP of +3 ºC, is acceptable), a Refrigeration Air Dryer will be provided instead of Heatless Air Dryer. Lower levels of contaminants can be provided if required. Systems of higher pressure can also be provided.

...more

Dew point measurement system

For continuous, online measurement system, the DP is determined by measuring change in capacitance of special sensor placed in the air stream. This change is transmitted to a device which displays the DP directly. This System is very expensive and is generally installed in Air Dryers for critical applications. Online measurement and monitoring of dew point in Compressed Air Systems and Gas Generators used in industry & research labs is becoming extremely important because of stringent quality requirements of products & processes. Sample gas is passed around an imported measurement cell using patented thin-film technology, which measures & transmits its moisture content for display. Standard instrument gives readout as atmospheric dew point. The Online Dew Point Meter has an option for connection to external Alarm through a relay. Online Dew Point Meter with other display units & ranges as well as battery-operated portable version are also available. Technical Specifications of Standard Instrument:

Weight : 1.5 Kg

...more

Auto Drain Valve

Draining of Compressed air equipment such as Air Receivers, Moisture Separators, Filters, etc. is commonly done by low cost, timer - operated Auto Drain Valves. While these are effective in their functioning, they will open at the set time whether there is any condensate to be drained or not. This will result in loss of compressed air (and hence loss of energy), when there is no condensate to be drained. The 'LEVEL SENSING Auto Drain Valve operation is level - based without any timer. The ADV has a Reservoir (in which condensate accumulates) connected to a drain valve which opens when condensate level reaches the top and closes when condensate level reaches the bottom. These operations are carried out by sensors placed at different levels of the reservoir. By this method only condensate is drained when the ADV opens and there is no loss of compressed air, resulting in saving of energy. The reservoir & valve sizes are matched with the size and type , equipment to be drained, so that the ADV does not operate too frequently. Isolation valve & strainer are provided along with the ADV, for easy cleaning & servicing.

...more

Air Dryers

Nitrogen Generators

Be first to Rate

Rate ThisOpening Hours