Salt Spray Chambers

Get Price Quote

We are the main supplier of this product.

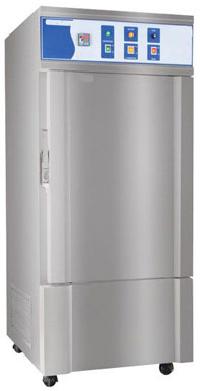

VERTICAL Salt Spray chambers

Get Price Quote

Innovative compact vertical models with front door and Italian design for corrosion testing.Vertical space saving test Chambers with large glass Front door for salt spray, Condensation tests andCyclic corrosion tests. New compact and functional design Salt Spray Tests Condensation Tests Corrosionbox improves comparison with outdoor resultsWorldwide, materials used by manufacturing industry are exposed to natural or industrialcorrosion in shape of salt fog, humidity, smoke and vehicle exhaust. Laboratorycorrosion tests are used extensively for selection of materials and their surfaceprotection.Corrosionbox chambers are what you need to predict corrosion resistance of materialssuch as paints and coatings. Salt spray testA corrosive solution is turned into a vapour mist through a nozzle located on the back side of the chamber. A fog diffusing structure distributes the fog over the entire test zone. The compressed air required for fog production is heated and saturated with moisture in a pressurized humidifier before it reaches the nozzle. One or more heating elements, depending on chamber capacity, ensure uniform temperature in the test chamber. Exhaust solution collected in the bottom of test chamber is drained away through a drain to the floor.Salt spray test can be executed with all chamber models. Condensation water testTest chamber bottom is filled with demineralised water. Water is heated and evaporates condensing on the surface of samples. Chamber temperature is 40 °C. Continuous condensation test can be executed with all chamber models.Cyclic corrosion testA large number of cyclic corrosion tests are made possible by combining salt spray environment with condensation humidity and air drying . Cyclic corrosion testing has become increasingly necessary in recent years. Dry Corrosion is one of the most popular cyclic tests alternating salt spray and air drying. Cyclic tests can be executed with all enhanced model chambers. Depending on cycletype some options have to be installed during chamber manufacturing. Chamber DesignChamber structure is overall 10mm thick Polypropylene. Option in PPS plastics to meet CSA flame test. Test chamber is insulated with a double wall. Access to the test chamber ismade through a window glass door. Control panel and all necessary control devices are on the rightside in ergonomic position. The Salt solution storage tank is on the left side. The electrical board is completely enclosed in a dedicated zone: next to it we find the electro-valves, humidifier and salt solution dosing pump zone. Each part is of easy access for simple and fast maintenance. Basic model Absolutely easy to use. The first step for test execution is to load timer with total test time (up to 9999 hours), second is to set test chamber temperature on the controller, then press Salt spray or Condensation push-button. During the whole time of the test, the timer counts down and its display will indicate decreasing time running to test end. To inspect samples, suspend test execution pressing Salt spray or Condensation push-button, then press ventilation push-button to drain testchamber before opening it.To resume test execution simply press Salt spray or Condensation push-buttonagain. When timer reaches zero test execution is finished Enhanced modelFree programming, up to 15 different test programs, inputs via keyboard with soft keys and easy to use structure of the Menu. Test status is continuously displayed on the large LCD display with 4 lines of 20 characters each. Control and monitoring of test chamber and humidifier temperature, monitoring of nozzle air pressure and dosing pump RPH. Self-diagnostic including warning messages, alarm messages and safety shut down. Complete test report: chamber and humidifier temperature, nozzle air pressure and dosing pump RPH are periodically measured and stored inthe controller memory together with test interruptions or alarms. By simply pressing a key a complete report of the test is printed. RS232-C interface is provided for serial printer connection. Cyclic test optionsEnhanced model control panel allows easy programming of cyclic test combining: Salt spray, Watercondensation, Dry off and Ambient condition. To perform cycling the test chamber must be completed with the following optional parts: Option for Dry Corrosion, Scab Corrosion cycle. An air heater is installed to heat purging air before introducing it in the test chamber and a Titanium panel on the bottom of test chamber turns a flooded bottom into a dry bottom. Only a dry chamber bottom allows fast drying of the samples.Option for ASTM G85-98 annex 5 Prohesion. In addition to parts installed for dry corrosion a bypass is installed on the humidifier to meet standard requirements with respect to fog production.Option for ASTM G85-98 annex 4 salt/SO2 spray testing. An external SO2 dosing system is supplied and a gas diffusing device is installed in the test chamber

Best Deals from Spray Chamber

Salt Water Spray Chamber

Get Price Quote

As per ASTM, ISO & IS standards Salt Water Spray Chamber is for testing the rust resistance grade of surface treatment of Electro-Plating, Paint Coating and Anodizing. Salt water spray tester is used for testing rust-proof treatment of material, such as metal surface that after painting, coating, electro-plating, anodizing, films of organic and non-organic...etc. It's a corrosion and Rust-Resistant test.. This test equipment is for checking the corrosion resistant of products (specimen) under long time corrosion after treatment like anodize, rustproof oil, chemical, etc

spray tower

Get Price Quote

spray tower, Frp Pressure Vessel, Packed Bed Scrubber

Salt Water Spray Chamber

Get Price Quote

We are leading Salt Water Spray Chamber, Manufacturers, Suppliers & Exporters Located in Dombivli Dist. Thane, Mumbai India. Salt Water Spray Chamber is for testing the rust resistance grade of surface treatment of Electro-Plating, Paint Coating and Anodizing. As per ASTM, ISO & IS standards Salt water spray tester is used for testing rust-proof treatment of material, such as metal surface that after painting, coating, electro-plating, anodizing, films of organic and non-organic...etc. It's a corrosion and Rust-Resistant test. This test equipment is for checking the corrosion resistant of products (specimen) under long time corrosion after treatment like anodize, rustproof oil, chemical, etc.