wire annealing furnaces

Continuous annealing furnaces are designed for the processing of SS or Copper wire, rod, strand, strip and tube products.These furnaces are ideally suited for copper, copper alloy, nickel, nickel chrome, titanium, stainless steel and refractory metals. The Furnaces are Gas Fired or Electrically Heated In case of gas fired furnace no of small Therm Process Make gas burners are provided to achieve excellent temperature uniformity.

...more

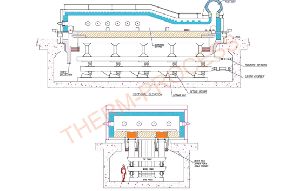

Walking Hearth Furnace

The walking beam furnace allows the product to be heated from all sides, where a walking hearth furnace only allows product to be heated from top • The walking hearth furnace allows the charge to be transported through the furnace by lift and shift mechanism. • There is no major mechanism difference between walking hearth and walking beam furnace. Attractive Features Simplicity of Design and Ease of Construction Very effective heating and soaking of billets. Ability to cater for different billet sizes (within limits), negligible water cooling energy losses and no physical markings on charge.

...more

Walking Beam Furnaces

The walking beam furnace allows the product to be heated from all sides, where a walking hearth furnace only allows product to be heated from top,The walking hearth furnace allows the charge to be transported through the furnace by lift and shift mechanism. There is no major mechanism difference between walking hearth and walking beam furnace.

...more

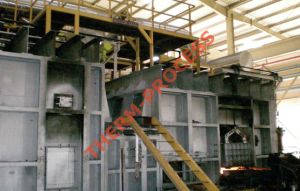

Tower Melting Furnace

This melting and holding furnace is designed for continuous operation and is suitable for aluminum die casting aluminum casting industries, Equipped with” Therm Process’s Super Low Speed Luminous Flame Burners” in the melting furnace. Electric heaters are used in the holding furnace.No Hard Oxidation Material, the temperature in the holding chambers is kept at about 50° c higher than that of molten metal. This minimizes possibility of formation of hard oxidation of material caused by over temperature condition.

...more

Strand Annealing Furnace

Continuous annealing furnaces are designed for the processing of SS or Copper wire, rod, strand, strip and tube products.These furnaces are ideally suited for copper, copper alloy, nickel, nickel chrome, titanium, stainless steel and refractory metals. Therm Process's Annealing Furnace features heavy-duty construction, an energy saving combination of fiber and brick insulation, precise temperature control and requires minimal maintenance.

...more

Strand Annealer

Continuous annealing furnaces are designed for the processing of SS or Copper wire, rod, strand, strip and tube products. These furnaces are ideally suited for copper, copper alloy, nickel, nickel chrome, titanium, stainless steel and refractory metals. Therm Process's Annealing Furnace features heavy-duty construction, an energy saving combination of fiber and brick insulation, precise temperature control and requires minimal maintenance. The Furnaces are Gas Fired or Electrically Heated In case of gas fired furnace no of small Therm Process Make gas burners are provided to achieve excellent temperature uniformity. In case of electrical heating type the heating elements are provided with either circular type or in grooved refractory. The design of heating element is very vital for long and trouble free life. Therm Process provides low watt density elements in the electric furnace.

...more

Steel Oil Burner

Application : Industrial

Brand Name : Therm Process

Material : Stainless Steel

...more

skelner furnace

This melting and holding furnace is designed for continuous operation and is suitable for aluminum die casting aluminum casting industries

...more

Roller Hearth Furnace

We have successfully designed, installed & commissioned roller hearth furnaces. Basic specifications include -capacity - 1500 kg hr,charge - cs tubes for bright annealing,charge size - 25 to 100 mm od x 3 to 8 mm thk.

...more

Roller Hearth Annealing Furnace

We have successfully designed, installed & commissioned roller hearth furnaces. Basic specifications include -

Production Capacity : 1500 Kg / Hr

...more

Reheating Furnaces

Heating Furnace are used for reheating of billets. Charging may be done as cold charging or hot charging. We have supplied , erected & commissioned these furnaces all around the world in the capacity range of 10 TPH to 65 TPH. These are suited for MS, CS, SS & Special alloy steels.

...more

Reheat Furnace

Re - Heating Furnace are used for reheating of billets. Charging may be done as cold charging or hot charging. We have supplied , erected & commissioned these furnaces all around the world in the capacity range of 10 TPH to 65 TPH. These are suited for MS, CS, SS & Special alloy steels.

...more

Industrial Recuperator

Details : For Waste heat recovery the Recuperator is provided in the flue duct between furnace & chimney By passing combustion air through recuperator , air can be preheated before entering furnace from burner. It is a special purpose counter flow or cross flow energy recovery heat exchanger. It is possible to recover 60-70 % of the waste heat and preheated air upto 150 to 500 °C

Type : Automatic

Material : Stainless Steel

Certification : ISI Certified

Application : Industrial Use

Finishing : Polished

Pressure : 5-10 Bars

temperatures : 0-100 ºC

...more

Ratio Regulator

Air- oil Ratio Regulator is used to control the Furnace temperature by controlling oil flow through burners.

...more

Radiation Recuperators

Radiation Type Construction - Annular Tubes Material - SS 310 / SS 304/ Carbon Steel Mounting - Above ground Air Flow - Unidirectional Flow / Cross Flow Application - Forging Furnaces, Heat Treatment Furnaces, Aluminum Melting Furnaces, Dryers, Pre-heaters

...more

pusher furnaces

Very popular in steel industries for Rolling Mill & Re- Rolling Mill. Relatively low installation and maintenance cost compared to moving hearth furnace,Possible to push the charge (Billets Ingots) along skids with water cooled supports that allow both the top and bottom faces of the charge (Billets ingots) to be heated.

...more

Pusher Furnace

ery popular in steel industries for Rolling Mill & Re- Rolling Mill. • Relatively low installation and maintenance cost compared to moving hearth furnace • Possible to push the charge (Billets / Ingots) along skids with water cooled supports that allow both the top and bottom faces of the charge (Billets / ingots) to be heated.

...more

Producer Gas Burner

Therm Process has been continuously providing a comprehensive range of Industrial Burner,Depending upon the various applications in Furnaces, Boilers, Bake Ovens and type of fuels used for Ignition.

...more

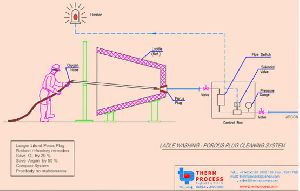

Porous Plug Cleaning System

Therm process is pleased to introduce New Oxygen washing control system to save costly Oxygen / Argon / Nitrogen Process Normally Oxygen washing operator cannot see Argon / Nitrogen purging process as both are on opposite side of Laddle.Oxygen washing operator does not know if porous plug is cleaned or not hence keeps Oxygen flame “ON”Thereby damaging costly refractory & causing wastage of Oxygen. Similarly Argon / Nitrogen purging process is not sure whether the plug is cleaned, hence keeps unnecessarily Argon supply “ON” The stopping of Oxygen & Argon is mostly carried out by assumptions & approximation. Improvement A Control box is provided with valves to regulate Argon / Nitrogen flow.Existing Argon / Nitrogen line shall be connected to control box inlet & outlet shall be connected to Ladle porous plug point.A flow switch & Argon solenoid valve is provided in control box.When plug is cleaned the Argon / Nitrogen flow starts. This gives flasher signal to Oxygen washing operator to stop. The signal also stop Argon gas automatically through solenoid valve. AdvantagesReduced Oxygen consumption at washing by 20%.Unnecessary erosion of Refractory is eliminated.Reduced Argon / Nitrogen consumption by also 50%.Operator Firendly.

...more

Pit Type Furnace

Pit Type Furnace Pit Furnaces are used for variety of Heat Treatment Processes Commonly used for tempering of Automobile parts and Annealing of M.S. wire. Mode of Heating - Electrical / L.D.O. Fired/ Gas Fired

...more

pit furnaces

Pit Furnaces are used for variety of Heat Treatment Processes, Commonly used for tempering of Automobile parts and Annealing of M.S. wire.Mode of Heating - Electrical L.D.O. Fired Gas Fired, Capacity - 300 Kg to 3 Tons.

Capacity : 300 Kg to 3 Tons

...more

Pinion Stand

Over Head Recuperator

Power : 0.25-10 kW

Oil Micro Valve

Precise control valve designed by Therm Process mainly used to set desired oil flow at the nozzle mix burners.

...moreBe first to Rate

Rate ThisOpening Hours