Four Strand Wire Feeding System

Get Price Quote

Welding Electrodes

Get Price Quote

Best Deals from Tig Torch Parts

Pull Through Wire Straightener Pneumatic Feeder

200,000 Per Piece

1 Piece (MOQ)

Welding Fire Blanket

Get Price Quote

Our payment procedure can be both physical and electronic. Physical modes can be cash payment, bank deposits and others. On the other hand, our electronic modes include instant payment gateway. Stringent quality checks have been employed upon the raw materials which we source. For this, we have hired special quality analysts who check the materials against different parameters.

Rectangular Vibro Screen

Get Price Quote

We, as a prominent Manufacturer and Supplier, bring forth Rectangular Vibro Screen. It is manufactured using first-class raw material ensuring its durability and high performance. Our team of experienced professional takes care of the designing and fabrication. We leave no stone unturned to ensure that it matches the various parameters and standards set by the industry. It is available in different customized specifications as per the request of the customer. Rectangular Screen – This type of screening machine used where more capacity expected with bigger size particles. Where 25 – 50 mm to 0.5 mm size particles and capacity require 1 Ton/Hr. to 30 Tons /Hr. mainly used in Mineral , Coal , Bulk drug, chemical , Cement, Ash, stones segregation. This Rectangular screening machine based on off- centre Vibration or 2 nos. Vibratory Motors. Nishi Techno-Sys offer equipment in SS304 & SS316

Plastic Welding Machine

Get Price Quote

We are offering hdpe pipe butt fusion jointing machine with all accessories.

Polyurethane Screen

Get Price Quote

Ranked amidst the celebrated Suppliers of Polyurethane Screen, we are customers' reliable choice in the industry. The basic material that we use for the production of the entire range is carefully sourced from the trusted vendors. Moreover, we strictly check the materials against all quality grounds before procurement. Approx. Price : Rs 950 / Square Feet Specifications : Polyurethane elastomer vibrating screen withstands the highest ability to resist abrasion and wear. It can highly flexible and elongated. Polyurethane screen can reduce the too much of weight and also reduce the cost. widely used in Mine, Metallurgy, Coal, Coke, Coal washing, oil and Chemical industry,Our ergineers will design screen panel configurations to suit your individual needs. Aperture opening sizes and designs can be varied depending upon the application. Panels can be custom designed and sized as required. Product Details : Brand -Perfect Color - Multicolor, Natural, Blue, Transparent, As Per Customer Requirement Size - As Per Customer Requirement Features : Longer service life Maintenance free Light weight Physical Properties Of Elastomers Screen : High wear resistance Oil-resistance High temperature-resistance Thermal ageing-resistance Radiation-resistance, etc. Advantages: Manufactured individually and specific to the application. Long lifetime. By hot casting, according to screened material and machine dimensions. wide range of hardness 60-95 shore A. Several hole widths (square, rectangular, oval, round, etc. Conical hole shapes to prevent materials from sticking in the holes. Slotted holes for dewatering, longitudinal holes for difficult materials. Retaining strips and deflectors to improve screening. Minimum noise. Self-cleaning ability.

Welding Machine

Get Price Quote

Based in Thane, Maharashtra, we are entrusted with the task of exporting and supplying the superlative range of Welding Machines to every nook and corner of the country. Our stock accommodates the and other varieties of Welding Machine in numerous specifications. These Machines are sourced from the reliable vendors after stringent quality checks. Moreover, we sell them at the cost-effective prices.

Welding Rotator

95,000 Per Piece

Manual HDPE Pipe Welding Machine

81,000 Per Set

1 Set(s) (MOQ)

Ball Screw

Get Price Quote

Ballscrew shafts HIWIN offers rolled, peeled and ground ballscrews - depending on the application requirements. For the selection of the appropriate shaft ...

Friction stir welding tool

2,000 Per unit

Head Protection

500 Per Piece

Polyurethane Screen

Get Price Quote

We offer polyurethane screen. Ashar locker make polyurethane screen panel for wet screening application.

Ceramic Weld Backing Tape

Get Price Quote

1000 Meter (MOQ)

We are offering ceramic weld backing tape. Cerback – ceramic welding backing tapes & strips for one side welding. These are used for all kind of welding processes & for almost all metals, for one side welding. Welding processes such as smaw, fmaw, gmaw, saw, co2, tig, mig etc. By using weld back up strips, welding cost is saved approx 50 to 60% whereas welding time is saved by 50%. Results are 100% radiographic welding. No back chipping, no back grinding or gouging, no purging required. Weld back up tape consists various profiles of non porous ceramic tiles for butt welding, fillet welding etc. We also manufacture siback - fiberglass weld backing tapes. This is what cerback backing does! • no need for back gouging, back chipping. • no back side grinding required. • no purging, no gas required. • no oxidation, no pollution, no hydrogen inclusion. • saves cost saves time. • x ray quality back beads. • perfect radiographic quality. • no scope of rejection, eliminates defects and reworks, improves quality. • deposit more weld metal for full penetration. • useful for different types of weld joints, i.e. Single & double v butt joints, dished ends shell to manhole hand hole, tube plate to shell etc. • ensures enhanced safety, comfort & best work environmental condition to the welder & fitter.

Friction stir welding tool

7,000 - 25,000 Per Piece

1 Piece (MOQ)

Wear Parts for Welding & Cutting ELectrode Industries

Get Price Quote

100 Piece(s) (MOQ)

we offer wear parts for welding & cutting electrode industries. roy wire drawing dies offer various types of wear parts for welding & cutting electrode industries. wire straightening & cutting machine parts and welding electrode extruder machine parts. we are specialized in this area and also provide customized solution.

Welding Positioner

100,000 - 1,000,000 Per No

1 Set (MOQ)

Semi automatic to Fully automatic welding postioner Available in 2 axis Programmable with panel attached HMI on demand ,PLC based

Handheld Wire Feeders

Get Price Quote

Vibrating Screens

Get Price Quote

Our Vibrating Screens are applicable in wide range of industries like food processing, chemical industry, paper, coal, clay and metal mining for the purpose of de-watering, washing, sizing, scalping, and many more. In addition also widely used on shale shakers for reclaiming drilling mud. We are the vibrating screen manufacturers that manufacture superior quality vibrating screens that are provided with square hook strips that enable screens to be kept under greater, more uniform tension and makes them distortion resistant.Screens for sizing and straining can be furnished with any style of edge preparation or hook strip, ready for installation into any type equipment. Often the edges of screens of woven of heavier than .250" are fabricated to hook on to the vibrating frame. however, most screens made of .250" and lighter wire have a hook strip supporting the edges. Absolutely square hook strips enable screens to be kept under greater, more uniform tension. This protects them against distortion and excessive vibration which causes metal fatigue and breakage .applications in a wide range of industries, including food processing, chemical, paper, coal, clay, and metal mining. Used for dewatering, washing, sizing, scalping, and more. Also widely used on shale shakers for reclaiming drilling mud.

WELD REMOVAL TOOLS

Get Price Quote

Hot Plate Welding Fixture

650,000 Per Piece

2D WELDING TABLE

Get Price Quote

We are offering wide range of Industrial Welding Table. The offered product is manufactured in adherence to set quality standards by utilizing premium quality raw material and sophisticated technology. Our offered product is widely acknowledged for high performance, sturdiness and longer service life. Features: Material: Steel D28 Hole Separation=100mm±0.05mm D16 Hole Separation=50mm±0.05mm Stiffener base increases stability One working surface Flatness=0.1/1000mm Spray anti-rust liquid to avoid damage Verticality=0.1/200mm Surface Roughtness=Ra3.2

Flash Back Arrester

Get Price Quote

HDPE and PPR Pipes Field Welding Machines

Get Price Quote

Aeromec Workshop and Field Welding Machines For HDPE and PPR Pipes. Aeromec welding machines are extensively designed as per International Standards to suits Indian environment and usability. Machines are enhanced for any layman to use with bare minimum controls. Field machines are very light and easy to carry with minimum man power. Workshop Models and band saw are designed to get very accurate angle of welding and cutting. Aeromec Field Welding machines are with robust and strong Hydraulics system.

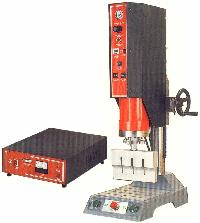

Ultrasonic Plastic Welding Machine

Get Price Quote

Our organization is involved in supplying an eclectic array of products out of which is Ultrasonic Plastic Welding Machine. Founded in shahapur(India), our company has been successful in capturing the local and domestic markets as trader of this product

HDPE Pipe Fusion Machine

Get Price Quote

lance holder

5,050 Per Piece

Welding Wires

Get Price Quote

A well known welding wires supplier company.

Vibrating Screens

Get Price Quote

ORTON vibrating screens work on the principle of linear displacement of the materials due to unbalance forces generated by two unbalance motors rotating in opposite direction. These screens are basically used to separate coarse materials from fine materials which exit in mixed form. Depending on the grading size details, the number of decks required are decided. Generally the screens are provided with on deck or two decks. In case more than two decks are required for a particular application then, two vibrating screens can be used in tandem in such a way that the finest output of the first screen can be fed as the input to the second screen. The second screen will further grade & separate the material as required. The selection of the screen deck mesh will depend on factors such as the materials to be screened, whether the material is dry & free flowing or is moist and sticky, particular size of the material to be screened, shape of the material etc. Utmost care is to be taken to ensure that the screen decks do not get clogged as this will result in reduced screening area thereby affecting the output of the screen. Basic Construction :The screen body is extremely sturdy & rugged made up of mild steel of adequate thickness. The thickness of the steel plates depends upon the size of the screen & the selected motor. Depending on the material to be screened, the sieve analysis & other related factors, suitable screen decks are provided. Normally these decks are in the form of wire mesh or perforated plates. These screens are mounted on the structural framework via specially designed mounting springs. The selection of these springs will depend on the total weight of the equipment & the motor rpm. These screens are usually base mounted, however they can also be suspended if the situation demands. The screens are provided with suitable inlet & outlet openings as required by the customer. The positioning of the outlets will depend upon the requirement of the customer