mechanical feeder

45,000 - 200,000 Per Piece

Mechanical Gripper Feeder are perfect solutions for feeding strips on medium high speed pressure. Round guides with Linear ball bushings. Capability to mount to any type of press. Transmission through bevel gear box and cardian shaft from the press. Lubrication oiling by grease nipple. Accuracy of +-0.025mm with mechanical pilot synchronisation Easy setting of pitch length. All adjustments are easily reachable. Quick opening of the gripper for the strip insertion.

Vibratory Feeder Bowl

Get Price Quote

We provide a large assortment of high efficacy Vibratory Feeder, which is used in various industries for specific applications. We are well-known as one of the prominent Vibratory Linear Feeders Manufacturers and Suppliers based in India. Our Vibratory Feeder is manufactured from the optimum quality raw materials to add durability and performance. Vibratory Feeder offered by us is available in various sizes and dimensions as per the need of the clients for Vibratory Bowl Feeding.

Best Deals from Vibratory Feeders

Vibratory Feeders

Get Price Quote

KILBURN- CARRIER Vibratory Feeders are available in various sizes and capacities to meet specific requirements. A variety of materials can be conveyed. The following pictures show some specific applications.

Vibratory finishing equipment

Get Price Quote

Our pursuit to provide surface engineering solutions tailored to suit the ever increasing demands of modern manufacturing environment has driven us from manufacturing standardized machines to providing customized solutions. Wide range of accessories can be integrated and automated to offer completely integrated finishing solution for consistent quality.

Bowl Vibratory Finishing Machine

65,000 Per Piece

Cushioned Pneumatic Linear Vibrator

3,800 Per Piece

1 Piece (MOQ)

Vibratory Bowl Feeder

Get Price Quote

In an automated manufacturing setup First and foremost requirement is of feeding the parts to the workstation. Vibratory Bowl feeder is used for segregating and orienting parts in the desired position. The oriented parts can then be fed into chute for their on ward transportation to workstation. The bowls are cast out of Aluminum alloy or are fabricated from stainless steel or mild steel sheets depending on the material of the parts to be fed. The inner side of the bowl is lined with appropriate lining material to reduce wear.

Vibratory Bowl Feeder

Get Price Quote

The electromagnetic vibratory feeder consists of a tray made of mild steel and a body housing the electromagnet. The tray which is connected to the armature of the magnet vibrates as the magnet gets energised. The vibration sets the material in motion. Controlling of vibration gives the controlled flow of the material. The body housing the electromagnet is made in totally enclosed design to prevent dusting. The electromagnetic vibratory feeder consists of a tray made out of mild steel or stainless steel and a body housing the electromagnet. The tray which is connected to the armature of the magnet vibrates, as the magnet gets energized. The vibration sets the material in motion. Controlling of vibration gives the controlled flow of the material. The body housing the electromagnet is made in totally enclosed design to prevent dust going inside.

Vibrating Feeder

Get Price Quote

Vibrating Feeder is a kind of linear-direction feeding equipment, in the mineral ore &rocks processing plants, it can send materials to crusher evenly and continuously. At the same time, it can screen materials roughly, increasing the practical handling capacity of the whole production line. Features Birnith heavy-duty feeders have good performance in the mining, construction, road building, bridge construction, and quarrying, recycling, aggregates and cement industries. Almost all kinds of minerals &rocks and some other materials processing plants can use the vibrating feeder. Stable performance &Reliable operation. Easy to adjust &Easy to maintain Long span life &No pollution with closed body Good performance-conditioning, it can be used in any severe environments

Loss-In-Weight Feeder

Get Price Quote

Loss in Weight system generates continuous mass flow.The system is provided with either Screw Feeder or Vibrator feeder for regulating the discharge, depending upon the characteristics of the material.The System comprises of a hopper with load cells.The weight of the material in hopper is measured and correspondingly, the output-feeding device regulates the flow & keeps it constant as per the set value.The Hi-low Level sensorswitches, which are provided in the hopper, regulate the refilling of hopper during continuous proportioning without interruption of the mass flow.

Twin Screw Loss-in-Weight Feeder

Get Price Quote

Twin screw loss-in-weight feeder twin screw loss-in-weight feeders are most effective for pigments, sticky, bridging or flooding powders, fiberglass.

Mechanical Gripper Feeder

Get Price Quote

Offers mechanical gripper feeder. Standard features round guides with linear ball bushings. capability to mount to any type of press. transmission through bevel gear box and cardian shaft from the press. lubrication oiling by grease nipple. accuracy of +-0.025mm with mechanical pilot synchronisation easy setting of pitch length. all adjustments are easily reachable. quick opening of the gripper for the strip insertion. release of the fixed gripper for die piloting in order to obtain & accurate positioning at high speed. adjustment for various thickness by means f knuckled knobs placed at the upper part of the feed. standard transmission for speeds uptill 300 strokes per minute including gear box, transmission shaft and rubber coupling. mounting stand bracket. cascade roll basket.

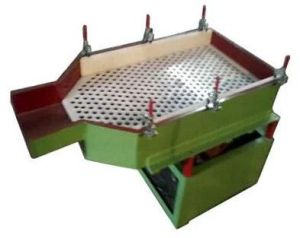

Vibratory Sorting System

60,000 Per Units

Electro Magnetic Vibrating Feeders

Get Price Quote

Electromagnetic vibrating feeders are equipped with electromagnetic drives which generate vibrations required for conveying of material. The electromagnetic drives are robust in construction with very high reliability factor. These conveyors come with a specially designed controller required for operation of the electromagnetic conveyor. These controllers convert the input AC supply voltage into pulsating DC output which results in generation of vibrations. A thyristor such as a silicon controlled rectifier is used for this purpose. The fringe angle of the SCR can be varied sleeplessly using a potentiometer or an analogous electrical signal / PLC signal from an external command variable unit, which in turn increases / decreases the amplitude of vibrations thereby controlling the output of the conveyor as required. As in the case of electromechanical feeders depending on the material conveyed, the conveyors can be supplied on two types viz, through type and tubular type. Suitable liners in case of through conveyors are provided where severely abrasive materials are handled as in the case of electromechanical conveyors. Advantages Easy & stepless variation of delivery of material either manually or automatically possible. Delivery remains generally constant in spite of fluctuations in supply voltage ( + 10% for voltage variation & + 3% for frequency variation. ) Drive is extremely robust and simple in construction. Electromagnetic drive is dustproof and is impervious to moisture

Electro Magnetic Vibrating Feeders

Get Price Quote

Electromagnetic vibrating feeders are equipped with electromagnetic drives which generate vibrations required for conveying of material. The electromagnetic drives are robust in construction with very high reliability factor. These conveyors come with a specially designed controller required for operation of the electromagnetic conveyor. These controllers convert the input AC supply voltage into pulsating DC output which results in generation of vibrations. A thyristor such as a silicon controlled rectifier is used for this purpose. The fringe angle of the SCR can be varied sleeplessly using a potentiometer or an analogous electrical signal / PLC signal from an external command variable unit, which in turn increases / decreases the amplitude of vibrations thereby controlling the output of the conveyor as required. As in the case of electromechanical feeders depending on the material conveyed, the conveyors can be supplied on two types viz, through type and tubular type. Suitable liners in case of through conveyors are provided where severely abrasive materials are handled as in the case of electromechanical conveyors. Advantages : Easy & stepless variation of delivery of material either manually or automatically possible. Delivery remains generally constant in spite of fluctuations in supply voltage ( + 10% for voltage variation & + 3% for frequency variation. ) Drive is extremely robust and simple in construction. Electromagnetic drive is dustproof and is impervious to moisture

VibroDyne-32 Vibratory Feeder Controller

Get Price Quote

VibroDyne-32 is a specialized solution for controlling electromagnet based vibratory feeders in the material processing and packaging industry. It has been designed around a 32 bit controller to offer a hoard of features currently unseen in the Indian market like: Controllable feed rate from 0 to 100% Nonvolatile memory for remembering previous settings Programmable ramp up and ramp down possibility Can communicate with PLCs and other automation systems Can be remote operated with optional GSM-GPRS modem

linear feeder

Get Price Quote

We are offering linear feeder type of machine: they are basically driven by electromagnetic forces. These linear vibrators feeders are made of m.s. Or stainless steel trays on the top and the body houses a electromagnet below the tray. The tray which is connected to the armature of the magnet vibrates. The vibration then sets the material in motion suitability : for any free flowing material, powder, chemicals, hardware parts, etc. Size : can be fabricated to the customers actual requirement. Control unit : it has dimmerstat controllers to vary the speed of the vibrations along with soft-start facility. Power : for standard applications - 230v ac, single phase, 50 hz accessories : (optional) sensors, plc controls, hoppers, various orientations, etc

Grizzly Feeder

Get Price Quote

Grizzly Feeder, Crushing Plant, Dewatering Screen, Dock Leveler

Vibratory finishing equipment

Get Price Quote

Vibratory finishing equipment, centrifugal finishing machines

vibrator feeder

Get Price Quote

Cable Reeling Drums, Cable Drag Chain, Hose Reel Drum, Vibrating Motor