POP Channel Roll Forming Machine

Get Price Quote

Timely delivery is our forte as we have up-to-date transit facilities and logistic services. Rely on us to buy the best in class Highway Grill Machine; we are a notable Supplier in this domain.

Double Roller Cotton Ginning Machine

100,000 - 200,000 Per Bag

Double roller ginning machine and spare parts

Best Deals from Rolling Machine

TCP-H-800 X 4000 CNC Roll Turning Lathe Machine

Get Price Quote

1 Piece (MOQ)

Optional Equipments : Hydraulic Quill Motorised Tailstock Steady Rest Motorised Turret Chip Conveyor Revolving Centre Tool Shank / Insert Stabilizer

Roll Forming Machine

1,850,000 - 2,650,000 Per Set

1 Set (MOQ)

Scaffolding Thread rolling machine

Get Price Quote

We Stand in the Midst of Specialized Circular Thread Roller Exporters. We Manufacture High Quality Thread Roller from Superlative Quality Raw Materials that Make Them Durable and Highly Resistant to Various Climatic Factors. We are One of the Predominant Flat Die Thread Roller Suppliers from India. These Thread Rollers are Manufactured as per International Standards, Under the Strict Vigil of Our Skilled Staff. as a Result, this Range of Our Unmatched Quality and High Performance Thread Rollers are Widely Demanded in National as Well as International Markets. in Addition to This, We Provide the Facility to Supply Variety of Thread Rolls as per the Client’s Specifications and Requirements. the 3 Rollers Hu-3r Rolling Machine Operates Hydraulically. the Simultaneously and Concentricity of Three Forces At 120º Assure Stability of the Work Piece During the Rolling and as a Consequence the Maximum Geometrical Precision of the Work Piece. the Elimination of the Support Blade Consents a Better Finishing of the Piece and the Execution of Particularly Delicate Profiles. the Machines is Suitable for Rolling Pipes, Lapping Work, Threading with a High Class Precision and for Mass Production of Scaffolding Pipe Jack and Solid Jacks Screws Etc. the Maximum Values Specified Above Can Not Be Achieved Simultaneously.

Hydraulic Thread Rolling Machine

295,000 Per Piece

1 Piece (MOQ)

Hydraulic Thread Rolling Machine

275,000 Per Unit

1 Unit (MOQ)

Automatic Roll To Sheet Cutting Machine

115,000 Per Piece

1 Piece (MOQ)

Three Roller Raymond Mill Plant

Get Price Quote

1 Unit (MOQ)

Roll To Roll Lamination Machine

Get Price Quote

1 Piece (MOQ)

bandage rolling machine

265,000 - 271,400 Per Piece

1 Piece (MOQ)

Main features of gauze bandage rolling machine Medical bandage rolling machine. Various rolling specification. Electronic counter meter & sensor proxy (digital) Easy to operate only need one operator. The machine can roll up to 30 meters, also special specification upon your request. Automatic rolling, and auto off machine, various rolling length by proxy Easy to operate - tight and loose rolling system. The max gauze diameter 5 inch. High production speed. Stable performance and low failure rate. Paper for packing. Terms & Condition:1. Payment: 50% advance with Purchase Order, 50% rest before delivery.2. Taxes: Extra as per 18% GST Applicable.3. Delivery: 1 month from the receipt of purchase order with advance.4. Installation: Charges are paid by customer.5. Fooding & lodging: Paid by the customer6. Packing & Transportation Charges: Paid by the Customer.

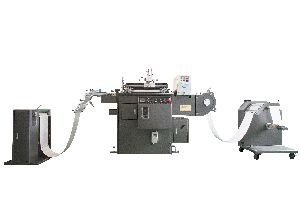

Roller Coater Machine

Get Price Quote

We are immersed in manufacturing and supplying of an extensive array of uv coating machine,roller coaster press machine.our product range is appreciated for its tough construction and excellent finish. These machines are used for uv coating, paper coating, paper, board, plastic sheet, metal glass, any type of plane sheets, etc. Further, these machines are equipped with dc drive for variable speed and smooth rubber rollers for coating. Our product range is also examined on set industry standards and is obtainable at market leading prices. sizes available : 18", 25", 30", 32", 36”, 40” with a rich industrial experience, we now specialize in offering printing machines solutions. We are the leading leading manufacturer, supplier and exporter of uv coating machines, uv curing machines, semi auto round screen printing machines, flat screen printing machines, uv coater, uv dryers, manual round screen printing machines, round filter printing machine, pen printing machine, pad printing machines, photo uv coating and curing machine, printing machines, online uv curing systems, pneumatic pad printing machine, mechanical pad printing machine, handy pad printing machine, mechanical flatbed screen printing machines, fully auto uv coating and curing machine, auto uv coating and curing machine, offset attachment with coater and uv dryer, uv attachment in offset printing machine, uv coater and uv dryer with offset machine, automatic uv coater and curing machine, round printing machine, uv lamps, uv offset attachment, printing machine for paper, printing machine for containers, printing machine for filters, screen printing presses, flame treatment machine, t-shirt printing machine, fabric stretching clamps, duplex printing machine, drying racks, roller coater machine and pvc profile printing, coating and curing machines in various sizes. We are looking for a supplier, dealer, business partners from indian states like uttarpardesh u.p. – kanpur, lucknow, punjab, haryana, gujarat, madya pardesh m.p., himachal pardesh h.p., jammu & kashmir, uttranchal u.k., delhi, rajasthan – jaipur, karnataka – bangalore, orrisa, bihar, andhrapardesh, maharashtra mumbai, west bengal – kolkatta, kerala, tamilnadu and countries like usa, uk, canada, australia, dubai, middle east, south africa, nigeria, bahrain, nepal, sri lanka, bangladesh, tanzania, saudi arabia, ukraine, zimbabwe and many other european, american, asian and african countries.

Hydraulic Roll Marking Machine

Get Price Quote

Clients can avail quality tested Hydraulic Roll Marking Machine from our company. Hydraulic Roll Marking Machine, available with us, is precision engineered and in compliance with the highest quality standards. The Hydraulic Roll Marking Machine is very easy to install and operate. A wide range of components can be marked with Hydraulic Roll Marking Machine. Features Easy to operate Automatic compensation for variation in workpiece diameters. Rigidly fabricated, reinforced steel frame. Stress relieved Can mark round workpiece upto 200 mm diameter Can mark flat workpiece upto 170 mm thickness Open back permits marking of long bars. Serial numbers can be marked with automatic indexing Can make upto 4 lines of 6 mm characters, or 8 lines of 3mm characters. Ample daylight permits extensive use of fixturing and tooling for alomost all shapes and sizes of components. Electrically controlled hydraulic operations : Hydraulic cyclinders operate table and marking die slide Table pressure controls depth of mark : ensuring uniform depth. One master foot-pedal control for operating table and die slide cylinders in proper sequence Specially designed cyclinder fitted with hardened bearing. Die slide moves on hardened plate with rollers for precision and long life Components that Can Be Marked : Shock Absorbers, Flanges, Elbows, Bends, Mortar Barrels, Gears, Fuses, Pistons, Couplings, Railroad Bearings, Shells, Axles, Propeller Shafts, Rock Drills, Magneto, Lock Body. Also Availabel Against Specific Orders special Purpose Machines Wherein Daylight can be increased to 425 mm. Stroke can be increased 250 mm. Marking capacity can be increased to 8 lines of 6 mm characters. Specifications Marking Capacity 4 Lines of 6 mm Characters ( in Mild Steel ) 6 Lines of 6 mm Characters 8 Lines of 3 mm Characters Die Slide Stroke : 10 mm Daylight : 285 mm Throat : 90 mm Open Back : Permits Marking of Long Bars Open Distance : 180 mm Between Up-Rights Output : Upto 600 Nos. per hour depending on Length of stroke and shape of component Table Size : 250 X 200 mm. Table Rise : 10 mm Hydraulically, 110 mm by handwheel. Table Pressure : 1T to 4T Floor Area : 2000 X 2000 mm Height : 1500 mm Nett Weight : 850 kg Motor : 3HP, 1500rpm, 440 V, 3-Phase, 50 Cycles Pump : 10 Litres / Min Hydraulic Tank : 75 Litres.

Ekl-2432 Rg 24 Feet Heavy Duty Roll Grooving Lathe Machine

1,500,000 - 1,700,000 Per piece

1 piece (MOQ)

Roll to Roll Lamination Machine 43"

265,000 - 385,000 Per

1 piece (MOQ)

Roll Grinding Machine

850,000 - 1,500,000 Per Piece

1 Piece (MOQ)

Hydraulic Plate Rolling Machine

1,000,000 Per Piece

1 Piece (MOQ)

Roll to Sheet Cutting Machine

175,000 Per Piece

Roll to sheet cutting machine 7" to 120" size are cutting accurate cutting size easy set the sheet size than cutting machine size:- 52" with manual book of sheet cutting size mentioned.

Roll To Roll Slitting Machine

Get Price Quote

1 Unit (MOQ)

paper rolling machine

Get Price Quote

5 Piece (MOQ)

close oven rock n roll rotational moulding machine

400,000 - 700,000 Per Piece

1 Piece (MOQ)

Three Roller Pipe Bending Machine

Get Price Quote

1 Piece (MOQ)

A three-roller pipe bending machine is a specialized type of section bending machine designed to bend pipes, tubes, and other profiles using three rollers to apply pressure. This type of machine is commonly used in industries like construction, automotive, shipbuilding, and metal fabrication, where precise and smooth curves are required in pipes or profiles. Key Components: Three Rollers: Top Roller: This is usually the adjustable roller that moves vertically (up and down) to control the bend’s radius. Bottom Rollers: These are fixed and rotate the pipe or profile through the machine while applying bending force. Electric or Hydraulic Power System: The machine can be powered by an electric motor or hydraulic system to move the rollers and provide the force needed to bend the pipe. Frame/Structure: A heavy-duty steel frame that holds the rollers in place and supports the machine during operation. Control Panel: Allows the operator to adjust the roller positions, bending speed, and pressure. Guide Rollers: Some machines are equipped with side guide rollers to help maintain the shape of the profile and ensure the bend is consistent. Types of Three-Roller Pipe Bending Machines: Manual: These machines are operated by hand, typically for small-scale or light-duty applications. Electric: Powered by an electric motor, these machines are more powerful and are used for larger pipes and more frequent bending tasks. Hydraulic: These use hydraulic power to move the top roller and provide force, suitable for bending larger diameter pipes or thicker materials. CNC: Computer-controlled versions that allow for precision bending and automation, often used in industrial applications where high accuracy and repeatability are needed. Working Principle: The pipe or profile is placed between the three rollers. The two lower rollers rotate the pipe while the upper roller applies pressure downward to bend the pipe into a curve or arc. By adjusting the position of the top roller, the operator can control the tightness of the bend. The machine can produce different radii and angles depending on the settings of the rollers. Bending Process: Loading the Pipe: The pipe or tube is placed between the three rollers, usually with the outer two rollers positioned at the desired spacing based on the pipe size. Adjusting the Rollers: The top roller is adjusted downward to begin bending the pipe while the two lower rollers rotate the pipe forward. Bending: As the pipe moves through the machine, the top roller continues to press the pipe, gradually forming the bend. Completing the Bend: The process continues until the desired angle or curve radius is achieved. Applications: Construction: Bending structural pipes for building frameworks, handrails, and curved beams., roll bars, and other curved components. Shipbuilding: Bending pipes and sections used in ship hulls and frames. Furniture: Used to form curved pipes and tubes for chairs, tables, and other metal furniture pieces. Aerospace: Bending precision pipes and profiles for aircraft parts.

Double Fold Opening & Rolling Machine

280,000 - 415,000 Per Piece

1 Piece(s) (MOQ)

We are a prominent manufacturer and supplier of all types of Double Fold Opening & Rolling Machine that are known for their study construction, high tolerance power and low maintenance. These Double Fold Opening & Rolling Machine are used to roll all type of fabrics.

Roller Tinning Machine (Hand Operating with Flywheel) (VPL-RTM)

Get Price Quote

SPECIFICATIONS Table top unit for tin/solder coating of PCB’s. Hand operated with fly wheel allows easy coating of boards (in ETARTM). Motor version with 220V AC Motor (in ETA-RTM-M). Maximum PCB width : *200mm×250mm (8″×10″) STANDARD *300mm×250mm (12″×10″) on demand.

Roll to Roll Screen Printing Machine

2,500,000 - 4,500,000 Per Unit

1 Set (MOQ)

About Product Introducing a game-changing solution for label printing – the Roll To Roll Screen Printing Machine. This cutting-edge machine is designed to elevate your label production, delivering unmatched quality and versatility that set your labels apart from the rest. Additional information Key Features: Print Brilliance: Say goodbye to limitations. Our Screen-Printing Machine brings your label designs to life with vibrant colors, intricate details, and exceptional clarity that captivates the eye. Seamless Roll-to-Roll Operation: With effortless roll-to-roll functionality, our machine ensures smooth transitions and uninterrupted printing, allowing you to maintain high efficiency and maximize your output potential. Versatile Adaptability: From diverse label materials to various sizes and shapes, our machine adapts seamlessly. Experience flexibility that empowers you to bring your creative visions to life. Precision in Every Print: Whether it’s fine text or complex graphics, our machine guarantees precise printing results that match your design’s intricacy, ensuring consistent excellence with every roll. User-Friendly Excellence: Simplify your printing process with intuitive controls and user-friendly features. Experience reduced setup time and streamlined operations, empowering your team to achieve outstanding results. Built to Perform: Crafted with the highest quality materials and advanced engineering, our Screen-Printing Machine is built to withstand the demands of high-volume production, ensuring longevity and reliability. Transform Your Label Printing: Step into the future of label production with the Roll To Roll Screen Printing Machine. It’s more than a machine; it’s a catalyst for creativity and innovation that reshapes how you present your brand. Ready to redefine your label game? Contact us today to explore how the Roll To Roll Screen Printing Machine can revolutionize your printing operations. Precision, versatility, and creativity converge – with the Roll To Roll Screen Printing Machine.

Hot Melt Roller Machine

105,000 Per Set

1 Set(s) (MOQ)

Roll Etching Machine

1,200,000 Per Piece

1 Piece (MOQ)

Cold Rolling Machine

Get Price Quote

1 Piece (MOQ)

Guide Forming Machine

Get Price Quote

Are you looking for the guide forming machine,best guide forming machine manufacturer in Mumbai? Panchal Engineering Works has known as the best company for sourcing these machines. Our company supplies certified products to customers all around the globe. We have built a huge clientele all around the world. Our customers and clients appreciate our products and are happy with our customer service.Why Choose Products From Us?Quality Assurance Quality is the biggest priority and we never comprise with it. We always make sure that the products of our company have unmatched quality and our customers get machines that meet their requirements. We check our products at every stage to make sure that it meets the international standard quality.Affordable Pricing The products of our company are listed at an affordable price for our customers. All our machines are sold at competitive pricing in the market.For more details call us. We will answer all your questions and will make sure that you get the best products for your use.

Roller Type Manual Pipe Bending Machine

17,300 Per Piece

1 Piece (MOQ)