Industrial Cyclone Separator

100,000 - 200,000 Per piece

1 Piece (MOQ)

Cyclone Separator

45,000 - 500,000 Per Piece

Our range of Cyclone Separator is acclaimed for its international quality standards. Our Cyclone Separator is equipped with advanced features that ensure its high operational effectiveness and quicker cleaning actions. The Cyclone Separator offered by us is designed with high capacity motor which helps in swift cleaning. Features Sturdy and long life Quick color change Powder bin cum hopper Less floor space occupation Easy maintenance Applications Cement industry Powder conveying industry Abrasive industry Rubber industry

Best Deals from Cyclone Separators

Cyclone Separator

Get Price Quote

1 Piece (MOQ)

Dust Waste Handling Systems

Get Price Quote

1 Unit (MOQ)

Schematic of a typical Dust Handling System for a Ginning Plant Dust / Waste Handling Systems particularly applicable to the handling of cotton / lint waste and associated trash created by machines in ginning plants. The system consists of a pneumatic ducting circuit connecting a filteration unit to all factory locations where waste and dust is generated. A fan creates an air flow in the ducting circuit to carry waste and dust therealong. The fan separates the air flow into major and minor portions and by centrifugal force transfers most of the waste and dust to the minor portion. The air in the major portion is directed back to the factory space via a filter to remove any dust contained in the major portion. A typical waste handling system we offer for removing waste and dust from a ginning factory has been shown. The major components of the waste/ dust handling systems comprise of : Pneumatic ducting line with G.I. Pipes, bends and diverters. Centrifugal fans already attached to the systems in case of existing plants to draw dust / trash from the trash generating machineries. Primary filter to seperate fibrous material from the conveying air and allows micro dust to pass to the secondary filters. Secondary filter to seperate micro dust from conveying air. Ventilator to pull microdust air along with fibrous waste from primary filter to compactor and again supply the excess to primary filter after compaction. Secondary ventilator to pull microdust from secondary filters and pass it to cyclone seperator and dust compactor with fresh air exit to secondary filters. Cyclone separator and dust compactor to separate microdust taken from secondary filter and allow to fresh air back to secondary filter. SALIENT FEATURES Better performance due to minimised pressure loss. Compact design and hence less space required. Waste is compacted and hence easy to handle. Optimum utilisation of fans ensures complete cleanliness. Cost effective. Can be incorporated in existing set ups. Easy to maintain, low maintenance costs. Sturdy gearbox design and high quality rotating parts and nozzles for longer life.

Cyclone Separator

50,000 Per Piece

1 Piece (MOQ)

Looking for a Cyclone separator? Look no further as starevertechnologies is here as your best Cyclone Separator manufacturer. Cyclone separators are indispensable in industries when it comes to effective dust control. These devices employ the principles of force called centrifugal. It is to filter out the particles from the air or any form of gas. Functioning on the principle of inertia, cyclones make the dusty air revolve. Thus throwing out the heavier particles outwards due to centrifugal force. Features of our Cyclone Separators In the case of our Cyclone Separator models, all our units are constructed using strong and high-quality materials for optimum performance. Manufactured for different industries, they provide optimum efficiency in demisting environments. They filter out very fine particles from the air or gaseous mixtures. This improves the quality of the latter and minimizes the frequency of maintenance. The following are the benefits of choosing our cyclone separators; ● High Efficiency: It has the capability of trapping dust particles at a rate of up to ninety-nine per cent. ● Low Maintenance: Strong and durable to give you long-lasting performance. ● Versatility: Ideal for various types of industries. Conclusion Specifically, at Starever Technologies we deal with the production of highly efficient and durable cyclone separators. Please browse through the range that we provide to get the right solution to dealing with dust.

Cyclone Separator

40,000 Per Piece

4 Piece (MOQ)

Mild Steel Cyclone Separator

350,000 Per Unit

1 Unit (MOQ)

Cyclone Separator

Get Price Quote

1 Piece (MOQ)

Cyclone Separator

Get Price Quote

1 Unit (MOQ)

Cyclone Separator

Get Price Quote

1 Unit (MOQ)

Cyclone Separators

300,000 Per Piece

1 Piece (MOQ)

Stainless Steel Cyclone

Get Price Quote

Cyclone Separator

Get Price Quote

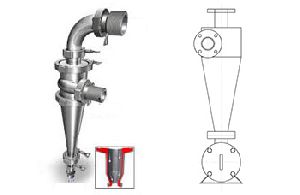

Cyclone Separator is mostly used for common dust removal in the industry. The Cyclone Dust Separator offered by us is simple in construction and can be used at a very high temperature. In cyclone separator the suspended particles are separated from the gas stream by the action of centrifugal and gravitational force. The dust-laden gas is introduced tangentially into the separation chamber and thereby vortex flow is formed. Consequently, in cyclone separator of small diameter, the separation of small suspended particles is effected and thus high degree of separation is achieved. For effectively working of dust collection systems with cyclone, efficient dust valves are vital and these dust valves are properly designed and supplied from our end. We provide availability of separator at affordable prices. We are considered as one of the foremost Multi Cyclone Separator Manufacturers from India.

Horizontal Cyclone Separator

Get Price Quote

1 Piece (MOQ)

A horizontal cyclone is a type of cyclone separator used to remove particulate matter from gas streams. It is a cylindrical vessel with tangential gas inlets that create a swirling motion within the vessel. The swirling motion causes the particulate matter to be separated from the gas stream and collected at the bottom of the vessel.Horizontal cyclones are often used in industrial settings, such as chemical and petrochemical plants, to remove particulate matter from gas streams before the gas is released into the environment or sent to other processing equipment. They are also used in power generation plants to remove particulate matter from the flue gas before it is released into the atmosphere.The advantages of using a horizontal cyclone include its ability to remove a wide range of particle sizes, its low maintenance requirements, and its relatively low cost compared to other types of particulate matter removal equipment. However, horizontal cyclones have some limitations, including their low efficiency in removing fine particles and their potential to create pressure drops in the gas stream.Overall, horizontal cyclones are an effective and widely used type of cyclone separator for particulate matter removal in industrial settings. Their design and operation have been refined over many years, making them a reliable and cost-effective solution for many applications.ApplicationHorizontal cyclones are widely used in industrial settings to remove particulate matter from gas streams. Here are some examples of their applications: Chemical and Petrochemical Plants: Horizontal cyclones are used in chemical and petrochemical plants to remove particulate matter from gas streams before the gas is released into the environment or sent to other processing equipment. They are used to remove particles that can cause damage to equipment, reduce efficiency, or pose a safety risk. Power Generation Plants: Horizontal cyclones are used in power generation plants to remove particulate matter from flue gas before it is released into the atmosphere. This helps to reduce air pollution and comply with environmental regulations. Mining and Mineral Processing: Horizontal cyclones are used in mining and mineral processing operations to remove particulate matter from gas streams created during the extraction and processing of minerals. They are used to remove dust and other particles that can cause equipment damage or pose a safety risk to workers. Food Processing: Horizontal cyclones are used in the food processing industry to remove particulate matter from gas streams created during food processing operations. They are used to remove dust and other particles that can contaminate food products or cause health and safety issues. Pharmaceuticals: Horizontal cyclones are used in the pharmaceutical industry to remove particulate matter from gas streams during the production of pharmaceuticals. They are used to remove dust and other particles that can cause product contamination or affect product quality. Overall, horizontal cyclones are an essential part of many industrial processes and are used in a wide range of applications to remove particulate matter from gas streams efficiently and reliably.

Cyclone Separators

125,000 - 670,000 Per Piece

1 Piece (MOQ)

Horizontal Cyclone Separator

Get Price Quote

1 Piece (MOQ)

Cyclone Separator

Get Price Quote

Stainless Steel Cyclone Separator

65,000 Per

1 Unit (MOQ)

Cyclone Separator

Get Price Quote

Stainless Steel Cyclone Separator

Get Price Quote

We offer secured online and offline payment processing methods. The transaction, done through online mode, is instantly forwarded to the payment system. We also accept bank account transfers, cash payments, etc. We are working with an aim of making available flawless lot of products and for this; we check the product quality on several grounds. The offered Stainless Steel Cyclone Separator is designed for minimal resistance to ensure lowest possible depositing and optimal discharge for a high degree of separation.