Hot Dip Galvanized Channel

49,000 - 57,000 Per Metric Ton

25 Metric Ton (MOQ)

Hot Dip Galvanizing

15 - 25 Per Kilogram

100 Kilogram (MOQ)

Looking for Hot Dip Galvanizing Service Providers

hot dip galvanizing services

Get Price Quote

Hot-dip galvanization is a form of galvanization. It is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around 840 °F (449 °C). When exposed to the atmosphere, the pure zinc (Zn) reacts with oxygen (O2) to form zinc oxide (ZnO), which further reacts with carbon dioxide (CO2) to form zinc carbonate (ZnCO3), a usually dull grey, fairly strong material that protects the steel underneath from further corrosion in many circumstances. Why Us? We, Maheshwari Hot Dip Galvanizers, established in 1996 are engaged in Hot Dip galvanizing of Iron and Steel Structures. Our Plant is located 20 Kms from Nasik, towards Mumbai, outside Octroi limit on Nasik Mumbai Highway. Our Plot area is 11000 Sqmtrs and Plant area is 16,700 Sq. Fts.Our production capacity is 24000 TPA. We are operating Two Zinc Bath Kettles of sizes as under: Bath 1 : 5.0 mtr(L) x 0.8 mtr(W) x 1.2 mtr(D) Bath 2 : 8.6 mtr(L) x 0.8 mtr(W) x 1.2 mtr(D) Our plant is equipped with all the necessary infrastructure like E.O.T Cranes, Material Handling Systems, Finished Material Stock Yard, Weigh Bridge, ETP, Power backup, Testing & Inspection Laboratory, Tower wise Bundling and Packing, etc. Hot Dip Galvanizing is carried out as per latest international standards and specific customer requirements by our highly qualified and experienced team.

Hot Dip Galvanizing

100 Per piece

100 Piece (MOQ)

hot dip galvanizing services

Get Price Quote

We are leading galvanizing company since 5 years. Our group is ISO certified 9001 :2015A unique combination of service and commitment to exceed your expectations through Hard Work, Innovation Technology, Customer Focus, Quality and Timely delivery are the Forte of Matrix Grating Pvt Ltd. We manufacture these products by strictly adhering to a number of internationally acclaimed standard and specifications. Our company has a highly sophisticated manufacturing unit equipped with advanced technologies. The unit isoperated by team of highly skilled techno crafts enriched with indepth knowledge in plating technologies & manufacturing process. As part of our ongoing commitment to excellence, we at Matrix Grating Pvt Ltd, follow a stringent quality control policy to ensure A-class quality in each and every product we manufacture at All the manufacturing process at our company are performed as per International norms and standards. We strictly adhere to a 7 tank process during galvanization of our products. Galvanizing is a central activity in the supply chain which offers scope for backward and forward integration. Fabrication for industrial and infrastructure projects. Trading of non-ferrous metal and scrap Open doors to Manufacturing/ trading of galvanized products such as cable trays, galvanized hardware, Transmission and electrical accessories, cold roll steel, structural steel like beams, TMT bars, Piping fo oil and sector Exposure to a various industries which require galvanizing and gain opportunities in expanding business. Application of Hot-Dip Galvanising Infrastructure Solar and wind energy Oil and Gas Railways Industrial Turnkey Project and many more……. Marine and Shipping Automobiles Telecommunication Electrical and Power Transmission

hot dip galvanizing services

Get Price Quote

Amit Sales Corporation Pvt Ltd offers exclusive Hot Dip Galvanizing services at reasonable prices in Ghaziabad. Our team of professionals provide magnificent services to the customers and also caters the need of the customers. Our services provide barriers and protection to the steel surface and are also durable to protect against corrosion. Hot-dip galvanizing helps in the reduction of maintenance of the equipment. Our services of hot-dip galvanizing not only provide protection but also provide brightness and also longer shelf life of the equipment. Our service provides complete protection against any type of imperfections. Our team of expert professionals takes care of severe quality checks of equipment after such services.

hot dip galvanizing services

Get Price Quote

We are a leading service provider of Hot Dip Galvanizing Services in Delhi, India. This is a process of coating iron and steel with a layer of zinc by immersing the metal in a bath of molten zinc. They are carried on in controlled environment under the guidance of highly skilled professionals. We provide these services at leading market prices. Details : Hot-dip galvanization is a form of galvanization. It is the process of coating iron and steel with a layer of zinc by immersing the metal in a bath of molten zinc at a temperature of around 840 °F (449 °C). When exposed to the atmosphere, the pure zinc (Zn) reacts with oxygen (O2) to form zinc oxide (ZnO), which further reacts with carbon dioxide (CO2) to form zinc carbonate (ZnCO3), a usually dull grey, fairly strong material that stops further corrosion in many circumstances, protecting the steel below from the elements. Galvanized steel is widely used in applications where corrosion resistance is needed without the cost of stainless steel, and can be identified by the crystallization patterning on the surface (often called a "spangle").[1] Galvanized steel can be welded; however, one must exercise caution around the resulting toxic zinc fumes. Galvanized steel is suitable for high-temperature applications of up to 392 °F (200 °C). The use of galvanized steel at temperatures above this will result in peeling of the zinc at the inter metallic layer. Electrogalvanized sheet steel is often used in automotive manufacturing to enhance the corrosion performance of exterior body panels; this is, however, a completely different process which tends to achieve lower coating thicknesses of zinc.

hot dip galvanized

Get Price Quote

Hot dip galvanized or powder coated Black or Green your option on top of Hot dip galvanized

hot dip galvanizing services

Get Price Quote

Fluxing The acid-cleaned steel article is immersed in a flux solution, usually 30% zinc ammonium chloride with wetting agents, maintained at about 65◦C. The flux solution removes the oxide film which forms on the highly reactive steel surface after acid cleaning and prevents further oxidation before galvanising. The work is then dried ready for galvanising. Galvanising On immersion in the galvanising bath the steel surface is wetted by the molten zinc and reacts to form zinc-iron alloy layers. To allow formation of the metallurgic bond the work remains in the bath until its temperature reaches that of the molten zinc, in the range 445◦C to 465◦C. The work is then withdrawn at a controlled The period of immersion in the galvanising bath varies from several minutes The resulting galvanised coating is tough and durable, comprising relatively pure zinc and zinc-iron alloy layers bonded metallurgically to the underlying steel, completely covering the article externally and internally, providing resistance to corrosion. The fact that hot dipped galvanising provides internal as well as external protection. Galvanising Facilities NSEPL Galvanizing 9 m long x 1.2m wide x 1.2m deep.NSEPL Galvanizing work 24 hours a day, offering industry leading turnarounds with the majority of work being galvanized within 2 days of receipt.The layout of the galvanizing facilities at Domjur, Howrah have been designed with customers in mind. The galvanizing facility is ‘in line’ allowing all our multi skilled employees to have access to any part of the production line. NSEPL Galvanizing have also set aside large areas for the checking in and out of the customer work aswell as a large, inside storage facility where quality is checked with diligence.NSEPL Galvanizing have been designed to cope with a wide variety of fabrications.Work galvanized by NSEPL Galvanizing comes from a wide spectrum of sectorsfrom Agricultural to Architectural. Advantages It worth considering the advantages of hot galvanizing in comparison with the most popular methods of metal treatment – painting and cold galvanizing. The advantagesof hot galvanizing are : Resistance to environmental impacts. Double corrosion protection High coating strength High wear resistance

Hot Dip Galvanizing Service

Get Price Quote

With the continuous support and sincere efforts put by our experienced professionals, we have been able to provide our clients the best quality Hot Dip Galvanized Job Work. Offered service is performed under the strict supervision of our experts using optimum grade tools and latest technology. Our professionals perform this service as per the requirements of our clients. Further, the provided service can be availed by our valuable clients at most competitive price.

Hot Dip Galvanizing

Get Price Quote

We are leading manufacturers and suppliers of a comprehensive range of color coated roofing sheets. There are three kinds of different materials to give the product their own features and the organically combined to make a new generation of heat insulation uPVC sheet to solve the product durability, corrosion resistance, small rigidity, a sense of space and aesthetics issues. VSI uses a superior paint technology that provides additional protection for longer life. The superior paint technology resists cracking and peeling even of paint. These Color coated Roofs are widely used in Residential buildings, Garages, Commercial buildings, Agricultural Storage units, Small Industrial sheds, Institutional buildings and for various other roofing applications.

Hot Dip Galvanizing

15 - 45 Per kg

1000 Kg (MOQ)

As a full-service coatings company, Jetcotech provides quality surface finishes that extend the service life and improve the appearance of metal products throughout the country. In fact, Jetcotech is one of the largest custom galvanizers in West Gujarat. Our processes and transportation capacities are designed to efficiently handle steel products of all shapes and sizes, for customers anywhere in the country. Through continuous innovation, Jetcotech has also developed quality processes for Galvanizing.The depth and breadth of our coatings services makes Jetcotech a one-stop solution for all of your galvanizing and coatings needs. From the largest steel structures to the smallest parts, our galvanizing facilities provide end to end service.Further, our strategically located galvanizing plants build off of each other's strengths to provide the right solution for every project, at the best price. So, you can depend on Jetcotech to deliver a high quality finished product, on time, through service that is meticulous and seamless.The combined capabilities of our state-of-the-art plants provide Jetcotech with the capacity to galvanize projects of any size, quickly and efficiently.Jetcotech provides quick turnaround and on-time deliveries for every project. Because of our quick response times, Jetcotech takes up less of a projects overall timeline, thus allowing fabricators more leeway in their production schedules. At Jetcotech, we promise to serve our customers with superior service, impeccable quality and on-time delivery at the best value.

Hot Dip Galvanizing

Get Price Quote

Hot dip galvanising plant on the surface of Steel, aluminium and iron metal with zinc coating for long lasting and quality finishing by professionals as per the client's need and demand. Hot dip galvanising plant used in the processing of galvanizing by our organization as Precimax online to deliver the best solutions that's why we are appreciated by our clients and clients positive feedback is our main assets. Galvanization is the process of coating defensive zinc coating on steels and irons into classify to find rusting, we take all cautions and supply and offer best to hot-dip galvanising plants since 1962 over more than 400 clients. Galvanizing equipments are the total option of products which is included as hot dip galvanising crash guard and guard rail, Galvanizing Plant, General Galvanizing Plant, Galvanizing Plant for Radiator and Transformer, Galvanizing Dryer, Wire Galvanizing Line. Hot dip galvanising is design and developing for the utilizing high grade of raw materials and heavy hot dip Galvanising machine in harsh conjunction with the industry set the norms and levels. Hot dip Galvanizing is usually very well tested in unique details in order that defect free products usually are sent from consumers' place. Hot dip Galvanising give some advantaged like limited pickling time period, short manufacturing charge, reduced creation price tag, improved productivity etc.

Hot Dip Galvanizing Service

Get Price Quote

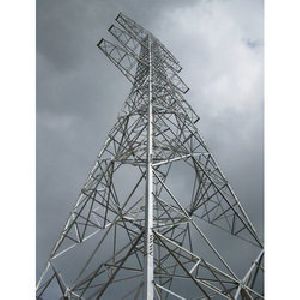

If you are looking for a trusted transmission tower fabrication service provider in Nashik (Maharashtra, India), then contact us. We have with us a dedicated team of professionals and highly advanced machines and tools using which we conduct the fabrication work of the transmission tower. We have with us experts who can easily conduct the welding service. Also, we can fabricate the towers as per the requirements of the clients.

Hot Dip Galvanizing

Get Price Quote

Our plant composes of : PRE-TREATEMENT DEPARTMENT GALVANIZING PLANT FINAL TREATMENT DEPARTMENT ECHOLOGICAL PLANT PRE-TREATEMENT DEPARTMENT

Hot Dip Galvanizing

Get Price Quote

Corrosion is destructive result of the chemical action between metal and its enviornment. It is the process of mrtal being worn away. If left unprotected, steel will react with surrounding enviornment and return to its more stable oxide compounds thus consuming the steel in the process. The most reliable way to protect steel being Hot Dip Galvanizing, is the practice of immersing clean, oxide free iron or steel into molten ZINC in order to form a zinc coating that is Metallurgically bonded to the iron or steel surface. The zinc coating process the against corrosion by providing protection to the iron or steel in the following ways: It shields the base metal from the atmosphere. Smooth and high quality coating even on awkward and intricate surfaces. Equally good coating on sharp edges and corners. Further maintenance on site rarely demanded Hot dip Galvanizing after fabrication is done as per IS:2629:1985 & 4759;1984 We are using the purest zinc available on the market(Special High Grade 99.995%)

hot dip galvanization

Get Price Quote

We are offering tanya galvanizers is a family owned business since 1956 currently it is managed by mr. C. K. Singh. He has been is in this line since 1995. He is well experienced in hot dip galvanizing process. Mr. C. K. Singh believes that providing a customer with the best service is the best way to do business.

Hot Dip Galvanizing

Get Price Quote

Hot-dip galvanizing, in comparison to the protection of steel surfaces using other means, represents single long-term protection. In combination with dying, the quality of protection may last more than fifty years. Hot-dip galvanizing has up till now in the world been the most efficient and ecologically acceptable method of protecting steel. In technological and economical terms, the hot-dip galvanizing method has mostly been used in protection against corrosion.

Hot Dip Galvanizing

Get Price Quote

We Introduce Our Selves As A ISO 9001 : 2008 Certified Company, Named M/S.Parmar Galvanisers. It Was Established In Year 2007 By Most Experienced And Dynamics Top Management. Top Management Of The Company Having Wide Experience In Metal Industries. We Are A Group Of Companies As PARMAR Group. At Present Engaged In HOT DIP GALVANISING Jobworks Activity & Fabrication Work As Per Customer Specification.We Are Dealing With Goverment Organizations And Provate Sectors Like Getco, Pgvcl, Pipavac Shipyard Limited, Jyoti CNC, Parmar Metal Pvt. Ltd.,Bhel Ranipet, Bhel Noida, BSNL Bhillai, BSNL Jabalpur,. Asia Motors Works, Enercon (India) Limited, Afcons Infrastructures Ltd., Echjay Industries Pvt. Ltd., Power High Engineers Pvt. Ltd.,Etc.. Hot-Dip Galvanising (HDG) Is The Process Of Coating Fabricated Steel By Immersing It In A Bath Of Molten Zinc. There Are Three Fundamental Steps In The Hot-Dip Galvanising Process; Surface Preparation, Galvanizing And Inspection. Our Infrastructures Is In 2500sq.Mtrs. Area Having 1000 Sq. Mtrs Built Up Area. Company Have Its Own State-Of-The Art Technology And Modern Dual Fuel Burners System (Gas Of Furnesh Oil) Of Hot Dip Galvanising Plant. Company Have Ethusiastic Skilled Work Force Of Employees. At Present Capacity Of Hot Dip Galvanising Is 900MT Per Month. We Introduce Our Selves For A Longterm Business Association With Your Esteemed Organizations With Assurance Of Good Quality, Reliability And Consistency. Company Having All The Required Certifications And Inhouse Laboratory Facility.

Hot Dip Galvanizing

Get Price Quote

Hot-dip galvanizing, in comparison to the protection of steel surfaces using other means, represents single long-term protection. In combination with dying, the quality of protection may last more than fifty years.