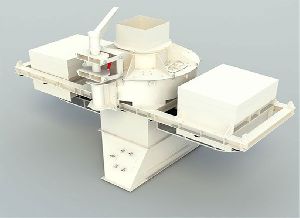

Vertical Shaft Impact Crusher Machine

Get Price Quote

1 piece (MOQ)

Jaw crusher

Get Price Quote

Jaw Crusher is one of the highly demanded products of our company. It is widely used for stone crushing at various construction sites. Our Crusher is easy to operate and require low maintenance. Our Jaw Crusher is highly durable in nature. We fabricate Jaw Crusher using high-grade metal and other raw materials to ensure superior quality. Jaw Crusher is corrosion and rust resistant. Buyers can acquire Jaw Crusher at the best price in the market.

Best Deals from Crushing Machine

Stone Crushing Plant

5,000,000 - 15,000,000 Per 100 ton

Jaw crusher

Get Price Quote

Cone Crusher

Get Price Quote

Cone Crusher

Get Price Quote

A cone crusher is a mechanical machinery used in many developing countries like Use of cone crusher in the industry has proven to help increase the productivity and quality level. This is the main reason why use of these cone crushers is rapidly increasing in most of the developing countries including India.

Jaw crusher

Get Price Quote

We Offer : Single Toggle Jaw Crusher Coal Crusher Double Toggle Jaw Crusher VSI Crusher Roller Crusher Horizontal Impact Jaw Crusher Features : Light Weight Easy Operation Less Maintenance Dimensional Accuracy

Single Toggle Grease Jaw Crusher

Get Price Quote

"KINGSON" Brand Single Toggle Grease Jaw Crusher is generally used where size distribution is not of paramount importance but productivity is to be maximized with lower power consumption as compared to Double Toggle Grease Lubricated Jaw Crusher and hence operating cost is lower.

US VERTICAL SHAFT IMPACT CRUSHER

Get Price Quote

The three-hole impact enclosed rotor is adopted to realize the crushing and forming of the materials entering the crusher through the principle of stone-hit-stone and self crushing. Meanwhile, crushing and forming of big particle can also be realized.

Mobile Impact Crusher

Get Price Quote

Putting crushing and screening process on wheels really boosts process efficiency. Mobile impact crusher offers maximum set-up flexibility, from course to fine crushing, and is cost efficient. It improves working safety, reduces the need for quarry road maintenance, and gives better access to material resources. A further benefit is that waste material can be separated on-site. Putting crushing and screening process on wheels really boosts process efficiency. Mobile impact crusher offers maximum set-up flexibility, from course to fine crushing, and is cost efficient. It improves working safety, reduces the need for quarry road maintenance, and gives better access to material resources. A further benefit is that waste material can be separated on-site. Features It is easy to adjust the crushing gap, enable to control grain-size and keep good particle shape. Complete crushing function, high productivity, mechanical wear and high comprehensive benefit. Easy to adapt and flexible to collocate with other machines Reliable performance and convenient maintenance Application Mobile impact crusher is mostly used for medium and fine crushing process in stone crusher plant. It well fits for crushing numerous medium and soft materials, such as limestone, feldspar, calcite, talc, barite, clay, tombar thite, kaolin, gypsum, graphite, etc.

Impact Crusher

Get Price Quote

Impact crusher adopts the newest manufacturing technology and unique structure design, so the discharged product is with cubic and perfect shape, no tension and crack. This crusher can crush materials with size smaller than 500mm and resisting strength less than 350MPa, such as granite, limestone, concrete aggregate, etc.

Hammer Crusher

Get Price Quote

Mobile Crusher Plant

Get Price Quote

We are offering mobile crusher plant. Mobile crushers are essential for the crushing of concrete and asphalt of various types. Available in different types, they are used as primary, secondary, as well as tertiary equipment for particle-on-particle crushing or for improving the quality of end material in terms of shape, size and texture as well as for decreasing the wear and tear of the machine and several other important results.

Vertical Shaft Impact Crusher

Get Price Quote

Industrial Crushers

Get Price Quote

We are specialist in making available Industrial Crushers in a wide spectrum of grades and specifications. We are immensely recognized for delivering the orders within the stipulated time frame and at desired Udaipur(India).

Jaw crusher

Get Price Quote

We are reckoned to be the leading Jaw Crusher Manufacturer, Supplier and Service Provider. These Jaw Crushers are manufactured using high grade components and are widely acknowledged by the clients for their optimum performance and easy maintenance. ConstructionBody : The main frame is constructed using M.S. Heavy Plates and is reinforced by heavy horizontal and vertical ribs. The durability of the bearing is enhanced by machining of the structure in one operation on both sides of the main bearing housing.Moving Jaw : The moving jaw has a box type structure and is made using M.S. Plates. Eccentric shaft is fitted into tapper roller bearing while machining the moving jaw. Jaw Plates : The fix and moving jaw plates are fabricated using Manganese Steel casting. To ensure easy fitting and removal, the fix jaw plate has a machined wedge plate.Fly Wheel : To ensure smooth running of the jaw crusher, two heavy Cast iron Fly wheels are fitted on Eccentric shaft. One of them with the arrangement of V- belt drive is useful for driving pulley.Shaft and Bearing : Self-aligning spherical heavy duty roller and taper roller bearings are fitted in the moving Jaw assembly and in main frame. Herein, the heavy eccentric shaft is fabricated from EN-8 Steel to endure the strain and stress of crushing. FeaturesRobust constructionLess wear and tearLong functional lifeHigh durabilityEasy to operate Technical Specifications Size in InchesABCDEFPowerRPMProduction Ton/Hr.SizeCapacity8 X 67406164653495436005 HP380201 ½ - 212 X 7100085059050065095410 HP380202-2 ½16 X 913701120730615920108620 HP380204-5

Jaw crusher

Get Price Quote

Jaw crusher, Grizzly Feeder, Vibrating Screen, Cone Crusher

Jaw crusher

Get Price Quote

We are offering jaw crusher. We are engaged in manufacturing a wide range of crusher spears, gun metal /bronze toggle pins, seats , & flywheel bushes which is widely being used in crusher machinery. These products are manufactured using high quality raw material, we customize these products as per the requirements of the clients. We make these products available at reasonable rates.

Jaw crusher

Get Price Quote

Stone Crushing Solutions Marble and Granite Processing Solutions Crane Solutions

Mining Crusher

Get Price Quote

Mining Crusher, Mineral Jig, Drilling Bucket, Mini Dumper, pol pipe