ELECTROMAGNETIC FLANGE MOUNTED BRAKE

1,300 - 4,500 Per Piece

1 Piece(s) (MOQ)

vna engineers manufacturer of vide range of products with brand name of 'indoflux ' . Offer a wide range of electromagnetic clutch , brake , bearing mounted clutch , bearing mounted brake , flange mounted clutch , flange mounted brake , clutch brake combination enclosed as well as open type , failsafe brake , rotor for failsafe brake , custom design of electromagnetic clutch brake as per customer requirements . aplication area - 1) textile machineries , lr c 1/3 card machine , draw frame , speed frame , ring frame , cheese winding etc . 2) packaging machinery - form fill seal machine , capping machine , levelling machine etc . 3) industrial washing machine , carnes , lifts etc. 4) marble processing machine such as dressing machine . 5) steel plants machinery 6) cement plants such as stacker reclaimer 7) machine tools , printing machinery , robotics 8) tyre making machinery , 9) construction machinery 10) coil winding machinery 11)wire drawing machinery 12)battery operated electric vehicles , wheel chair , x- ray machines , 13)cranes and hoists , servo motors , presses , tower cranes , goods lifts , golf carts and many more

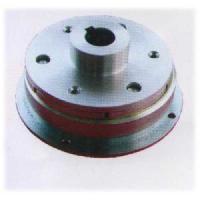

Flange Mounted Brakes

Get Price Quote

We manufacture and supply highly efficient Flange Mounted Brakes that are widely appreciated for their efficiency. Our Flange Mounted Brakes work effectively and assures smooth functioning. Our Flange Mounted Brakes are widely used in various industries for their excellent features. We further, make them available at highly economical price. Applications Textile machines, material handling equipments, conveyors, machine tools, glass making machines, marble cutting machines, stone polishing machines, photocopiers, packaging machines, etc. Working These type of brakes are normally-off type and operates on power. When power is given to the stator (coil), thearmature is attracted towards the asbestos free friction liner of the brake stator which clamps the rotatingcomponent stop at once. On switching off the electric power, the unique prestressed spring pulls the armatureplate back into its original position and brake positively released with no residual torque. Switching Normally off type clutches operate on D.C. voltage, hence A.C. to D.C. conversion is done by means of asuitable rectifier. Switching of the brake can be on either side. However, once application demands, higherswitching frequency / faster engagement and disengagement time,switching must be carried out on D.C. Side.To restrict the high inductive voltage / back EMF a suitable supressor and capacitor network is provided acrossthe contactor coil.

Best Deals from Flange Mounted Brake

ELECTROMAGNETIC FLANGE MOUNTED BRAKE

Get Price Quote

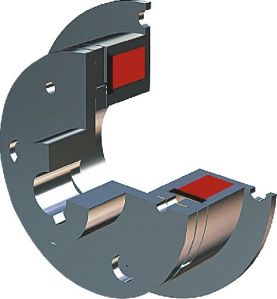

Textile Machines, Printing Machines, Machine Tools, Pick & Place Robots, Plastic Machinery, Conveyors, Laundry Machines, Brake Motors, Paper Machines, Bottle Washing Machines, Wire Drawing Machines, Coil Winding Machines, Packaging Machines... etc. COMPONENT DESCRIPTION : 1. Stator2. Coil3. Friction Lining4. Armature Plate5. Leaf Spring6. Flanged Hub WORKING These type of brakes are normally-off type and operates on power. When power is given to the stator (coil), the armature is attracted towards the asbestos free friction liner of the brake stator which clamps the rotating component stop at once.On switching off the electric power, the unique prestressed spring pulls the armature plate back into its original position and brake positively released with no residual torque. SWITCHING Normally off type clutches operate on D.C. voltage, hence A.C. to D.C. conversion is done by means of a suitable rectifier.Switching of the brake can be on either side. However, once application demands, higher switching frequency / faster engagement and disengagement time, switching must be carried out on D.C. side. To restrict the high inductive voltage / back EMF a suitable supressor and capacitor network is provided across the contactor coil.

Flange Mounted Brake

Get Price Quote

Salient Features Simple Construction Single Plate Dry Type Maintenance free long life Stationary Field (No Slip Ring) Coil with Class 'F' Insulation Simple wear adjustment Special Friction Material High Operating Frequency Simple Installation Working of EFMB When DC Voltage is supplied to the coil(6) the armature (4) is attracted towards the brake liner(5) of the stator(7)and the friction stops the rotating component. When supply is cut off the "prestressed" spring(3) pulls back the armature plate and hence the brake is free Description 1. Flange 2. Rivet 3. Spring 4. Armature Plate 5. Brake Liner 6. Coil 7. Brake Stator Size Selection Ordering Information Approximate necessary Torque or Size of a unit for applications involving low inertia & low operating frequency is determined as ; TORQUE = [ 9550 x (K.W. / SPEED)] x SAFETY FACTOR [K] SAFETY FACTOR [K] To ensure necessary transmission safety also under extreme operating conditions adequate safety factor must be considered the value of which depends on operating conditions namely, the type of load, prime mover etc. Typically [K] For Electric drive Low masses equal loading & non-intermittent operation [2.0] Low masses light shock load & intermittent operation [2.5] Medium masses, light shock load & intermittent operation [3.0] Large masses, light shock load & intermittent operation [3.0] Non-overhauling loads [2-3] Overhauling loads [3-4] Diesel engine drive [4-5] Compressor driven [5-6] However, we recommend you to perform detailed calculations for which please consult us. Life Of Friction Material The life of the friction liner depends on a number of factors namely, the inertia to be retarded or stopped, the relative speed, the operating frequency, the temperatures at the friction surfaces etc. These brakes must run dry. Oil, grease, foreign materials & other lubricants affect life and characteristics of friction material. Electrical Connections The Brakes are operated with DC. connection from three phase or AC mains network can be made via a transformer rectifier, bridge rectifier or half wave rectifier. To restrict the high inductive voltage / back EMF a suitable Supressor and Capacitor network is provided across the connector coil as shown in fig.

ELECTROMAGNETIC FLANGE MOUNTED BRAKE

Get Price Quote

Normally off type clutches operate on D.C. voltage, hence A.C. to D.C. conversion is done by means of a suitable rectifier.Switching of the brake can be on either side. However, once application demands, higher switching frequency / faster engagement and disengagement time, switching must be carried out on D.C. side. To restrict the high inductive voltage / back EMF a suitable supressor and capacitor network is provided across the contactor coil.

ELECTROMAGNETIC FLANGE MOUNTED BRAKE

Get Price Quote

FL series power-on clutches are used to couple two parallel shafts. The armature hub assembly is mounted to the same shaft as rotor assembly. The armature hub accommodates a pulley, gear, sprocket, etc., to transmit torque to second shaft. The field assembly is mounted to bulkhead that perpendicular to input shaft.

Flange Mounted Brakes

Get Price Quote

Flange Mounted Brakes, Electromagnetic Clutches, Brake Motors

Flange Mounted Brakes

Get Price Quote

Flange Mounted Brakes, Electromagnetic Clutch Brake, bearing mounted clutches