Two Heads Stone Round Table Cutting Machine

225,000 - 280,000 Per Nos

1 piece (MOQ)

The SLP Engineers Two Heads Stone Round Table Cutting Machine is an innovative and highly efficient tool designed specifically for the furniture industry, particularly for cutting round table tops from granite and marble stones up to 50 mm in thickness. This advanced machine features two cutting heads: the first head is dedicated to cutting round shapes from the stone slab, while the second head is equipped for molding the edges of the table top, ensuring a smooth and aesthetically pleasing finish. The auto-down cutting blade mechanism, powered by two 5 hp motors, provides precise and powerful cutting capabilities, making it the best machine for producing round table tops for the furniture industry. The distribution process of this sophisticated machine involves a comprehensive approach to ensure its seamless integration into the customer’s operations and maximize its utility. The process starts with extensive market research to identify potential customers, including furniture manufacturers, stone processing companies, and custom stone furniture makers. Market segmentation is carried out to target specific segments based on geographical location, business size, and industry type. Following market identification, customer outreach is executed through multiple channels such as trade shows, digital marketing, and direct sales calls. Detailed product presentations and demonstrations are essential components of the outreach strategy, providing potential customers with in-depth information about the machine’s features, benefits, and operational capabilities. Marketing materials, including brochures, videos, and customer testimonials, are created to highlight the unique aspects of the machine, such as its dual-head cutting system, precision, and ease of use. Once potential customers express interest, detailed quotations are prepared, covering the machine’s price, delivery terms, and payment schedules. Negotiations are conducted to finalize the terms, ensuring mutual agreement on all aspects. Upon order confirmation, the manufacturing process is initiated, adhering to stringent quality control measures to ensure the machine meets the highest standards of performance and reliability. The manufacturing process includes component fabrication, assembly, and rigorous testing to verify the cutting accuracy and overall functionality of the machine. Logistics planning follows, involving the selection of the most appropriate transportation mode—whether road, sea, or air—to ensure safe and timely delivery. Robust packaging is employed to protect the machine during transit, and all necessary shipping documents, such as invoices, packing lists, warranty certificates, and user manuals, are meticulously prepared. The dispatch process is closely monitored to ensure the machine reaches the customer on schedule, with regular communication maintained to provide tracking updates and confirm delivery details. Upon delivery, the installation team ensures the machine is correctly set up and operational at the customer’s site, conducting commissioning tests to verify its performance. Comprehensive training is provided to the customer’s operators, covering operational procedures, routine maintenance, and safety protocols to ensure effective and efficient use of the machine. Post-delivery support is a crucial aspect of the distribution process, offering ongoing technical assistance to address any operational issues and conducting regular follow-ups to ensure customer satisfaction. By following this detailed and structured distribution approach, SLP Engineers ensures that the Two Heads Stone Round Table Cutting Machine is not only delivered and installed seamlessly but also integrated effectively into the customer’s operations, providing long-term value and enhancing their productivity. This thorough distribution process underscores SLP Engineers’ commitment to quality

Brand Name : SLP

Material : CI BODY

Finishing : Coated

Color : White

Condition : New

Automatic Grade : Semi Automatic

Power Source : Electric

Power Consumption : 10 HP

Speciality : High Precision Cutting

Usage : Industrial, Stone Cutting

Certification : ISO 9001:2008 Certified

Voltage : 440V

Cutting Capacity : 50 MM

Overall size : 10 X6 FEET

Table Size : 5 feet Round Table Cutting

Machine Weight : 800 kg

Phase : Three Phase

Warranty : 1 Year

Country of Origin : India

Motor Speed : 1440 rpm

Max Cutting Thickness : 50mm

...more

Trolley Type Granite Edge Cutting Machine

165,000 - 245,000 Per Piece

1 Piece (MOQ)

The Trolley Type Edge Cutting Machine you described sounds like a versatile and efficient solution for cutting marble and granite slabs up to 100 mm thickness. Here's a summary of its features and capabilities: Suitable for Marble and Granite: The machine is specifically designed to cut both marble and granite slabs, making it a versatile option for stone processing operations. Heavy Channel Fabricated Table: The machine features a sturdy table made from heavy channel fabrication. This ensures stability and support for the stone slab during the cutting process. Dual Rail Line System: The machine has two rail lines mounted on the table. One is an inverted V rail line, and the other is a square rail line. These rail lines provide a smooth and precise path for the moving trolley. Moving Trolley with Four Wheels: The trolley, which carries the cutting blade, is equipped with four wheels that travel on the rail lines. This design ensures smooth movement and reduces friction during operation. Caterpillar Unit for Stability: The caterpillar unit, mounted on the backside of the trolley, further enhances stability and ensures precise cutting. Adjustable Cutting Blade: The cutting blade can be adjusted both vertically and horizontally, allowing for precise and custom cuts to achieve the desired marble slab size. Special Feature for Degree Cutting: The machine has a special feature that enables cutting marble slabs at different angles or degrees. This feature is useful for creating beveled edges or custom shapes. Handle Wheel for Trolley Movement: The trolley is equipped with a handle wheel, allowing the operator to move it forward and backward with ease. With these features, the Trolley Type Edge Cutting Machine provides a comprehensive solution for cutting marble and granite slabs with precision and efficiency. The ability to adjust the cutting blade and the special feature for degree cutting allows for greater flexibility in stone processing, catering to various customer requirements. Given its robust construction and versatile capabilities, this machine is likely to be an essential tool in stone fabrication workshops, contributing to increased productivity and quality in the production of marble and granite slabs.

Brand Name : SLP

Color : White

Condition : New

Automatic Grade : Manual,Manual

Certification : ISO 9001:2008, ISO 9001:2008 Certified

Voltage : 440V

Overall size : 7*3 Trolley

Warranty : 1year, 1 Year

Frequency Range : 50Hz

Country of Origin : India

...more

stone edge cutting machine

200,000 - 250,000 Per piece

The trolley-type stone block cutting machine manufactured by SLP Engineers in Udaipur, India, is a sturdy and efficient tool with the following features: - Manufacturer: SLP Engineers, based in Udaipur, India. - Motor: It is equipped with a 15 hp motor operating at 50 Hz frequency, providing ample power for cutting operations. - Machine Body: The entire machine body is made of CI (cast iron) material, ensuring durability and robustness. - Cutting Size: The machine can cut stone blocks with dimensions up to 1000 mm in length and 600 mm in width, and it can handle thicknesses of up to 400 mm. - Blade Compatibility: The machine's blade can be adjusted up and down, allowing the use of blades with diameters ranging from 600 mm to 1000 mm, providing versatility for various cutting tasks. - Design: It has a single pillar design, contributing to stability and precision during cutting operations. - Movement: The machine's movement, including up-down and front-back, is manual, providing precise control over the cutting process. - Trolley: The trolley is manually operated with a handle and runs on a rail line. Its size is 1200x750 mm, making it suitable for handling stone blocks effectively. - Rail Line Length: The rail line on which the trolley operates is 3000 mm long, providing ample space for cutting large stone blocks. - Installation: The machine is fixed on an MS (mild steel) structure stand, which ensures a stable base for cutting operations. - Portability: Thanks to its easy-to-shift design, the machine can be conveniently moved around, enhancing its usability in various work environments. - Suitable Materials: This cutting machine is best suited for cutting soft stones, lettered stones, and sandstones, making it versatile for a wide range of stone cutting applications. With these specifications and the reputable manufacturer, the machine is well-suited for efficiently and accurately cutting various types of stones, making it a valuable tool in stone cutting operations. The CI material used for the machine body adds to its strength and longevity, ensuring reliable performance over time.

Brand Name : SLP

Driven Type : Elecric

Color : Grey

Condition : New

Rated Power : 15 hp

Automatic Grade : Manual

Certification : ISO 9001:2008

Voltage : 440 volt

Machine Type : Block Cutting

Type : Trolley

Weight : 1000-2000kg

Warranty : 1year

Country of Origin : India

Warrenty : 1 Year

...more

Stone Cutting Machine

150,000 - 220,000 Per Bag

1 Piece (MOQ)

Heavy duty stone & granite cuttting machine.Slabe,small size block,AAC Brick,laterite stone,,sand stone block cutting machine.

Frequency Range : 50HZ

Brand Name : SLP

Certification : ISO 9001:2008 Certified

Voltage : 440V

Automatic Grade : Manual

Material : Mild Steel

Cutting Capacity : 300mm

Machine Weight : 800 kg

Table Size : 2.5x2.5 feet

Overall Length : 20-30 Inch

...more

STONE CHOKHAT PATTAM CUTTING MACHINE DOUBLE BLADE

250,000 - 350,000 Per Nos

1 piece (MOQ)

Machine Type: STONE CHOKHAT PATTAM CUTTING MACHINE DOUBLE BLADECompatible Materials: Granite, Marble, Jodhpur StoneBlade Configuration: Two blades: one vertical and one horizontal Both blades operate simultaneously for cutting door frames Machine Design: Trolley TypeBlade Mounting: Blades fixed on pillarsTrolley Movement: Trolley runs on rail lines Customizable sizes: 83 feet, 103 feet, or as per customer requirementsConstruction: Entire body made of cast iron (CI) Key Features: Dual-blade system for efficient cutting Trolley design for easy maneuverability Customizable trolley sizes to accommodate different door frame dimensions Sturdy cast iron construction for durability and stability This machine seems tailored to meet the specific needs of cutting door frames from various types of stone. With its dual-blade setup, trolley design, and sturdy construction, it offers efficiency, precision, and durability for stone processing tasks.

Brand Name : SLP

Material : CI BODY

Finishing : Coated

Color : White

Condition : New

Automatic Grade : Manual

Power Source : Electric

Power Consumption : 15 HP

Speciality : High Precision Cutting

Usage : Industrial, Stone Cutting

Certification : ISO 9001:2008 Certified

Voltage : 440V

Cutting Capacity : 100mm

Overall size : 22 x6 Feet

Table Size : 8x3 Feet Trolley

Machine Weight : 1800 KG

Phase : Three Phase

Warranty : 1 Year

Country of Origin : India

Motor Speed : 1440 rpm

Max Cutting Thickness : 100 mm

Water Consumption : 15 ltr/MINT

...more

Granite Edge Cutting Machine

142,000 Per Piece

1 Piece (MOQ)

Portable Edge Cutting Machine is best suited for cutting Granite & Marble Slab and tiles. It has MS Channel Fabricated bed upon which bridge is mounted. Cutting Blade unit moves on bridge and cutter moves forward and Backward manually by moving Handle. Machine is Heavy Duty, Durable, doesnt create vibration while work. It is powered by Branded Motor mounted above the cutter unit and it drive V belt pulley which provide rotational movement in cutting blade

Brand Name : SLP

Certification : ISO 9001:2008 Certified

Voltage : 440V

Automatic Grade : Manual

Corrosion Resistance : Yes

Material : Mild Steel

Color : White

Phase : Three Phase

Warranty : 1 Year

Condition : New

Power Source : Electric

Speciality : High Precision Cutting

Cutting Capacity : 50 Mm

Country of Origin : India

...more

single arm slab polish machine pneumatic

125,000 - 150,000 Per Bag

1 Piece (MOQ)

Design and Construction: The machine has an arm-type design, where a rotating arm extends over the surface of the stone slab. It is built with a sturdy metal frame and components to ensure stability and durability during operation. The arm mechanism allows the polishing head to cover a wide area of the stone slab uniformly. Pneumatic System: The machine is equipped with an air cylinder pressurized by compressed air. This pneumatic system is responsible for providing the force required to press the polishing head against the stone surface with the desired pressure. The pneumatic system ensures consistent and controlled polishing pressure across the entire slab. Polishing Head and Attachments: At the end of the arm, there is a polishing head that holds multiple polishing attachments, such as diamond abrasive pads or polishing discs. The size and configuration of the polishing head may vary, depending on the manufacturer's design. Main Motor: The main motor of the machine is a 7.5 hp electric motor, running at 50 Hz frequency. This powerful motor drives the rotation of the polishing head, enabling efficient and effective polishing. Water Feed System: To cool down the stone surface and the polishing attachments during operation, the machine features a water feed system. The water is continuously sprayed onto the stone slab as the polishing head moves, preventing overheating and providing a better finish. Manual Handle: The machine is designed to be operated by a single person. The operator controls the movement of the polishing arm using a manual handle. The manual handle allows for precise control over the polishing process, making it easy to achieve the desired results. Easy Operation: The machine is designed to be user-friendly and straightforward to operate. With simple controls and ergonomic design, the operator can easily maneuver the arm to cover the entire slab surface evenly. Safety Features: Safety is a crucial aspect of any machine operation. The machine may include safety features such as emergency stops and safety guards to ensure the operator's well-being during use. This arm-type pneumatic stone slab polishing machine offers significant advantages in terms of efficiency, speed, and uniformity of polishing compared to manual methods. It is commonly used in stone fabrication workshops and factories to polish large stone slabs quickly and with consistent quality. Proper training and adherence to safety guidelines are essential for safe and effective operation.

Brand Name : SLP

Driven Type : Electric

Automatic Grade : Manual

Power : 9-12kw

Application : Slab Polish MAchine

Size : 3000*1500 Mm

Certification : ISO 9001:2008

Voltage : 440V

Type : Single Arm Polish

Weight : 100-1000kg

Warranty : 1 Year

Country of Origin : India

Main motor power : 7.5 HP

Overall Dimensions : 3600* 1500 mm

...more

single arm slab polish machine Manual

78,000 - 105,000 Per Bag

1 Piece (MOQ)

The single-arm slab polishing machine you described is a manual, up-down machine capable of polishing stone slabs with dimensions of 30001500 mm. It features a main motor of 5 Hp, operating on 3-phase 50Hz power supply. The machine has a manual handle for operation and is constructed with an MS (Mild Steel) body. To install the machine, it requires a foundation with dimensions of 600600 mm and should be mounted on four bolts for stability. Here's a summary of the machine's specifications: Design: Single-arm slab polishing machine with manual, up-down mechanism. Slab Size Capacity: Can polish stone slabs up to 3000*1500 mm in size. Main Motor: 5 Hp electric motor operating on 3-phase 50Hz power supply. Body Material: Constructed with an MS (Mild Steel) body for durability. Manual Operation: The machine is operated manually using a handle. Water Feed System: Likely equipped with a water feed system to cool the stone slab during polishing. Installation: Requires a foundation with dimensions of 600*600 mm for stable mounting. Mounting: The machine should be installed on four bolts for secure attachment to the foundation. This machine is suitable for smaller fabrication workshops or projects that do not require fully automated polishing equipment. Its manual operation and relatively compact size make it a practical choice for polishing stone slabs within the specified dimensions. However, since it requires a foundation with precise dimensions and proper mounting, it is essential to ensure the installation is done correctly to maintain stability and safety during operation. Proper training and adherence to safety guidelines are necessary for the operator to use the machine effectively and safely.

Brand Name : SLP

Driven Type : Electric

Color : Grey

Condition : New

Automatic Grade : Manual

Power : 6-9kw, 5 hp

Application : Slab Polish MAchine

Certification : ISO 9001:2008

Voltage : 440V

Type : Single Disc Polishing Machine

Warranty : 1 Year

Country of Origin : India

Size : 3000*1500 mm

...more

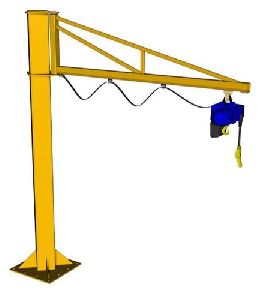

Jib Crane

201,000 Per Piece

1 Piece (MOQ)

Brand Name : SLP

Mounting : Floor Mounted

Material : Mild Steel

Power Source : Electric

...more

Double Blade Kota Stone Cutting Machine

225,000 - 260,000 Per piece

1 piece (MOQ)

The SLP ENGINEERS Double Pillar Kota Stone Cutting Machine is a highly efficient and robust tool specifically designed for precision cutting of Kota stone, marble, and granite tiles. Featuring a 14-inch dual-blade system, this machine can cut two sides of Kota stone simultaneously, significantly enhancing productivity and cutting accuracy. Powered by a powerful 7.5 hp motor, it ensures consistent, high-performance cutting suitable for demanding, heavy-duty applications. The machine's cutting housing includes two units, providing additional stability and precision during operation, while the integrated 4x2.5 feet trolley facilitates smooth handling and transportation of stone, ensuring a seamless workflow and operational efficiency. This cutting machine is meticulously engineered to meet the needs of stone processing industries, tile manufacturers, and construction companies, offering an unparalleled combination of power, precision, and durability. The distribution process for the SLP ENGINEERS Double Pillar Kota Stone Cutting Machine involves several critical steps to ensure seamless delivery and ultimate customer satisfaction. It begins with thorough market research to identify potential markets, including stone processing industries, construction companies, and tile manufacturers, both domestically and internationally. Identifying these markets involves segmenting them based on geographical location, industry type, and business size to effectively target the appropriate audience. Following market identification, customer outreach is conducted through various channels such as trade shows, online marketing, and direct sales calls. This outreach is supported by detailed product presentations, live demonstrations, and comprehensive marketing materials that highlight the machine's unique features and benefits, including its cutting capacity, motor power, and operational efficiency. Upon receiving customer inquiries, detailed quotations are prepared, covering pricing, delivery terms, and payment schedules, followed by negotiations to finalize the terms and ensure mutual agreement. Once an order is confirmed, the manufacturing process begins, adhering to stringent quality control measures to ensure the machine meets the highest standards of performance and reliability. This involves component fabrication, assembly, and rigorous testing to verify cutting accuracy and overall functionality. The logistics planning phase involves selecting the appropriate transportation mode—be it road transport for domestic deliveries or sea and air freight for international shipments—ensuring robust packaging to protect the machine during transit, and preparing all necessary shipping documents, including invoices, packing lists, warranty certificates, and user manuals. Upon dispatch, the delivery process is closely monitored, and clear communication is maintained with the customer to confirm delivery schedules and provide tracking updates. Post-delivery, the installation team ensures the machine is correctly set up and operational at the customer’s site, conducting commissioning tests to verify performance and providing comprehensive training to the customer’s operators. This training covers operational procedures, routine maintenance, and safety protocols to ensure effective use of the machine. Ongoing technical support is provided to address any operational issues, along with regular follow-ups to ensure customer satisfaction. The SLP ENGINEERS Double Pillar Kota Stone Cutting Machine stands out as the best machine for making Kota, marble, and granite tiles, offering unmatched efficiency, precision, and reliability. Its powerful motor, dual-blade system, and sturdy construction make it an invaluable asset for any stone processing or construction business. By following a meticulous distribution process that includes market research, customer outreach, detailed product presentation, negotiation, quality manufacturing, efficient logistics, and compreh

Brand Name : SLP

Material : CI BODY

Finishing : Coated

Color : White

Condition : New

Automatic Grade : Manual

Power Source : Electric

Power Consumption : 15 HP

Speciality : High Precision Cutting

Usage : Industrial

Certification : ISO 9001:2008 Certified

Voltage : 440V

Cutting Capacity : 50 MM

Overall Length : 10 FEET

Overall size : 10 X6 FEET

Table Size : 4*2.5 FEET

Machine Weight : 1000 KG

Phase : Three Phase

Warranty : 1 Year

Country of Origin : India

Motor Speed : 1440 Rpm

Max Cutting Thickness : 50mm

Water Consumption : 15 Ltr/MINT

...more

Automatic Granite Edge Cutting Machine

208,000 - 230,000 Per Piece

1 Piece (MOQ)

The Portable Edge Cutting Machine Automatic seems to be an excellent choice for cutting both Granite and Marble slabs and tiles. Here's a summary of its key features: Material Compatibility: The machine is designed to handle both Granite and Marble slabs and tiles, making it a versatile tool for stone cutting tasks. MS Channel Fabricated Bed with Bridge: The machine's foundation consists of a sturdy MS (Mild Steel) channel fabricated bed upon which a bridge is mounted. This design ensures stability and support for the cutting process. Automatic Cutter Movement: The cutting blade unit moves on the bridge, and the cutter itself automatically moves forward and backward. This automatic movement is powered by a gearbox motor, enhancing the machine's efficiency and reducing the need for manual intervention. Heavy Duty and Durable: The machine is built to be heavy-duty and durable, capable of withstanding the demands of continuous stone cutting operations. Vibration-Free Operation: The machine's design and construction ensure that it operates without creating excessive vibrations during cutting. This is crucial for maintaining accuracy and preventing unnecessary wear on the equipment. Branded Motor and V Belt Pulley System: The machine is powered by a reliable branded motor mounted above the cutter unit. The motor drives a V belt pulley system, providing the necessary rotational movement to the cutting blade. The combination of an automatic cutter movement, durable construction, and vibration-free operation makes this Portable Edge Cutting Machine Automatic an efficient and user-friendly tool for stone fabrication workshops. Its ability to handle both Granite and Marble materials allows for greater versatility and flexibility in production. With its automatic features, such as automatic cutter movement and a reliable motor drive, the machine streamlines the cutting process, potentially leading to higher productivity and reduced manual labor. This is particularly beneficial in high-volume stone processing environments. Overall, the Portable Edge Cutting Machine Automatic appears to be a reliable and efficient solution for cutting Granite and Marble slabs and tiles, catering to the needs of stone fabrication businesses and contributing to improved cutting precision and productivity.

Brand Name : SLP

Driven Type : Elecric

Color : Grey

Condition : New

Rated Power : 5-7kw

Automatic Grade : Automatic

Certification : ISO 9001:2008

Voltage : 440 volt

Type : Automatic Granite Cutting Machine

Weight : 1000 Kg

Country of Origin : India

Warrenty : 1 Year

...moreOpening Hours