Sponge Iron

Get Price Quote

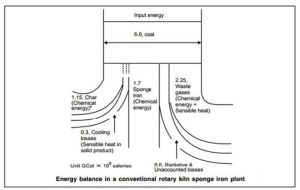

Sponge iron kilns are energy intensive. 30% of the energy input to the kiln is lost to the atmosphere through flue gas. Many sponge iron plants with kiln capacity higher than 200 tons, the heat in the exhaust flue gas is already utilised to generate steam and generate power. However, sponge iron plants with a capacity less than 200 tons normally let out the flue gas into the atmosphere after cooling the same in forced draft cooler(FDC). Hence there is a great oppurtunity for these plants to install ORC power systems for conversion of waste-heat to power.As per conservative estimates, it is possible to generate upto 1.5MW electrical power from the waste flue gas emnating from a 200 ton sponge iron kiln.

Sponge Iron

4 Per Kilogram

50 Ton (MOQ)

Our company is enlisted among the reputed Suppliers of Sponge Iron. The Sponge Iron we make available is used for the production of various steel and iron based products like bars, pipes and tubes. Courtesy our brilliant Logistics network, we are capable of delivering bulk orders of it within the promised timeframe. The entire range of the Sponge Iron is reasonably priced by us.

Best Deals from Sponge Iron

Sponge Iron

Get Price Quote

200 Ton (MOQ)

We are a prominent Wholesale Supplier of Sponge Iron. The Sponge Iron is known for high ferrous content. The Sponge Iron is properly processed and shaped. The Sponge Iron is stringently tested to ensure superior quality. The Sponge Iron is highly-appreciated by our valued clients because of their superior strength and long-life.

Sponge Iron

Get Price Quote

We specialize in exporting and supplying Sponge Iron, which is high on demand by steel making and iron industry. Fabricated as per set industrial standards and norms, Sponge Iron we offer has no other alternative in the market. The quality of Sponge Iron is determined by the percentage of metallization (removal of oxygen) that is the ratio of metallic iron to the total iron existing in the same. Clients can avail the same at most reasonable prices and secured packaging.

Sponge Iron

28,000 - 30,000 Per Tonne

30 Tonne (MOQ)

Sponge iron is made by heating iron ore with a reducing gas that contains hydrogen and/or carbon to produce metallic iron. The reaction takes place at a temperature of around 1100°C.

Sponge Iron

Get Price Quote

We are the Manufacturer & Supplier of this product. Sponge Iron is a high quality metallic product produced from Iron Ore, Pallets etc. as a feedback, Electric Arc and Induction furnaces, and other Iron and Steel making processes. Sponge Iron can be used in steel units where DRI reduction unit is a situated at the site of steel making plant. Specification( % ) Fe(T) 790-92 min Fe (M) 75-78 min Metallization 85-88 min S&P 0.15(Max) C 0.2 (Max) Non Mag 1.5 Max Size 4-18 mm

Sponge Iron

30,000 - 34,000 Per Metric Ton

25 Metric Ton (MOQ)

Sponge Iron

Get Price Quote

1 Ton (MOQ)

Sponge Iron

Get Price Quote

Sponge Iron

Get Price Quote

We are engaged in the supplying of pure Sponge Iron. Our sponge iron holds great demand in various industrial applications. We offer superior quality sponge iron that is also known as direct-reduced iron. We provide high grade sponge iron which holds diverse applications in various industries. We assure our sponge iron to pass through various strength and durability tests before delivery in the market.

Sponge Iron

Get Price Quote

Sponge Iron

40,000 - 42,000 Per Metric Ton

100 Metric Ton (MOQ)

Supply Condition: Sponge Iron may be supplied in Lumps or as Fines either in loose or bagged in HDPE bags, as may be required by the customer. Standard: As per BIS: 15774, 2007 Material Specification: Note : Above size tolerance is valid at dispatch end only. Storage Precautions Needed: It is advisable to keep Sponge Iron under cover to avoid any direct contact with moisture before usage. Moisture promotes oxidation thus reducing metallization. Sponge Iron needs special care during storage and transportation for which IS:10852 stipulations may be followed. Special care is taken while dispatching Sponge Iron from the plant by putting proper sealing over the material loaded on vehicles to protect against environmental deterioration.

Sponge Iron

Get Price Quote

Sponge Iron

Get Price Quote

2 Metric Ton (MOQ)

Sponge Iron

Get Price Quote

We are well-known for the manufacturing and supplying of Sponge Iron. The Sponge Iron is the key raw material for the manufacturing of steel. The appropriate percentage of metallization (removal of oxygen) ensures the high quality of the Sponge Iron. The percentage of metallization is the ratio of metallic iron to the total iron present in the product. For the various applications of Sponge Iron, it has been consistently demanded by the steel industries. Metals : SulphurPhosphurCarbonIron Technical Specifications Fe Total88 % ±2 %Fe Metal76 % ±2 %Metallization85 % ±2 %Sulphur0.05 % MaxPhosphur0.06 % MaxCarbon0.2 % MaxFe Total88 % ±2 %Size4 to 20 mmSponge Iron - FinesFe Total85 % ±2 %Fe Metal70 % ±2 %Metallization78 % ±2 %Sulphur0.05 % MaxPhosphur0.06 % MaxCarbon0.2 % MaxSize1 to 4 mm

Sponge Iron

900 - 1,500 Per Tonne

100 Metric Ton (MOQ)

Sponge Iron

35,000 - 38,000 Per Tonne

50 Ton (MOQ)

Sponge Iron

Get Price Quote

Avail from us premium quality Industrial Sponge Iron that is widely used as a raw material for the making of steel. The High Graded Sponge Iron is sourced from the reliable vendors who lay special emphasis on the quality. High Graded Sponge Iron provided by us is not contaminated from any kind of foreign material. We have carved a niche as one of the major Sponge Iron Suppliers based in India.

Sponge Iron

Get Price Quote

We are backed by the most sophisticated transit system, thus buyers can stay rest assured for timely delivery of the orders. To protect our products from being damaged during transit/ handling, we use industrial grade packaging materials. Furthermore, we ensure the packs are appealing for marketing purposes.

Sponge Iron

Get Price Quote

we offer superior quality sponge iron that is also known as direct-reduced iron. we are proud to be counted as one of the key sponge iron manufacturers and high graded sponge iron suppliers in karnataka. features we offer it in various grades assured to be purefree from contamination uses it is processed in order to create wrought ironused in various applications in direct steel pants packaging we have a ready to supply sponge iron ore in monthly basis normal quantity