Zinc/ epoxy coated tmt bars

100 - 200 Per Kilograms

100 Kilogram (MOQ)

JB Engineering Zinc Coated /Epoxy Coated TMT Bars are highly corrosion resistant variant of steel bars which are protected by Fusion Bonded Epoxy coating. Fusion Bonded Epoxy coating, commonly used to protect concrete TMT bars, steel pipes, piping connections etc. used in construction. Fusion Bonded Epoxy coatings are in the form of dry powder at normal atmospheric temperature. The powder is applied electrostatically to the surface of cleaned steel bars and cured to form a protective film after undergoing various chemical processes. The epoxy coated bars last longer due to the protective application and contribute to the quality of construction. JB Engineering Fusion Epoxy Coated TMT Bars are available in Grades 500D/550D/600D/670/800/950/1050 Mpa & Sizes From 6mm to 50mm.

Brand Name : JB Engineering

Brand Name : JB Engineering Zinc Coated /Epoxy Coated TMT Bars

Material : Epoxy,TMT / ZINC

Shape : Round

Color : Black, Silver, Blue, Green, White, Client Specifications

Application : Construction Engineering

Certification : ISO 9001:2008 Certified, ISO 14001-2015

Length : Upto 12 m

Grade : 500D/550D/600D/670/800/950/1050 Mpa

Width : Standard

Dimension : Standard

Technique : Cold Drawn, Hot Rolled

Type : Epoxy Coated Drum, Client Specifications

Thickness : Standard

Country of Origin : India

...more

Tunnel Support System

70 - 6,000 Per piece

1000 Piece (MOQ)

JB Engineering Manufactures Scaffolding & Form work Materials at the factory in Distt Una Himachal Pradesh INDIA by making use of sophisticated machinery and procedures to ensure that all products meet the required specifications as determined by the Clients. We pride ourselves in custom designed products for our clients. JB Engineering never compromise on safety and quality and guarantees that: All products are manufactured from The BIS Confirming steel. Welders all have the rich Experience & relevant certification. Refurbishing is done with the strictest control Our service levels are of the highest standards Quality The Quality Manual used by JB Engineering contains policies and guidelines relevant to the functions and operations which have an effect on the quality of the products, services & processes to ensure conformance to specified requirements. We follow the guidelines as per the quality standards set up by BIS 3696 -2 and International Quality Standards. Pipe Umbrella System--Ground Engineering Fore Poling Technology. JB Engineering Pipe Umbrella System is a pre-support measure used in weak ground conditions in conventional as well as mechanized Tunneling. Long fore poling using the pipe umbrella or canopy method is typically applied to increase safety and stability in the working area of standard advance operations, portals, and for re-excavating collapsed sections. Another application is ground improvement and waterproofing in combination with all tunnel construction methods. JB Engineering Pipe umbrella pipes – installed into the ground prior to excavation – increase the stability in the working area by transferring loads in the longitudinal direction and decrease excavation induced deformations. JB Engineering has developed a superior pipe connection type, which allows the reduction of installation cycle times while increasing the load-bearing capacity. State-of-the art pipe umbrella support systems are installed self-drilling where the casing provides an immediate support of the borehole, compared to outdated pre-drilling systems where borehole drilling and pipe installation takes place in two different working steps. Fully mechanized installation is becoming a mandatory safety standard in the global Tunneling business. JB Engineering is the leading system supplier in the development and application of safe and efficient pipe umbrella installation technology. JB Engineering system comprises steel pipes installed from the tunnel face to form a roof to stabilize the tunnel headings. By distributing the load in longitudinal direction, it can decrease deformation during excavations. Fields Of Application: ❖ Advances in Weak or Sheared Grounds ❖ Ground Conditions Prone to Subsidence ❖ Advances in Fault zones, sediments Frequently Changing Ground Conditions ❖ Portal Section ❖ Re-Excavation of Collapsed Drifts or Tunnels ❖ Urban Tunnelling Advantages: ❖ Immediate support for the excavation tunnels ❖ Strong and robust support system ❖ Strong Safety due to Fully Mechanised Installation ❖ Installation with Conventional Drilling Machines ❖ Piecewise Pipes Installation Allows Flexible Lengths ❖ Simple Application in Confined Spaces ❖ Superior Load Bearing Capacity of Innovative Pipe Couplings.

Brand Name : JB Engineering

Material : Iron, Metal

Color : Black, Silver,Client Specifications

Application : Construction Use

Type : Cuplock Scaffolding System,Clients Specifications

Country of Origin : India

...more

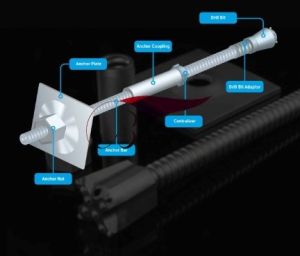

Self Drilling Anchors

1,000 - 6,000 Per Sets

100 Sets (MOQ)

jb-self drilling anchor bolts the self-drilling hollow bar anchor-system is comprised of a hollow threaded bar with an attached drill bit that can perform drilling, anchoring and grouting in a single operation. the hollow bar allows air and water to freely pass through the bar during drilling to remove debris and then allow grout to be injected immediately after drilling is completed. grout fills the hollow bar and completely covers the entire bolt. couplers can be used to join hollow bars and extend the bolt length while nuts and plates are used to provide the required tension. jb engineering offers self drilling anchors in variants of r25, r32, r38, r51 and t76 and their accessories including the anchor nut, anchor plate, anchor coupler and drilling bits depending on the geological condition of the project site (type ex, exx, es,ess,ey,eyy). product features: • 3 in 1 concept : drilling rod, anchor rod & grouting pipe • suitable for both permanent and temporary applications • optimum bonding & load transfer • complete solution including plate and bolts • splicing system to adjust to custom lengths. • standard sacrificial drill bits for every ground conditions. benefits • flexible installation: core injection to suit all ground conditions. • safely: visual control of full encapsulation. • one step installation with sacrificial drill bits. drilling, placing, grouting. • no cased borehole allowing ground preservation. corrosion protection: • for temporary applications the corrosion protection is achieved through encapsulation with grout. • for permanent applications, in-anchor hollow rock bolts can be hot dip galvanized according to en·1461, epoxy coated or supplied with a sacrificial thickness if accounted for all design stage.

Brand Name : JB Engineering

Material : Carbon Steel

Color : Silver

Length : Clients Specification

Type : Self Drilling Anchors

Thickness : 25 Mm-76 Mm

Country of Origin : India

Application : Construction

Size : Clients Specification

Grade : 355-900

Technics : Pre-Galvanized

Diameter : 25mm-76mm

...more

Scaffolding Materials

70 - 6,000 Per Piece

100 Kilogram (MOQ)

JB Engineering Manufactures Scaffolding & Form work Materials at the factory in Distt Una Himachal Pradesh INDIA by making use of sophisticated machinery and procedures to ensure that all products meet the required specifications as determined by the Clients. We pride ourselves in custom designed products for our clients. JB Engineering never compromise on safety and quality and guarantees that: All products are manufactured from The BIS Confirming steel. Welders all have the rich Experience & relevant certification. Refurbishing is done with the strictest control Our service levels are of the highest standards Quality The Quality Manual used by JB Engineering contains policies and guidelines relevant to the functions and operations which have an effect on the quality of the products, services & processes to ensure conformance to specified requirements. We follow the guidelines as per the quality standards set up by BIS 3696 -2 and International Quality Standards. Pipe Umbrella System - Ground Engineering Fore Poling Technology JB Engineering Pipe Umbrella System is a pre-support measure used in weak ground conditions in conventional as well as mechanized Tunneling. Long fore poling using the pipe umbrella or canopy method is typically applied to increase safety and stability in the working area of standard advance operations, portals, and for re-excavating collapsed sections. Another application is ground improvement and waterproofing in combination with all tunnel construction methods. JB Engineering Pipe umbrella pipes – installed into the ground prior to excavation – increase the stability in the working area by transferring loads in the longitudinal direction and decrease excavation induced deformations. JB Engineering has developed a superior pipe connection type, which allows the reduction of installation cycle times while increasing the load-bearing capacity. State-of-the art pipe umbrella support systems are installed self-drilling where the casing provides an immediate support of the borehole, compared to outdated pre-drilling systems where borehole drilling and pipe installation takes place in two different working steps. Fully mechanized installation is becoming a mandatory safety standard in the global Tunneling business. JB Engineering is the leading system supplier in the development and application of safe and efficient pipe umbrella installation technology. JB Engineering system comprises steel pipes installed from the tunnel face to form a roof to stabilize the tunnel headings. By distributing the load in longitudinal direction, it can decrease deformation during excavations. Fields Of Application: ❖ Advances in Weak or Sheared Grounds ❖ Ground Conditions Prone to Subsidence ❖ Advances in Fault zones, sediments Frequently Changing Ground Conditions ❖ Portal Section ❖ Re-Excavation of Collapsed Drifts or Tunnels ❖ Urban Tunnelling Advantages ❖ Immediate support for the excavation tunnels ❖ Strong and robust support system ❖ Strong Safety due to Fully Mechanised Installation ❖ Installation with Conventional Drilling Machines ❖ Piecewise Pipes Installation Allows Flexible Lengths ❖ Simple Application in Confined Spaces ❖ Superior Load Bearing Capacity of Innovative Pipe Couplings.

Application : Tunnel Construction, Form Work Building, Tunnel And Dam Construction

Material : Iron, Metal

Finishing : Natural

Color : Client Specifications

Condition : New, Used

Surface Treatment : Coloured, Hot Dip Galvanized

Application : Construction Use, Civil Construction/ Slope Protection

Certification : ISI Certification, ISO 14001-2015

Grade : BS

Feature : Anti Corrosive, Durable, Eco-Friendly, High Quality

Pipe Length : 20ft

Type : Scaffolding Materials

Country of Origin : India

...more

S N Bolts

100 - 10,000 Per Sets

100 Sets (MOQ)

JB ROCK BOLT SYSTEM Grouted Rock bolts have been commonly used world- wide in mining and civil engineering applications. The most used grouted Rock bolt is the fully grouted rebar or threaded bar made of steel. Cement or resins are used as grouting agent. The rebar used with resin creates a system commonly used for tensioned rock bolt but the rebar or the threaded bar with cement grout can also be used for un tensioned bolts JB Engineering Soil Nails JB Engineering Soil Nailing is a technique that can be used either on natural or excavated slopes, where the slope is reinforced by the insertion of tendons. The nails address the slope stability, which are connected in turn to a facing system and provides surficial stability. JB Engineering Offers different types of anchor bars for use in conjunction for rockfall protection and natural hazard mitigation. These are used for numerous applications. JB Engineering Anchor Bars are Available in different Diameters 25mm,32mm, 36mm, 40mm , steel strengths and corrosion protection, as per IS Code 12594-1988, and/ or epoxy coated- as per IS 13620;1993. JB Engineering Make Accessories Like Joint Couplers, Anchor Plates and Anchor Bolts are also available as per Project requirements and ground conditions. The Various Components of JB Engineering Make Soil Nails are: 1. Steel Reinforcing Bars: The solid steel Reinforcement Bars with minimum strength of Grade 500/550, 670/800,950/1050 are the main Components of the soil Nailing System.These are Placed in predrilled drill holes and grouted in place. 2. Centralizers: PVC Centralizers are fixed to the soil nails to ensure that the soil nail iscenter in the drill hole. 3. Nail Head: The Nail head is the threaded end of the soil Nail that protrudes from the wall facing. It is a square shape Steel Structure, which includes Bearing Plates, Nuts.JB RE-BAR Couplers are used to extend the Length as per designs of the Project. This Part of the Structure Provides the soil Nail bearing strength, and Transfer bearing loads from the soil mass to Soil Nail. 4. Hex Nut Washers and Bearing Plates are attached to the soil nails Heads and are used for connecting the soil Nails to the facing. Bearing Plate distributes the force at nail end to temporary shotcrete facing.

Brand Name : JB Engineering

Material : Mild Steel, M S/HT

Color : Silver, Black, Epoxy Coated Black/ Zinc/Green Epoxy Coated

Type : Ms Bolt Nut, Clients Specifications

Country of Origin : India

...more

Re-Bar Couplers

40 - 490 Per Piece

5000 Piece (MOQ)

JB RE-BAR Couplers – (100%- Make in India Product) are a mechanical splicing system for the connection of Reinforcement Bars from12 mm to 50 mm Dia. ❖ JB RE-BAR Couplers are manufactured at ISO-9001-2015 & 14001-2015 certified plants in Himachal Pradesh – INDIA. JB RE-Bar couplers are the 100% indigenous products manufactured in compliance with BIS-16172: 2014: IS1608, IS 1786; IS 456-2000, ACI-318, BS-8110-1, ASTM A-1034/A1034M meets the international Standards. ❖ JB RE-BAR Couplers: o Provides Continuity of TMT Bars. o Allows full ductile elongation of TMT Bars. o NO Reduction of TMT Bar Cross sectional area o Full Tension Splicing. Bar Break under tensile load o Trustworthy alternative to lap splicing o Solves bar congestion problems o Reduces steels wastages o Shortens Construction cycle time o Easy Installation. o 100% traceability of materials origin & production lots o Each joint with JB RE-BAR coupler is stronger by125% & above of TMT Bars

Brand Name : JB Engineering

Material : Iron, Metal, Mild Steel, Stainless Steel, EN 8D / CK 45/M S

Finishing : Non Polished, Polished

Shape : Round

Color : Black, Grey, Light Brown, Silver, White, Zinc Coated/Epoxy Coated

Condition : New

Application : Jointing

used : Construction

Size : 16mm - 50mm

Length : 1inch, 2inch, 3inch, 4inch, Upto 12 Inches

Grade : ASTM, BS, DIN, JIS, EN8D

Feature : Corrsion Proof, Crack Resistance, Durable, Fine Finished, Light Weight, Corrosion Protection

Surface Type : Clean & Bolted

Thread Type : MM /BSW

Type : Rebar Coupler

Diameter : 10-15mm, 15-20mm, 20-25mm, 25-30mm, 30-75mm

Thickness : 10-20mm, 20-30mm, 30-40mm, 40-50mm, 90mm

Weight : 0-10kg, 10-20kg

Tensile Strength : 120 -1050

Country of Origin : INDIA/BHARAT

thread pitch : MM & Inches

Thread Angle : 60Degree

Fit For Rebar Diameter : 10mm To 50mm

Rebar Diameter : 10mm To 50mm

Key Words : JB Engineering RE-Bar Couplers

Size diameter : 10mm To 50mm

...more

Micro piling Tubes

90 - 135 Per kgs

100 Meter (MOQ)

M S /CS/API 5CT GR N 80 Tubes, / Pipes & Tubes From 12mm Dia to 4000 mm Dia / as per clients specifications

Size : 12mm-4000mm

Model Number : JB 15

Brand Name : JB Engineering

Material : MS/CS/ AS

Shape : Round

Application : Pipes & Tunnels

Shelf Life : 100 Years

Gender : N A

Feature : Construction

Density : TS

Taste : NA

Form : Steel

Automatic Grade : MS/CS/AS

Packaging Type : Export Worthy Packing

Melting Point : NA

Customization : Yes

Lead Time : 30 Days

Protein : NA

Refractive Index : NA

Solubility : NA

Boiling Point : NA

Packaging Size : Bulk

Calcium : NA

Automation Grade : BIS

Potassium : MTC

Features : SOLID

Colour : BLACK

Usage/Application : CONSTRUCTION

Bending Material : YES

Brand : JB Engineering

Mobile Brand : NA

...more

H Type RE-BAR Couplers

40 - 490 Per Piece

5000 Piece (MOQ)

JB RE-Bar Couplers – (100%- Make IN INDIA Product) are a mechanical splicing system for the connection of Reinforcement Bars from 12 mm to 50 mm Dia. JB RE-Bar Couplers are manufactured at ISO-9001-2015 & 14001-2015 certify plants in the State of Himachal Pradesh – in INDIA. JB RE-Bar couplers are the 100% indigenous products manufactured in compliance with BIS-16172: 2014: IS1608, IS 1786; IS 456-2000, ACI-318, BS-8110-1, ASTM A-1034/A1034M meets the international Standards. JB RE-Bar Couplers: o Provides Continuity of TMT Bars. o Allows elongation of TMT Bars. o NO Reduction of TMT Bar Cross sectional area o Full Tension Splicing. Bar Break under tensile load o Trustworthy alternative to lap splicing o Solves bar congestion problems o Reduces steels wastages o Shortens Construction cycle time o Easy Installation. o 100% traceability of materials origin & production lots o Each joint with JB RE-Bar coupler is stronger by 125% & above of TMT Bars

Brand Name : JB Engineering,JB Engineering

Material : Iron, Metal, Mild Steel, Stainless Steel, EN 8D / CK 45 / M S

Finishing : Non Polished, Polished

Shape : Round

Color : Black, Grey, Light Brown, Silver, White, Zinc Coated/ Epoxy Coated

Condition : New

Application : Jointing

used : Construction

Size : 16mm - 50mm

Length : 1inch, 2inch, 3inch, 4inch, Upto 12 Inches

Grade : ASTM, BS, DIN, JIS, EN8D

Feature : Corrsion Proof, Crack Resistance, Durable, Fine Finished, Light Weight, Corrosion Protection

Surface Type : Clean & Bolted

Thread Type : MM /BSW

Type : Rebar Coupler

Diameter : 10-15mm, 15-20mm, 20-25mm, 25-30mm, 30mm-75mm

Thickness : 10-20mm, 20-30mm, 30-40mm, 40-50mm, Upto 90mm

Weight : 0-10kg, 10-20kg

Tensile Strength : 120 -1050

Country of Origin : India

thread pitch : MM & Inches

Thread Angle : 60Degree

Fit For Rebar Diameter : 10mm to 50mm

Rebar Diameter : 10mm to 50mm

Key Words : JB Engineering RE-Bar Couplers

Size diameter : 10mm to 50mm

...more

Glass Fibre Reinforced Polymer Rebar (GFRP Rebars)

100 - 200 Per kgs

100 kgs (MOQ)

JB Engineering Glass Fibre Reinforced Polymer (GFRP) Rebars (8mm,10mm,12mm,16mm,20mm,25mm,28mm,32mm, 36mm) tensile strength and twice stronger and four times lighter than TMT bars. These offers several advantages like corrosion resistance, stronger, lighter, cheaper are the important advantages of GFRP Rebars for Construction. JB Engineering Glass Fibre Reinforced Polymer (GFRP) Rebars offers several Advantages for Construction which can contribute to cost savings, improved sustainability, and enhanced construction efficiency and can be narrated as under: 1. Structural Integrity & Load-Bearing Capacity: GFRP Rebars provides the Strength which is necessary to support various loads, including dead loads , live loads , and environmental loads. 2. Durability: GFRP REBARS being a Strong materials and well-constructed structures are more durable and can withstand weather, aging, and wear and tear. GFRP Rebar is a corrosion-resistant material and increases the lifespan of construction. 3. Lower Transportation Cost: GFRP Rebars Being a Lighter material, is easier to transport and cost-effective. 4. Faster Construction: GFRP Rebars Being a Lightweight material, are easy to install and carry from one location to another. This can result in a faster construction process and reduce labour costs. 5. Design Flexibility: GFRP Rebars being a Lightweight material offers flexible design, allowing architects and builders to explore innovative and unconventional design options. 6. Non-metallic Composition: GFRP Rebar comprises Glass Fiber embedded with polymer resin. It lacks metal components and does not rust when exposed to moisture, oxygen, chemicals. These are resistant to a wide range of chemicals, including acids and alkalis, often present in corrosive environments. 7. Moisture resistance: GFRP rebar does not absorb water or moisture, a critical factor in preventing Corrosion. GFRP Rebar is highly resistant to saltwater, making it an ideal choice for marine and coastal construction projects. 8. Durability in Aggressive Environments: GFRP rebar excels in aggressive environments, such as wastewater treatment facilities, chemical plants, and structures exposed to de-icing salts or corrosive gasses. It maintains its structural integrity and does not corrode under these conditions. 9. Cost-effective: GFRP Rebar is a cost-effective material. It is a more robust, lighter, cheaper, Corrosion resistant, non- conductive material. It increases the life span of construction. It decreases the maintenance and replacement of construction. It is a cost-effective material. It is an ideal choice for construction.

Brand Name : JB Engineering

Color : Green, Red, Client Specifications

Application : Construction, Building

Width : Standard

Country of Origin : India

...more

DCP Anchors

1,800 - 2,500 Per Sets

50 Sets (MOQ)

JB Engineering’s Double Corrosion Protection (DCP) Anchors are HOT DIP ZINC Coated & Fusion EPOXY COATED which provides protection from Corrosion for minimum 100 Years with two independent barriers between the anchor tendon and the environment. Grouted corrugated sheathing with controlled crack width and are for permanent use. Mostly used in high rise construction for heavy reinforcement. Ground anchors are unique as they can provide active restraint to the structures. Anchors avoid movements by applying a compressive load to a structure. JB Engineering’s (DCP) - DOUBLE CORROSION PROTECTION Anchors classifies as like below: The application of ground anchors is increasing as they enable construction in densely populated areas. This increase is due to the reductions in available space for traditional construction methods. In areas of limited easement, removable anchors can be used. For projects where further underground construction, like adjacent developments of tunnels is anticipated engineers can use resized anchors produced from composite materials. Features of DOUBLE CORROSION PROTECTION Anchors are: Hot Zinc Coated / Fusion Epoxy Coated anchors provide minimum 100 Years Corrosion Protection. Bond length and free length to enable pre-stressing. Capacities: bars 4,500 kN, strand15,900 kN(+) Anchors with diameter range12-75mm strand anchors up to 63mm(+) Full compatibility with infrastructure intelligence, utilizing multiple sensor types. How ground anchors work: - JB Engineering Pre-stressed grounds Double Corrosion Protection (DCP) Anchors are HOT DIP ZINC Coated & Fusion EPOXY COATED provides protection from Corrosion for Minimum 100 Years & more actively contribute to the stability of a structure throughout its design life. The performance of the anchor is critical to the stability of the structure. Stressing jacks are used to pre-stress the anchor and elongate the tendon. Once the necessary load has been established, the anchor is locked off at the head. The anchor then applies a compressive load to the structure to arrest movement. The anchor is un-bonded from the ground between the structure and the load-bearing strata to prevent load from being transferred in to unsuitable material and to ensure that sufficient elongation of the tendon is possible. Upon reaching the desired depth, the tendon is directly bonded to the ground, forming the two fundamental elements of the ground anchor: the free length and the bond length. In permanent work, anchors need to be protected against corrosion in line with internationally recognized anchor design standards. Double corrosion protection (DCP) is provided with HOT DIP ZINC coating process & fusion EPOXY COATED process which provides protection from Corrosion for Minimum 100 years with two independent barriers between the anchor tendon and the environment. Introducing JB Engineering Smart Technologies: JB Anchors are the first in a series of smart products developed by JB Engineering.

Brand Name : JB Engineering,JB Engineering

Material : Iron, M S / As Per Requirements

Finishing : Polished, Power Coated, Zinc Coated

Color : Silver, ZINC White/ Green,Zinc/ Epoxy Green

Application : Ships,Marines,All Major Industries

Certification : ISO 9001:2008 Certified, ISI Certified, ISO 14001-2015

Length : 0-50inch, 100-150inch, 150-200inch, 50-100inch, 432inches

Grade : ASME, ASTM, BS, IS, JIS, BIS

Feature : Accuracy Durable, Auto Reverse, Corrosion Resistance, Dimensional, Hardend & Temper, High Quality, High Tensile

Technics : Black Oxide, Hot Dip Galvanized, White Zinc Plated, Yellow Zinc Plated, Epoxy Coated

Type : Slop Protection / Buildings/ Mining/Anchors,Threaded Bars/ TMT Bars/ Round Bars

Thickness : 0-10mm, 10-20mm, 20-40mm, 40-80mm, As Per Clients Specifications

Weight : 0-5kg, 10-20kg, 20-40kg, 40-80kg, 5-10kg, 80-160kg, As Per Clients Specifications

Country of Origin : India

...more

Slope Protection Materials

Gantry Structure Fabrication

100 - 200 Per Kilogram

100 Piece (MOQ)

JB Engineering Manufactures Scaffolding & Form work Materials at the factory in Distt Una Himachal Pradesh INDIA by making use of sophisticated machinery and procedures to ensure that all products meet the required specifications as determined by the Clients. We pride ourselves in custom designed products for our clients. JB Engineering never compromise on safety and quality and guarantees that: All products are manufactured from The BIS Confirming steel. Welders all have the rich Experience & relevant certification. Refurbishing is done with the strictest control Our service levels are of the highest standards Quality The Quality Manual used by JB Engineering contains policies and guidelines relevant to the functions and operations which have an effect on the quality of the products, services & processes to ensure conformance to specified requirements. We follow the guidelines as per the quality standards set up by BIS 3696 -2 and International Quality Standards.

Material : MS/CS/ AS

Application : Fabrication

Type : Clients Specification

Thickness : Clients Specification

...moreBe first to Rate

Rate ThisOpening Hours