EHF 300 D/E Hand Feed Concrete Mixer

Get Price Quote

1 Piece (MOQ)

Features : Built to Last, Robust Design. Easy to operate & maintain. Casted Drum - Less Wear & Tear. Wear Resistant Bearing, Reduced power loss and increased Reliability. Sturdy Base Frame for stability & longer life. Easy to Transport. WHEELS: Pneumatic or MS Wheels with towing bar. Prime Mover Electric Motor or Diesel Engine Optional : Dual Drives : Electric Motor & Diesel Engine on the same chassis. Easy Interchangeability of Power Source. Industrial Application : Machine Mounted on Foundation for Special / Industrial Applications.

Ribbon Blender

125,000 Per Piece

1 Piece(s) (MOQ)

Best Deals from Animal Feed Making Machine

Maize Hammer mill

200,000 - 2,000,000 Per Nos

( sieve size 2.5/3mm - groundnut/Maize, etc)RPM : 3000 Directt coupled to Milling RotorCoupling : Flexible Tyre CouplingSize of Beaters : 120x50x6Material : 8 mm Thk Ms Base Frame self supporting with AVMDrive : Electric Motor 3000RPM/415V/50 Hz

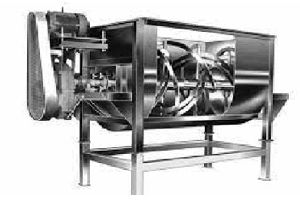

Ribbon Blender

Get Price Quote

we are the prime manufacturer and supplier of ribbon blender, which is engineered with precision to give superior performance. The ribbon blender mixes the homogenously. The high quality ribbon blender is used in multiple industries such as chemical, pharmaceuticals etc. characteristics : high efficiency low maintenance cost easy to use easy to clean low energy consumption applications : minerals pesticides chemicals pigments pharmaceuticals dye stuffs

Poultry Feed Plant Automation

600,000 - 2,500,000 Per Nos

1 Piece (MOQ)

Hammer Mill

200,000 - 1,000,000 Per piece

1 Piece (MOQ)

Pellet Cooler

Get Price Quote

PELLET MAKING PLANT

Get Price Quote

The Pin Palletizer Mixer is a high-speed mixer, agglomerate that conditions and micro-pelletizes by converting the fine powders into small agglomerates through the action of a high speed rotor shaft with pin assembly in a MACHINED STATIONARY CASING.The Pelletizer produces spherical micro-pellets, granules by combining the dry feed with a liquid binder/water mixture. Pellets are formed when the dry feed particles are dispersed by the rotor in the first section of the chamber that comes in contact with fine sprays of binder solution or water. The high-speed rotation of the rotor with atomizing of spray, coats individual powder particles with the binder that pelletizes the particles into roundish spheres, granules.The Pelletizer speed can be varied from 100 to 750 RPM. The gap between the Rotating Rotor and casing can also be varied from 3mm to 6mm . Accordingly the pellets size dia will be determined .

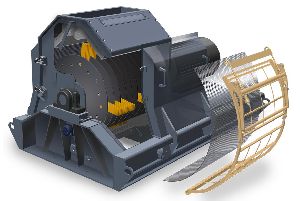

full circle hammer mill

Get Price Quote

Our Hammer mill is basically all purpose grinder which can be used for grinding wide range of feed stuff, Such as Oil Cakes, Extraction meal, Broken rice, Roots, Dry Herbs, Oat, Hulls and maize. The matter to be ground is subjected to the beating action of Hammers until is reduced to the fineness necessary to pass through the sieve. Hammer mill is constructed for high speed continuous grinding. It consists of fabricated body. The grinding chamber is usually formed by a series of steel plates build up on a shaft and separated sufficiently to allow the beaters to be mounted between them upon transverse spindles or pins with pass through the beaters are made from alloy steel (hardened). The rotor is dynamically balanced and mounted on two self aligned bearings. The grinding chamber and the motor are directly coupled and are mounted on a common base frame. Vibration dampers are provided to check any sort of vibrations occurring due to the running of the machine. Features :- High Capacity Stable Performance Easy to Handle/Maintain Handy Gap Adjusting Mechanism for Course/Fine Grinding Heavy Duty Structure Heavy Bearing Housing M – Shaped Beaters for Higher Capacity Air vent/Discharge Provision for Heat Dissipation generated during grinding. Installed with Special Purpose Bearing Designed for Higher RPM/Continuous Working with Grease Lubrication. Pneumatically Operated Mechanism provided at Inlet to remove Iron Particles

Ribbon Blender

Get Price Quote

We are offering the superior quality ribbon blenders from us. The ribbon blenders are constructed with stainless steel and mild steel. The blenders are provided with stuffing boxes that have been proven to be very effective for stopping leakage. It consists of a hopper and a discharge for loading and unloading of the processed material. The range of ribbon blenders offered by us is appreciated for their easy installation, smooth functionality and trouble free operation.

Twin Screw Side Feeder

Get Price Quote

Our wide range also includes win Screw Side Feeder for feeding minerals like glass, calcium, and other mineral with force from side to main line. The Feeder has high DO-DI Volume & efficiency output and is controlled through AC inverter. These co rotating / counter rotating twin-screw side feeders are specifically designed to handle the higher rates and to achieve the required objective of extrusion.

Ribbon Blender

Get Price Quote

2 Piece (MOQ)

Screw Feeders

Get Price Quote

Our company offers screw feeders, which are used in various industries for the metering of material into a production process. These are engineered to perfection and are in high demand across various industries. Available in various dimensions, designs, sizes and working capacities these are high in performance, sturdy in construction and are appreciated for low power consumption.

Non Reversible Hammer Mill

150,000 Per Piece

Hammer Mill

Get Price Quote

We are main supplier of this product.

SCREW FEEDER

Get Price Quote

Screw Feeders

Get Price Quote

Screw feeders are used in various industries for the metering of material into a production process. Screw feeder design closely resembles that of a screw conveyor, but unlike a screw conveyor, a screw feeder is required to be very precise and accurate. The screw in a screw feeder is completely filled with material, compared to a screw conveyor which is typically 40-50% filled. That is part of the reason the material is accurately discharged when the feeder screw is rotating at a controlled rate. Application Challenges: Fast ResponseCapable of accurately regulating material feed. Load DetectionCapable of detecting an overload or no material in the screw situation. Speed RangeBe able to provide the required amount of torque throughout the speed range. Trip-less OperationThe product must be capable of continuing to operate after a momentary power loss or a fault

Maize Cattle Feed Plant

Get Price Quote

Ribbon Blender

40,000 Per Piece

We are offering ribbon blender

Hammer Mills

Get Price Quote

PICS Hammermills are durable utility grinders capable of grinding most free-flowing materials. Hammer grinding mills operate on the principle that most materials will grind or crush upon impact with the hammers.

Animal Feed Plant

Get Price Quote

Animal Feed Plant, pellet crumbler, full circle hammer mill

Pellet Mill

Get Price Quote

Pellet Mill, bagging machines, Industrial Elevators, Pressure Blower

SCREW FEEDER

Get Price Quote

SCREW FEEDER, Coal Handling Plant, IMPACTOR, Roll Crusher, FEEDER

Ribbon Blender Mixer

Get Price Quote

Ribbon Blender Mixer, Double Paddle Mixer, Pressure Vessels

full circle hammer mill

Get Price Quote

full circle hammer mill, auto batching system, feed mill plant, pellet mills

poultry feed plant

Get Price Quote

poultry feed plant, biscuit plant, Oil Mill Machinery, animal feed plants

SCREW FEEDER

Get Price Quote

SCREW FEEDER, Vibrating Feeder, twin conveyor, product storage silo

Hammer Mill

Get Price Quote

Hammer Mill, FEEDER, Horizontal Shaft Impactor

Hammer Mills

Get Price Quote

Pics hammer mills are durable utility grinders capable of grinding most free-flowing materials. Hammer mills operate on the principle that most materials will grind or crush upon impact with the hammers. Pics hammer mill are designed for fine crushing of soft up till medium hard, non abrasive and non adhesive materials, such as bituminous coal, limestone etc.

Ribbon Blender

Get Price Quote

Ribbon Blender, Engineering Products, industrial reactors