Wiped Film Evaporators - Metallic

We are one of the corrosion resistant Wiped Film Evaporators Manufacturers based in India. Wiped Film Evaporator is a Thin Film Evaporator and consists of a jacketed glass / SS / other corrosion resistant pipe section in which is rotating a corrosion resistant PTFE / SS / other corrosion resistant wiper system with suitable rows of blades supported by suitable bearings. Wiped Film Evaporators give a high wiping frequency and therefore, an optimum renewal speed of the boundary layer, which are pre-requisites for thorough mixing of the liquid film and for high evaporation rates. The Thin Film Evaporators are forced against the evaporator wall by centrifugal force, and this can be varied via the speed of rotation of the drive, depending on the viscosity of the liquid. Inherent Features of Our Wiping Film Evaporators : Made of corrosion resistant materialsLowest possible working temperatures possibleVery low residence timeVisual observation while using Borosilicate glassLow Hold-upModular system for all glass components that permits flexible design and rapid assembly of the unitDigital control of motor speedHigh level of automation (optional)

...more

Wiped Film Evaporators Glass

We are one of the corrosion resistant Wiped Film Evaporators Manufacturers based in India. Wiped Film Evaporator is a Thin Film Evaporator and consists of a jacketed glass / SS / other corrosion resistant pipe section in which is rotating a corrosion resistant PTFE / SS / other corrosion resistant wiper system with suitable rows of blades supported by suitable bearings. Wiped Film Evaporators give a high wiping frequency and therefore, an optimum renewal speed of the boundary layer, which are pre-requisites for thorough mixing of the liquid film and for high evaporation rates. The Thin Film Evaporators are forced against the evaporator wall by centrifugal force, and this can be varied via the speed of rotation of the drive, depending on the viscosity of the liquid. Inherent Features of Our Wiping Film Evaporators : Made of corrosion resistant materialsLowest possible working temperatures possibleVery low residence timeVisual observation while using Borosilicate glassLow Hold-upModular system for all glass components that permits flexible design and rapid assembly of the unitDigital control of motor speedHigh level of automation (optional)

...more

wiped film evaporators

We are one of the corrosion resistant Wiped Film Evaporators Manufacturers based in India. Wiped Film Evaporator is a Thin Film Evaporator and consists of a jacketed glass / SS / other corrosion resistant pipe section in which is rotating a corrosion resistant PTFE / SS / other corrosion resistant wiper system with suitable rows of blades supported by suitable bearings. Wiped Film Evaporators give a high wiping frequency and therefore, an optimum renewal speed of the boundary layer, which are pre-requisites for thorough mixing of the liquid film and for high evaporation rates. The Thin Film Evaporators are forced against the evaporator wall by centrifugal force, and this can be varied via the speed of rotation of the drive, depending on the viscosity of the liquid. Inherent Features of Our Wiping Film Evaporators : Made of corrosion resistant materials Lowest possible working temperatures possible Very low residence time Visual observation while using Borosilicate glass Low Hold-up Modular system for all glass components that permits flexible design and rapid assembly of the unit Digital control of motor speed High level of automation (optional)

Type : Wiped Film Evaporator

Material : As Per Requirement

Application : As Per Requirement

Voltage : As Per Requirement

Automatic Grade : As Per Requirement

Phase : As Per Requirement

Steam Pressure : As Per Requirement

Evaporation Capacity : As Per Requirement

...more

wiped film evaporator

Wiped Film Evaporators Manufacturers based in India. Wiped Film Evaporator is a Thin Film Evaporator and consists of a jacketed glass SS other corrosion resistant pipe section in which is rotating a corrosion resistant PTFE SS other corrosion resistant wiper system with suitable rows of blades supported by suitable bearings. Wiped Film Evaporators give a high wiping frequency and therefore, an optimum renewal speed of the boundary layer, which are pre-requisites for thorough mixing of the liquid film and for high evaporation rates. The Thin Film Evaporators are forced against the evaporator wall by centrifugal force, and this can be varied via the speed of rotation of the drive, depending on the viscosity of the liquid.

...more

thin film evaporator

We are one of the corrosion resistant Wiped Film Evaporators Manufacturers based in India. Wiped Film Evaporator is a Thin Film Evaporator and consists of a jacketed glass SS other corrosion resistant pipe section in which is rotating a corrosion resistant PTFE SS other corrosion resistant wiper system with suitable rows of blades supported by suitable bearings. Wiped Film Evaporators give a high wiping frequency and therefore, an optimum renewal speed of the boundary layer, which are pre-requisites for thorough mixing of the liquid film and for high evaporation rates. The Thin Film Evaporators are forced against the evaporator wall by centrifugal force, and this can be varied via the speed of rotation of the drive, depending on the viscosity of the liquid.

...more

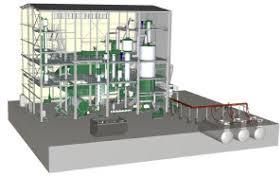

Sulphuric Acid Manufacturing Plant

1 Set (MOQ)

BVR Provides complete turnkey solutions for the manufacturing plant projects of Sulphuric acid from Sulphur & allied products, for commercial and laboratory grades. Our services include preparation of preliminary estimation, pre-feasibility reports, DPR, Plant technology, know-how, basic & detail engineering, project execution, procurement, fabrication, erection supervision and plant commissioning.

Voltage : As Per Requirement

Power : As Per Requirement

...more

Sulphuric Acid Dilution Plant

1 Set (MOQ)

Sulphuric acid is a heavy chemical and finds numerous applications in the industry. It is the product of ‘Contact Process’ and commercially available as 98.5% (w/w) H2SO4 or stronger in the form of oleum. However, many of the processes and applications utilizing sulphuric acid require weaker acid than this. As a result, dilution equipment is often necessary in order to meet the requirement for this weaker acid. During dilution considerable heat is generated depending on the extent of dilution desired. The Integral heat of solution of sulphuric acid is plotted in fig.1. The heat liberated sometimes is sufficient to produce boiling of the acid and so, provision is made for the re-circulation of a portion of cooled dilute acid, thus ensuring working at controlled temperature. From the above it will be clear that intimate mixing and efficient heat transfer form the pre-requisites for sulphuric acid dilution unit to avoid excessive temperature and local heating and uniform product concentration. Process Description : Metered quantity of sulphuric acid is introduced to a heat exchanger with re-circulation of water through a pump from the tank containing pre-determinant quantity of water. The turbulence created in the heat exchanger ensures both intimate mixing and efficient heat transfer. When desired strength of acid is reached, the content of the tank is transferred to storage and fresh batch can be started again. System Benefits : 1.High product quality is guaranteed as glass is completely inert to sulphuric acid. 2.Available in wide range of concentrations and capacities. 3.Simple and easy to operate. 4.Operational reliability due to maintenance free in working. 5.Corrosion Resistant

Voltage : As Per Requirement

Power : As Per Requirement

...more

sulphuric acid concentration plant

We have firmly positioned ourselves as one of the dependable Sulphuric Acid Plant Manufacturers and suppliers based in India. We deal in two types of Sulphuric Acid Chemical Plant that includes : Sulphuric Acid Concentration plant Sulphuric Acid Dilution Sulphuric Acid Concentration Plant Sulphuric acid is used in many processes in chemical plants, thus making spent acid quite diluted. Disposing of this spent acid becomes an environmental pollution problem besides a waste of precious resource. The diluted spent acid can be efficiently re-concentrated up to a maximum concentration of 96% (w/w) and reused in the main plant process, thus saving the environment and that too by improving the economical bottom line. Thus, sulphuric acid recovery or concentration plant is a fantastic option for high sulphuric acid users in process plants. Concentration of Sulphuric acid is mostly performed under vacuum in order to reduce the operating temperature, especially for high concentrations. We offer turnkey solutions right from know-how & technology, to supply, installation & commissioning. Our plant comprises of equipments wherin the wetted parts are made up of Borosilicate glass 3.3, Fluoropolymers (PTFE, PFA, FEP, PVDF, PP, etc), High Nickel alloys, Graphite & exotic metals (Ta, Ti, Nb, etc.). The plants can be totally automated by PLC or DCS based systems and even integrated with computers (SCADA etc). Sulphuric Acid Dilution Sulphuric acid is a heavy chemical and finds numerous applications in the industry. It is the product of ‘Contact Process’ and commercially available as 98.5% (w/w) H2SO4 or stronger in the form of oleum. However, many of the processes and applications utilizing sulphuric acid require weaker acid than this. As a result, dilution equipment is often necessary in order to meet the requirement for this weaker acid. During dilution, considerable heat is generated depending on the extent of dilution desired. The Integral heat of solution of sulphuric acid is plotted in fig.1. The heat liberated sometimes is sufficient to produce boiling of the acid and so, provision is made for the re-circulation of a portion of cooled dilute acid, thus ensuring working at controlled temperature. From the above it will be clear that intimate mixing and efficient heat transfer form the pre-requisites for sulphuric acid dilution unit to avoid excessive temperature and local heating and uniform product concentration. Process Description Metered quantity of sulphuric acid is introduced to a heat exchanger with re-circulation of water through a pump from the tank containing pre-determinant quantity of water. The turbulence created in the heat exchanger ensures both intimate mixing and efficient heat transfer. When desired strength of acid is reached, the contents of the tank are transferred to storage and fresh batch can be started again. Benefits of Industrial Sulphuric Acid Plant High product quality is guaranteed, as glass is completely inert to sulphuric acid Available in wide range of concentrations and capacities Simple and easy to operate Operational reliability due to maintenance free in working Corrosion Resistant

Voltage : As Per Requirement

Power : As Per Requirement

...more

Stainless Steel Pilot Plant

We are one of the well-reputed manufacturers and exporters of Industrial Pilot Plant, Piloting assemblies, Multipurpose Units / Assemblies & Bioreactors that are multi-purpose modular units having operational flexibility. Our Pilot Plant has been standardized by incorporating all basic & essential functional features such as heating, stirring, condensation, fractionation, cooling etc. for multipurpose use. These units find use in educational institutions, R&D centers and industries. Recovery Pilot Plant can be conveniently and quickly modified according to specific process needs due to modular construction. Borosilicate glass offers additional benefits of universal corrosion resistance, visibility and cleanliness. Besides, these units are also made with SS & other metals. These equipments may be used in simple laboratory scale pilot plant to large commercial scale production for various applications like Distillation, Absorption, Reaction, Evaporation, Mixing, Extraction etc. The corrosion resistant equipments & assemblies are made up of Borosilicate 3.3 Glass as per ISO 3585, designed , fabricated & engineered as per ENBS 1595 , AD2000 Merkblatt, ASME Section VIII Div.1, & TEMA and are available with CE Marking ; designed & made in compliance with the relevant directives namely ; The PED - 97/23/EC, The Machine Directive - 98/37/EC, The European Low Voltage Directive - 73/23/EEC , The EMC Directive - 89/336/EEC. We have a multi-disciplinary engineering team with mechanical, electrical, chemical & instrumentation engineering expertise that enables us to develop your concept to its greatest potential. We design systems so as to customize equipments providing the greatest value and fastest deliveries. We are aware of the latest innovations in hardware, instrumentation, controls & automation software and select components and materials from industry standard suppliers recognized for high quality performance & durability of their products.

...more

solvent recovery plant

1 Set (MOQ)

Recovery of solvents like : Acetone, Toluene, IPA, Ethanol, Methylene Chloride and many other norganic and organic solvents (VOCs)from liquid & gaseous effluents. Processes employed are Distillation (including azeotropic distillation), Extraction (Liquid-liquid & solid-liquid), Absorption, Adsorption, etc. We take up studies for the best possibilities of recovering solvents and other important chemicals from the liquid discharges as well as gaseous exhausts. Solvent recovery from liquid effluents can be from chemical & pharmaceutical manufacturing plants. Solvent & VOC recovery from Solvent Laden Air (SLA) can be from Rotogravure & coating machines used in polyester printing setups. Gasket, electrical part manufacturers, which use organic solvents in their processes. We offer turnkey projects for the above comprising of the following : TECHNOLOGY DEVEOPMENT : Piloting to scale up plant design & engineering BASIC ENGINEERING - Mass and energy balances , Piloting,Process flow diagram (PFD), Preliminary Plant layout , other apparatus and equipment specifications DETAIL ENGINEERING - P&ID , General arrangement drawing , E&I Specifications PROJECT MANAGEMENT - Scheduling, Resource management, Interface Management, Control INSTALLATION & COMMISSIONING – Construction management, Loop Check, Test run, Performance Test & Trouble-shooting. Solvent Recovery Plant from SLA Schematic Drawing

Application : As Per Requirement

Weight : As Per Requirement

Voltage : As Per Requirement

Automatic Grade : As Per Requirement

Power : As Per Requirement

Driven Type : As Per Requirement

...more

Solvent Extraction Plant

Liquid extraction, sometimes called solvent extraction, it the separation of a liquid of a liquid solution by contact with another insoluble liquid. The Fully Automatic Solvent Extraction Plant described is for semi-batch operation. The liquid to be extracted is poured into extraction vessel. Solvent is boiled in a reboiler vessel and condensed in an overhead condensed, the condensed liquid in a reflux divider and passing through pipe work to the extraction vessel. The pipe work incorporates valve in order that the solvent can enter the extraction vessel at either the base of the top, depending on the relative density of the solvent and liquid to be extracted. The solvent and the extracted liquid pass back to the reboiler and the process is reputed until the extraction is complete. The extraction vessel is than drained and the solvent evaporated from the reboiler vessel and collected in the extraction vessel enabling the two liquids to be drained from their respective vessel. The Solvent Extraction Plant is available in vessel size upto 500 Ltr. and is suitable for operation under atmosphere pressure and vacuume. Today, we have carved a niche as one of the prime Modular Solvent Extraction Plant Exporters based in India.

Type : Solvent Extraction Plant

Application : Solvent Extraction

Weight : As Per Requirement

Voltage : As Per Requirement

Automatic Grade : As Per Requirement

Power : As Per Requirement

Driven Type : As Per Requirement

...more

Rotary Film Evaporator

Our Rotary Film Evaporator is available with CE Marking as per PED - 97/23/EC, The Machine Directive - 98/37/EC, The European Low Voltage Directive - 73/23/EEC, The EMC Directive - 89/336/EEC. We have carved a niche as one of the overruling Rotary Evaporator Manufacturers based in India. In addition to this, we are also counted among the major Rotary Vaccum Film Evaporators Suppliers. The Rotary Film Evaporator is essentially a Thin Film Evaporator incorporating a rotating evaporation flask. The rotary evaporator will evaporate solvent at a much faster rate than systems using stationary evaporation flasks, due to higher convectional heat transfer coefficient. The rotation transfers a thin film of the liquid to the whole of the inner surface of the flask, markedly increasing evaporation rate due to higher heat transfer between the flask, bath and the thin film. The rotating flask and vapour duct have a sealing system, which allows operation under vacuum, further accelerating the evaporation process because of the reduction in boiling point of the solvent and efficient removal of the vapour. Besides the reduction in boiling point, there is a considerable decrease in the residence time of the fluid, which also permits heat sensitive materials to be successfully concentrated without degradation. The evaporators can be evacuated down to less than 1 mbar if the vacuum seals are maintained in good condition. A continuous feed facility considerably increases the capacity of the units and distillate withdrawal facilities on some units allow uninterrupted operation. Features Digital display & auto control of rotation speed, vapor temperature and bath temperature. Miniature circuit breaker and separate power switches for control panel and heating bath offers safety. Vacuum Controller (Optional) RS-232 / 485 interface (Optional) The units can be offered with full automation incorporating a PLC based system or even SCADA for real time data acquisition and control. There is a range of models covering an evaporation flask capacity from 1 litre 5 litres. The majority of these models may be used on the laboratory bench; the larger models (10, 20, 50, 100 litres and above) are designed for use in pilot plants and production facilities.

Type : Rotary Film Evaporator

Material : As Per Requirement

Application : As Per Requirement

Feature : As Per Requirement

Voltage : As Per Requirement

Automatic Grade : As Per Requirement

Phase : As Per Requirement

Steam Pressure : As Per Requirement

Evaporation Capacity : As Per Requirement

...more

Rotary Film Evaporator-03

Our Rotary Film Evaporator is available with CE Marking as per PED - 97/23/EC, The Machine Directive - 98/37/EC, The European Low Voltage Directive - 73/23/EEC, The EMC Directive - 89/336/EEC. We have carved a niche as one of the overruling Rotary Evaporator Manufacturers based in India. In addition to this, we are also counted among the major Rotary Vaccum Film Evaporators Suppliers. The Rotary Film Evaporator is essentially a Thin Film Evaporator incorporating a rotating evaporation flask. The rotary evaporator will evaporate solvent at a much faster rate than systems using stationary evaporation flasks, due to higher convectional heat transfer coefficient. The rotation transfers a thin film of the liquid to the whole of the inner surface of the flask, markedly increasing evaporation rate due to higher heat transfer between the flask, bath and the thin film. The rotating flask and vapour duct have a sealing system, which allows operation under vacuum, further accelerating the evaporation process because of the reduction in boiling point of the solvent and efficient removal of the vapour. Besides the reduction in boiling point, there is a considerable decrease in the residence time of the fluid, which also permits heat sensitive materials to be successfully concentrated without degradation. The evaporators can be evacuated down to less than 1 mbar if the vacuum seals are maintained in good condition. A continuous feed facility considerably increases the capacity of the units and distillate withdrawal facilities on some units allow uninterrupted operation. Features Digital display & auto control of rotation speed, vapor temperature and bath temperature. Miniature circuit breaker and separate power switches for control panel and heating bath offers safety. Vacuum Controller (Optional) RS-232 / 485 interface (Optional) The units can be offered with full automation incorporating a PLC based system or even SCADA for real time data acquisition and control. There is a range of models covering an evaporation flask capacity from 1 litre 5 litres. The majority of these models may be used on the laboratory bench; the larger models (10, 20, 50, 100 litres and above) are designed for use in pilot plants and production facilities.

...more

Rotary Film Evaporator-02

Our Rotary Film Evaporator is available with CE Marking as per PED - 97/23/EC, The Machine Directive - 98/37/EC, The European Low Voltage Directive - 73/23/EEC, The EMC Directive - 89/336/EEC. We have carved a niche as one of the overruling Rotary Evaporator Manufacturers based in India. In addition to this, we are also counted among the major Rotary Vaccum Film Evaporators Suppliers. The Rotary Film Evaporator is essentially a Thin Film Evaporator incorporating a rotating evaporation flask. The rotary evaporator will evaporate solvent at a much faster rate than systems using stationary evaporation flasks, due to higher convectional heat transfer coefficient. The rotation transfers a thin film of the liquid to the whole of the inner surface of the flask, markedly increasing evaporation rate due to higher heat transfer between the flask, bath and the thin film. The rotating flask and vapour duct have a sealing system, which allows operation under vacuum, further accelerating the evaporation process because of the reduction in boiling point of the solvent and efficient removal of the vapour. Besides the reduction in boiling point, there is a considerable decrease in the residence time of the fluid, which also permits heat sensitive materials to be successfully concentrated without degradation. The evaporators can be evacuated down to less than 1 mbar if the vacuum seals are maintained in good condition. A continuous feed facility considerably increases the capacity of the units and distillate withdrawal facilities on some units allow uninterrupted operation. Features Digital display & auto control of rotation speed, vapor temperature and bath temperature. Miniature circuit breaker and separate power switches for control panel and heating bath offers safety. Vacuum Controller (Optional) RS-232 / 485 interface (Optional) The units can be offered with full automation incorporating a PLC based system or even SCADA for real time data acquisition and control. There is a range of models covering an evaporation flask capacity from 1 litre 5 litres. The majority of these models may be used on the laboratory bench; the larger models (10, 20, 50, 100 litres and above) are designed for use in pilot plants and production facilities.

...more

Rotary Film Evaporator-01

Our Rotary Film Evaporator is available with CE Marking as per PED - 97/23/EC, The Machine Directive - 98/37/EC, The European Low Voltage Directive - 73/23/EEC, The EMC Directive - 89/336/EEC. We have carved a niche as one of the overruling Rotary Evaporator Manufacturers based in India. In addition to this, we are also counted among the major Rotary Vaccum Film Evaporators Suppliers. The Rotary Film Evaporator is essentially a Thin Film Evaporator incorporating a rotating evaporation flask. The rotary evaporator will evaporate solvent at a much faster rate than systems using stationary evaporation flasks, due to higher convectional heat transfer coefficient. The rotation transfers a thin film of the liquid to the whole of the inner surface of the flask, markedly increasing evaporation rate due to higher heat transfer between the flask, bath and the thin film. The rotating flask and vapour duct have a sealing system, which allows operation under vacuum, further accelerating the evaporation process because of the reduction in boiling point of the solvent and efficient removal of the vapour. Besides the reduction in boiling point, there is a considerable decrease in the residence time of the fluid, which also permits heat sensitive materials to be successfully concentrated without degradation. The evaporators can be evacuated down to less than 1 mbar if the vacuum seals are maintained in good condition. A continuous feed facility considerably increases the capacity of the units and distillate withdrawal facilities on some units allow uninterrupted operation. Features Digital display & auto control of rotation speed, vapor temperature and bath temperature. Miniature circuit breaker and separate power switches for control panel and heating bath offers safety. Vacuum Controller (Optional) RS-232 / 485 interface (Optional) The units can be offered with full automation incorporating a PLC based system or even SCADA for real time data acquisition and control. There is a range of models covering an evaporation flask capacity from 1 litre 5 litres. The majority of these models may be used on the laboratory bench; the larger models (10, 20, 50, 100 litres and above) are designed for use in pilot plants and production facilities.

...more

PTFE Gasket & Fittings

1 Set (MOQ)

As a promising name, we bring forth high quality product range that is designed and developed using the best in class raw material and modern work methodologies. Besides, we make sure that the basic material is sourced from the trusted places. With our modern transportation facility, timely and safe deliveries are guaranteed with us.

Material : As Per Requirement

Usage : As Per Requirement

Automation Grade : As Per Requirement

Shape : As Per Requirement

Dimension : As Per Requirement

Size : As Per Requirement

Thickness : As Per Requirement

...more

Pilot Plant

We are one of the well-reputed manufacturers and exporters of Industrial Pilot Plant, Piloting assemblies, Multipurpose Units / Assemblies & Bioreactors that are multi-purpose modular units having operational flexibility. Our Pilot Plant has been standardized by incorporating all basic & essential functional features such as heating, stirring, condensation, fractionation, cooling etc. for multipurpose use. These units find use in educational institutions, R&D centers and industries. Recovery Pilot Plant can be conveniently and quickly modified according to specific process needs due to modular construction. Borosilicate glass offers additional benefits of universal corrosion resistance, visibility and cleanliness. Besides, these units are also made with SS & other metals. These equipments may be used in simple laboratory scale pilot plant to large commercial scale production for various applications like Distillation, Absorption, Reaction, Evaporation, Mixing, Extraction etc. The corrosion resistant equipments & assemblies are made up of Borosilicate 3.3 Glass as per ISO 3585, designed , fabricated & engineered as per ENBS 1595 , AD2000 Merkblatt, ASME Section VIII Div.1, & TEMA and are available with CE Marking ; designed & made in compliance with the relevant directives namely ; The PED - 97/23/EC, The Machine Directive - 98/37/EC, The European Low Voltage Directive - 73/23/EEC , The EMC Directive - 89/336/EEC. We have a multi-disciplinary engineering team with mechanical, electrical, chemical & instrumentation engineering expertise that enables us to develop your concept to its greatest potential. We design systems so as to customize equipments providing the greatest value and fastest deliveries. We are aware of the latest innovations in hardware, instrumentation, controls & automation software and select components and materials from industry standard suppliers recognized for high quality performance & durability of their products.

Type : Pilot Plant

Material : As Per Requirement

Application : As Per Requirement

Voltage : As Per Requirement

Power : As Per Requirement

Electric : As Per Requirement

Max Pressure : As Per Requirement

Automation Grade : As Per Requirement

Pilot Plant : As Per Requirement

...more

NOx Absorption Plant

1 Set (MOQ)

NOx is the generic name given to Nitrogen Oxides. NOx is generated from many processes including nitration process, for both organic and several inorganic compounds (including a few important metals). This is generated due to the partial degradation of Nitric Acid used in the nitration process, as well as to the final treatment of the "spent" acid. These gases are also formed in the nitration of aromatic compounds (toluene, naphtalenes and many of their derivatives), including the production of practically all types of explosives, in the attack of some relevant metals (like copper, bismuth, etc.), in gold & silver refineries and also in the "Nitric Acid Concentration (NAC)" Plants. BVRs NOx Absorption Plants, uses water or caustic solution as per the need. Proper oxidation of NO is completed for the optimum absorption efficiency with minimal energy consumption. When absorbed with water Nitric acid produced can be re-used for re-use in the main process. Both absorption under atmospheric pressure and higher pressures are possible. At lower pressures the acid concentration is low and so is the absorption efficiency with a higher level of emissions. With Pressurised absorption the acid concentration could reach upto 50%w/w and the emission would be considerable lower too.

Application : As Per Requirement

Voltage : As Per Requirement

Power : As Per Requirement

...more

nitric acid concentration plant

7,500,000 Per Set

Concentrated Nitric Acid CNA ( i.e. high-strength nitric acid at 98 -99% w/w.) is an important chemical for Chemical & Pharmaceutical industries in general (like polymers & plastics, dyestuff, bulk drugs, explosives, Fertilizers and other important organic nitro-compounds). This acid is frequently used as "nitrating acid". Industrially manufactured Nitric acid is obtained as a weak acid solution, at a concentration of about 65% -67% w/w (max.), which is of no use whatsoever for the various processes stated above Owing to the physical behaviour of the nitric acid / water system, it is not possible to remove excess water from this weak acid by a fractional distillation process because this solution forms an azeotrope, a constant acid / water boiling composition at about 68% w/w. acid. To concentrate this acid further an extractive distillation process by adding concentrated sulphuric acid needs to be employed. While the water goes this sulphuric acid gets diluted, which can be again re-concentrated and reused for the concentration of dilute nitric acid again. Reconcentration of weak Sulphuric Acid The dilute sulphuric acid stream coming off the bottom of the Extractive Distillation Column is reconcentrated back to the same service by using BVR's sulphuric acid re-concentration plant, which can be coupled directly with the nitric acid concentration system so that no cooling of the weak sulphuric acid is necessary, thus saving a large amount of heating energy for the economical benefit of the user. NOx Absorption The NOx gases escaping from the Nitric acid Concentration System, along with bleaching air, are absored in BVR's special NOx absorption plant and is recycled back into the main system as an aqueous solution of nitric acid to the same System : the residual gases vented to the atmosphere have NOx. content below the acceptable values as per environmental norms. Pre-concentration of weak NA upto 60% by Fractional Distillation.

Type : Capacities upto 150MTPD

Brand Name : BVR

...more

Mixer Settler

Mixer-Settler Extraction Unit The Mixer-settler system is fabricated and assembled in a compact modular design. The mixer as well as the settler are both integrated together instead of being separate entities. This allows the system to be compact and ideal for laboratory and R&D usage. A single stage of Mixer-Settler consists of a mixing zone and settler decanting zone connected to each other through a Weir zone. A brief description of the zones is as follows : Mixing System The Laboratory mixer consists of a special glass / SS (as per choice) mixing zone, suitable high-speed agitator and a variable speed drive. Besides providing an intimate dispersion the stirrer provides the necessary pumping action. This eliminates the need for external pumps and ensures a large interfacial area for mass transfer. The energy required to produce this dispersion will depend very much on the characteristics of the material and the system used (interfacial tension, viscosity, flow rates, etc). Between the mixing and separation zones, a weir is incorporated to prevent back mixing taking place and maintains the level of liquid in the mixing zone. Besides this, it also acts as a baffle to dampen the flow of liquid into the decanter (settler) for enhancing efficient phase separation. Settling System The settler comprises a horizontal cylindrical pipe which depending upon size may be one or more pipe sections. From the settler, the outlet of the heavy phase, is controlled by an overflow valve. The design of the settler will be influenced by the throughput of both phases and the material physical properties (density difference, viscosity, interfacial tension etc). Multi-Staging Mixer-Settlers Different stages can be connected to each other and the interconnecting pipelines can be done as per your required flow logic. The whole assembly would be controlled through a control panel consisting of suitable circuit breaker MCBs, Relays, digital controllers etc.

Application : As Per Requirement

Voltage : As Per Requirement

Capacity : As Per Requirement

Frequency : As Per Requirement

Phase : As Per Requirement

Automation Grade : As Per Requirement

...more

hydraulic test rig

We are Test Rigs Exporters based in India Our Test Rigs are perfect for various experiments performed in chemical engineering laboratories or R&D units pertaining to various processes like distillation, absorption, heat & mass transfer, decantation etc. Besides this, we also offer Test Rigs for performance of falling film and packed towers with different packing for absorption process.

...more

Heat Exchanger

We have firmly positioned ourselves as one of the leading Tube Heat Exchanger manufacturers and Exporters based in India. Our Industrial Heat Exchangers are manufactured from glass, SS or exotic metals, SiC (Silicon Carbide), other internals could be of PTFE or other Fluoropolymers. These are suitable for chemical processes with aggressive media. The shell & tube-type heat exchangers with SiC tubes have a number of additional features : Increased operating safety due to very high mechanical strength of the SiC tubes Much higher heat transfer coefficient due to very high thermal conductivity of SiC which allows for a very compact design Extremely high resistance to corrosion, oxidation and erosion over the entire operating temperature range Very good temperature and thermal shock resistance Sintered SiC is a monolithic material, which contains no further constituents in its structure other than SiC thus rendering it suitable for highest purity applications. Universal Chemical Stability Borosilicate glass 3.3, SiC and PTFE, as well as the engineered design makes it efficiently suitable for the chemical and pharmaceutical industry. SiC heat exchangers are suitable for long-term operation as condensers, evaporators or coolers for highly corrosive media and can be used in multi purpose plants or for stand alone applications too.

Material : As Per Requirement

Weight : As Per Requirement

Grade : As Per Requirement

Voltage : As Per Requirement

Automatic Grade : As Per Requirement

Power : As Per Requirement

Temperature : As Per Requirement

...more

HCl Gas Generation Unit

These can be done by three different routes : Sulphuric Acid Route Up to 200 Kg / Hr. Spent Acid (70% H2SO4) as by product. Azeotropic Boiling Route Up to 200 Kg./Hour. Spent Acid (20% HCL) as byproduct. Extraction or CaCl2 Route General Features Turn-down ratio of 25% Continuous operation. Practically maintenance free operation. Low cost of production. Intrinsic safety tool.

Output Type : As Per Requirement

Frequency : As Per Requirement

Cooling System : As Per Requirement

Noise Level : As Per Requirement

Speed : As Per Requirement

...more

hcl gas absorbers

Raw materials which are used for the production of our entire range of products are carefully checked against varied quality parameters as these are essential bottleneck assets. Development of modular control inside our warehouse helps in proper organization of the products and ensure complete safety while storage. The entire system is properly managed by our warehousing experts.

...more

Turnkey Projects

Technology development, engineering and turnkey solutions for chemical recovery from Industrial liquid and gaseous effluents. Turnkey projects for standard chemical manufacturing plants like Sulphuric, Nitric, Hydrochloric acid, Nitrates, Sulphates and other allied chemicals. Corrosion resistant Equipment & Plants made up of SS, Borosilicate 3.3 glass, Fluoropolymers & Exotic Metals (Ta, Ti, etc). Design, Engineering, Fabrication , Installation, Commissioning, Project management, Turnkey project execution. BASIC ENGINEERING - Mass and energy balances, Process flow diagram (PFD), Preliminary layout of the plant other apparatus and equipment specifications DETAIL ENGINEERING - P&ID,General arrangement drawing, E&I Specifications PROJECT MANAGEMENT- Scheduling, Resource management, Interface Management, Control INSTALLATION & COMMISSIONING – Construction management, Loop Check, Test run, Performance Test & Trouble-shooting Equipment & Plants Designed & Fabricated as per Latest International Standards like the European CE Norms, ASME, ISO, HEI , GMP , etc. Multi-disciplinary engineering staff comprising of Mechanical , Electrical , Chemical & Instrumentation engineers System Integration of self-fabricated & Sourced materials Material Sourcing from industry standard suppliers recognized for high quality performance and durability of products. Oriented to Customer Specific Requirements

...more

Process Design Services

We render end-to-end Process Design & Engineering Services for Distillation, Extraction, Absorption, Reaction, Separation and other unit operations from Lab to Production scale. Backed by an experienced team of professionals, we have been rendering optimal solutions of Process Design Services. Today, we have carved a niche as one of the reliable providers of Process Design Solutions. Our services include : P&ID Development Process Modelling Heat Exchanger Design Equipment Specifications & Datasheets preparation Heat & Material Balance Pump Design Piping Design Process Optimization Process Validation & documentation (3Q / 4Q) Experience in dealing with equipment requirements, automation at lab or plant level, Onsite installation, commissioning and training Specifications Investigation and analysis calculations: pumps, valves, flow meters and temperature/pressure measuring devices. Preparation of documents / manuals / qualification for clients as per protocols and 3Q/4Q We use variety of software to simulate processes, setup and configuration of modeling and control software. Detailed process design PFD, BFD, Mass Balance, preparation of Equipment datasheets, Basis of Safety study � for new product launch- scaling up from Lab to Pilot scale before final production. Heat, Mass balance, HYSYS Simulation, Vessel/Separator, Columns, Pumps, Heat Exchanger sizing & design. Project Management, Process Design, Commissioning, Equipment Maintenance, Process Monitoring, Testing, Validation (as per the standard procedures), Plant Data Monitoring, Process Software Troubleshooting, Maintenance Life Plans, HAZOP, Basis of Safety study , SIL etc. , Awareness of H&S regulations, CDM Regulations, API, BS-EN, European Directive Standards, Awareness - HAZOP Equipment Condition Survey, Capex Plan Estimates

...more

Process Design And Engineering

Opening Hours