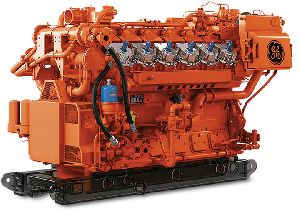

Waukesha VHP Engines and Generator

Waukesha VHP Engines and Generator Sets Dependable, Long-Lasting, Versatile GE’s Waukesha Series Four rich-burn engines are the engines of choice for the harshest and most demanding gas compression, power generation and mechanical drive applications. The engines can reliably produce more power on hot field gases, at high altitudes, and in remote locations, all while delivering low emissions when paired with a 3-way catalyst (non-selective catalytic reduction). Benefits Built for dependability, longevity and durability. Reliable, proven fuel flexibility across a wide nephelometric turbidity units (NTU) range Maintains consistent power output across changing field conditions Low emissions across range, meaning less impact on the environment Features Hot fuel tolerant Extended service intervals Simple to package with a pony skid or tailboard skid for plug and play operation Jacket water outlet increases dresser coupling Both rich burn and lean burn models available High-altitude capability available - 8000 feet (2438 metres) without de-rate Wide turn down range available 700-1200 rpm Hot fuel tolerant 600 – 2350 Btu/ft3 Empact system sized to achieve emissions as much low as 0.5 g NOx/g CO or 0.15 NOx/0.13g CO using catalyst For more than 40 years, VHP engines have proved their dependability, longevity and durability while operating in many different operating conditions involving natural gas production applications. With a power output of 315 kW to 1.5 MW (405 bhp to 2,560 bhp), VHP engines give you low emissions across a variety of applications, as well as a wide turndown range of 700 rpm to 1,200 rpm.

...more

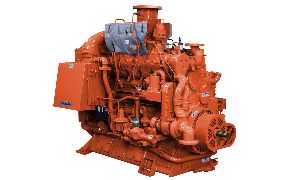

Waukesha VGF Engine

Durable, Compact, Fuel-Flexible The VGF series of high-speed engines are built with the durability expected from a medium-speed engine. Purposefully designed for a wide range of stationary, spark ignited, gaseous fuel applications, the compact VGF engine has a high power- to-weight ratio. The foundation for exceptional long-term performance is attributed to the core VGF family design. The VGF series was structurally designed from the inside out to deliver continuous output whether in the most rugged destination or compact location. And it’s a GE engine built with industrial strength to handle continuous 1800 revolutions per minute (rpm) operation up to 1175 brake horse power (bhp). Now with three decades in the field, the VGF line of engines is proven in both design and durability. Benefits More uptime earning better profitability Maximum high speed continuous duty providing durable stationary power Compact size means less packaging costs High power-to-weight ratio ensures long life and reduced operation costs High speed engines with durability of low speed engines Features Fuel quality and pressure variance application options In-line and V configuration have major component commonality Built to last with reduced vibration designs High-altitude turbocharger that allows operating up to 5,500 feet (1,676 metres) on some lean burn models, and up to 5,000 feet (1,524 metres) on some rich burn models. Speed range 1400-1800 rpm Quick load step capabilities for optimal operation. Versatile fuel pressure configurations; available as draw-through for low pressure, or blow through for higher pressure fuel. If you operate within a wide range of stationary, spark-ignited, gaseous-fueled (from 400 btu to 2,300 btu) applications, the durable, compact Waukesha* VGF high-speed engines are designed for you. VGF engines have a power output of 120 kW to 800 kW (265 bhp to 1,175 bhp) and feature a high-altitude turbocharger, quick load step capabilities and versatile fuel pressure variances. VGF engines are consistent performers in extreme conditions.

...more

Waukesha Mobileflex gas engine

New Standard for Drilling Rig Power Generation The mobileFLEX portfolio is the latest advancement from GE to deliver lower-cost, lower-emission power to drill rigs, artificial lift enhanced oil recovery and oilfield equipment. An all-gas alternative to diesel units, mobileFLEX is an EPA mobile-certified solution that provides a cost advantage to energy producers and operational advantage to drilling contractors by utilising field gases. For oilfield power applications, the mobileFLEX engine portfolio is a superior power solution for drill rigs, liquids reinjection, lift pumps, and temporary accommodations. Benefits Cost saving- provides power like a diesel without the cost of diesel fuel Flexibility – reliable, proven fuel flexibility across a wide British thermal unit (Btu) range Features Operates on Liquefied natural gas (LNG), compressed natural gas (CNG) HD-5 propane and high-Btu field gases with minimal gas treatment Exceptional fuel tolerance : Operation on natural gases 950-1,650 Btu/ft3 higher heating value (HHV) without component changes and on propane gas 2600 Btu/ft3 without component changes Diesel-like load acceptance - Upto 65% load steps and 100% load-shed Emission control with low cost 3 way catalyst The mobile-certified VHP multi-fuel engine set the new standard for reliable, efficient drill rig power generation. Delivering up to 95 percent lower emissions and 80 percent lower fuel costs than diesel with similar transient load response, this engine represents a game-changing, fuel-flexible solution for the drilling industry and artificial lift industry. The VHP rich burn solution is available with power outputs of 1,000 and 1,200 kW @ 1,200 rpm. GE’s gas engine technology is an ideal transition from diesel power. No load banks Rich-burn engines deliever diesel-like load acceptance Up to 65% load steps and 100% load shed Exceptional fuel tolerance with more power on high-Btu field gases Emission control with low-cost three-way catalyst Eliminates dependence on diesel fuel Oilfield Power Applications Drill rig Lift pumps Liquids reinjection Temporary accommodations

...more

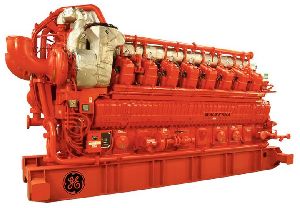

Waukesha Gas Engines

More Power, Longer Engine Life GE’s Waukesha 275GL+ represents the most advanced generation of high-horsepower engines in the gas compression segment. A combination of robust construction and innovative technology, the 275GL+ lean-burn engine delivers excellence in fuel flexibility, efficiency, power output and emissions for unmatched performance. For maximum uptime and profitability, you can depend on the 275GL+ to get the job done year after year. Designed to demanding specifications of the gas compression industry, GE’s Waukesha 275GL+ Enginator is the right choice for rugged oilfield power generation and associated gas applications. Benefits Fuel flexibility The 275GL+ is an easy to use package. More power in more unconventional gas applications Features The 275GL+ delivers excellent power output and efficiency that directly improve the bottom line. The 16-cylinder model is rated 5000 bhp (3728 kWb), with the 12-cylinder version rated 3750 bhp (2800 kWb). The 275GL+ and its fuel-efficiency advantage provide low unburned methane—a greenhouse gas that has 25 times the effect of CO2—minimising its carbon footprint and effect on the environment. The Engine System Manager (ESM) dramatically reduces on-site setup time and simplifies engine operation. Closed loop NOx based air-fuel ratio control The ecomagination1-qualified 275GL+ lean burn engine has more power in unconventional gas applications – efficiency with a power output of 1,887 kW – 3,605 kW and emissions performance. Its Engine System Manager* (ESM) control sharply reduces onsite setup time and requirements. That saves days on commissioning and adds years to engine life. The 275GL+ makes no compromise between power and emissions control, or between fuel efficiency and fuel flexibility.

...more

Natural Gas Generator

GE s Jenbacher Engine

The GE's Jenbacher Type-2 gas engine was introduced in 1974 and is the engine with the longest development history of the range. The 208 has 8 inline cylinders and is available at electrical output from 249kWe or 335kWe. The J208 is renowned for its robust design and highest levels of component durability. It is particularly well suited to troublesome gases such as landfill gas. The generator has a long service life, with a major overhaul not scheduled until 60,000 hours of operation. Optimised components and a provide control and monitoring concept give this engine outstanding reliability. The J208 genset, with no heat recovery, is available in a compact 20 foot container. Benefits High electrical and thermal efficiency for maximum return on investment. Robust, flexible design with high reliability on difficult gases. Available as containerised ‘plug-and-play’ units for quick installation. Features Optimised combustion for maximum efficiency. Turbocharger bypass evens out extreme operating conditions. High-performance, long-life spark plug for reliable operation. Knocking control compensates for methane number fluctuation. LEANOX® lean burn control ensures minimal emissions. Compact engine control with integrated network synchronisation. Visit the GE's Jenbacher website to read more about the Type 2 GE's Jenbacher engine.

...more

gas engine

Bio Gas Generator

gas generator sets

Power Plant

biogas engine

Gas Turbine

Be first to Rate

Rate ThisOpening Hours