EHF 200 D/E Hand Feed Concrete Mixer

Get Price Quote

1 Piece (MOQ)

Concrete Mixer Machine

100,000 Per Piece

1 Piece (MOQ)

Best Deals from Concrete Mixers

Concrete Batching Plant Automation

4,000,000 Per Piece

1 Piece (MOQ)

Small Batching Machine

275,000 - 570,000 Per Set

1 Set(s) (MOQ)

we have pleasure in introducing our Small Batching Machine, which definitely goes a long way towards solving the batching problems that come across while batching and improving the production capacity.

Centrifuge Machine

Get Price Quote

We specialize in the standard top discharge type. Our Centrifuges are renowned for their well-designed and sturdy construction, providing low current consumption, powerful and efficient braking systems, and smooth acceleration with minimum vibration. Our Centrifuges have gained widespread acceptance and a reputation for quality and workmanship, both in India and abroad. Our primary customers come from the Chemical, Pharmaceutical, Food, and Textile processing industries. We also offer exceptional customization options for customers with unique needs, including high RPM baskets and basket lifting attachments. Centrifuge Models Mild Steel Basket & Mild Steel Outer case Stainless Steel Basket & Stainless Steel Outer case Stainless Steel Basket & Mild Steel Outer case Stainless Steel Basket & Mild Rubber lined Outer case Stainless Steel Basket & Mild Steel FRP Lined Outer case Mild Steel Rubber lined Basket & Mild Rubber lined Outer case Panchsheel Industries manufactures Centrifuges in a range of types and models to suit our customers’ diverse needs. We are committed to providing our customers with the best solutions for their centrifugation needs, backed by exceptional service and support. Our Centrifuges are designed and manufactured to the highest standards of quality and reliability, ensuring long-lasting performance and trouble-free operation.

Concrete Pipe Making Machine

401,000 Per Units

1 Pices (MOQ)

Potato Peeling Machine

Get Price Quote

Potato Peeling Machine offered by us is ideal for peeling of this vegetable in large scale. Heavily used in large kitchens, canteens, restaurants etc. our machine is highly capable of providing an efficient and quick service. Our Potato Peeling Machine is available in various models and capacities and can be delivered to any country on a postulated time. This is why we are a celebrated Manufacturer, Supplier and Exporter of Potato Peeling Machine from Vadodara, Gujarat.Features : Equipment to add ease, convenience and speed to peeling operation. Stainless steel body. Stainless Steel drum with high quality emery lining. Oven backed contoured shaped emery disk for perfect tossing and peeling of potatoes.

Cement Concrete Mixer

Get Price Quote

We are leading manufacturer and supplier of Cement Concrete Mixer Machines. We offer wide range of cement concrete mixer machines like concrete mixer with mechanical hopper, with hydraulic hopper and without hopper in various different models as per the customer’s requirement.Our machines are widely appreciated for its various features like longer functional life, optimum performance and sturdy construction. These concrete mixers are also known in the market for their durable finish standards and high quality performance.These mixer machines are suitable to be used for mixing cement & concrete at the construction site. The prime advantage of these machines is their low maintenance and operating cost.

Drum Mixer

Get Price Quote

Inject batch coding machine

Get Price Quote

Our valuable customers can acquire from us an exclusive collection of Inspection Doctoring Rewinding Machine. which is highly demanded for their smooth finish. Our presented assortment is manufactured by utilizing supreme grade raw material and ultra modern technology in compliance with international quality standards and principles. In addition to this, these are obtainable in varied sizes and dimensions. Application: Multiline Packaging and Printing Machine for Rapper Film, Foil and Pouch Online Printing of MRP, MFG Date, Exp. Date, Batch No. Salient Feature Advanced Design for Efficient Power Consumption. Hydraulic Web Guide System. Tension Controlled By Manual Break. Provision For Incorporating Inkjet Printing System. Advance Structure Design For Vibration Free Working. Rubber Cork Material For Avoid Slippage. Clear Roll Paper Winding & Finishing.

Concrete Mixer Machine

122,000 Per Piece

concrete coring machine

16,000 Per Piece

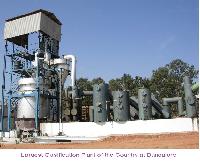

Solid Waste for Energy Project

Get Price Quote

Positioned with leading names, we are an emerging name operating from Vadodara(India). We have hired expert warehousing personnel who keep a stringent check on the entire range of stored lot ensuring zero damage to the products till the final dispatch to the clients. Capacity - 50 TPD to 500 TPD from any type of Solid Waste for Energy Project to energy

Cement Concrete Mixer

Get Price Quote

half bag concrete mixer

51,000 Per Piece

CONCRETE MACHINERY mechanical hopper

Get Price Quote

Technical Specifications 10/7 cft. (285/200 ltr.) capacity. Robust chassis. Channel type loading hopper. Tilting type drum mounted on fabricated yoke fitted with taper roller bearings for easy operation. Drum & Pinion Shafts are from EN8, duly ground. Prime - mover Diesel Engine Electric Motor Engine and Motor together (Conversion from one to other can be done in 5 minutes without the use of tools) Pneumatic road wheels. Cabin open from all three sides for ease in maintenance Cabin provided with reinforced and pressed ribs to prevent vibration

Mixer Muller

Get Price Quote

Mixer-Muller is a very popular and important machine used to get the optimum Green Sand Moulding Strength & Compactibility. To achieve the best quality & fluffy moulding sand, this machine, can be also supplied with IN-BUILT AERATOR. The Mixer-Muller is used to prepare a proper product mix or SAND-Bentonite- Coal dust – Water & Fine Dust by kneading & mixing principle. An Automatic weighing/batching, hopper is also available along with the machine to maintain consistency in the sand mix quality.

Mild Steel Concrete Mixer

36,000 - 37,000 Per Piece

Centrifuge Machine

45,000 Per Piece

Smart Batch Composting Machine

Get Price Quote

To carry out the mixing and crushing process the machine is empowered by a geared motor for mixing & churning purpose and a high speed motor to crush the tough waste material. The critical components of the machine are manufactured in SS 304 for longer life and better results.The Process:The 100% segregated bio-degradable waste has to be treated in this composting machine. The machine works in two stages, in the first stage it first crushes the waste and then mixes it homogeneously with the bio decomposition culture.In the second stage this homogeneous mixture is further mixed & churn with saw dust / bagasse, to soak the excess water content from the biomass which ultimately deodorizes it. Later this pre-composted mass is kept for curing in the Curing Bays for about 12 days. After the 12th day the container is ready with compost and can be used for field applications. We supply the complete system including the Smart composter and curing system including irrigation system to effectively treat the organic biodegradable portion of MSW to convert into compost.Features:Compact designQuick and easy process