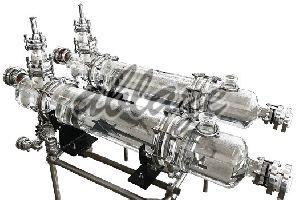

Glass Mixer Settler

Get Price Quote

The MIXER -SETTLER is a revolutionary new device, which makes phase separation automatic and simple, irrespective of the concentration of two phases (interface height). The mixer-settler is the name given to a type of EXTRACTOR made up of a number of mixing and settling chambers connected alternately in series. In the mixing chambers, optimum mass transfer is achieved by through mixing of two phases with the aid of pumps and stirrers. In the simplest case, the MIXER -SETTLER consist of an adjustable overflow valve, stirrer drive assembly and settling zone. The Mixer Settler has a wide application in the Process Industry , Particularly in Azeotropic Distillation Extractive Distillation Steam Distillation Esterification Distillation Stirrer Drive Assembly The mixing chamber consists of a cylindrical glass cover in which a variable speed stirrer drive is fitted. Glass impeller Stirrer creates a negative pressure at the inlet, which can be used to draw liquid from a previous stage in the process. In the mixing zone, a turbine stirrer with variable speed unit mixes the two phases and the mass transfer takes place during dispersion. Separation Zone Separation of phases takes place in two phases. Firstly, The turbulent flow in the mixing zone must be brought under control and converted into axial flow. Then the mixer passes into the separation zone where the two phases separate, due to their specific gravity difference. Auto Continuous Separation The adjustable overflow valve assembly at one end of the vessel can be set for any interface height. The position of the overflow weir is adjusted to suit the relative densities of the two phases. This valve can be operated externally such that the interface height can be set or reset depending on the operating process conditions. The separating head incorporates an internal overflow weir, which is manually adjusted using a hand wheel. Visual Monitoring The transparency of Borosilicate glass facilitates the adjustment of the overflow valve by visual monitoring whereby any change in the process conditions resulting into a change in layer (interface) height can be immediately adjusted by resetting the overflow valve. The resetting of the separation height is very simply achieved by rotating the hand wheel of the overflow valve assembly in the clock or anti-clock direction. Large Interface Plane Area The horizontal glass vessel of the MIXER-SETTLER provides a large interface area of separation two immiscible liquid phases for a given volume. This enhances the efficiency of the separation process. Overview Of The System The system consists of the following adjustable overflow valve, stirrer drive assembly and settling zone.

Mixer Settler

Get Price Quote

Mixer-Settler Extraction Unit The Mixer-settler system is fabricated and assembled in a compact modular design. The mixer as well as the settler are both integrated together instead of being separate entities. This allows the system to be compact and ideal for laboratory and R&D usage. A single stage of Mixer-Settler consists of a mixing zone and settler decanting zone connected to each other through a Weir zone. A brief description of the zones is as follows : Mixing System The Laboratory mixer consists of a special glass / SS (as per choice) mixing zone, suitable high-speed agitator and a variable speed drive. Besides providing an intimate dispersion the stirrer provides the necessary pumping action. This eliminates the need for external pumps and ensures a large interfacial area for mass transfer. The energy required to produce this dispersion will depend very much on the characteristics of the material and the system used (interfacial tension, viscosity, flow rates, etc). Between the mixing and separation zones, a weir is incorporated to prevent back mixing taking place and maintains the level of liquid in the mixing zone. Besides this, it also acts as a baffle to dampen the flow of liquid into the decanter (settler) for enhancing efficient phase separation. Settling System The settler comprises a horizontal cylindrical pipe which depending upon size may be one or more pipe sections. From the settler, the outlet of the heavy phase, is controlled by an overflow valve. The design of the settler will be influenced by the throughput of both phases and the material physical properties (density difference, viscosity, interfacial tension etc). Multi-Staging Mixer-Settlers Different stages can be connected to each other and the interconnecting pipelines can be done as per your required flow logic. The whole assembly would be controlled through a control panel consisting of suitable circuit breaker MCBs, Relays, digital controllers etc.

Best Deals from Continuous Mixers

chemical mixers

250,000 Per Pack

1 Set(s) (MOQ)

Mixer Settler

Get Price Quote

The MIXER -SETTLER is a revolutionary new device, which makes phase separation automatic and simple, irrespective of the concentr two phases (interface height). The mixer settler is the name given to a type of EXTRACTOR made up of a number of mixing and chambers connected alternately in series. In the mixing chambers optimum mass transfer is achieved by through mixing of two phases waid of pumps and stirrers. In the simplest case, the MIXER -SETTLER consist of adjustable overflow valve, stirrer drive assembly and zone.

magma mixer

Get Price Quote

Rotary Mixer

Get Price Quote

This is an accessory for ESR Analyzer . It is preparing the perfect samples before the test .It will save the man hours and improve the results by better samples. To mix or get dissolved pre coated chemicals or reagents with sample blood in Up to 12.7mm diameter tubes.

Chemical Mixer

Get Price Quote

The top-grade Chemical Mixer, supplied by us, is acclaimed for its durability and precise engineering.Our comprehensive range of products is packed in sturdy, safe, and industrial grade materials that safeguard the contents inside from harm, dampness, dust, movement etc. Besides, the packing has printed product information. We are based in Vadodara(India) and known for providing amazing deals and lucrative offers to the clients.

Glass Mixer Settler

Get Price Quote

Glass Mixer Settler, Glass Pilot Plant, rotary evaporators, Bioreactor

Multi Stage Mixer Settlers

Get Price Quote

Multi Stage Mixer Settlers are used for liquid-liquid extraction process wherever there is huge demand towards flexibility in plant operations. Frequently changing products, alterations to the number of stages required or wide variation in through put can play decisive factors in this process.

High Shear Mixer

Get Price Quote

High Shear Mixer, Agitator, magnetic agitator, Magnetic Stirrer, Mixer

Twin Shaft Mixer

Get Price Quote

Twin Shaft Mixer

Twin Shaft Mixer

Get Price Quote

Twin Shaft Mixer, Concrete Batching Plant

Color Mixer

Get Price Quote

Color Mixer, Plastic Processing Machinery, plastic scrap grinder machine

twin shaft mixers

Get Price Quote

twin shaft mixers, Vertical Screw Conveyor, hydraulic cotton baling press

colour mixer

Get Price Quote

colour mixer

high speed dispenser

Get Price Quote

high speed dispenser

colour mixer machine

Get Price Quote

colour mixer machine, Grinding Machine, Plastic Grinder Machine